Tính chất chống đâm xuyên của vải dệt dùng sợi liên tục Aramid

Abstract

Keywords:

Body protection; Stabbing;

Filament yarns; Aramid,

Woven fabric; Drop tower

test.

Aramid fibers are well known as the material with high tenacity and thermal

stability. They have mainly been used for industrial applications and

especially for protecting human body against stab and ballistic threats. This

research investigated the effect of aramid fibers on the anti-stab resistance

with various specifications of filament yarns and fabric conditions. The stab

resistance properties of various fabric specimens were tested and compared

according to the NIJ standard-0115.00. With the aramid filament yarns, in

order to get the best anti-stabbing performance, we should apply thin yarn and

high density woven fabric.

Tóm tắt

Từ khóa:

Bảo vệ cơ thể người; Đâm

xuyên; Sợi liên tục; Vải dệt;

Tháp thử nghiệm rơi.

Sợi Aramid được biết đến như vật liệu có độ bền cao và ổn định nhiệt. Chúng

chủ yếu được sử dụng cho các ứng dụng trong công nghiệp và đặc biệt là để

bảo vệ cơ thể con người chống lại các mối đe dọa đâm xuyên và đạn đạo.

Nghiên cứu này đã xác định được ảnh hưởng của sợi aramid đến tính chống

đâm với các thông số kỹ thuật khác nhau của sợi aramid liên tục và của vải

dệt. Tính chất chống đâm xuyên của các mẫu vải khác nhau đã được kiểm tra

và so sánh theo tiêu chuẩn NIJ-0115.00. Với tao sợi liên tục aramid để đạt đặc

tính chống đâm tốt nhất thì chúng phải sử dụng vải dệt có kích thước tao sợi

nhỏ và mật độ dệt cao.

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Trang 6

Trang 7

Trang 8

Tóm tắt nội dung tài liệu: Tính chất chống đâm xuyên của vải dệt dùng sợi liên tục Aramid

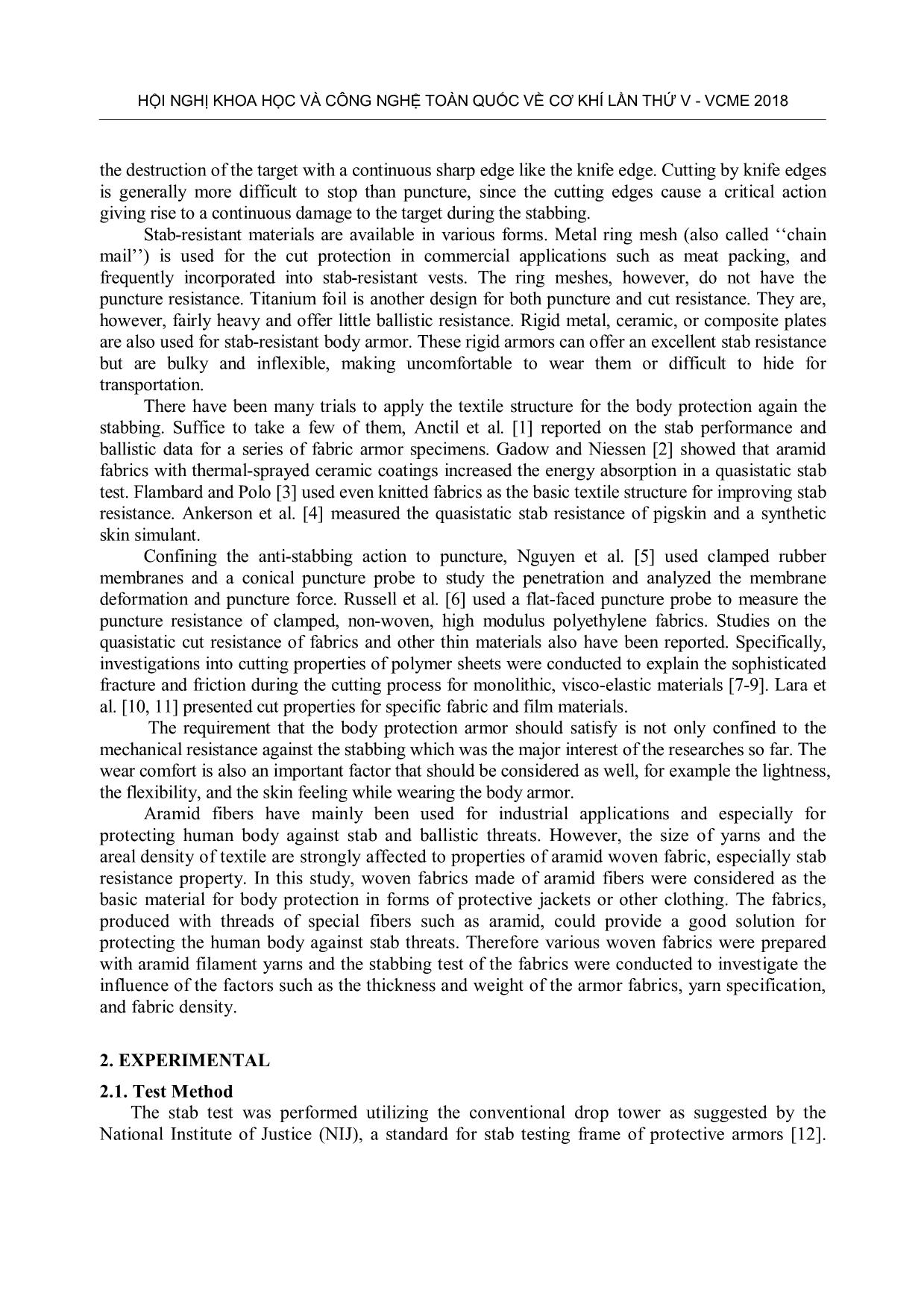

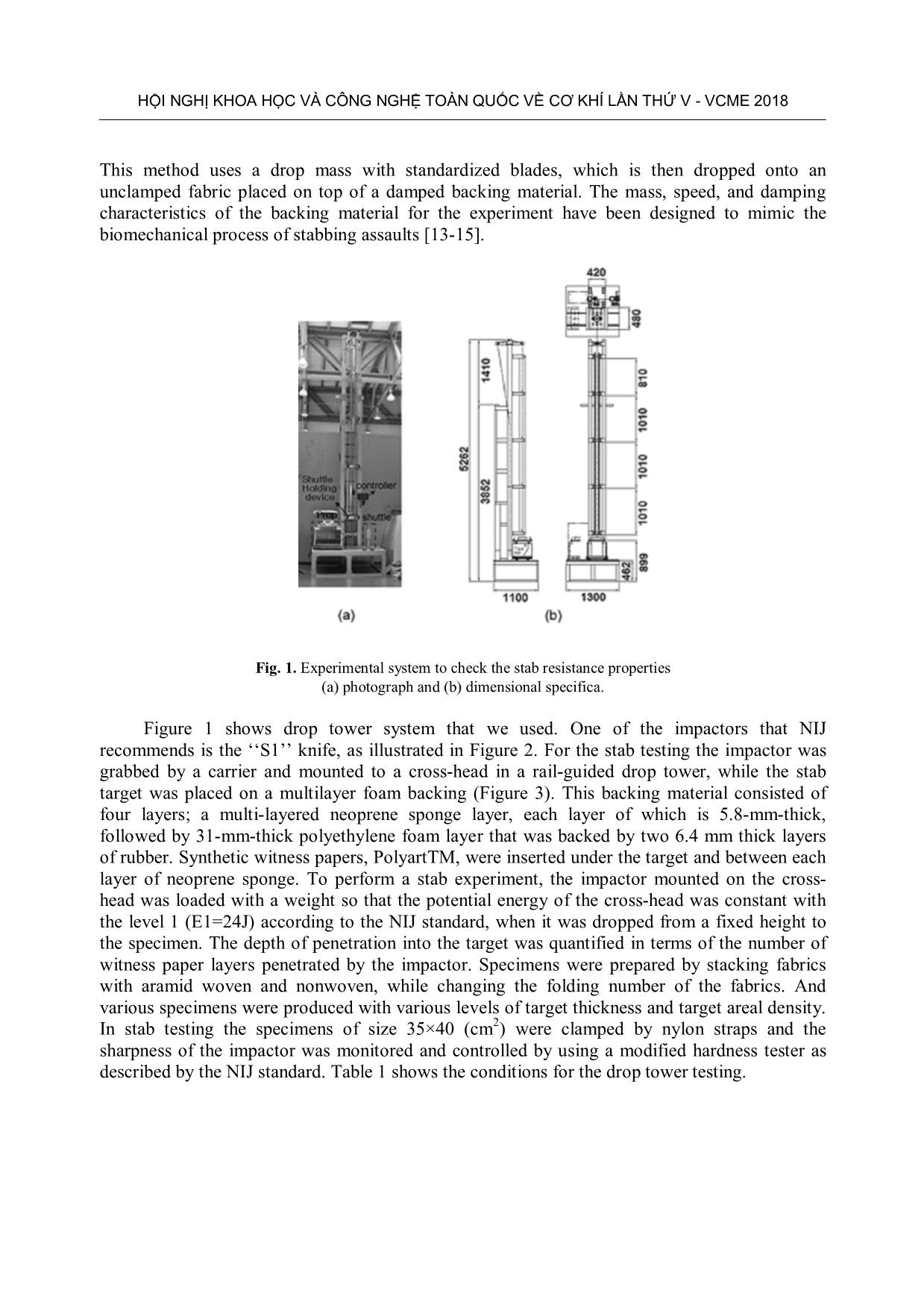

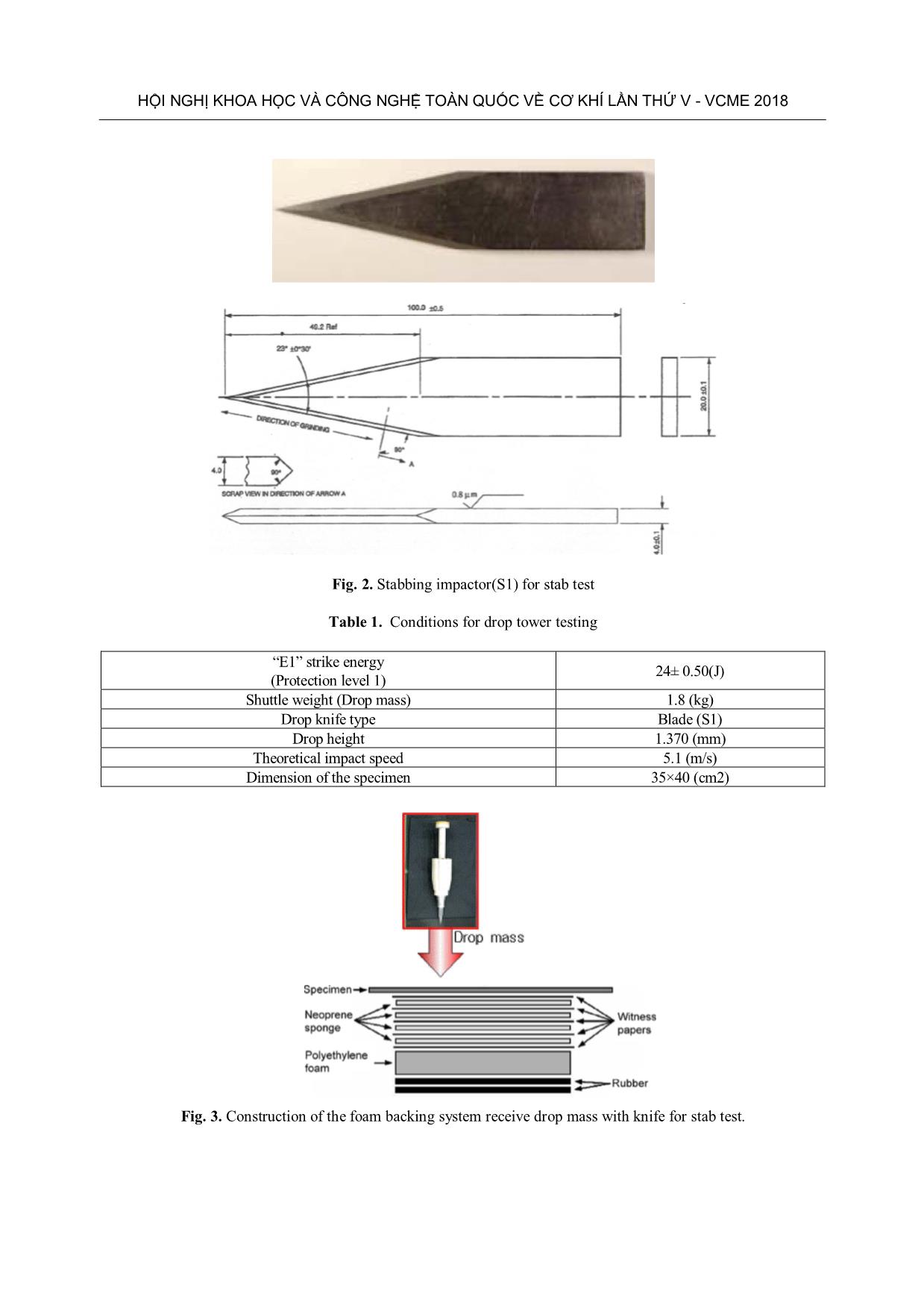

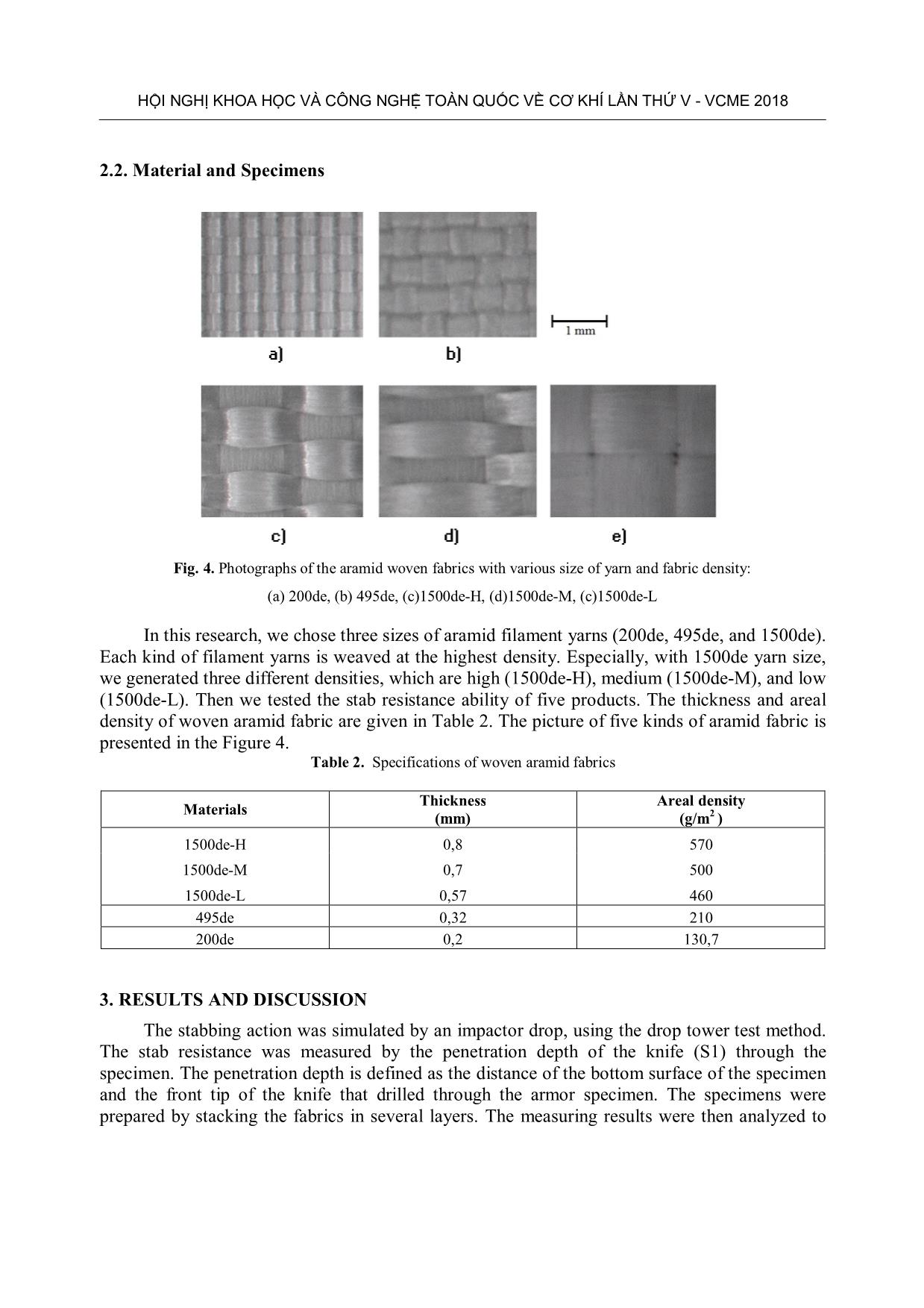

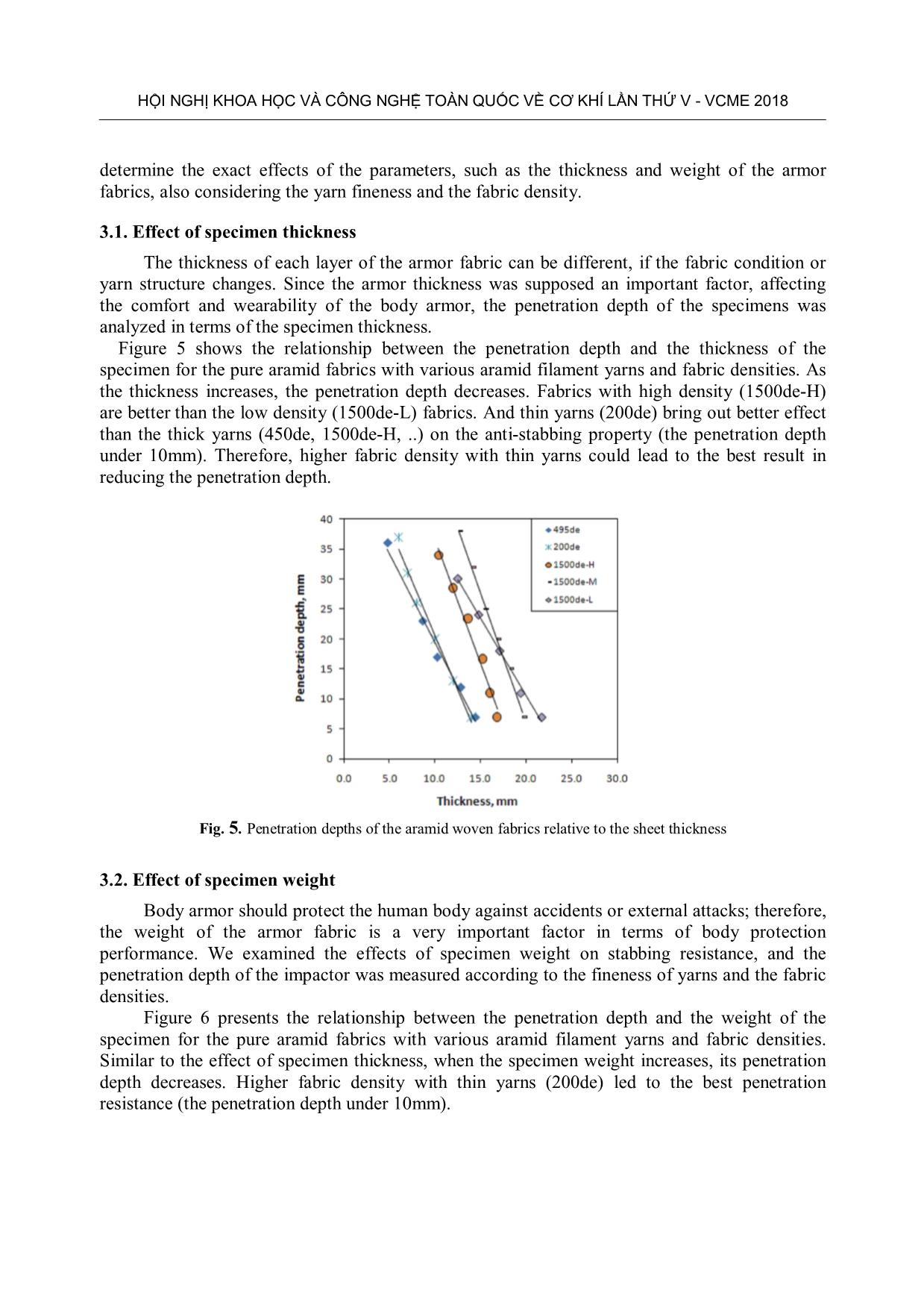

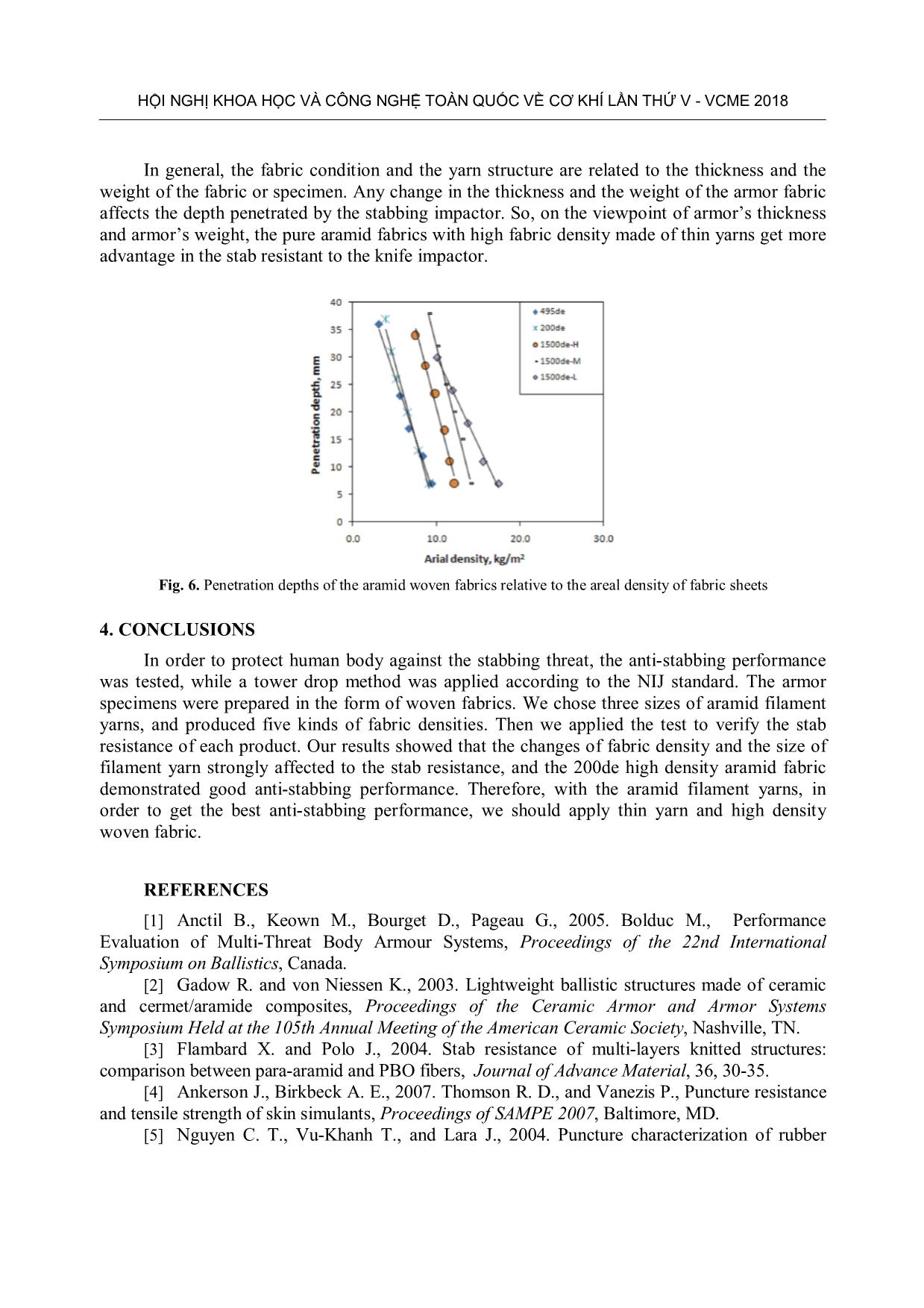

HỘI NGHỊ KHOA HỌC VÀ CÔNG NGHỆ TOÀN QUỐC VỀ CƠ KHÍ LẦN THỨ V - VCME 2018 Stab resistance of woven fabrics with aramid fillament yarns Tính chất chống đâm xuyên của vải dệt dùng sợi liên tục Aramid Dương Tử Tiên Department of Mechanical Engineering, Nha Trang University Email: tiendt@ntu.edu.vn Mobile: 0905299810 Abstract Keywords: Aramid fibers are well known as the material with high tenacity and thermal Body protection; Stabbing; stability. They have mainly been used for industrial applications and Filament yarns; Aramid, especially for protecting human body against stab and ballistic threats. This Woven fabric; Drop tower research investigated the effect of aramid fibers on the anti-stab resistance test. with various specifications of filament yarns and fabric conditions. The stab resistance properties of various fabric specimens were tested and compared according to the NIJ standard-0115.00. With the aramid filament yarns, in order to get the best anti-stabbing performance, we should apply thin yarn and high density woven fabric. Tóm tắt Từ khóa: Sợi Aramid được biết đến như vật liệu có độ bền cao và ổn định nhiệt. Chúng Bảo vệ cơ thể người; Đâm chủ yếu được sử dụng cho các ứng dụng trong công nghiệp và đặc biệt là để xuyên; Sợi liên tục; Vải dệt; bảo vệ cơ thể con người chống lại các mối đe dọa đâm xuyên và đạn đạo. Tháp thử nghiệm rơi. Nghiên cứu này đã xác định được ảnh hưởng của sợi aramid đến tính chống đâm với các thông số kỹ thuật khác nhau của sợi aramid liên tục và của vải dệt. Tính chất chống đâm xuyên của các mẫu vải khác nhau đã được kiểm tra và so sánh theo tiêu chuẩn NIJ-0115.00. Với tao sợi liên tục aramid để đạt đặc tính chống đâm tốt nhất thì chúng phải sử dụng vải dệt có kích thước tao sợi nhỏ và mật độ dệt cao. Received: 01/07/2018 Received in revised form: 01/9/2018 Accepted: 15/9/2018 1. INTRODUCTION Body armors for Army personnel have traditionally been designed to provide protection from fragmentation and ballistic threats. However, the increasing relevance of close-quarters, urban conflict necessitates the development of protective, flexible armor systems with additional stab- resistant capabilities. Stab threats encountered by soldiers in the field include direct attacks from knives and sharpened instruments, as well as physical contact with debris, broken glass, and razor wire. The demand for improved stab protection has also been motivated by civilian police forces, particularly in Viet Nam or in Europe, where restrictions on gun ownership have led to an increase in the proportion of assaults which are committed with knives. Stab threats can be classified into two categories: puncture and cut. Puncture refers to the penetration of an object with pointed tips through a target, such as ice picks or awls. Cut refers to HỘI NGHỊ KHOA HỌC VÀ CÔNG NGHỆ TOÀN QUỐC VỀ CƠ KHÍ LẦN THỨ V - VCME 2018 the destruction of the target with a continuous sharp edge like the knife edge. Cutting by knife edges is generally more difficult to stop than puncture, since the cutting edges cause a critical action giving rise to a continuous damage to the target during the stabbing. Stab-resistant materials are available in various forms. Metal ring mesh (also called ‘‘chain mail’’) is used for the cut protection in commercial applications such as meat packing, and frequently incorporated into stab-resistant vests. The ring meshes, however, do not have the puncture resistance. Titanium foil is another design for both puncture and cut resistance. They are, however, fairly heavy and offer little ballistic resistance. Rigid metal, ceramic, or composite plates are also used for stab-resistant body armor. These rigid armors can offer an excellent stab resistance but are bulky and inflexible, making uncomfortable to wear them or difficult to hide for transportation. There have been many trials to apply the textile structure for the body protection again the stabbing. Suffice to take a few of them, Anctil et al. [1] reported on the stab performance and ballistic data for a series of fabric armor specimens. Gadow and Niessen [2] showed that aramid fabrics with thermal-sprayed ceramic coatings increased the energy absorption in a quasistatic stab test. Flambard and Polo [3] used even knitted fabrics as the basic textile structure for improving stab resistance. Ankerson et al. [4] measured the quasistatic stab resistance of pigskin and a synthetic skin simulant. Confining the anti-stabbing action to puncture, Nguyen et al. [5] used clamped rubber membranes and a conical puncture probe to study the penetration and analyzed the membrane deformation and puncture force. Russell et al. [6] used a flat-faced puncture probe to measure the puncture resistance of clamped, non-woven, high modulus polyethylene fabrics. Studies on the quasistatic cut resistance of fabrics and other thin materials also have been reported. Specifically, investigations into cutting properties of polymer sheets were conducted to explain the sophisticated fracture and friction during the cutting process for monolithic, visco-elastic materials [7-9]. Lara et al. [10, 11] presented cut properties for specific fabric and film materials. The requirement that the body protection armor should satisfy is not only confined to the mechanical resistance against the stabbing which was the major interest of the researches so far. The wear comfort is also an important factor that should be considered as well, for example the lightness, the flexibility, and the skin feeling while wearing the body armor. Aramid fibers have mainly been used for industrial applications and especially for protecting human body against stab and ballistic threats. However, the size of yarns and the areal density of textile are strongly affected to properties of aramid woven fabric, especially stab resistance property. In this study, woven fabrics made of aramid fibers were considered as the basic material for body protection in forms of protective jackets or other clothing. The fabrics, produced with threads of special fibers such as aramid, could provide a good solution for protecting the human body against stab threats. Therefore various woven fabrics were prepared with aramid filament yarns and the stabbing test of the fabrics were conducted to investigate the influence of the factors such as the thickness and weight of the armor fabrics, yarn specification, and fabric density. 2. EXPERIMENTAL 2.1. Test Method The stab test was performed utilizing the conventional drop tower as suggested by the National Institute of Justice (NIJ), a standard for stab testing frame of protective armors [12]. HỘI NGHỊ KHOA HỌC VÀ CÔNG NGHỆ TOÀN QUỐC VỀ CƠ KHÍ LẦN THỨ V - VCME 2018 This method uses a drop mass with standardized blades, which is then dropped onto an unclamped fabric placed on top of a damped backing material. The mass, speed, and damping characteristics of the backing material for the experiment have been designed to mimic the biomechanical process of stabbing assaults [13-15]. Fig. 1. Experimental system to check the stab resistance properties (a) photograph and (b) dimensional specifica. Figure 1 shows drop tower system that we used. One of the impactors that NIJ recommends is the ‘‘S1’’ knife, as illustrated in Figure 2. For the stab testing the impactor was grabbed by a carrier and mounted to a cross-head in a rail-guided drop tower, while the stab target was placed on a multilayer foam backing (Figure 3). This backing material consisted of four layers; a multi-layered neoprene sponge layer, each layer of which is 5.8-mm-thick, followed by 31-mm-thick polyethylene foam layer that was backed by two 6.4 mm thick layers of rubber. Synthetic witness papers, PolyartTM, were inserted under the target and between each layer of neoprene sponge. To perform a stab experiment, the impactor mounted on the cross- head was loaded with a weight so that the potential energy of the cross-head was constant with the level 1 (E1=24J) according to the NIJ standard, when it was dropped from a fixed height to the specimen. The depth of penetration into the target was quantified in terms of the number of witness paper layers penetrated by the impactor. Specimens were prepared by stacking fabrics with aramid woven and nonwoven, while changing the folding number of the fabrics. And various specimens were produced with various levels of target thickness and target areal density. In stab testing the specimens of size 35×40 (cm2) were clamped by nylon straps and the sharpness of the impactor was monitored and controlled by using a modified hardness tester as described by the NIJ standard. Table 1 shows the conditions for the drop tower testing. HỘI NGHỊ KHOA HỌC VÀ CÔNG NGHỆ TOÀN QUỐC VỀ CƠ KHÍ LẦN THỨ V - VCME 2018 Fig. 2. Stabbing impactor(S1) for stab test Table 1. Conditions for drop tower testing “E1” strike energy 24± 0.50(J) (Protection level 1) Shuttle weight (Drop mass) 1.8 (kg) Drop knife type Blade (S1) Drop height 1.370 (mm) Theoretical impact speed 5.1 (m/s) Dimension of the specimen 35×40 (cm2) Fig. 3. Construction of the foam backing system receive drop mass with knife for stab test. HỘI NGHỊ KHOA HỌC VÀ CÔNG NGHỆ TOÀN QUỐC VỀ CƠ KHÍ LẦN THỨ V - VCME 2018 2.2. Material and Specimens Fig. 4. Photographs of the aramid woven fabrics with various size of yarn and fabric density: (a) 200de, (b) 495de, (c)1500de-H, (d)1500de-M, (c)1500de-L In this research, we chose three sizes of aramid filament yarns (200de, 495de, and 1500de). Each kind of filament yarns is weaved at the highest density. Especially, with 1500de yarn size, we generated three different densities, which are high (1500de-H), medium (1500de-M), and low (1500de-L). Then we tested the stab resistance ability of five products. The thickness and areal density of woven aramid fabric are given in Table 2. The picture of five kinds of aramid fabric is presented in the Figure 4. Table 2. Specifications of woven aramid fabrics Thickness Areal density Materials 2 (mm) (g/m ) 1500de-H 0,8 570 1500de-M 0,7 500 1500de-L 0,57 460 495de 0,32 210 200de 0,2 130,7 3. RESULTS AND DISCUSSION The stabbing action was simulated by an impactor drop, using the drop tower test method. The stab resistance was measured by the penetration depth of the knife (S1) through the specimen. The penetration depth is defined as the distance of the bottom surface of the specimen and the front tip of the knife that drilled through the armor specimen. The specimens were prepared by stacking the fabrics in several layers. The measuring results were then analyzed to HỘI NGHỊ KHOA HỌC VÀ CÔNG NGHỆ TOÀN QUỐC VỀ CƠ KHÍ LẦN THỨ V - VCME 2018 determine the exact effects of the parameters, such as the thickness and weight of the armor fabrics, also considering the yarn fineness and the fabric density. 3.1. Effect of specimen thickness The thickness of each layer of the armor fabric can be different, if the fabric condition or yarn structure changes. Since the armor thickness was supposed an important factor, affecting the comfort and wearability of the body armor, the penetration depth of the specimens was analyzed in terms of the specimen thickness. Figure 5 shows the relationship between the penetration depth and the thickness of the specimen for the pure aramid fabrics with various aramid filament yarns and fabric densities. As the thickness increases, the penetration depth decreases. Fabrics with high density (1500de-H) are better than the low density (1500de-L) fabrics. And thin yarns (200de) bring out better effect than the thick yarns (450de, 1500de-H, ..) on the anti-stabbing property (the penetration depth under 10mm). Therefore, higher fabric density with thin yarns could lead to the best result in reducing the penetration depth. Fig. 5. Penetration depths of the aramid woven fabrics relative to the sheet thickness 3.2. Effect of specimen weight Body armor should protect the human body against accidents or external attacks; therefore, the weight of the armor fabric is a very important factor in terms of body protection performance. We examined the effects of specimen weight on stabbing resistance, and the penetration depth of the impactor was measured according to the fineness of yarns and the fabric densities. Figure 6 presents the relationship between the penetration depth and the weight of the specimen for the pure aramid fabrics with various aramid filament yarns and fabric densities. Similar to the effect of specimen thickness, when the specimen weight increases, its penetration depth decreases. Higher fabric density with thin yarns (200de) led to the best penetration resistance (the penetration depth under 10mm). HỘI NGHỊ KHOA HỌC VÀ CÔNG NGHỆ TOÀN QUỐC VỀ CƠ KHÍ LẦN THỨ V - VCME 2018 In general, the fabric condition and the yarn structure are related to the thickness and the weight of the fabric or specimen. Any change in the thickness and the weight of the armor fabric affects the depth penetrated by the stabbing impactor. So, on the viewpoint of armor’s thickness and armor’s weight, the pure aramid fabrics with high fabric density made of thin yarns get more advantage in the stab resistant to the knife impactor. Fig. 6. Penetration depths of the aramid woven fabrics relative to the areal density of fabric sheets 4. CONCLUSIONS In order to protect human body against the stabbing threat, the anti-stabbing performance was tested, while a tower drop method was applied according to the NIJ standard. The armor specimens were prepared in the form of woven fabrics. We chose three sizes of aramid filament yarns, and produced five kinds of fabric densities. Then we applied the test to verify the stab resistance of each product. Our results showed that the changes of fabric density and the size of filament yarn strongly affected to the stab resistance, and the 200de high density aramid fabric demonstrated good anti-stabbing performance. Therefore, with the aramid filament yarns, in order to get the best anti-stabbing performance, we should apply thin yarn and high density woven fabric. REFERENCES [1] Anctil B., Keown M., Bourget D., Pageau G., 2005. Bolduc M., Performance Evaluation of Multi-Threat Body Armour Systems, Proceedings of the 22nd International Symposium on Ballistics, Canada. [2] Gadow R. and von Niessen K., 2003. Lightweight ballistic structures made of ceramic and cermet/aramide composites, Proceedings of the Ceramic Armor and Armor Systems Symposium Held at the 105th Annual Meeting of the American Ceramic Society, Nashville, TN. [3] Flambard X. and Polo J., 2004. Stab resistance of multi-layers knitted structures: comparison between para-aramid and PBO fibers, Journal of Advance Material, 36, 30-35. [4] Ankerson J., Birkbeck A. E., 2007. Thomson R. D., and Vanezis P., Puncture resistance and tensile strength of skin simulants, Proceedings of SAMPE 2007, Baltimore, MD. [5] Nguyen C. T., Vu-Khanh T., and Lara J., 2004. Puncture characterization of rubber HỘI NGHỊ KHOA HỌC VÀ CÔNG NGHỆ TOÀN QUỐC VỀ CƠ KHÍ LẦN THỨ V - VCME 2018 membranes, Theoretical and Applied Fracture Mechanics, 42, 25-33. [6] Russell S. J., Pourmohammadi A., Ezra I., and Jacobs M., 2005. Formation and properties of fluid jet entangled HMPE impact resistant fabrics, Composites Science and Technology, 65, 899-907. [7] Thi B., Vu N., Vu-Khanh T., and Lara J., 2005. Effect of friction of cut resistance of polymers, Journal of Thermoplastic Composite Materials, 18, 2005, 23-35. [8] Cho K. and Lee D., 1998. Viscoelastic effects in cutting of elastomers by a sharp Object, Journal of Polymer Science, Part B, Polymer Physics, 36, 1283-1291. [9] Gent A. N. and Wang C., - Cutting resistance of polyethylene, Journal of Polymer Science, Part B, Polymer Physics, 34, 1996, 2231-2237. [10] Lara J., Turcot D., Daigle R., and Boutin J., 1996. New test method to evaluate the cut resistance of glove materials, ASTM Special Technical Publication, 1237, 23–31. [11] J Lara J., Turcot D., Daigle R., and Payot F. Payot., 1996. Comparison of two methods to evaluate the resistance of protective gloves to cutting by sharp blades, ASTM Special Technical Publication, 1237, 32–42. [12] Standard, 2005. Stab Resistance of Personal Body Armor NIJ Standard-0115.00, National Institute of Justice, USA. [13] Horsfall I., Watson C., Champion S., Prosser P., and Ringrose T., 2005. The effect of knife handle shape on stabbing performance, Applied Ergonomics, 36, 505–11. [14] Chadwick E. K. J., Nicol A. C., Lane J. V., and Gray T. G. F., 1999. Biomechanics of knife stab attacks, Forensic Science International,105, 35–44. [15] Horsfall I. I., Prosser P. D., Watson C. H., and Champion S. M., 1999. An assessment of human performance in stabbing, Forensic Science International, 102, 79–89.

File đính kèm:

tinh_chat_chong_dam_xuyen_cua_vai_det_dung_soi_lien_tuc_aram.pdf

tinh_chat_chong_dam_xuyen_cua_vai_det_dung_soi_lien_tuc_aram.pdf