Supplier selection criteria in Vietnam: A case study in textile and apparel industry

The Vietnamese textile industry originated in the late 1950s in the north and in 1970 in

the south with the construction of large factories by the French in Nam Dinh, Hai Phong,

and Hanoi (Manpower, 2015). Since then, the textile and apparel (T&A) industry of Vietnam

has been a key contributor to the country’s fast-growing, export-oriented economy as the

second largest export, representing 10% to 15% of GDP and employing more than 2.5 million

labourers (Virac, 2016). Furthermore, Vietnam has also enrolled itself in the list of the ten

largest T&A exporters in the world for years (Vietrade, 2017). The Vietnamese T&A industry

has a significant role not only in Vietnam’s economy but also in the world. However, the

added value that Vietnamese T&A companies and the country received is not critical

enough because 65% of Vietnamese T&A companies undertake the basic form of garment

manufacturing, which is cut-make-trim (BSC, 2016). Therefore, currently, the Vietnam

Textile and Apparel Association offers various programmes to encourage Vietnamese T&A

companies to upgrade their production into higher value-added processes such as fabric

sourcing, designing, marketing, or branding (Vũ Lê, 2017). Vietnamese T&A companies are

also in the process of upgrading to the higher form of manufacturing (Viện Nghiên cứu

Chiến lược, Chính sách công nghiệp, 2012; Chung Thủy, 2017). Nonetheless, the ability to

upgrade is dependent on the sourcing of materials (Nadvi et al., 2004). Effective sourcing

can contribute tremendously to the competitive advantage of an organization (Novack &

Simco, 1991; Murray, 2001); however, it is not an easy task, as purchasers need to select from

a great number of suppliers that are capable of supplying the buyer with the right quality

products and/or services at the right price in the right quantity and at the right time (Cengiz

et al., 2017). A set of criteria to select the appropriate suppliers are truly of necessity for

Vietnamese T&A companies.

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Trang 6

Trang 7

Trang 8

Trang 9

Trang 10

Tải về để xem bản đầy đủ

Tóm tắt nội dung tài liệu: Supplier selection criteria in Vietnam: A case study in textile and apparel industry

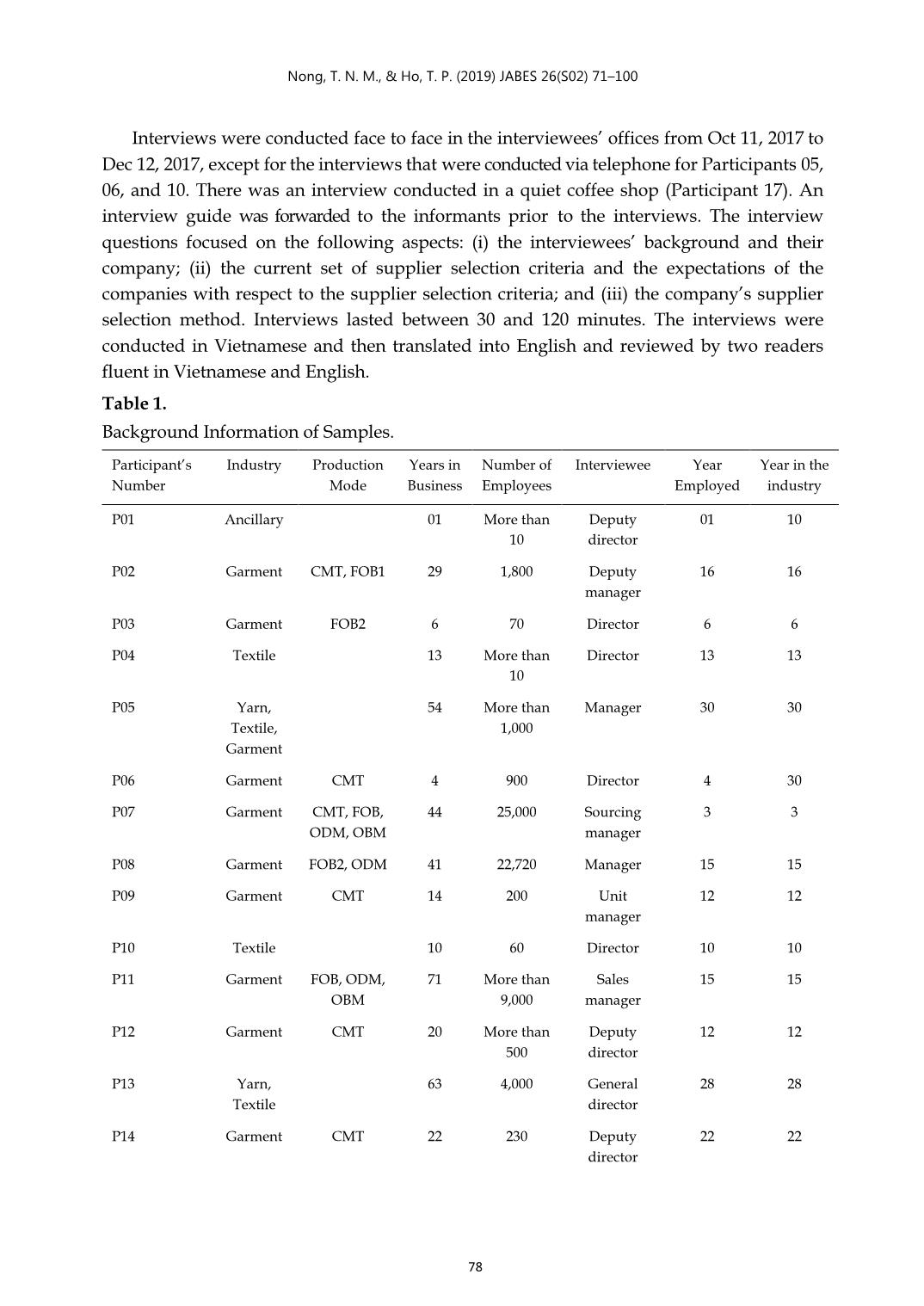

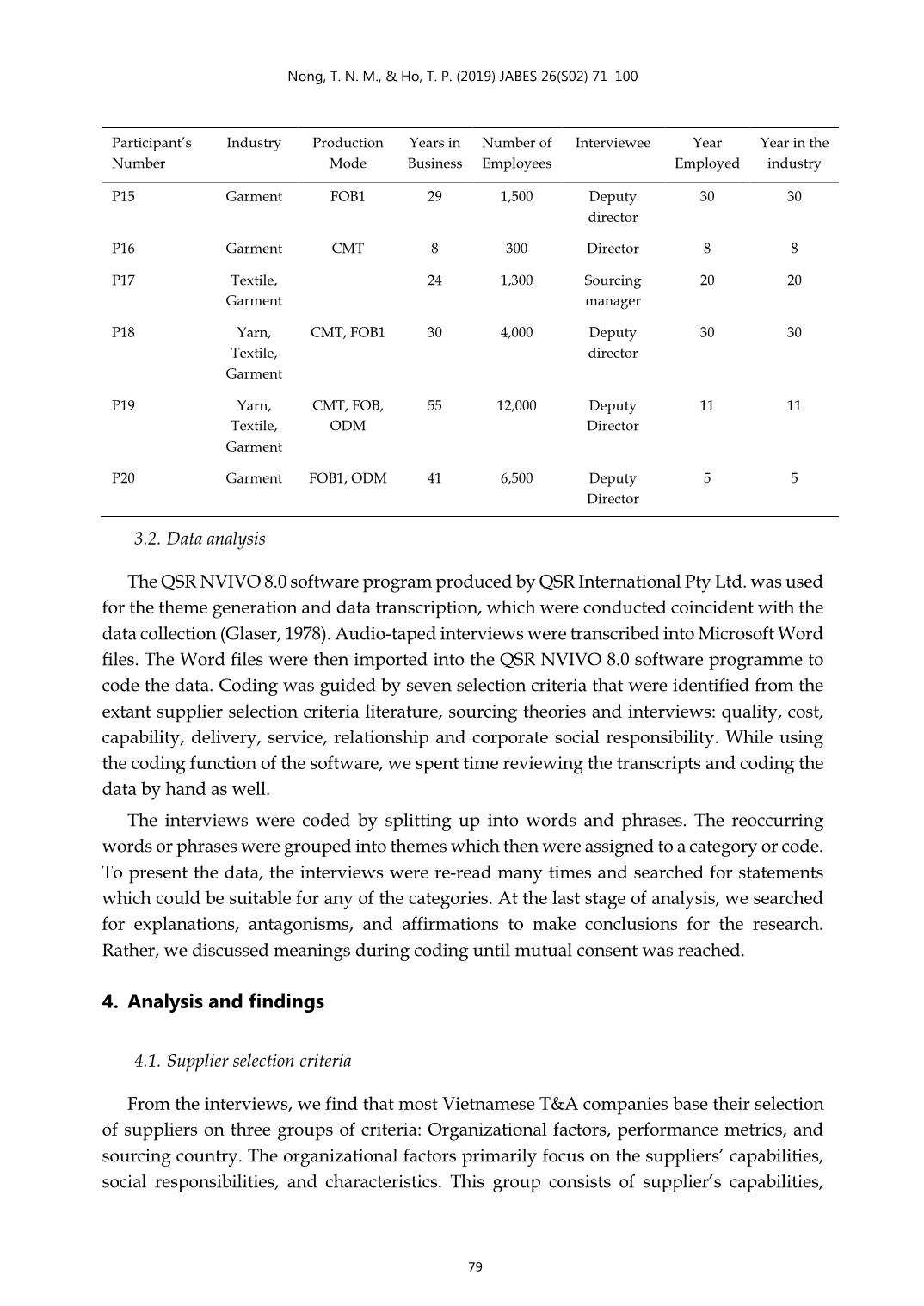

Journal of Asian Business and Economic Studies Volume 26, Special Issue 02 (2019), 71–100 71 www.jabes.ueh.edu.vn Journal of Asian Business and Economic Studies Supplier selection criteria in Vietnam: A case study in textile and apparel industry NONG THI NHU MAI a,*, HO THANH PHONG b a International University – Vietnam National University, Vietnam b Hong Bang International University, Vietnam A R T I C L E I N F O A B S T R A C T Received: Dec 11, 2018 Revised: Mar 11, 2019 Accepted: Jul 29, 2019 Available online JEL classification: D80, D81, Z39 Keywords Supplier selection criteria; Procurement; Textile and apparel; Vietnam. Supplier selection is a significant phase of procurement. However, a little systematic research on supplier selection criteria in the textile and apparel industry has been conducted in Vietnam. The purpose of this study is to identify criteria that constitute to the supplier selection decision of purchasers. An integrated approach involving purposeful sampling and theoretical sampling is used. Qualitative data are collected via expert interviews from 20 companies ranging from spinning to textiles to garments as well as ancillary industries in both southern and northern Vietnam. The data are analyzed using NVIVO 8.0 software. We assume that exploring the extant supplier selection criteria used by Vietnamese textile and apparel companies will contribute to the literature concerning procurement in particular and supply chain management in general. * Corresponding author. Email: nongthinhumai@gmail.com (Nong Thi Nhu Mai), phonght@gmail.com (Ho Thanh Phong). Please cite this article as: Nong, T. N. M., & Ho, T. P. (2019). Supplier selection criteria in Vietnam: A case study in textile and apparel industry. Journal of Asian Business and Economic Studies, 26(S02), 71–100. Nong, T. N. M., & Ho, T. P. (2019) JABES 26(S02) 71–100 72 1. Introduction The Vietnamese textile industry originated in the late 1950s in the north and in 1970 in the south with the construction of large factories by the French in Nam Dinh, Hai Phong, and Hanoi (Manpower, 2015). Since then, the textile and apparel (T&A) industry of Vietnam has been a key contributor to the country’s fast-growing, export-oriented economy as the second largest export, representing 10% to 15% of GDP and employing more than 2.5 million labourers (Virac, 2016). Furthermore, Vietnam has also enrolled itself in the list of the ten largest T&A exporters in the world for years (Vietrade, 2017). The Vietnamese T&A industry has a significant role not only in Vietnam’s economy but also in the world. However, the added value that Vietnamese T&A companies and the country received is not critical enough because 65% of Vietnamese T&A companies undertake the basic form of garment manufacturing, which is cut-make-trim (BSC, 2016). Therefore, currently, the Vietnam Textile and Apparel Association offers various programmes to encourage Vietnamese T&A companies to upgrade their production into higher value-added processes such as fabric sourcing, designing, marketing, or branding (Vũ Lê, 2017). Vietnamese T&A companies are also in the process of upgrading to the higher form of manufacturing (Viện Nghiên cứu Chiến lược, Chính sách công nghiệp, 2012; Chung Thủy, 2017). Nonetheless, the ability to upgrade is dependent on the sourcing of materials (Nadvi et al., 2004). Effective sourcing can contribute tremendously to the competitive advantage of an organization (Novack & Simco, 1991; Murray, 2001); however, it is not an easy task, as purchasers need to select from a great number of suppliers that are capable of supplying the buyer with the right quality products and/or services at the right price in the right quantity and at the right time (Cengiz et al., 2017). A set of criteria to select the appropriate suppliers are truly of necessity for Vietnamese T&A companies. In addition, in Vietnam, the unavailability of T&A materials and the inability of Vietnamese companies to produce high-quality materials exist (Investvietnam, n.d.). Approximately 35% of T&A companies currently involved in fabric sourcing, designing, marketing, or branding must import most of their materials (approximately 70–80%) from China, Taiwan, and Korea (Virac, 2016). Although most of the materials are globally sourced, many Vietnamese T&A companies lack official supplier selection criteria. The identification of criteria for the selection of suppliers has been the major concern of many practitioners (Thiruchelvam & Tookey, 2011). Still, Vietnamese T&A companies merely rely on their managers’ opinions to make decision. For example, in one of the interviews in this study, a manager of a large garment corporation stated, “When we communicate with suppliers, we observe whether they build trust through their actions and responsibility for a long-ter ... . That risk can be foreseen or cannot be foreseen. We cannot negotiate with them. For example, we buy 10,000 m for the first time, it is ok. Next time, out of 10,000 m of fabric, there are 1,000 m of defective fabrics. In addition to defective fabrics, we cannot fulfil our production of garment, which results in other corollaries, workers do not have materials to do, they are free, and many other costs that we cannot calculate. We work with our suppliers in a spirit of cooperation. Therefore, in payment we can negotiate to utilize deferred payment (T/T or L/C) after a specific period in order that in case there are any problems, we use that sum to cover that. For new suppliers, it is quite difficult, but if suppliers are selected by us, we know clearly their prestige, how they work, cooperation There are many criteria for us to consider when selecting a supplier. A: In terms of payment method you have just mentioned, it is also a criterion that you can base on to evaluate the final price, so what payment methods do you often use? R: uhm. In case of fabrics, materials, for suppliers having long-term relationship with us, they often offer deferred payment after 30 days by T/T. For new suppliers, we have to open L/C at sight. For inconsiderable amount, it can be T/T against documents, or T/T before shipment. It depends. Generally speaking, we will negotiate. A: Is payment method also a criterion that affects our selection decision R: Yes, it affects our price. A: Does your company consider tariffs because it also affects the price? R: For the textile and apparel industry, the import tariff is 0%. If the company cannot use up materials, the government will collect arrears. Therefore, tariffs do not affect. A: Besides the price and quality, you also mentioned delivery, so which sub-criteria of delivery do you consider? R: We will negotiate with the suppliers. When suppliers complete production, they will send us Proforma Invoice which shows the delivery time. As usual, the lead time today is not so long as before. The lead time can be from 20 days to 30 days from the date of order. In the past, the lead time could be from 45 days to 60 days. Nong, T. N. M., & Ho, T. P. (2019) JABES 26(S02) 71–100 96 A: Is the lead time among supplies the same or different? R: It depends on the quantity of orders, complex materials, or simple materials. A: For the same materials, is the lead time among suppliers similar or different? R: It is not similar because the lead time depends on many things. There are two companies producing the same products, and having the same scope. In this period, company A has fewer orders, so its lead time will be faster. Company B has more orders so it will set priorities for companies having sooner orders. It can deliver partially (partial shipment) in order that we have materials to produce our products. A: Is that a criterion you base on to select suppliers? R: In case the time of our order is short, we will base on lead time. If our orders last for 9 or 10 months a year, our supplier must produce materials continuously for us, we do not care the lead time in this case. That means we also care the lead time, but not much. A: In terms of delivery, which sub-criteria do you care? R: We require: firstly, the goods quality must meet our requirements, secondly the materials must be packed in good condition. Thus, any problems with the materials are beyond their control. When they ship the materials to the port, one or two rolls of fabrics are torn or dirty outside, which they also do not know. Or while the materials are shipped in damaged containers, they suck rain water or sea water. When the materials get here, we find out that risk. In case we purchase materials under FOB, we will buy insurance. If we purchase materials under CIF, the suppliers have bought insurance under A clause already. Therefore, the insurance company will be responsible for that risk. This case is also force majeure. For our company, this risk is not much. The delivery time from China to Vietnam is maximum 10 days which is not a long period. There were also one or two consignments that the containers were holed, the fabric absorbed salt. When the fabrics got here, they were dry outside, but they were still wet inside. For these consignments, we had to reduce the volume of production. If our supplier delivered reparation, we also could not produce in time. For this loss, the insurance company would pay for us, but it quite takes time. A: Is the geographic distance between your company and your suppliers a criterion for your company to select suppliers? R: If we select suppliers, we do not select suppliers far from us. We prefer domestic suppliers because we have the same language, same currency. It is easier for us to negotiate. Nong, T. N. M., & Ho, T. P. (2019) JABES 26(S02) 71–100 97 A: You mean that the cultural affinity is also one of the criteria affecting your selection decision. R: To select domestic suppliers, it is quite difficult because the level of auxiliary and material development in our country is limited. A: Are your main suppliers from China? R: Currently, we are purchasing lots of materials from China. But we mainly apply on- spot export–import, we have to make abroad payment, not domestic payment. With materials from China, currently we are applying 100% on-spot export–import. Chinese or Taiwanese invest into Vietnam and build factory to make materials under processing. A: In terms of service criterion, which services do you care? R: Before signing contracts, we do not mention. After signing the contract, we lay emphasis on the delivery time. After taking delivery, any problems arise, suppliers must support us. For the defective fabric, when we need, they must handle the case quickly. A: Are there any other criteria? R: If we want to execute any orders, we need prices or designs , they must support and cooperate with us. We also care the ease of communication, flexibility. A: In terms of their flexibility, in case you want to change something like the volume of the order or the quality of the materials, are your suppliers willing to change? Do you lay your emphasis on this? R: Yes, we cannot predict the changes of our customers, that change affect our ordered materials. The change is often on quantity, not quality because for this industry, there are lots of small stuffs. Before we produce in mass, our customers have to test many things. For example, at the beginning, for each color of fabric, we order 1,000 yards, but after that we decrease the quantity of this color and increase the quantity of the other color. At that time, the suppliers must be willing to meet our requirements. In case they have finished production, they will not change for us. If we sign a contract with T/T payment method, we can change that contract. But if we use L/C, the suppliers are not willing to amend the L/C although we pay the L/C amendment charge. If we do not take full delivery, the materials will be in stock and cannot be sold to other purchasers. However, there are also many suppliers cooperating with us because if we do not use up all materials, we have to be burdened with import duties let alone our capital is stuck. In some cases, we can negotiate with them to keep the materials in their stock, we will take them in the next order. Generally speaking, many suppliers are open to changes. There are also many suppliers not so willing. Nong, T. N. M., & Ho, T. P. (2019) JABES 26(S02) 71–100 98 A: If suppliers are not willing to change, does your company keep on doing business with them? R: If they are appointed by our customers, we have to keep on doing business with them. If suppliers are selected by us, their behavior will be different. A: In addition to the trust which impacts the long-term relationship, are there any other sub- criteria also affecting the relationship between your company and your suppliers? R: My company is old. Before, we had lots of domestic suppliers. The supplier selection criteria were not so difficult as those of today. Our products were only exported to small countries. Today, we export to many big markets which have more difficult criteria. Domestic suppliers cannot meet those criteria. However, we still maintain the relationship with them in order that when we are in need, we can find them. A: To develop the relationship, you used to mention the cultural affinity, does your company base on the cultural affinity to select suppliers? R: It is not the top priority. Most of our materials are imported, so there is no cultural affinity. Maybe there is the affinity in larger scope, for example we import from ASIA, particularly China. China has some similarities with us. But for us the cultural affinity is not an important criterion. Given that a supplier has competitive price, good quality, and service, we can maintain the relationship. A: You mentioned many criteria like price, quality, delivery, service, relationship, does your company pay attention to the supplier’s competence? R: Yes, if the suppliers do not have production capacity, they cannot fulfil our orders, we cannot process production. A: How to determine their competence. R: For new companies, we will request their profiles. A: What information in the profile does your company pay attention to? R: For domestic companies, we will visit their factories. For foreign companies, we only base on their profiles to find the products that they are strong in, their production capacity in a week, a month, or a year. We also find the suppliers’ information through the industry or our customers. A: What else does your company consider when your company study their profiles? R: If we select suppliers by ourselves, we will consider the financial capacity of suppliers. But if suppliers are appointed by our customers, we do not care. In addition, we also care their reputation. Some domestic suppliers are well-known in the industry, it is easier to do business with them. Nong, T. N. M., & Ho, T. P. (2019) JABES 26(S02) 71–100 99 A: In terms of suppliers’ competence, do you have any sub-criteria to consider like human resources? R: In some fields like weaving, they do not need many laborers, they only need machines. Only garment industry needs lots of human resources. For auxiliary manufacturing industry, machines are mainly used. A: In the coming time, does your company supplement any more criteria? R: We have revised our set of criteria many times, but I find that main criteria are what we have just mentioned. A: Does your company intend to revise and supplement any criteria? R: We revised the criteria in 2011. Every time we revise the criteria, we do not revise by ourselves and then publish them. We have to send them to Editor of ISO - a third party to approve after we finish revising the criteria. This one is related to our ISO document. We need to hire a Consultant company to make a complete document and publish it legally. When foreign partner checks, we have an official document. A: In the future, if our industry has a clear set of supplier selection criteria for the textile and apparel companies, is your company willing to apply that set? R: Actually, it is good to have one because that one is a common set of criteria of the industry. When that set is delivered to member companies, they can customize the set to be appropriate to their companies or apply all to their companies. If that set is better than the one of our Company, our company is willing to apply. A: Your company has lots of supplier selection criteria, do you define the weights for criteria? R: Yes, we do but I do not remember exactly the weights. In my company, we have a set of criteria to select and evaluate suppliers before we do business with them. For example, we search information about them, then we evaluate them. If their marks are in the allowable range, we will continue to do business with them. If not, we will stop. During the transaction time or after 1 year we will re-evaluate those suppliers. We have that set of criteria as well as their weights. This set will be submitted to the Board of Leaders for approval. A: Board of Leaders means Board of Director? R: That’s right. A: Your company has criteria and their weights, so which method does your company apply to select suppliers? R: For one material, we have two to three suppliers. Firstly, we have a basis to compare suppliers in terms of price, quality, competence, so on in case this supplier cannot meet Nong, T. N. M., & Ho, T. P. (2019) JABES 26(S02) 71–100 100 our order, we will choose another supplier. Three suppliers work with us in different ways. The prices will be different, payment time will also be different in different points of time. This season the price can be high, but the next season it can be lowered. During the time doing business with them, we can withdraw comments on each supplier unofficially. We can find a supplier that is easy to do business with or easy to cooperate. After a period doing business with him, we can give marks for the supplier. The three suppliers will have different marks. A: How to give marks for suppliers? R: We have marking scheme. For example, with price criterion, it can get from 1 to 3 marks. If the price is good, we can mark maximum 3. It has instruction for us to give the mark. A: Then you sum up the marks R: That’s right. But we take the average mark because we have many criteria to give marks to. A: Does your company have a board or an individual to give marks? R: Each department will give marks for one criterion. For example, for quality, the Quality department will give mark for this criterion. That quality department can have 2 or 3 persons. Each supplier supplies materials for different orders. Each person in the quality board will give a mark and then take average for the quality criterion. For the price criterion, the sales department will give marks Not only one person evaluates suppliers, but each department will evaluate and give marks for each criterion. Our company built up the first set of criteria in 2003 subject to the requirements of ISO. The first time, there were only some criteria. When we have more customers, we export to the USA and some other markets. They have some new requirements that need to be added to the set of criteria. We have revised that set many times. The latest set was revised in 2011. Recently, there are some stuffs that need to be added to the set, but it takes quite a lot of time to invite a third party to consult to do that set. Thanks for your cooperation!

File đính kèm:

supplier_selection_criteria_in_vietnam_a_case_study_in_texti.pdf

supplier_selection_criteria_in_vietnam_a_case_study_in_texti.pdf