Simulating 3r robot dynamics using imported cad in maplesim

With the development of information technology, many applications of robots are

increasingly being applied to support research, learning, and teaching. This

paper mainly investigates the modeling and simulation of a robotic arm with 3

degrees of freedom (dofs) for different applications. First, Kinematics and

dynamics model of the robot based on the standard Denavit Hartenberg (D-H)

modeling method, where the forward kinematics of robot is analyzed and

computed to obtain by using the inverse kinematics, and then the solution of the

robot dynamics is derived. Second, a CAD model of the robot is designed on

CATIA software to convert to MapleSim software to simulation and control.

Final, numerical simulation is presented to display results. This work provides a

potential basis for the realization of the robotic arm in the industrial, education,

and research field, which is of great significance for improving manufacturing

efficiency and support teaching and research in the robot field.

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Trang 6

Trang 7

Trang 8

Trang 9

Trang 10

Tải về để xem bản đầy đủ

Tóm tắt nội dung tài liệu: Simulating 3r robot dynamics using imported cad in maplesim

Thu Dau Mot University Journal of Science – Volume 2 – Issue 4-2020

401

Simulating 3r robot dynamics using imported cad in Maplesim

by Nguyen Van Tan (Thu Dau Mot University)

Article Info: Received 20 Oct 2020, Accepted 25 Nov 2020, Available online 15 Dec, 2020

Corresponding author: tannv@tdmu.edu.vn

https://doi.org/10.37550/tdmu.EJS/2020.04.084

ABSTRACT

With the development of information technology, many applications of robots are

increasingly being applied to support research, learning, and teaching. This

paper mainly investigates the modeling and simulation of a robotic arm with 3

degrees of freedom (dofs) for different applications. First, Kinematics and

dynamics model of the robot based on the standard Denavit Hartenberg (D-H)

modeling method, where the forward kinematics of robot is analyzed and

computed to obtain by using the inverse kinematics, and then the solution of the

robot dynamics is derived. Second, a CAD model of the robot is designed on

CATIA software to convert to MapleSim software to simulation and control.

Final, numerical simulation is presented to display results. This work provides a

potential basis for the realization of the robotic arm in the industrial, education,

and research field, which is of great significance for improving manufacturing

efficiency and support teaching and research in the robot field.

Keywords: Inverse kinematics, Forward Kinematics, MapleSim, Robot arm

1. Introduction

With the development of information and mechanical technologies, robots have been

invented and applied to the manufacturing process, which can improve the production

efficiency, enhance productivity, improve the working conditions and accelerate the

industrial automation [1-2]. Several other applications of robot arms were used in the

Nguyen van Tan– Volume 2– Issue 4-2020, p.

402

automotive industry and are often used for welding, painting, loading, and unloading [3]

as well as in the medical field [4, 5]. The robotic arm extends and expands the functions

of the hand, foot, and brain. It can replace people's work in harsh environments such as

danger, harmfulness, toxic, low temperature, and high heat: instead of people doing

heavy and monotonous repetitive work, which can improve labour productivity and

ensure product quality. Its application has been extended to the field of space

exploration, deep-sea development, nuclear science research and medical welfare. A

robot arm is a new technology emerging in the field of modern automatic control and

has become an important part of modern industrial systems [6]. The robot arm consists

of the robot arm, controller, servo drive system, detection and sensing components. It is

a type of automated production equipment with features such as human-like operation,

automatic control, reprogrammable, and can complete various operations in three-

dimensional space.

To support robot research, learning, and research, many applications software support

the design, calculation, analysis, simulation, and optimization of the robot control

process has been rapidly developing in it. Some software is used a lot such as

Simmechanics to simulation robot arm which was shown in [7, 8], and MSC Adams to

analysis and simulation robot arm that was also shown in [9, 10], then, MapleSim has

used analysis, dynamics simulation and optimization shown in [11-13]. Particularly,

with LMS AmeSim, Simcenter, and MSC Adams, the simulation results are treated as

real results that can be accepted in [14, 15].

Figure 1. The robot arm model 3R

In this paper, An application study of the Maplesim software to control and simulate a

3R robot arm. First, the robot arm model is built in CAD software such as Solidwork or

Inventor, or Catia that is shown in Figure 1. From this, this model is imported to

MapleSim. And then, establish constraints, the relationships of robot arm components

Thu Dau Mot University Journal of Science – Volume 2 – Issue 4-2020

403

as well as DC motor actuators to control the robot arm. Here, PID controllers are also

utilized in the control process.

2. Denavit and Hartenbergh Representation

The kinematic equations use matrix algebra to build constrain functions between the

joint variables and the world coordinate location of the end-effector (position and

orientation) based on the spatial configuration of a particular robot arm. A systematic

and generalized approach to represent the kinematic equations of a serial link robot arm

was proposed by Denavit & Hartenbergh (D-H).

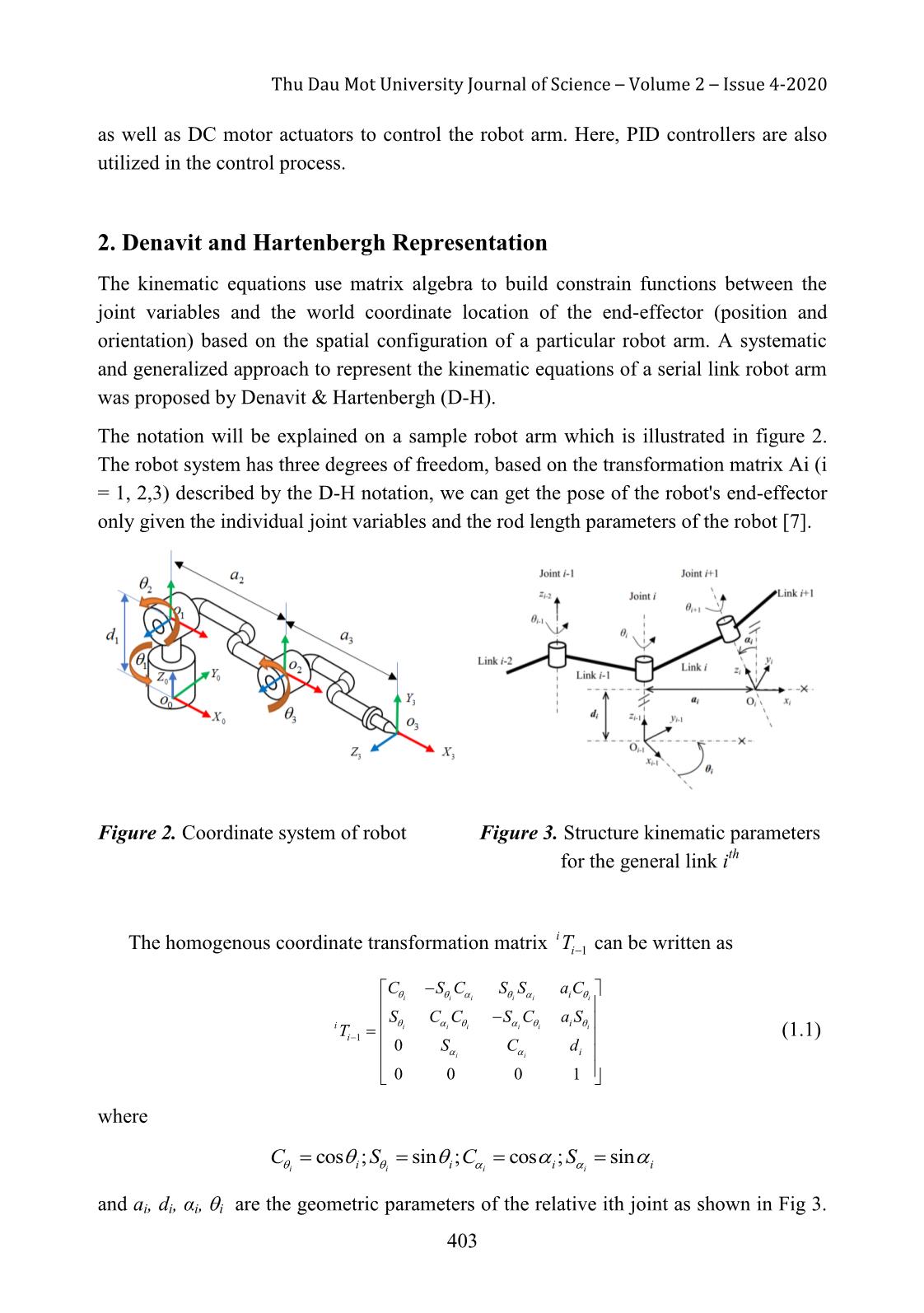

The notation will be explained on a sample robot arm which is illustrated in figure 2.

The robot system has three degrees of freedom, based on the transformation matrix Ai (i

= 1, 2,3) described by the D-H notation, we can get the pose of the robot's end-effector

only given the individual joint variables and the rod length parameters of the robot [7].

Figure 2. Coordinate system of robot Figure 3. Structure kinematic parameters

for the general link i

th

The homogenous coordinate transformation matrix 1

i

iT can be written as

1

0

0 0 0 1

i i i i i i

i i i i i i

i i

i

ii

i

i

C S C S S a C

S C C S C a S

T

S C d

(1.1)

where

cos ; sin ; cos ; sin

i i i ii i i i

C S C S

and ai, di, αi,i are the geometric parameters of the relative ith joint as shown in Fig 3.

Nguyen van Tan– Volume 2– Issue 4-2020, p.

404

They can be defined as:

αi is the angle between zi-1 and zi about xi

di is the distance between origin oi-1 and the intersection of the zi-1 axis with the xi

axis along zi-1

θi is the angle between xi-1 and xi about zi-1.

ai is the distance between origin Oi and the intersection of the zi-1 axis with the xi

axis along xi

If a position vector Pi is given in the i

th

coordinate frame, then it can be expressed in the

(i-1)

th

coordinate system as the vector Pi-1 by

1 1

i

i i ip T p (1.2)

The homogenous transformation matrix from the n

th

coordinate frame to the base

coordinate frame can be determined by multiplying 1

i

iT (i = 1, 2,, n) together in

sequence, such as

1 2

0 0 1 1...

n n

nT T T T (1.3)

Therefore, a position vector pn of the n

th

coordinate frame can be determined for the

base coordinate system as:

1

0 0

o n

np T p

(1.4)

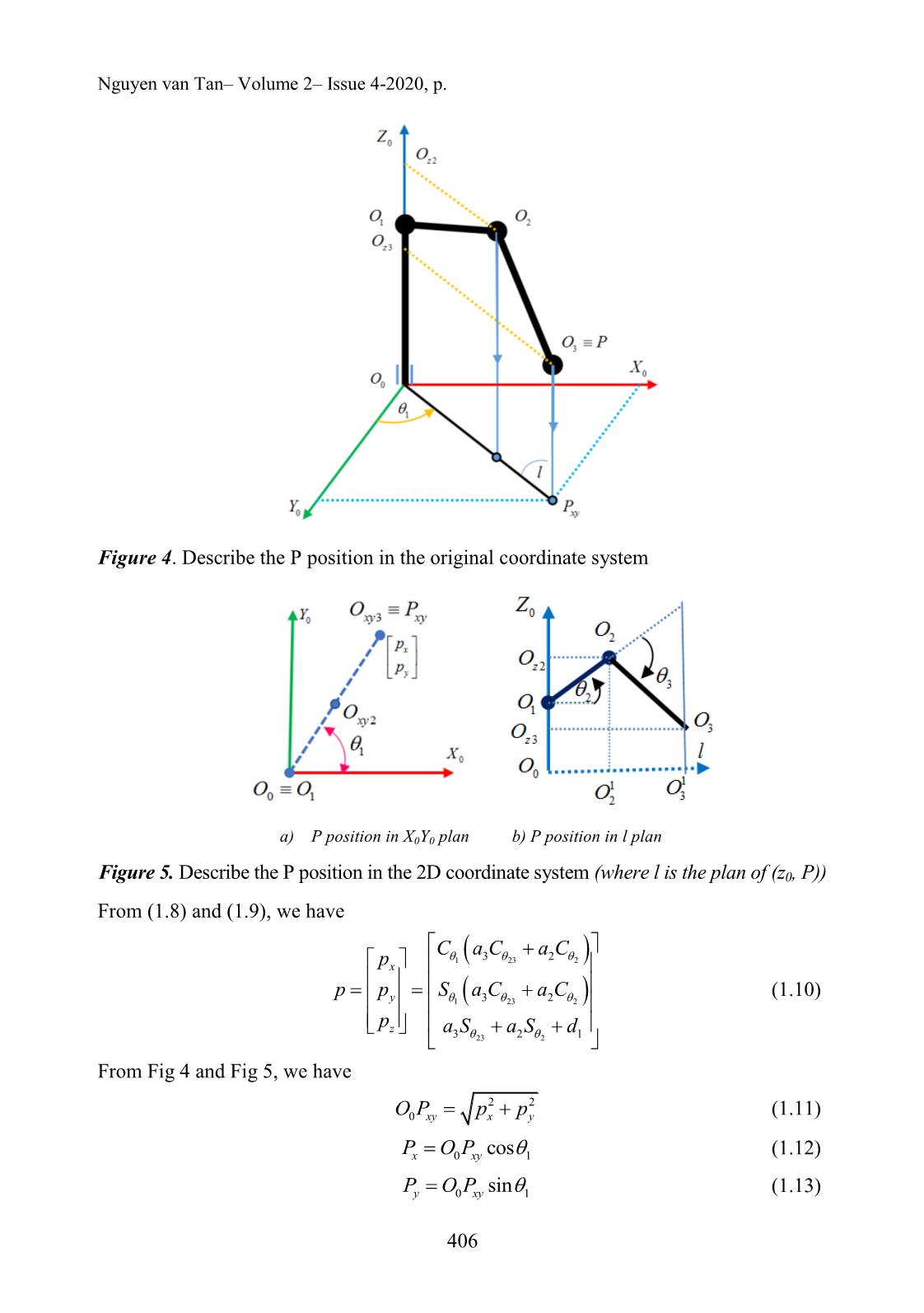

Using the D-H procedure, the coordinate frames are defined and the structural

geometric parameters of the three-link robot arm are presented in Table 1.

TABLE 1. Joint-Link Parameters for 3R Robot arm

Link ai i di i

1 0 90

0

d1 1

2 a2 0 0 2

3 a3 0 0 3

Therefore, the coordinate transformation matrices 1

i

iT (i = 1, 2, 3) relating the

coordinates of the i

th

frame to those of the (i-1)

th

frame can be written using equation

(1.1) as follows

Thu Dau Mot University Journal of Science – Volume 2 – Issue 4-2020

405

1

11

0

0 0

0 0

0 1 0

0 0 0 1

i

i

i

C S

S C

T

d

(1.5)

2 2 2

2 2 2

2

22

1

0

0

0 0 1 0

0 0 0 1

C S a C

S C a S

T

(1.6)

0

3

3 3 3

3 0

3

3 3 32

0 0 1 0

0 0 0 1

C S a C

S C a S

T

(1.7)

The homogenous transformation matrix 3 0T from the coordinate frame attached to the

end-effector to the base coordinate frame can be represented as

1 23 1 23 1 1 23 2

1 23 1 23 1 1 23 2

23 23 23 2

3 1 2 3

0 0 1 2

3 2

3 2

3 2 10

0 0 0 1

T T T T

C C C S S C a C a C

S C S S C S a C a C

S C a S a S d

(1.8)

Where

23 232 3 2 3

cos( ); sin( );C S

Based on this transformation matrix, the forward kinematics can determine a precise

coordinates of the robot arm in the workspace according to the value of each joint angle

variable.

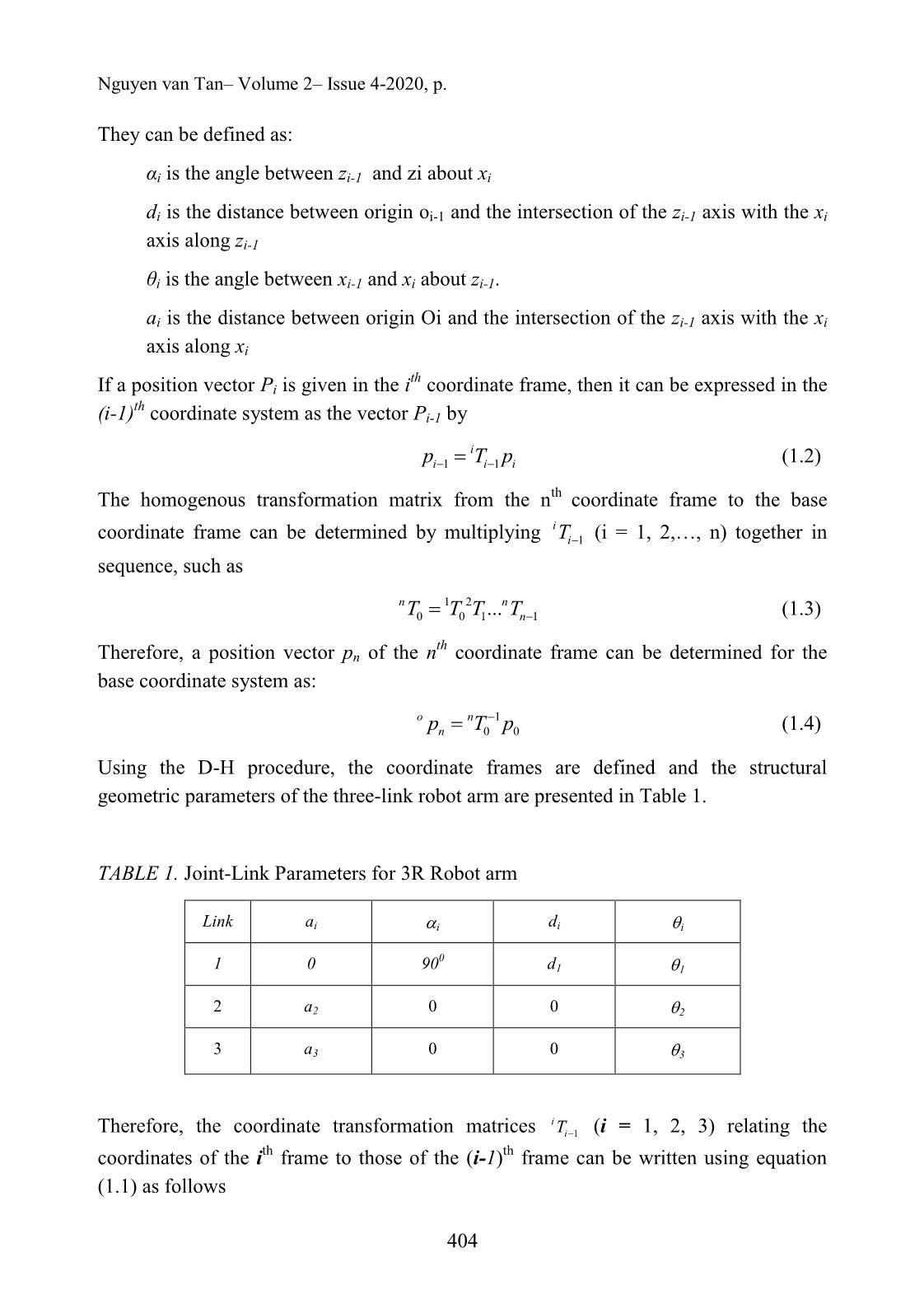

The geometric approach is applied to find the inverse kinematics of the three-link robot

arm shown in Fig 4. A point P representing a given position of the end-effector, which

is the origin of the last coordinate frame concerning the base coordinate system, can be

expressed by

T

x y zp p p p (1.9)

Nguyen van Tan– Volume 2– Issue 4-2020, p.

406

Figure 4. Describe the P position in the original coordinate system

a) P position in X0Y0 plan b) P position in l plan

Figure 5. Describe the P position in the 2D coordinate system (where l is the plan of (z0, P))

From (1.8) and (1.9), we have

1 23 2

1 23 2

23 2

3 2

3 2

3 2 1

x

y

z

C a C a C

p

p p S a C a C

p a S a S d

(1.10)

From Fig 4 and Fig 5, we have

2 20 xy x yO P p p (1.11)

0 1cosx xyP O P (1.12)

0 1siny xyP O P (1.13)

Thu Dau Mot University Journal of Science – Volume 2 – Issue 4-2020

407

Therefore, 1 variable can be calculated as

11 tan

y

x

p

p

(1.14)

Moreover, in Fig. 5. We have

1 1 1 10 3 0 2 2 3 2 2 3 2 3cos cosO O O O O O a a (1.15)

0 3 0 1 1 2 1 3

1 2 2 3 2 3sin sin

z z zO O O O O O O O

d a a

(1.16)

where

1 2 2

0 3 0 0 3;xy x y z zO O O P p p O O p

Solve equations (1.15) and (1.16) we have

22 2 2 2

1 2 3

3

2 3

cos

2

x y zp p p d a a

q

a a

(1.17)

2

3sin 1 q (1.18)

Therefore, θ3 can finally be calculated as

2

1

3

1

tan

q

q

(1.19)

and θ2 can be calculated as

2

1

2 3

1

tan

(1.20)

where

2 2

1

1

tan

x y

z

p p

p d

;

22 2 2 2

1 3 2

22 2

3 12

x y z

x y z

p p p d a a

a p p p d

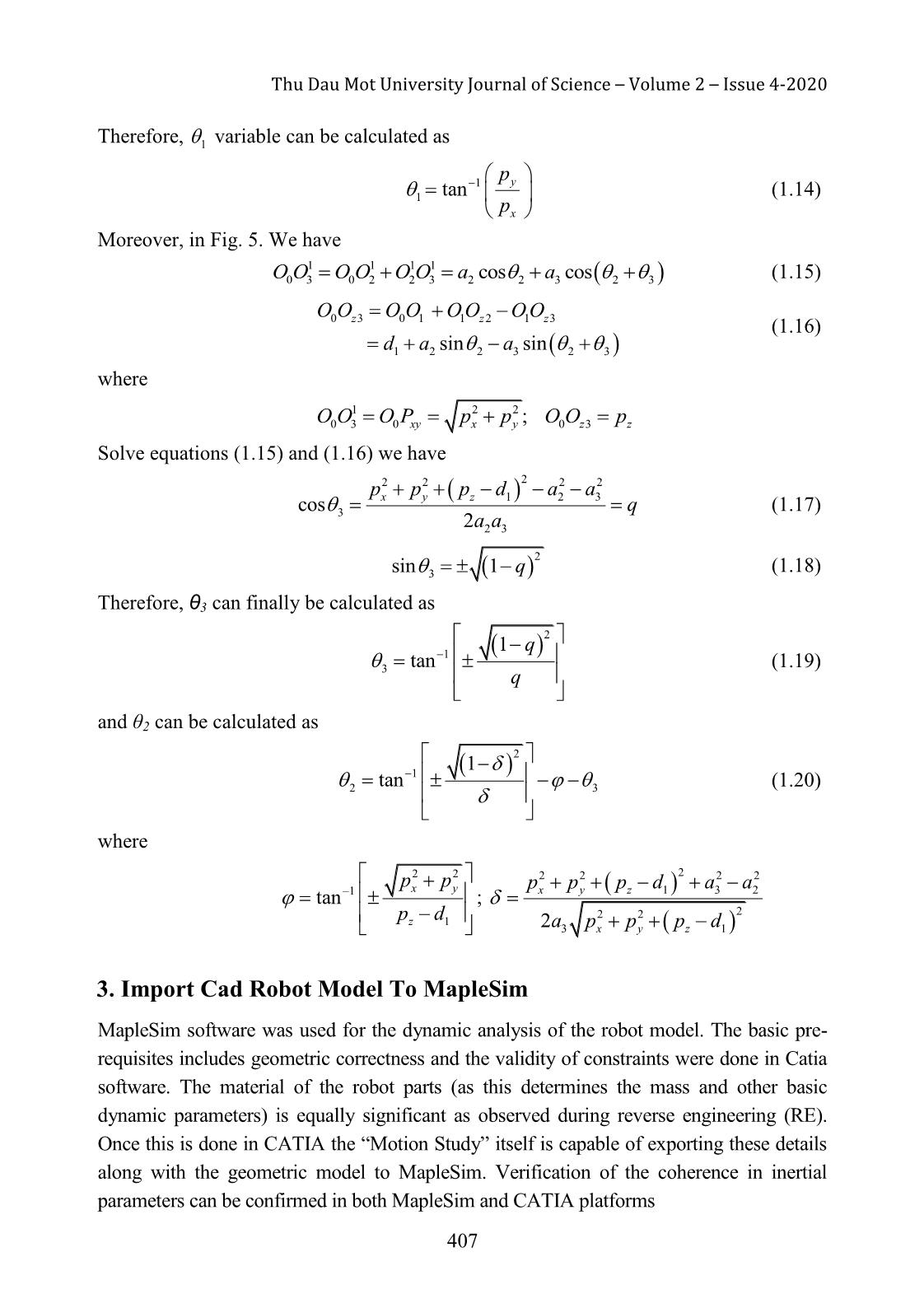

3. Import Cad Robot Model To MapleSim

MapleSim software was used for the dynamic analysis of the robot model. The basic pre-

requisites includes geometric correctness and the validity of constraints were done in Catia

software. The material of the robot parts (as this determines the mass and other basic

dynamic parameters) is equally significant as observed during reverse engineering (RE).

Once this is done in CATIA the “Motion Study” itself is capable of exporting these details

along with the geometric model to MapleSim. Verification of the coherence in inertial

parameters can be confirmed in both MapleSim and CATIA platforms

Nguyen van Tan– Volume 2– Issue 4-2020, p.

408

Figure 6. Robot arm model in MapleSim

To import CAD to Maplesim, from the menu, you choose a file then select Import CAD

as shown in figure 6. Inertial parameters of the robot parts are calculated automatically

as shown in figure 7.

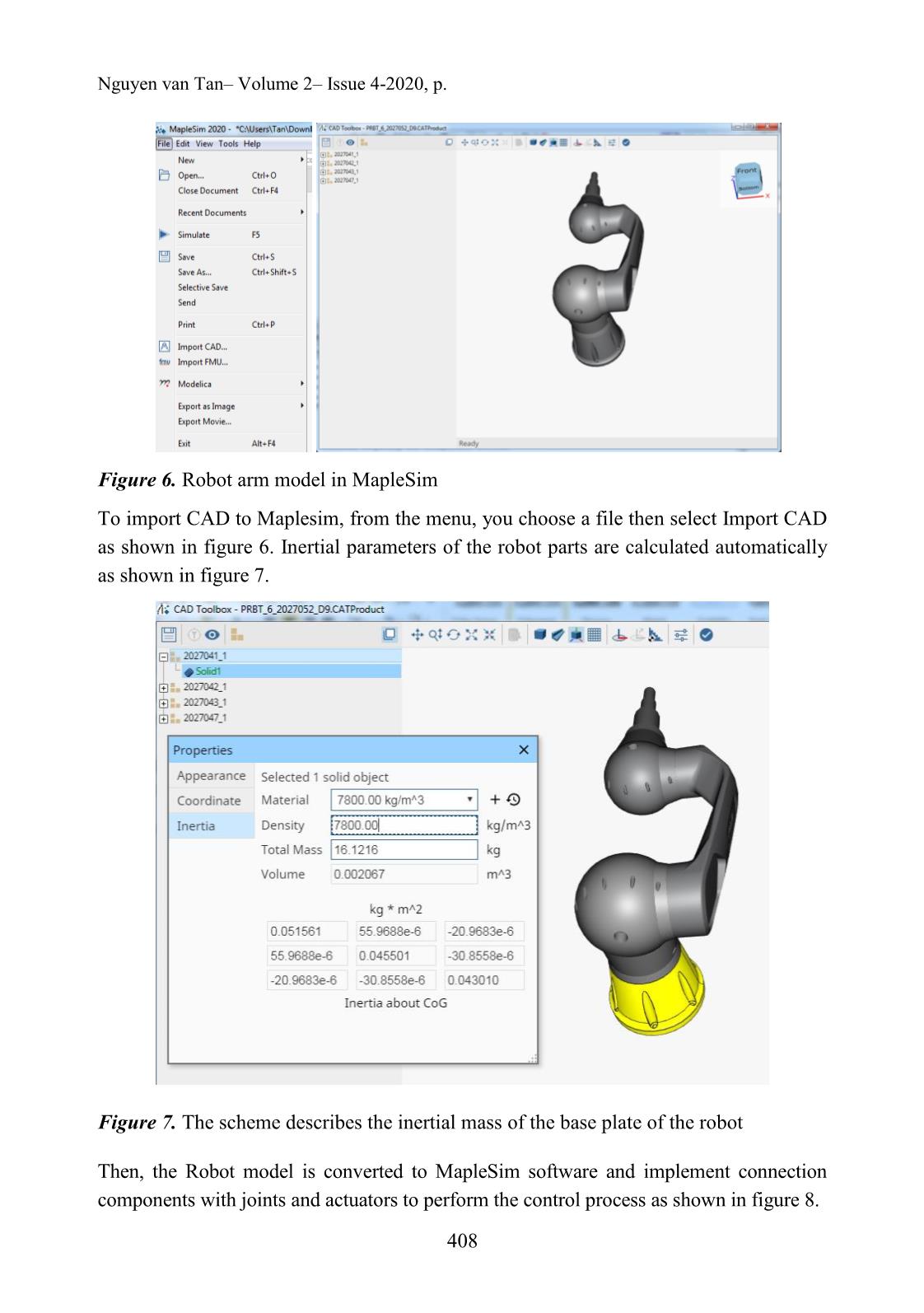

Figure 7. The scheme describes the inertial mass of the base plate of the robot

Then, the Robot model is converted to MapleSim software and implement connection

components with joints and actuators to perform the control process as shown in figure 8.

Thu Dau Mot University Journal of Science – Volume 2 – Issue 4-2020

409

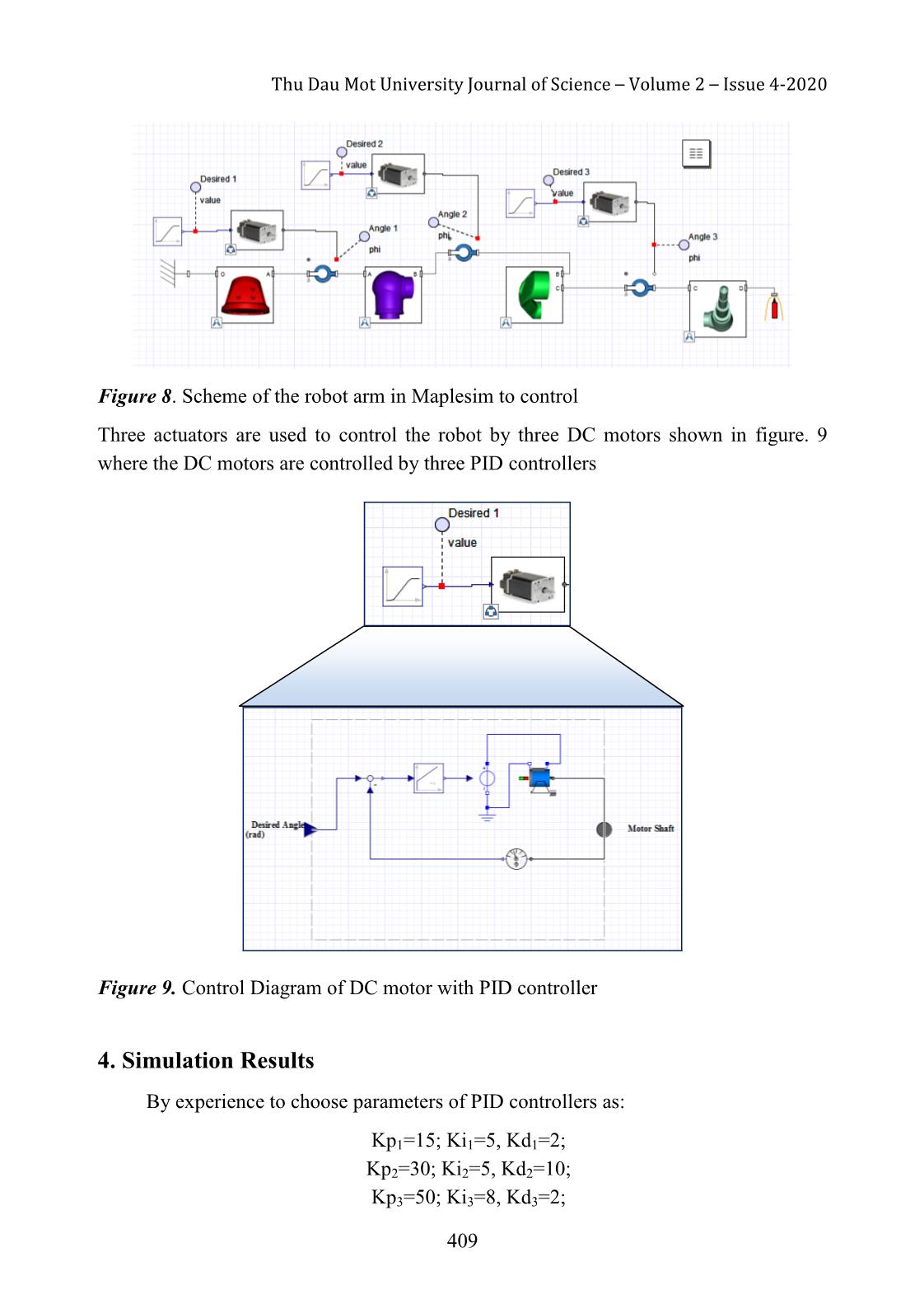

Figure 8. Scheme of the robot arm in Maplesim to control

Three actuators are used to control the robot by three DC motors shown in figure. 9

where the DC motors are controlled by three PID controllers

Figure 9. Control Diagram of DC motor with PID controller

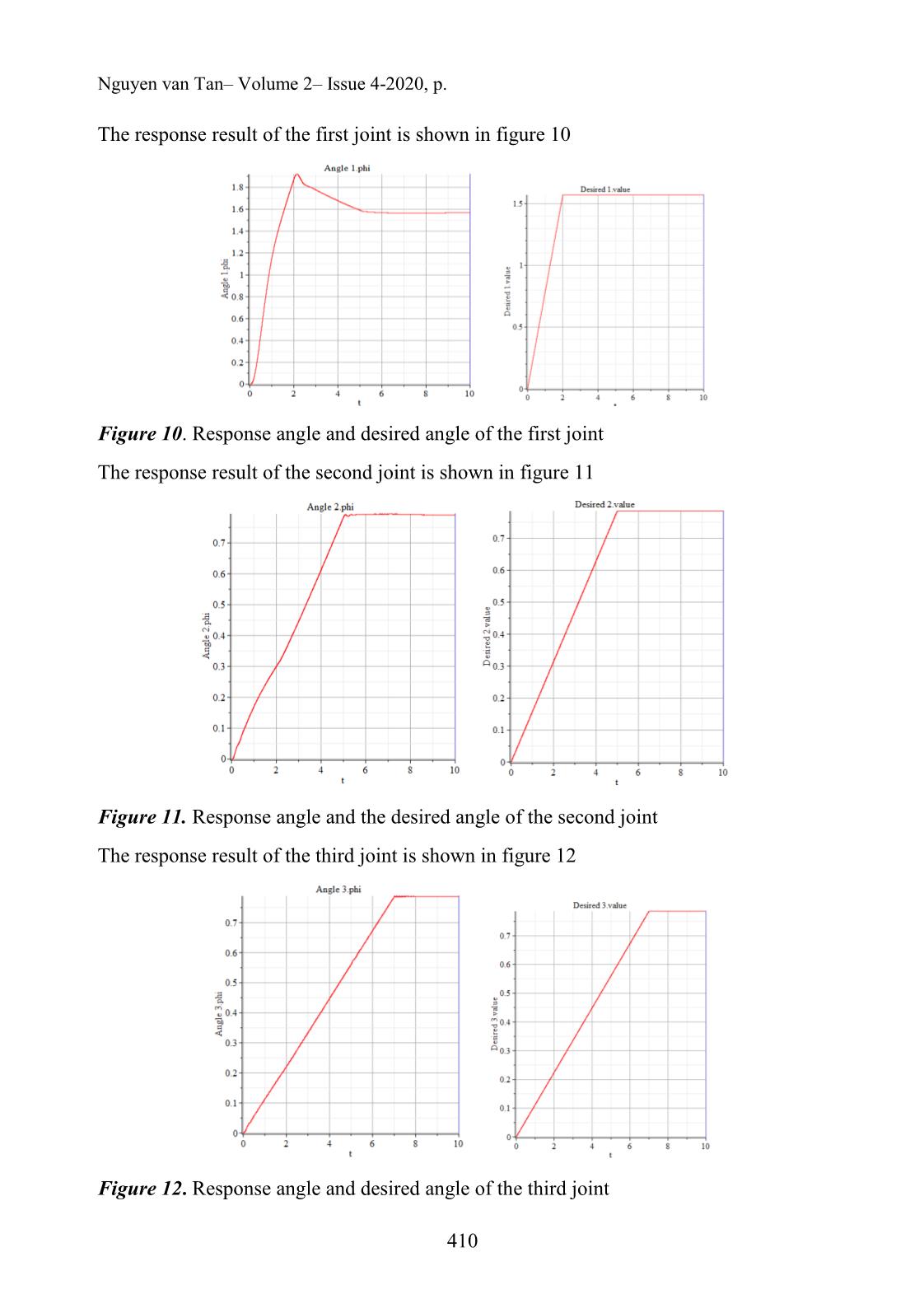

4. Simulation Results

By experience to choose parameters of PID controllers as:

Kp1=15; Ki1=5, Kd1=2;

Kp2=30; Ki2=5, Kd2=10;

Kp3=50; Ki3=8, Kd3=2;

Nguyen van Tan– Volume 2– Issue 4-2020, p.

410

The response result of the first joint is shown in figure 10

Figure 10. Response angle and desired angle of the first joint

The response result of the second joint is shown in figure 11

Figure 11. Response angle and the desired angle of the second joint

The response result of the third joint is shown in figure 12

Figure 12. Response angle and desired angle of the third joint

Thu Dau Mot University Journal of Science – Volume 2 – Issue 4-2020

411

The simulation result of the robot arm is shown in figure 13.

3D simulation robot result is stimulated when given three angles of three axes shown in

figure 10, figure. 11, and figure 12. The trajectory of the end-effector is displayed by the

red trajectory as shown in figure 13.

Figure 13. The simulation result of the robot in 3D Maplesim

5. Conclusion

The rotation angles of the robot arm joints are calculated based on inverse kinematics of

the D-H convention. The robot is designed in CATIA to easy converted to Maplesim

software. The robot arm is set up in maplesim to control and simulation. Simulation

results were obtained as expected under using PID controller that shown in the figures

from figure 10 to figure 13.

Adknowledge: This Research is support by Truong Dai hoc Thu Dau Mot, Binh Duong

province, Viet Nam

References

Nguyen van Tan– Volume 2– Issue 4-2020, p.

412

[1] Y. He et al., (2019). Dynamic Modeling, Simulation, and Experimental Verification of a

Wafer Handling SCARA Robot With Decoupling Servo Control. IEEE Access, vol. 7, pp.

47143-47153, doi: 10.1109/ACCESS.2019.2909657.

[2] Taylan Das M, Canan Dulger L., (2005). Mathematical Modelling, simulation and

experimental verification of a SCARA Robot. Simulation Modelling Practice and Theory,

Vol 13, pp. 257-271;.

[3] W. Jin, et al., (2020). Wire Arc Additive Manufacturing of Stainless Steels: A Review.

Appl. Sci. , 10(5), 1563; https://doi.org/10.3390/app10051563

[4] M. Wei, Q. Liu, and , et al., (2015). Recent development of mechanisms and control

strategies for robot-assisted lower limb rehabilitation. Mechatronics 31, 132-145

[5] S. S. KAMLESH, A. KUMAR, and et al., (2016). Review on Application of Robot Arm in

Medical Field with Special Forcus on Image Guided Biopsies. International Journal of

Mechanical And Production Engineering, 4(11),

[6] Toz, Met in, and Serdar Kucuk (2010). Dynamics simulation toolbox for industrial robot

robot arms. Computer Applications in Engineering Education, 18(2), 319-330.

[7] J. Liu, Q. Luo, (2019). Modeling and Simulation of Robotic Arm in MATLAB for

Industrial Applications. 11th International Conference on Intelligent Human-Machine

Systems and Cybernetics (IHMSC), 978-1-7281-1859IEEE

DOI 10.1109/IHMSC.2019.00086

[8] J. ZATOPEK, and et al., (2018). Dynamic simulation of the CAD model in SimMechanics

with multiple uses. Turkish Journal of Electrical Engineering & Computer Sciences, urk J

Elec Eng & Comp Sci ., 6: 1278 { 1290

[9] T, Amit., “Forward Kinematic Analysis, Simulation & Workspace Tracing of

Anthropomorphic Robot Robot arm By Using MSC. ADAMS”. International Journal of

Innovative Research in Science, Engineering and Technology. 04. Doi:

10.15680/IJIRSET.2015.0401009.

[10] Ratiu, Mariana, and et al., (2018). Modeling in ADAMS of a 6R industrial robot. MATEC

Web of Conferences. Doi: 10.1051/matecconf/201818402006.

[11] J. Hřebíček, and et al., “Modelling with Maple and MapleSim”. Proceedings 22nd

European Conference on Modelling and Simulation ©ECMS Loucas S. Louca, Yiorgos

Chrysanthou, Zuzana Oplatková, Khalid Al-Begain (Editors) ISBN: 978-0-9553018-5-8 /

ISBN: 978-0-9553018-6-5 (CD)

[12] D. Wright and O. Soroka (2012). Modeling and simulation of a linear piezoelectric stepper

motor in maplesim. IEEE International Ultrasonics Symposium, Dresden, pp. 2746-2749,

doi: 10.1109/ULTSYM.2012.0688.

[13] Korobkine, A., Boimer, R., Pantelic, V., Shah, S. et al., (2018). Automatic Calibrations

Generation for Powertrain Controllers Using MapleSim. SAE Technical Paper

https://doi.org/10.4271/2018-01-1458.

[14] P, Aron, and et al., (2015). Real-time co-simulation platform for electromechanical vehicle

applications). 9th International Symposium on Advanced Topics in Electrical Engineering,

ATEE (2015). 240-243. Doi:10.1109/ATEE.2015.7133772.

[15] X. Feixiang and et al., (2018). Modeling and co-simulation based on Adams and AMESim

of pivot steering system. The Journal of Engineering. Doi: 10.1049/joe.2018.9018.

Thu Dau Mot University Journal of Science – Volume 2 – Issue 4-2020

413

File đính kèm:

simulating_3r_robot_dynamics_using_imported_cad_in_maplesim.pdf

simulating_3r_robot_dynamics_using_imported_cad_in_maplesim.pdf