Nghiên cứu sự thay đổi của vi sinh vật và yếu tố lí hóa trong quá trình sản xuất bánh men rượu phần

Bánh men rượu Phần (Fen-Daqu) vừa là tác nhân đường hóa, vừa là tác nhân lên men trong sản xuất rượu Phần, một loại rượu trắng có hương thanh nhẹ nổi tiếng ở tỉnh Sơn Tây, Trung Quốc. Nó được sản xuất bởi quá trình lên men tự nhiên từ nguồn nguyên liệu đại mạch và đậu Hà lan. Phương pháp nuôi cấy vi sinh vật truyền thống và các kĩ thuật phân tích trực tuyến được sử dụng trong phân tích sự thay đổi của các nhóm vi sinh vật và các yếu tố lí hóa.

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Trang 6

Trang 7

Trang 8

Trang 9

Trang 10

Tải về để xem bản đầy đủ

Bạn đang xem 10 trang mẫu của tài liệu "Nghiên cứu sự thay đổi của vi sinh vật và yếu tố lí hóa trong quá trình sản xuất bánh men rượu phần", để tải tài liệu gốc về máy hãy click vào nút Download ở trên

Tóm tắt nội dung tài liệu: Nghiên cứu sự thay đổi của vi sinh vật và yếu tố lí hóa trong quá trình sản xuất bánh men rượu phần

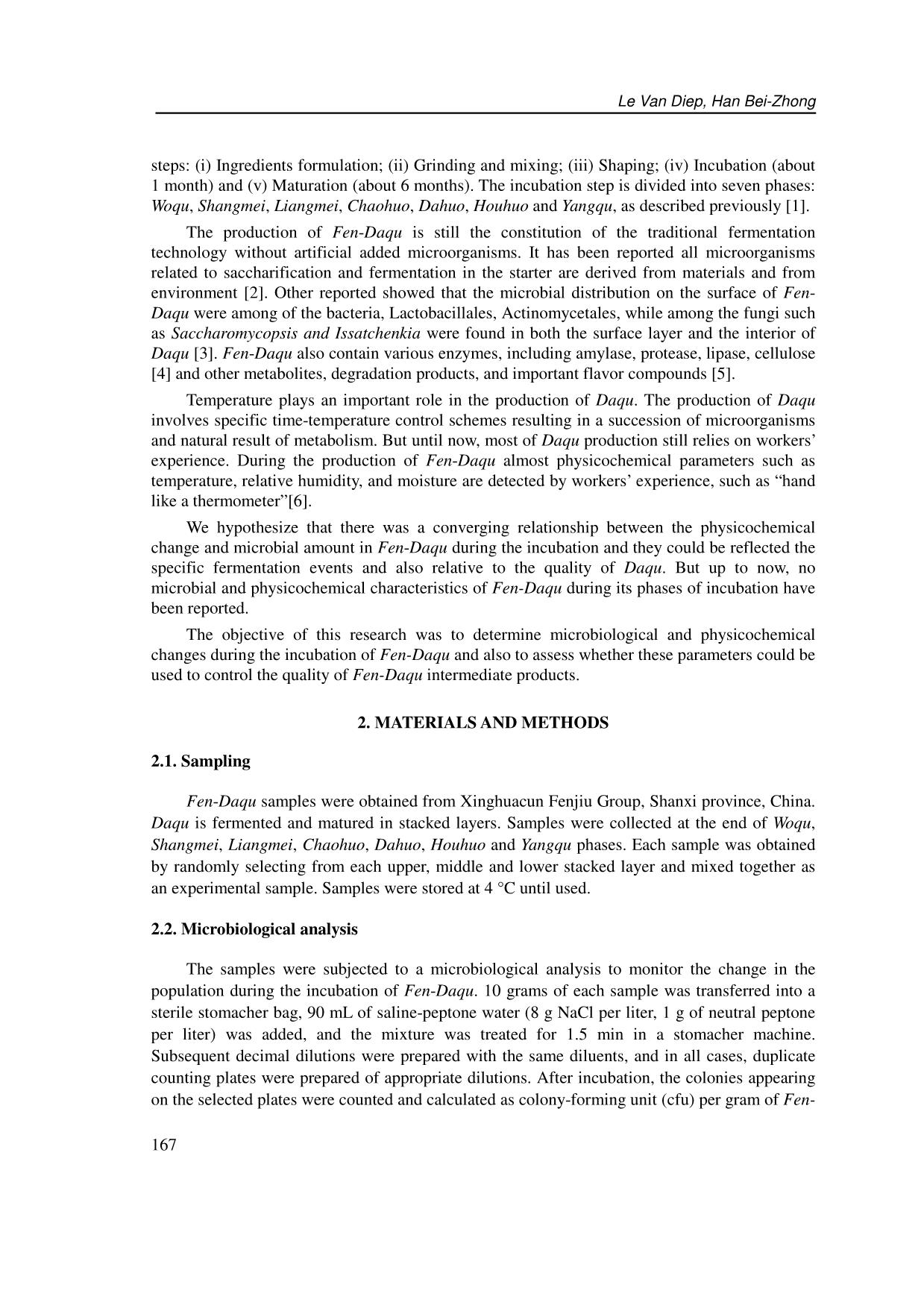

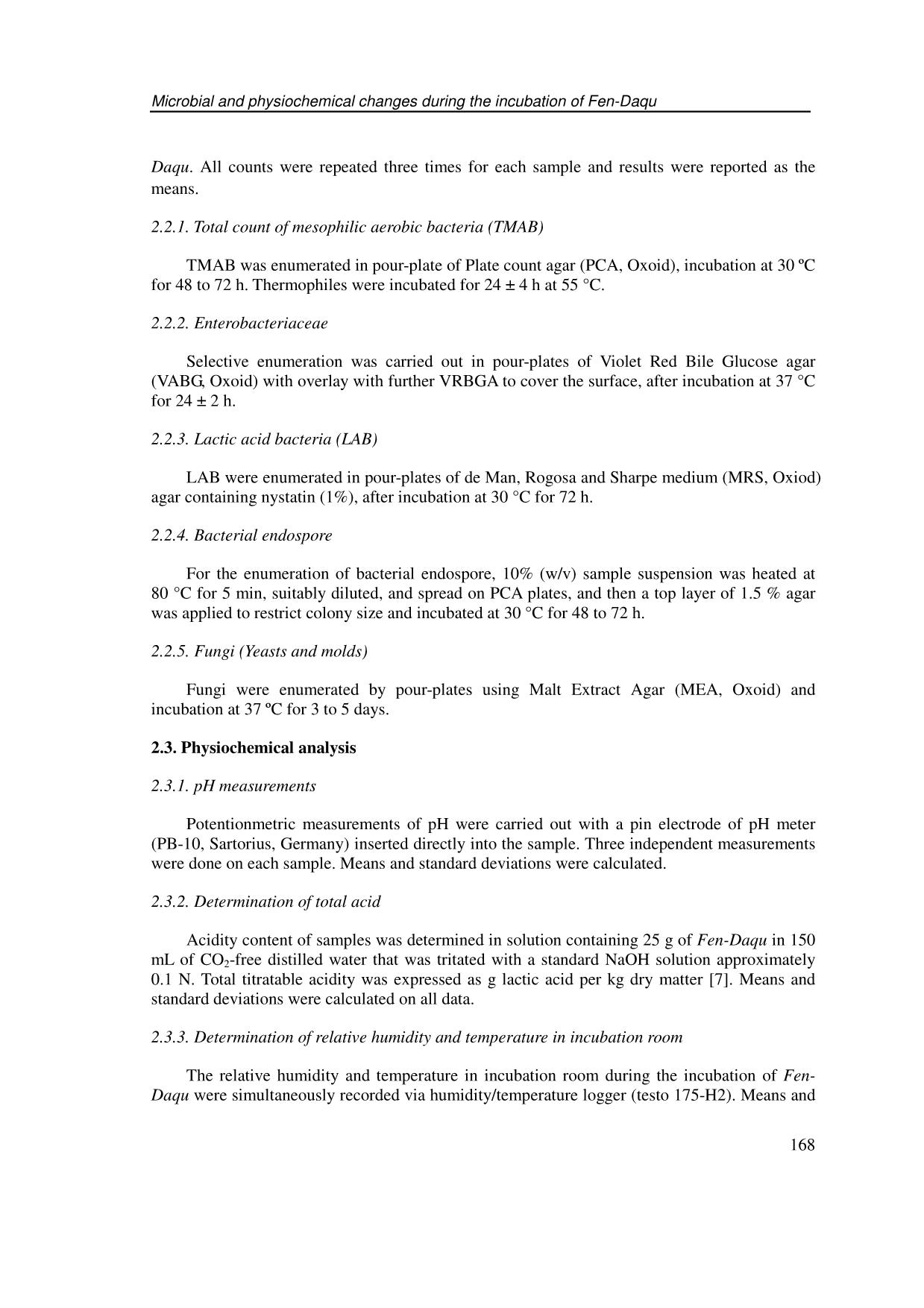

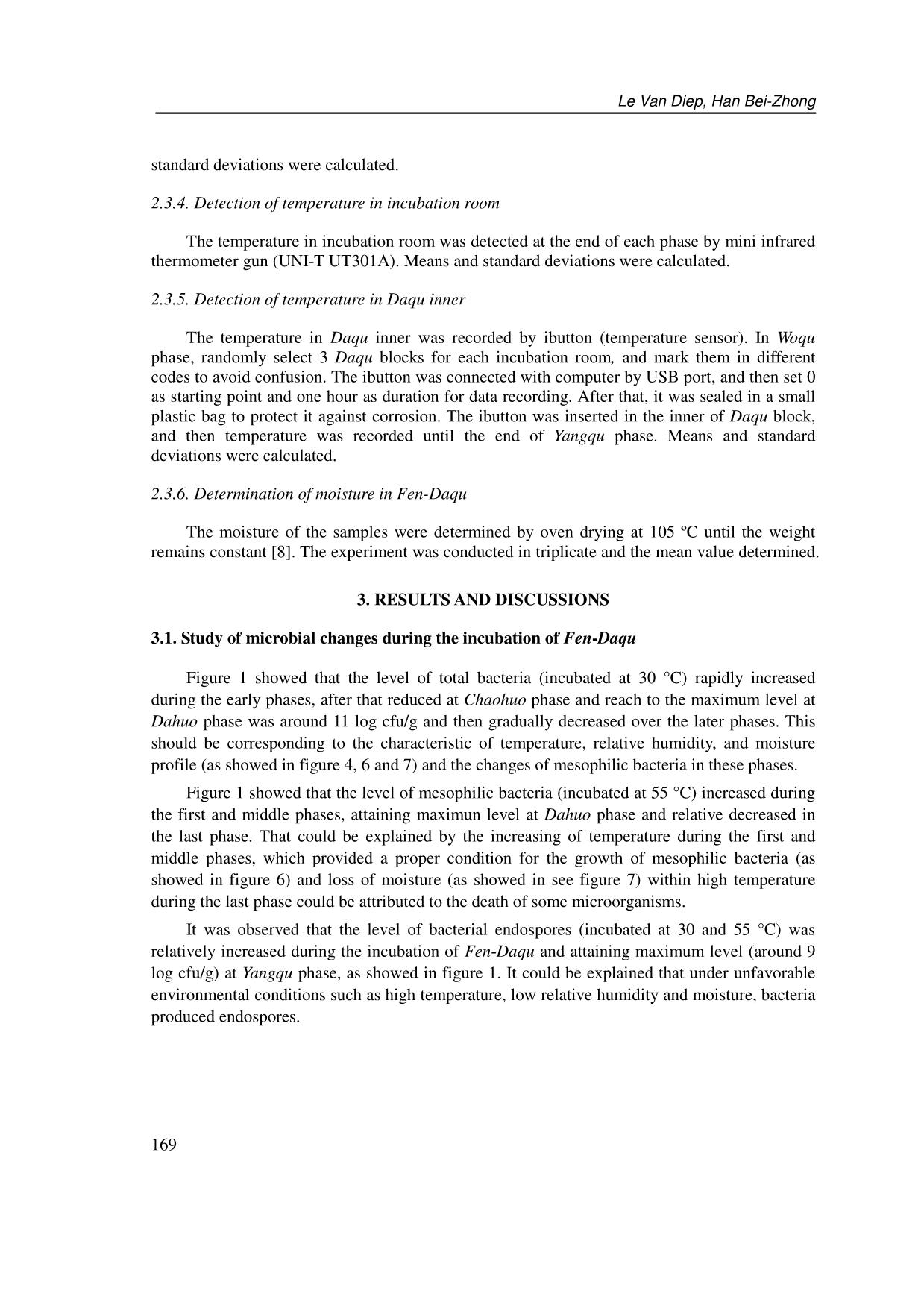

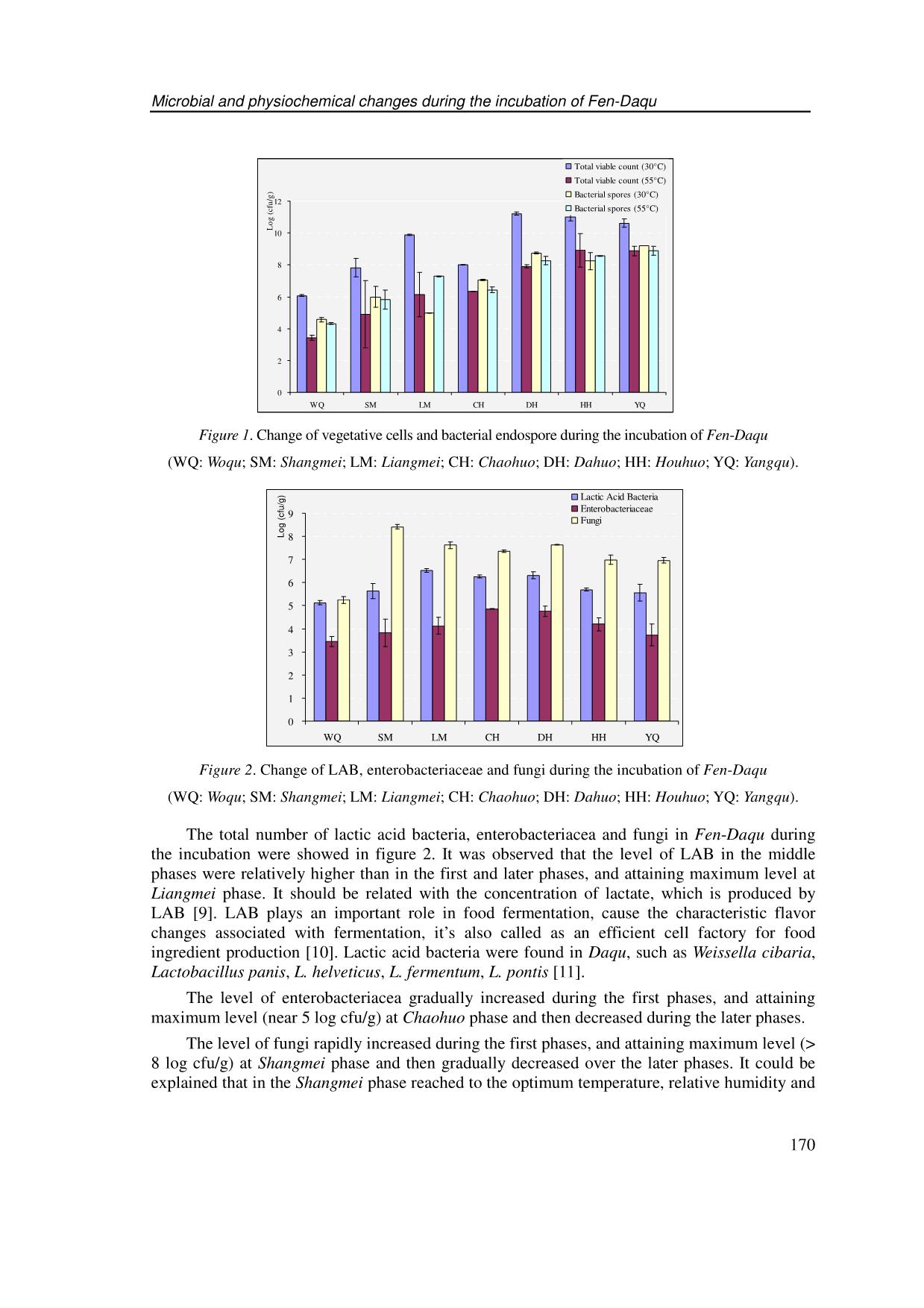

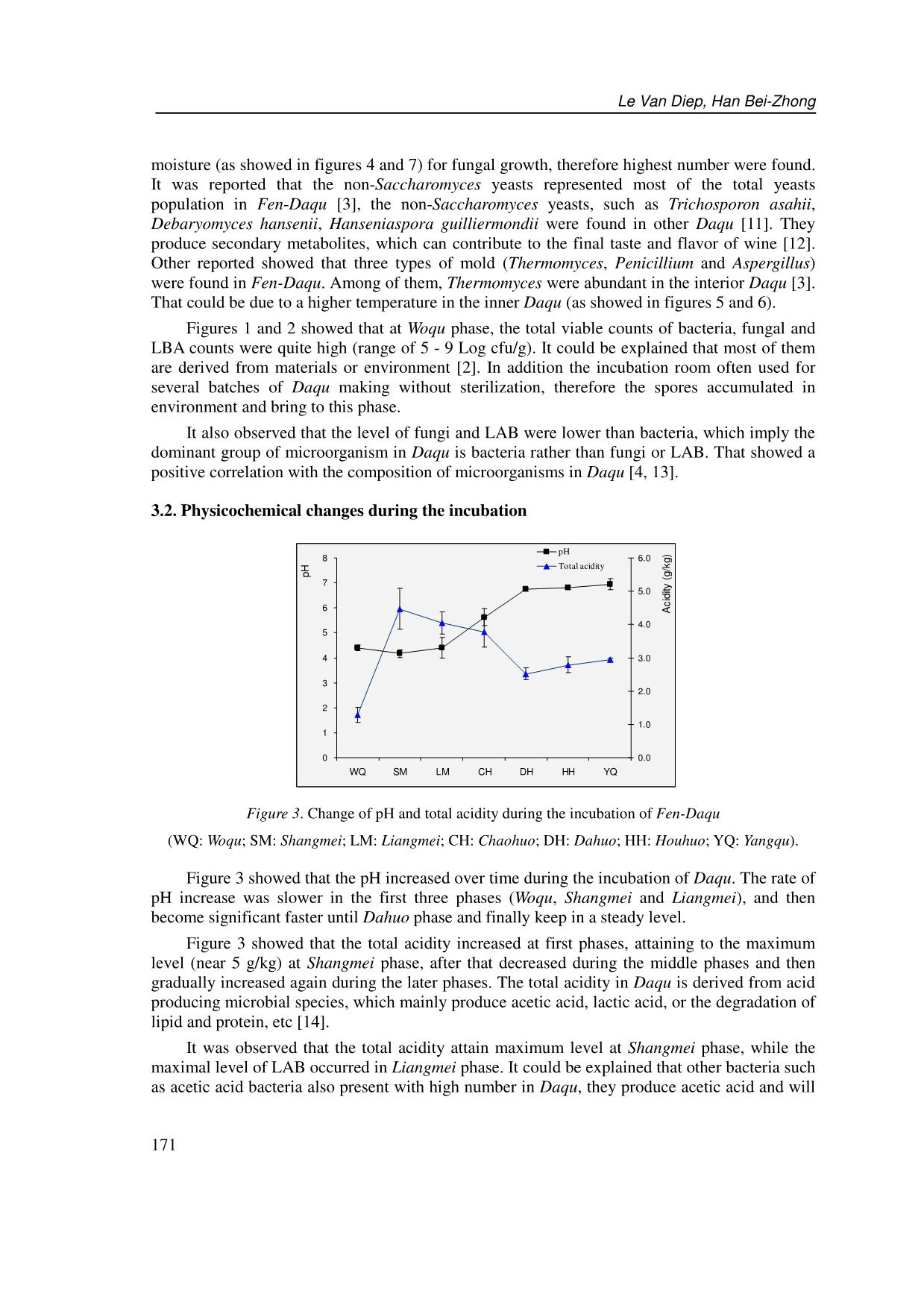

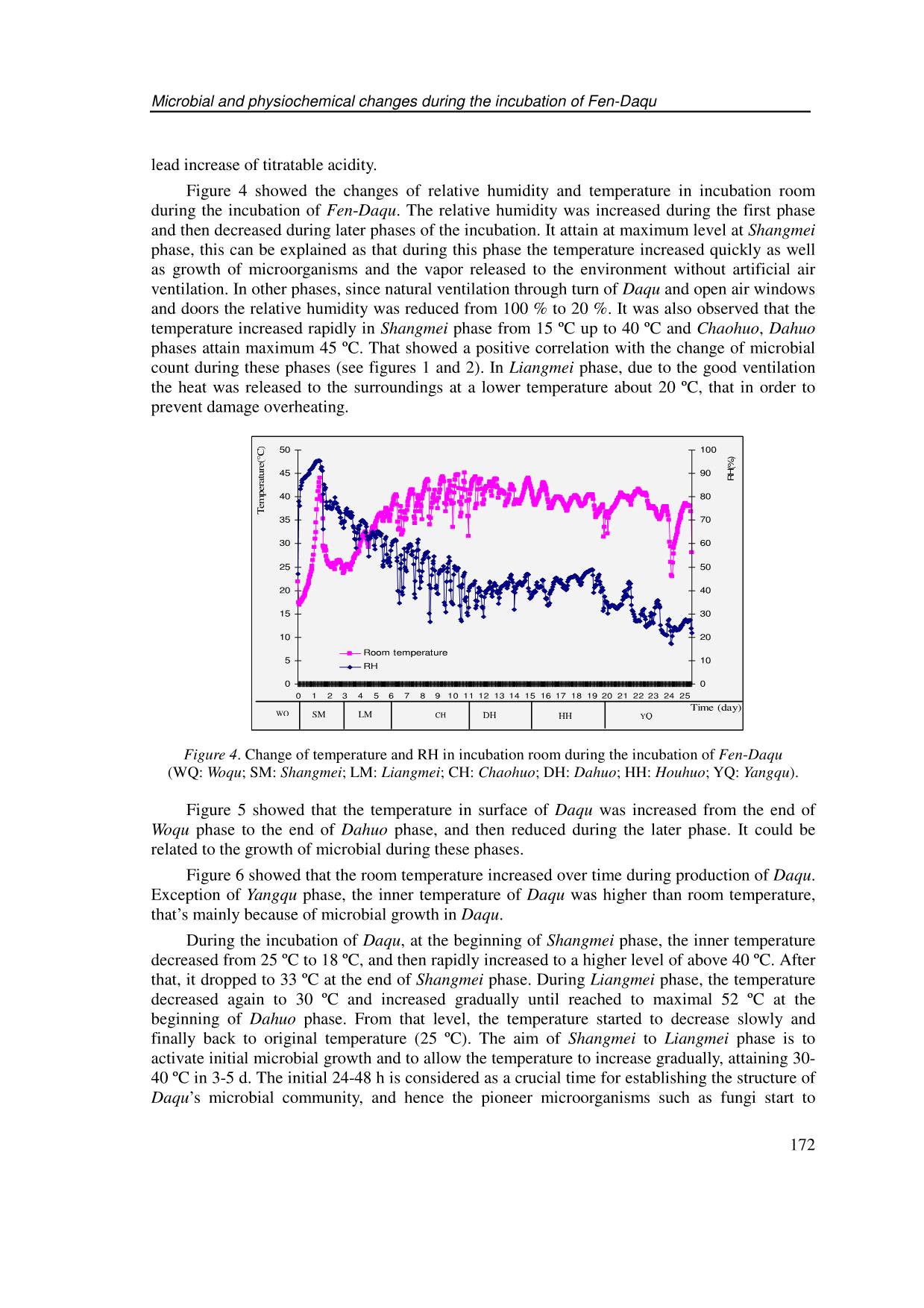

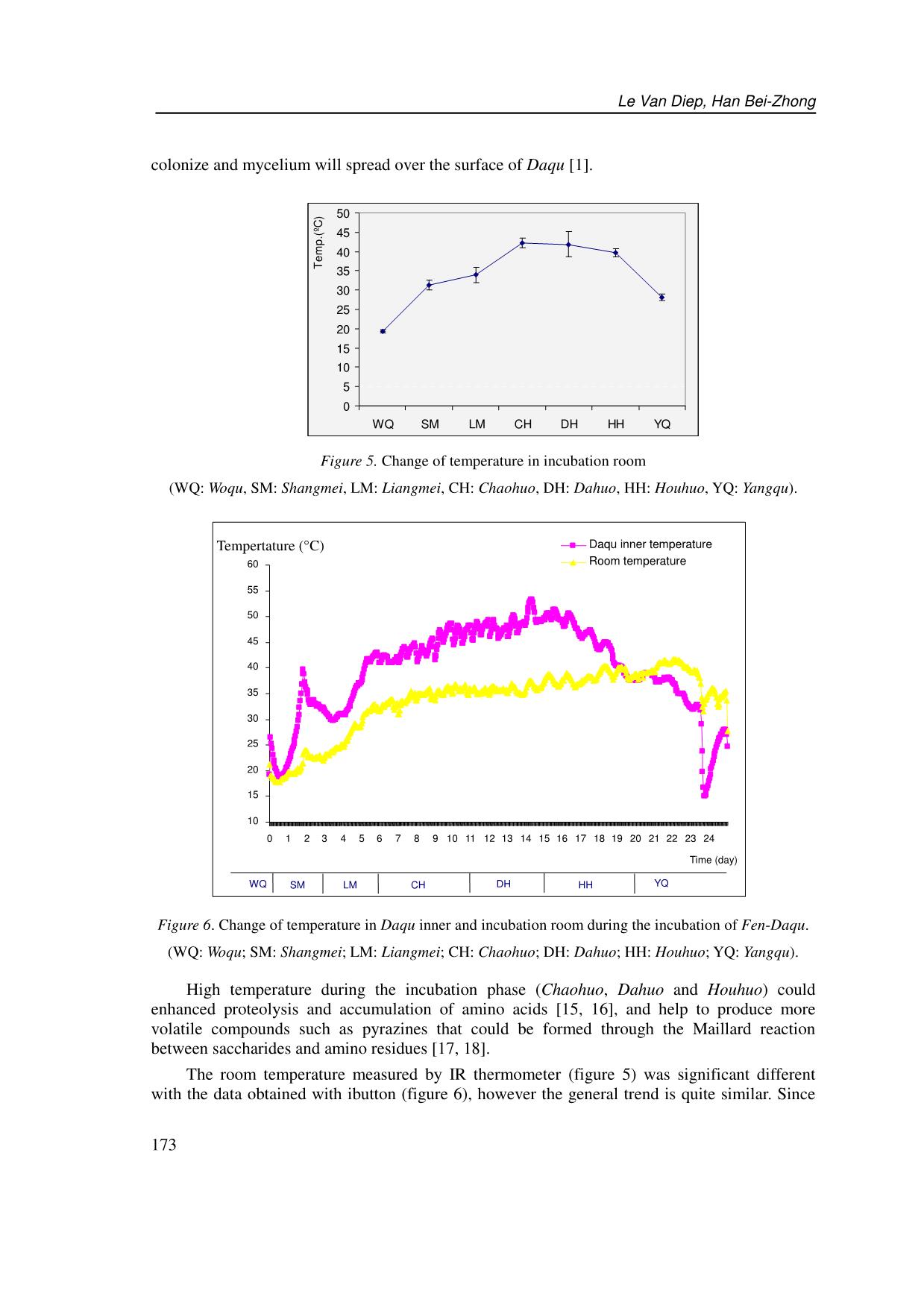

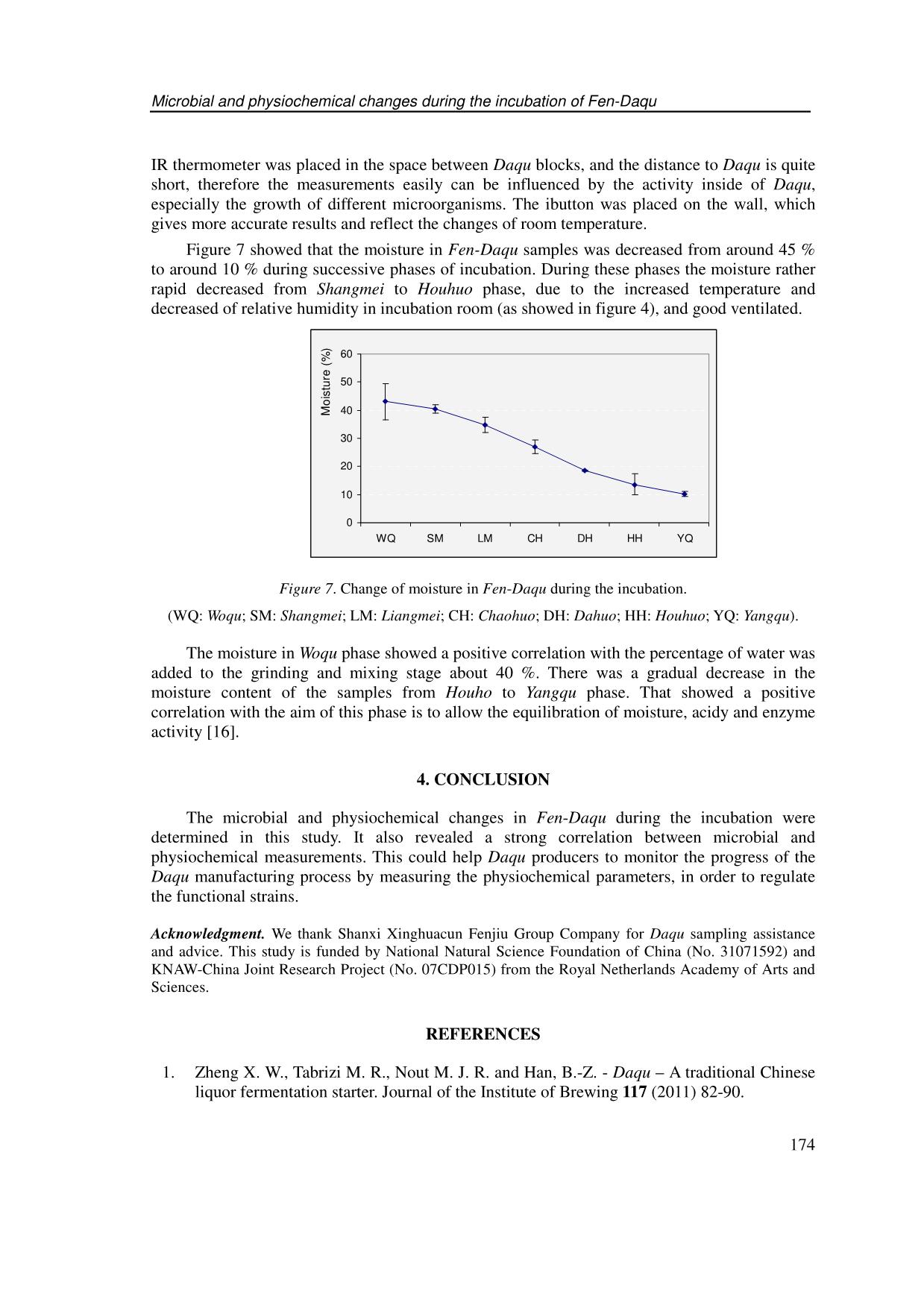

Tạp chí Khoa học và Công nghệ 52 (2) (2014) 167-176 MICROBIAL AND PHYSIOCHEMICAL CHANGES DURING THE INCUBATION OF FEN-DAQU Le Van Diep1, *, Han Bei-Zhong2 1Faculty of Chemistry, Vinh University, 182, Le Duan Street, Vinh City, Nghe An province 2College of Food Science and Nutritional Engineering, China Agricultural University, China *Email: levandiep@vinhuni.edu.vn Received: 19 October 2012; Accepted for publication: 24 February 2014 ABSTRACT Fen liquor is typical of Chinese light-flavor liquor, which is fermented from sorghum with Fen-Daqu powder. Fen-Daqu is a saccharifying agent and fermentation starter obtained by natural solid-state fermentation under non-sterile conditions. The standard plate count and the online measurement methods were used to enumerate the surviving microorganisms, and measure the physiochemical in Fen-Daqu during the incubation. Total counts of mesophilic aerobic bacteria (30 °C and 55 °C), bacterial endospore (30 °C and 55 °C), lactic acid bacteria, enterobacteriaceae and fungi starting with minimum level around 106, <104, <105, <105, 105, < 104 and 105 cfu/g and attaining maximum around 1011, 109, 109, 109, 107, 105 and 108 cfu/g, respectively. During the incubation of Daqu the microorganisms increased from Woqu to Liangmei periods and gradually decreased during the later phases. The pH in Daqu was increased over time during the incubation. The total acidity in Daqu increased and reaches to maximum at Shangmei phase (around 4.5 g lactic acid per kg Daqu) and then gradually decreased over the time. The relative humidity in incubation room was reduced from around 100 % to around 20 %. Temperature in incubation room was increased over time from the first to middle period and decreased in the Yangqu phase. Temperature in Daqu inner was rapidly increased from around 20 to 40 ºC at Shangmei phase, dropped to 30 ºC at Liangmei phase, and then increased gradually until reached to maximal 52 ºC at Dahuo phase, finally decreased to original temperature (25 ºC). The moisture was decreased from around 45 % to around 10 % during successive phases of incubation. Based on these results, a microbiological regulation for the production of Fen-Hongxin Daqu is proposed. Keywords: Chinese liquor starter; Chinese liquor; traditional fermented; food microbial. 1. INTRODUCTION Fen-Daqu is a natural fermentation starter, especially for distilled Chinese Fen liquor and traditional Chinese Fen vinegar production. Fen-Daqu is prepared from barley and peas by five Le Van Diep, Han Bei-Zhong 167 steps: (i) Ingredients formulation; (ii) Grinding and mixing; (iii) Shaping; (iv) Incubation (about 1 month) and (v) Maturation (about 6 months). The incubation step is divided into seven phases: Woqu, Shangmei, Liangmei, Chaohuo, Dahuo, Houhuo and Yangqu, as described previously [1]. The production of Fen-Daqu is still the constitution of the traditional fermentation technology without artificial added microorganisms. It has been reported all microorganisms related to saccharification and fermentation in the starter are derived from materials and from environment [2]. Other reported showed that the microbial distribution on the surface of Fen- Daqu were among of the bacteria, Lactobacillales, Actinomycetales, while among the fungi such as Saccharomycopsis and Issatchenkia were found in both the surface layer and the interior of Daqu [3]. Fen-Daqu also contain various enzymes, including amylase, protease, lipase, cellulose [4] and other metabolites, degradation products, and important flavor compounds [5]. Temperature plays an important role in the production of Daqu. The production of Daqu involves specific time-temperature control schemes resulting in a succession of microorganisms and natural result of metabolism. But until now, most of Daqu production still relies on workers’ experience. During the production of Fen-Daqu almost physicochemical parameters such as temperature, relative humidity, and moisture are detected by workers’ experience, such as “hand like a thermometer”[6]. We hypothesize that there was a converging relationship between the physicochemical change and microbial amount in Fen-Daqu during the incubation and they could be reflected the specific fermentation events and also relative to the quality of Daqu. But up to now, no microbial and physicochemical characteristics of Fen-Daqu during its phases of incubation have been reported. The objective of this research was to determine microbiological and physicochemical changes during the incubation of Fen-Daqu and also to assess whether these parameters could be used to control the quality of Fen-Daqu intermediate products. 2. MATERIALS AND METHODS 2.1. Sampling Fen-Daqu samples were obtained from Xinghuacun Fenjiu Group, Shanxi province, China. Daqu is fermented and matured in stacked layers. Samples were collect ... phases, and attaining maximum level (> 8 log cfu/g) at Shangmei phase and then gradually decreased over the later phases. It could be explained that in the Shangmei phase reached to the optimum temperature, relative humidity and 0 1 2 3 4 5 6 7 8 9 WQ SM LM CH DH HH YQ Lo g (cf u /g ) Lactic Acid Bacteria Enterobacteriaceae Fungi 0 2 4 6 8 10 12 WQ SM LM CH DH HH YQ Lo g (cf u /g ) Total viable count (30°C) Total viable count (55°C) Bacterial spores (30°C) Bacterial spores (55°C) Le Van Diep, Han Bei-Zhong 171 moisture (as showed in figures 4 and 7) for fungal growth, therefore highest number were found. It was reported that the non-Saccharomyces yeasts represented most of the total yeasts population in Fen-Daqu [3], the non-Saccharomyces yeasts, such as Trichosporon asahii, Debaryomyces hansenii, Hanseniaspora guilliermondii were found in other Daqu [11]. They produce secondary metabolites, which can contribute to the final taste and flavor of wine [12]. Other reported showed that three types of mold (Thermomyces, Penicillium and Aspergillus) were found in Fen-Daqu. Among of them, Thermomyces were abundant in the interior Daqu [3]. That could be due to a higher temperature in the inner Daqu (as showed in figures 5 and 6). Figures 1 and 2 showed that at Woqu phase, the total viable counts of bacteria, fungal and LBA counts were quite high (range of 5 - 9 Log cfu/g). It could be explained that most of them are derived from materials or environment [2]. In addition the incubation room often used for several batches of Daqu making without sterilization, therefore the spores accumulated in environment and bring to this phase. It also observed that the level of fungi and LAB were lower than bacteria, which imply the dominant group of microorganism in Daqu is bacteria rather than fungi or LAB. That showed a positive correlation with the composition of microorganisms in Daqu [4, 13]. 3.2. Physicochemical changes during the incubation Figure 3. Change of pH and total acidity during the incubation of Fen-Daqu (WQ: Woqu; SM: Shangmei; LM: Liangmei; CH: Chaohuo; DH: Dahuo; HH: Houhuo; YQ: Yangqu). Figure 3 showed that the pH increased over time during the incubation of Daqu. The rate of pH increase was slower in the first three phases (Woqu, Shangmei and Liangmei), and then become significant faster until Dahuo phase and finally keep in a steady level. Figure 3 showed that the total acidity increased at first phases, attaining to the maximum level (near 5 g/kg) at Shangmei phase, after that decreased during the middle phases and then gradually increased again during the later phases. The total acidity in Daqu is derived from acid producing microbial species, which mainly produce acetic acid, lactic acid, or the degradation of lipid and protein, etc [14]. It was observed that the total acidity attain maximum level at Shangmei phase, while the maximal level of LAB occurred in Liangmei phase. It could be explained that other bacteria such as acetic acid bacteria also present with high number in Daqu, they produce acetic acid and will 0 1 2 3 4 5 6 7 8 WQ SM LM CH DH HH YQ pH 0.0 1.0 2.0 3.0 4.0 5.0 6.0 Ac id ity (g/ kg )pH Total acidity Microbial and physiochemical changes during the incubation of Fen-Daqu 172 0 5 10 15 20 25 30 35 40 45 50 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 Time (day) Te m pe ra tu re (°C ) 0 10 20 30 40 50 60 70 80 90 100 RH (% ) Room temperature RH WQ CH DH HH YQ SM LM lead increase of titratable acidity. Figure 4 showed the changes of relative humidity and temperature in incubation room during the incubation of Fen-Daqu. The relative humidity was increased during the first phase and then decreased during later phases of the incubation. It attain at maximum level at Shangmei phase, this can be explained as that during this phase the temperature increased quickly as well as growth of microorganisms and the vapor released to the environment without artificial air ventilation. In other phases, since natural ventilation through turn of Daqu and open air windows and doors the relative humidity was reduced from 100 % to 20 %. It was also observed that the temperature increased rapidly in Shangmei phase from 15 ºC up to 40 ºC and Chaohuo, Dahuo phases attain maximum 45 ºC. That showed a positive correlation with the change of microbial count during these phases (see figures 1 and 2). In Liangmei phase, due to the good ventilation the heat was released to the surroundings at a lower temperature about 20 ºC, that in order to prevent damage overheating. Figure 4. Change of temperature and RH in incubation room during the incubation of Fen-Daqu (WQ: Woqu; SM: Shangmei; LM: Liangmei; CH: Chaohuo; DH: Dahuo; HH: Houhuo; YQ: Yangqu). Figure 5 showed that the temperature in surface of Daqu was increased from the end of Woqu phase to the end of Dahuo phase, and then reduced during the later phase. It could be related to the growth of microbial during these phases. Figure 6 showed that the room temperature increased over time during production of Daqu. Exception of Yangqu phase, the inner temperature of Daqu was higher than room temperature, that’s mainly because of microbial growth in Daqu. During the incubation of Daqu, at the beginning of Shangmei phase, the inner temperature decreased from 25 ºC to 18 ºC, and then rapidly increased to a higher level of above 40 ºC. After that, it dropped to 33 ºC at the end of Shangmei phase. During Liangmei phase, the temperature decreased again to 30 ºC and increased gradually until reached to maximal 52 ºC at the beginning of Dahuo phase. From that level, the temperature started to decrease slowly and finally back to original temperature (25 ºC). The aim of Shangmei to Liangmei phase is to activate initial microbial growth and to allow the temperature to increase gradually, attaining 30- 40 ºC in 3-5 d. The initial 24-48 h is considered as a crucial time for establishing the structure of Daqu’s microbial community, and hence the pioneer microorganisms such as fungi start to Le Van Diep, Han Bei-Zhong 173 10 15 20 25 30 35 40 45 50 55 60 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 Time (day) Tempertature (°C) Daqu inner temperature Room temperature WQ CH DH HH YQ SM LM 0 5 10 15 20 25 30 35 40 45 50 WQ SM LM CH DH HH YQ Te m p. (ºC ) colonize and mycelium will spread over the surface of Daqu [1]. Figure 5. Change of temperature in incubation room (WQ: Woqu, SM: Shangmei, LM: Liangmei, CH: Chaohuo, DH: Dahuo, HH: Houhuo, YQ: Yangqu). Figure 6. Change of temperature in Daqu inner and incubation room during the incubation of Fen-Daqu. (WQ: Woqu; SM: Shangmei; LM: Liangmei; CH: Chaohuo; DH: Dahuo; HH: Houhuo; YQ: Yangqu). High temperature during the incubation phase (Chaohuo, Dahuo and Houhuo) could enhanced proteolysis and accumulation of amino acids [15, 16], and help to produce more volatile compounds such as pyrazines that could be formed through the Maillard reaction between saccharides and amino residues [17, 18]. The room temperature measured by IR thermometer (figure 5) was significant different with the data obtained with ibutton (figure 6), however the general trend is quite similar. Since Microbial and physiochemical changes during the incubation of Fen-Daqu 174 IR thermometer was placed in the space between Daqu blocks, and the distance to Daqu is quite short, therefore the measurements easily can be influenced by the activity inside of Daqu, especially the growth of different microorganisms. The ibutton was placed on the wall, which gives more accurate results and reflect the changes of room temperature. Figure 7 showed that the moisture in Fen-Daqu samples was decreased from around 45 % to around 10 % during successive phases of incubation. During these phases the moisture rather rapid decreased from Shangmei to Houhuo phase, due to the increased temperature and decreased of relative humidity in incubation room (as showed in figure 4), and good ventilated. Figure 7. Change of moisture in Fen-Daqu during the incubation. (WQ: Woqu; SM: Shangmei; LM: Liangmei; CH: Chaohuo; DH: Dahuo; HH: Houhuo; YQ: Yangqu). The moisture in Woqu phase showed a positive correlation with the percentage of water was added to the grinding and mixing stage about 40 %. There was a gradual decrease in the moisture content of the samples from Houho to Yangqu phase. That showed a positive correlation with the aim of this phase is to allow the equilibration of moisture, acidy and enzyme activity [16]. 4. CONCLUSION The microbial and physiochemical changes in Fen-Daqu during the incubation were determined in this study. It also revealed a strong correlation between microbial and physiochemical measurements. This could help Daqu producers to monitor the progress of the Daqu manufacturing process by measuring the physiochemical parameters, in order to regulate the functional strains. Acknowledgment. We thank Shanxi Xinghuacun Fenjiu Group Company for Daqu sampling assistance and advice. This study is funded by National Natural Science Foundation of China (No. 31071592) and KNAW-China Joint Research Project (No. 07CDP015) from the Royal Netherlands Academy of Arts and Sciences. REFERENCES 1. Zheng X. W., Tabrizi M. R., Nout M. J. R. and Han, B.-Z. - Daqu – A traditional Chinese liquor fermentation starter. Journal of the Institute of Brewing 117 (2011) 82-90. 0 10 20 30 40 50 60 WQ SM LM CH DH HH YQ M o ist u re (% ) Le Van Diep, Han Bei-Zhong 175 2. Xiong Z. S. - Research on three flavor type liquors in china (III) Fen-flavor Liquor- Xinghuacun, Liquor-Making Science & Technology 133 (2005) 17–21. 3. Shi J. H., Xiao Y. P., Li X. R., Ma E. B., Du X. W., Quan, Z. X. - Analyses of microbial consortia in the starter of Fen Liquor, Letters in Applied Microbiology 48 (2009) 478-485. 4. Li C., Mu L., Wang J. Y., Lei Z. H., Chen J. Y., Han, B. Z. - Physiochemical and microbiological analysis of Fen-type Daqu, China Brewing 1 (2009) 140-142 (in Chinese). 5. Wu X. H., Zheng X. W., Han B. Z., Vervoort J., Nout M. J. R. - Characterization of Chinese liquor starter, "Daqu", by flavor type with 1H NMR-based nontargeted analysis,. Journal of Agricultural and Food Chemistry 57 (2009) 11354-11359. 6. Di H., Zhang R. P., Yang Z. J. - Discussion on the improvement of the production of Fen- Daqu. Shanxi Food Industry 01 (1995)(in Chinese). 7. Hou M. L. - Food analysis. Chemical Industry Press Beijing, 2004. 8. AOAC, Official methods of analysis (15th ed.), In Association of Official Analytical Chemists: Washington, DC, 1990. 9. Liu S. Q. - Practical implications of lactate and pyruvate metabolism by lactic acid bacteria in food and beverage fermentations, International Journal of Food Microbiology 83 (2003) 115-131. 10. Hugenholtz J. - The lactic acid bacterium as a cell factory for food ingredient production, International Dairy Journal 18 (2008) 466-475. 11. Gao Y. B. - Investigation of microbial community of Chinese liquor Daqu by polymerase chain reaction-denaturing gradient gel electrophoresis. Jiangnan University, Master thesis 2010 (in Chinese). 12. Braulio E. Z., Manzanares P., Ramön D., Quero A. - The role of non-Saccharomyces yeasts in industrial winemaking, International Microbiology 1 (1998) 143-148. 13. Wang C. L., Shi D. J., Gong G. L. - Microorganisms in Daqu: a starter culture of Chinese Maotai-flavor liquor, World Journal of Microbiology and Biotechnology 24 (2008) 2183- 2190. 14. Shen C. H., Hong Y., Xu D. F. - Study on Daqu Quality Standards (IV) —Investigation on Physiochemical Property Indexes of Daqu. Liquor-making Science & Technology 9 (2005) (in Chinese). 15. El-Ella W. M. A., Baky A. A. A., Aly M. E., Fox P. F. - Effect of ripening temperatures on proteolysis and lipolysis in the outer and inner regions of Ras-type cheese made by various salting methods, Food chemistry 28 (1988) 1-16. 16. Zheng X. W., Tabrizi M. R., Nout M. J. R., Han B. Z. - Daqu – A traditional Chinese liquor fermentation starter, Journal of the Institute of Brewing 117(2011) 82-90. 17. Owens J. D., Allagheny N., Kipping G., Ames J. M. - Formation of volatile compounds during Bacillus subtilis fermentation of soya beans, Journal of the Science of Food and Agriculture 74 (1997) 132-140. 18. López-Galilea I., Fournier N., Cid C., Guichard E. - Changes in headspace volatile concentrations of coffee brews caused by the roasting process and the brewing procedure, Journal of Agricultural and Food Chemistry 54 (2006) 8560-8566. Microbial and physiochemical changes during the incubation of Fen-Daqu 176 TÓM TẮT NGHIÊN CỨU SỰ THAY ĐỔI CỦA VI SINH VẬT VÀ YẾU TỐ LÍ HÓA TRONG QUÁ TRÌNH SẢN XUẤT BÁNH MEN RƯỢU PHẦN Lê Văn Điệp1, *, Han Bei-Zhong2 1Khoa Hóa học, Trường Đại học Vinh, 182 Lê Duẫn, TP. Vinh, Nghệ An. 2 Khoa Công nghệ Thực phẩm, Trường Đại học Nông Nghiệp Trung Quốc. *Email: levandiep@vinhuni.edu.vn Bánh men rượu Phần (Fen-Daqu) vừa là tác nhân đường hóa, vừa là tác nhân lên men trong sản xuất rượu Phần, một loại rượu trắng có hương thanh nhẹ nổi tiếng ở tỉnh Sơn Tây, Trung Quốc. Nó được sản xuất bởi quá trình lên men tự nhiên từ nguồn nguyên liệu đại mạch và đậu Hà lan. Phương pháp nuôi cấy vi sinh vật truyền thống và các kĩ thuật phân tích trực tuyến được sử dụng trong phân tích sự thay đổi của các nhóm vi sinh vật và các yếu tố lí hóa. Sự thay đổi của vi sinh vật phân biệt theo từng nhóm hiếu khí (30 °C), vi sinh vật ưa nhiệt (55 °C), bào tử vi khuẩn (30 °C và 55 °C), vi khuẩn lactic, enterobacteriaceae và nấm từ mức thấp nhất khoảng 106, 104, 105, 105, 105, 104 and 105 cfu/g và đạt cực đại ở khoảng 1011, 109, 109, 109, 107, 105 and 108 cfu/g. Trong quá trình ủ vi sinh vật thay đổi theo xu thế tăng dần từ Woqu đến Liangmei và sau đó giảm dần theo thời gian. pH tăng dần, còn độ ẩm phòng giảm dần từ khoảng 100 % xuống còn 20 % và thủy phần bánh men giảm dần từ khoảng 45 % xuống còn khoảng 10 % theo thời gian quá trình ủ. Nhiệt độ phòng ủ tăng dần từ pha đầu cho đến pha giữa và giảm nhẹ ở pha sau. Nhiệt độ bên trong bánh men tăng nhanh ở giai đoạn Shangmei đạt 40 ºC sau đó giảm xuống còn 30 ºC ở giai đoạn Liangmei, tiếp đó tăng và đạt đến cực đại 52 ºC tại Dahuo, cuối cùng giảm dần đến nhiệt độ phòng (25 ºC) ở pha sau. Từ các kết quả trên và qua phân tích sự tác động qua lại giữa chúng có thể ứng dụng vào quá trình điều chỉnh sự phát triển của vi sinh vật trong quá trình sản xuất bánh men. Từ khóa: bánh men rượu, rượu trắng, lên men truyền thống, vi sinh vật.

File đính kèm:

nghien_cuu_su_thay_doi_cua_vi_sinh_vat_va_yeu_to_li_hoa_tron.pdf

nghien_cuu_su_thay_doi_cua_vi_sinh_vat_va_yeu_to_li_hoa_tron.pdf