Improving properties of Viscose fabric by water repellent finish

Viscose is the most abundantly available man-made cellulose fibers. Viscose has several good functional properties such as high water absorption, easier dye ability, comfort feel when wearing. Most

of the apparel products are made of cellulose based fabrics. However, the disadvantages of viscose

fabrics include the low dimensional stability, easy wrinkle. To enhance the functional properties of

viscose fabrics, many finishing processes have been applied such as water repellent finishing. One

of the acrylate polymers was used to finish textiles is fluorocarbons. They applied to the cellulose

fabric surface can significantly improve contact angle between water drops and fabric surface as

well as other properties. In this paper, Nuva1811, Ruco Dry ECO, FW-500D were evaluated the impact on viscose fabric. The efficiency of the process implementation was determined by measuring

and analyzing the physical properties of fabric samples. Viscose fabric treated with Nuva 1811 60

g/l was evalutated the high water repellency with level 4 after finishing. However, the washing

fastness properties was decreased slightly. When applied in the fiber, the polymer will form a structure that presents CF3 outer surface for maximum repellency. Fluorocarbons provides fiber surfaces

with the lowest surface energies of all repellent finishes. The results show that the viscose reveals

the higher wet strength, indicating the possibility of FC deposited on the surface of fibers to the

capillary inter fiber or inter yarn spaces in the fabric. Tensile strength of viscose fabric was increased

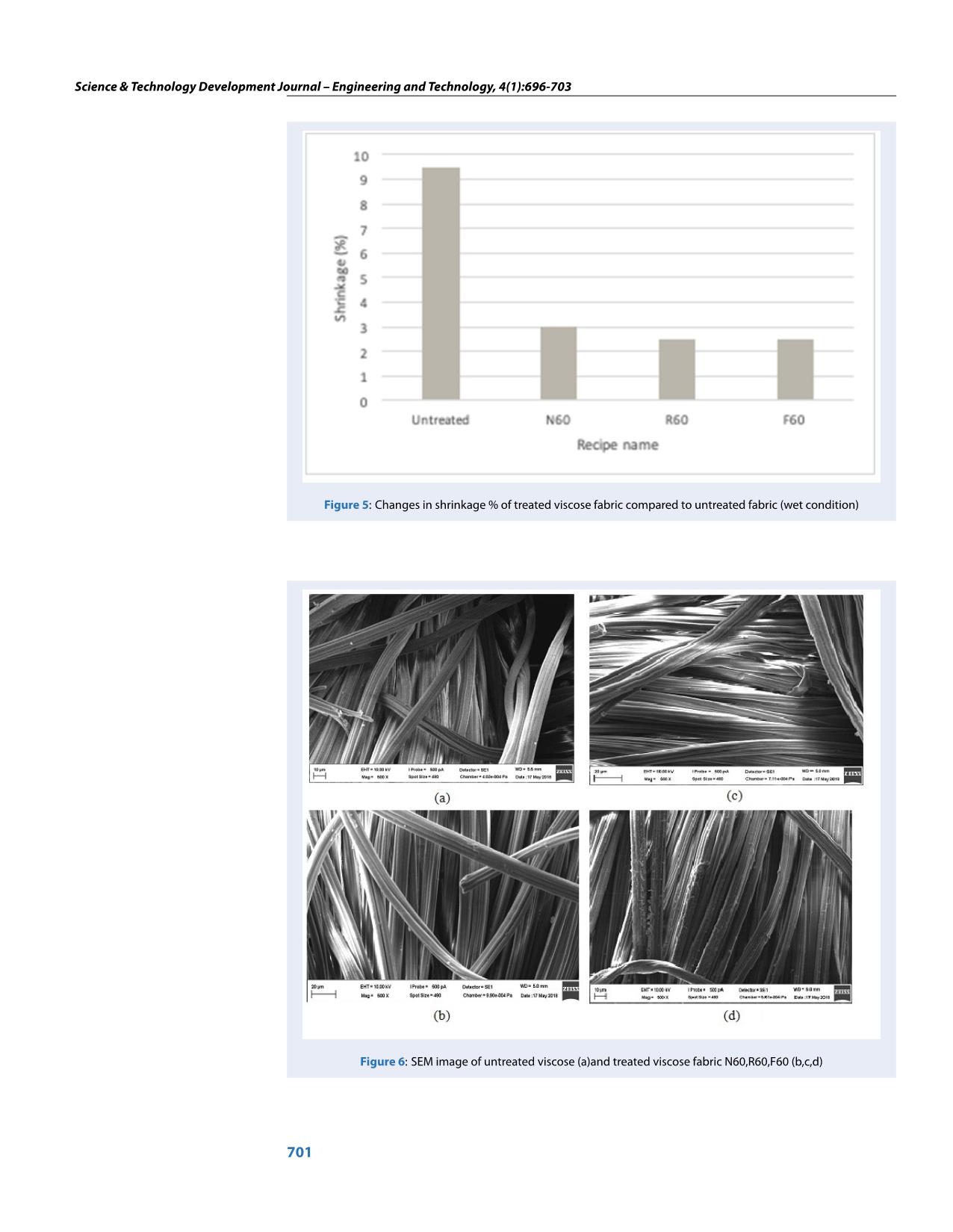

24.6%. The shrinkage percentage of coated viscose was decreased (only 3% when was treated with

Nuva 1811 compare to the untreated fabric 9.5%). Furthermore, the abrasion resistance of viscose

fabric has increased because the weight loss of fabric was decreased (0.42% when was treated with

Nuva 1811 for 1000 cycles compare to the untreated fabric 1.4%). The morphology of the untreated

and treated viscose fabrics were characterized via a scanning electron microscope.

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Trang 6

Trang 7

Trang 8

Tóm tắt nội dung tài liệu: Improving properties of Viscose fabric by water repellent finish

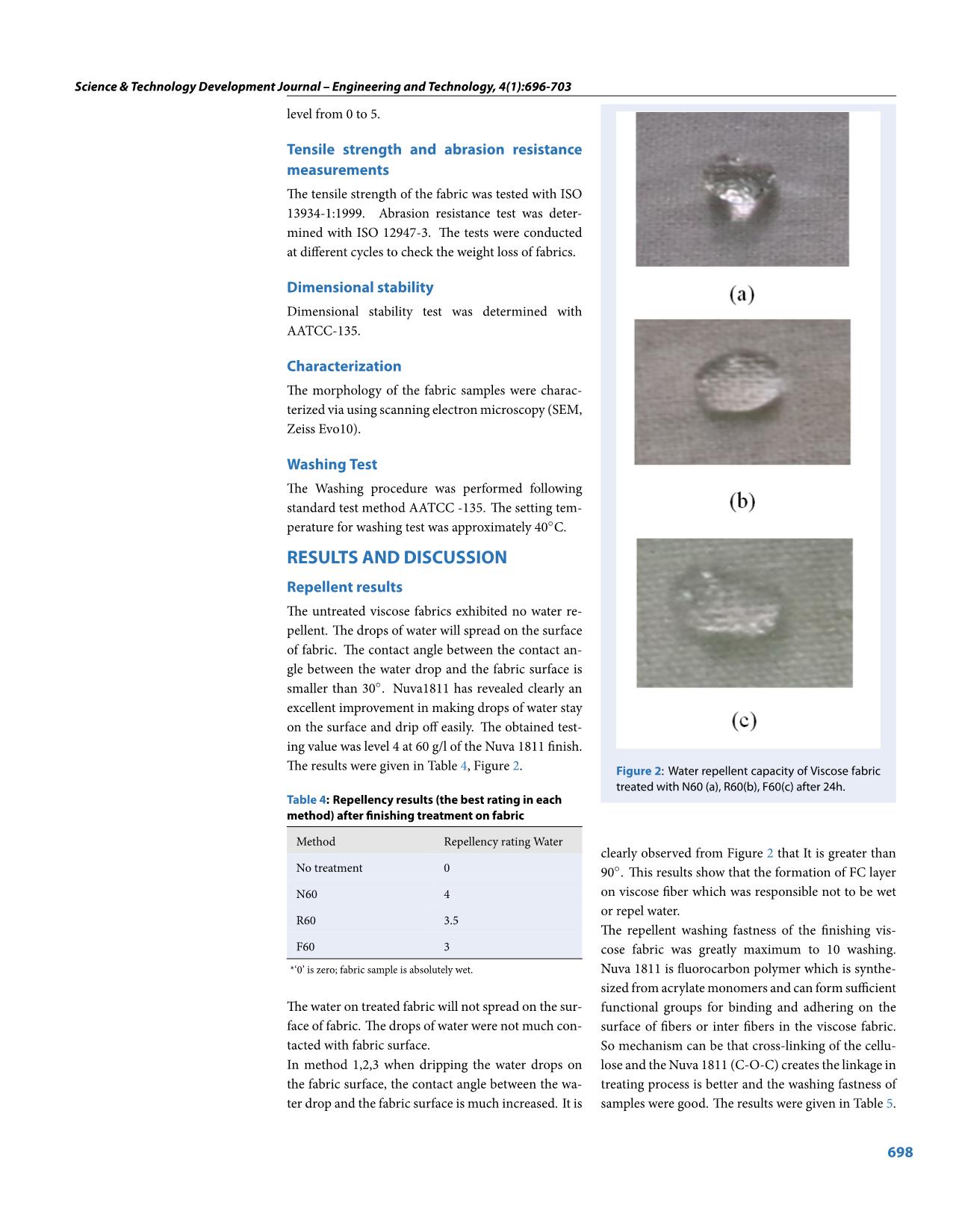

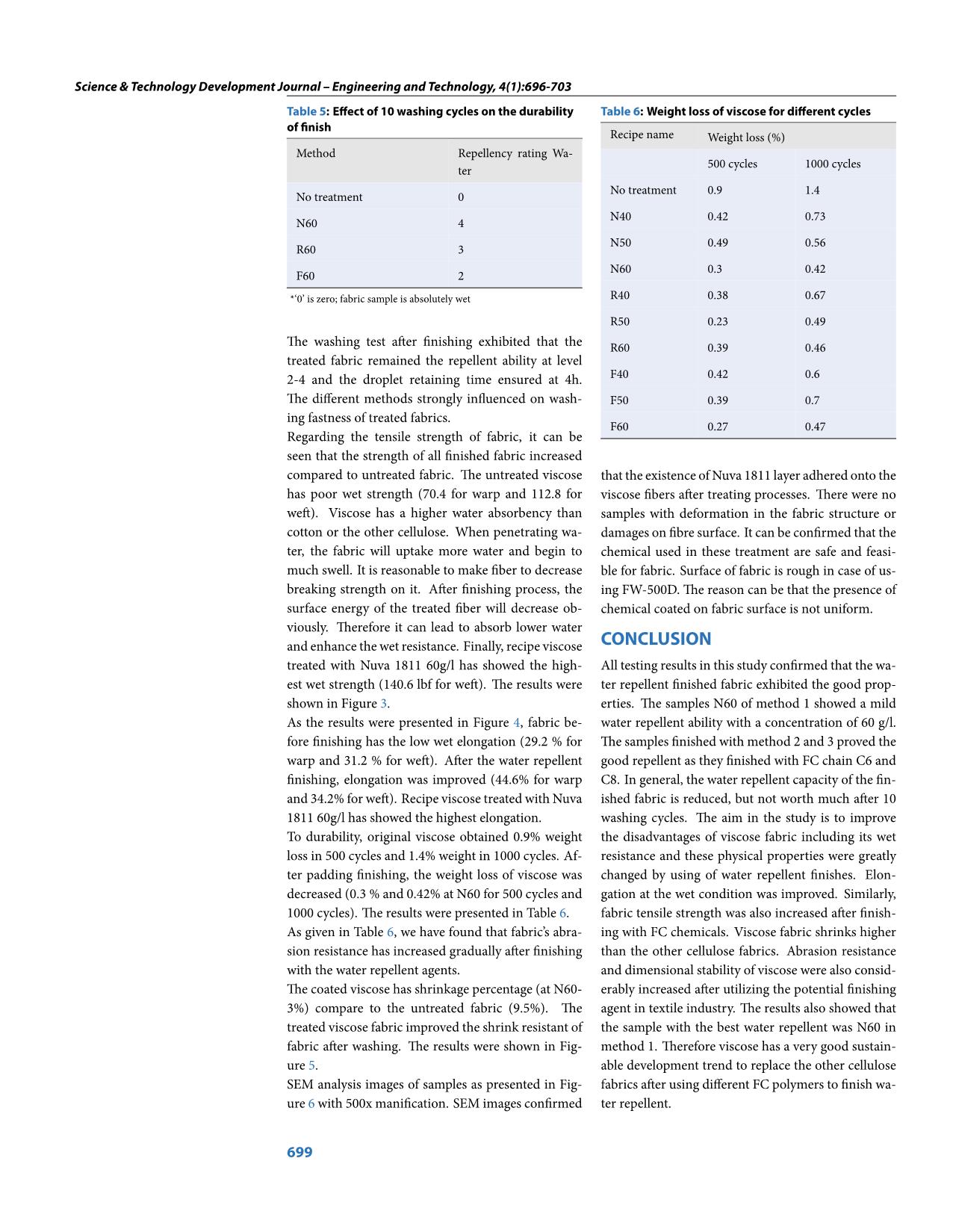

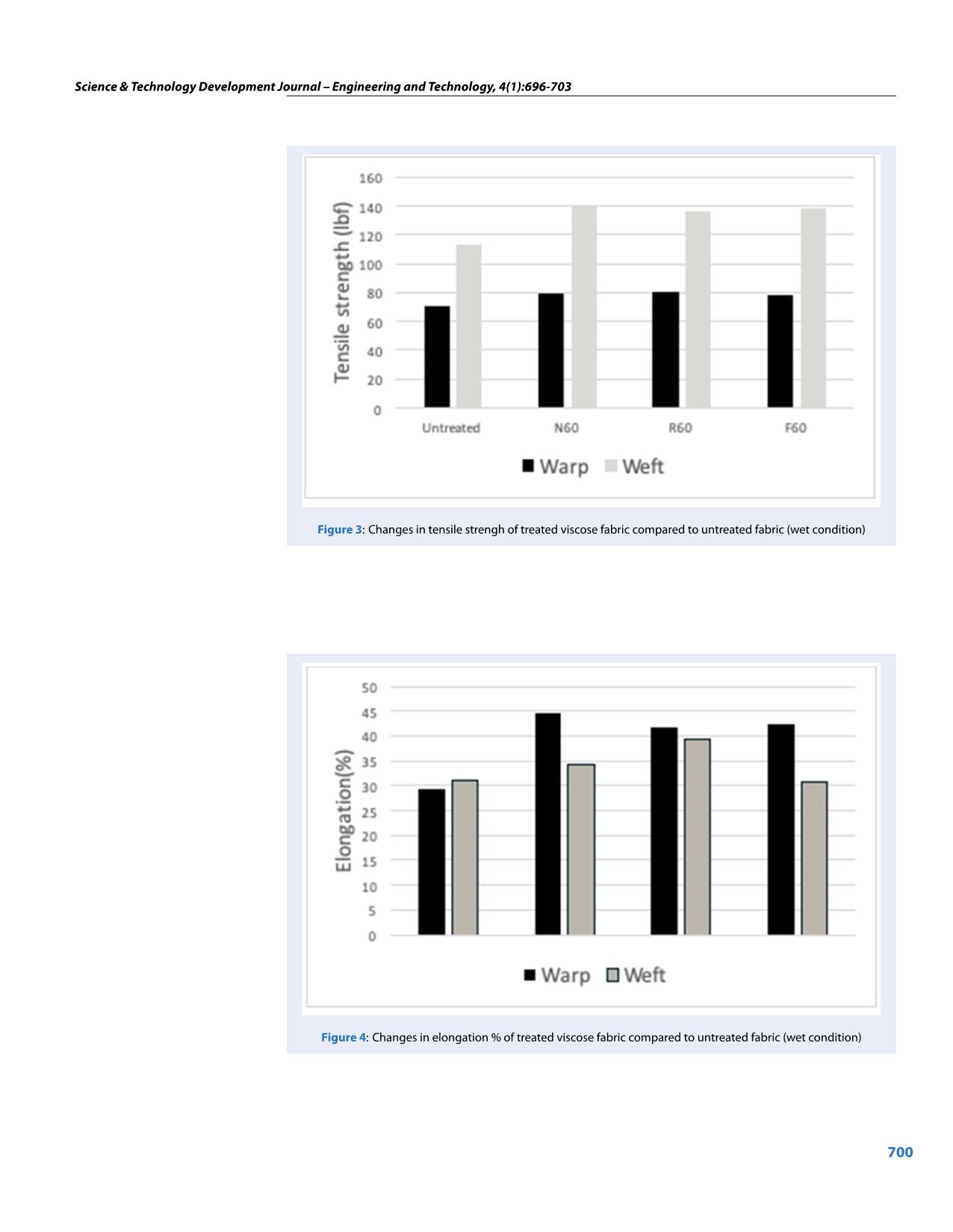

Science & Technology Development Journal – Engineering and Technology, 4(1):696-703 Open Access Full Text Article Research Article Improving properties of Viscose fabric by water repellent finish Trinh Thi Kim Hue*, Bui Mai Huong ABSTRACT Viscose is the most abundantly available man-made cellulose fibers. Viscose has several good func- tional properties such as high water absorption, easier dye ability, comfort feel when wearing. Most Use your smartphone to scan this of the apparel products are made of cellulose based fabrics. However, the disadvantages of viscose QR code and download this article fabrics include the low dimensional stability, easy wrinkle. To enhance the functional properties of viscose fabrics, many finishing processes have been applied such as water repellent finishing. One of the acrylate polymers was used to finish textiles is fluorocarbons. They applied to the cellulose fabric surface can significantly improve contact angle between water drops and fabric surface as well as other properties. In this paper, Nuva1811, Ruco Dry ECO, FW-500D were evaluated the im- pact on viscose fabric. The efficiency of the process implementation was determined by measuring and analyzing the physical properties of fabric samples. Viscose fabric treated with Nuva 1811 60 g/l was evalutated the high water repellency with level 4 after finishing. However, the washing fastness properties was decreased slightly. When applied in the fiber, the polymer will form a struc- ture that presents CF3 outer surface for maximum repellency. Fluorocarbons provides fiber surfaces with the lowest surface energies of all repellent finishes. The results show that the viscose reveals the higher wet strength, indicating the possibility of FC deposited on the surface of fibers to the capillary inter fiber or inter yarn spaces in the fabric. Tensile strength of viscose fabric was increased 24.6%. The shrinkage percentage of coated viscose was decreased (only 3% when was treated with Nuva 1811 compare to the untreated fabric 9.5%). Furthermore, the abrasion resistance of viscose fabric has increased because the weight loss of fabric was decreased (0.42% when was treated with Nuva 1811 for 1000 cycles compare to the untreated fabric 1.4%). The morphology of the untreated and treated viscose fabrics were characterized via a scanning electron microscope. Key words: Viscose, wet strength, water repellent, chemical finish, fabric Department of Textile Garment Engineering, Faculty of Mechanical Engineering, Ho Chi Minh City University of Technology, VNU-HCM, INTRODUCTION the form of droplets on the surface of the fabric, caus- Vietnam ing water droplets not to spread over the surface and Today viscose is an important cellulosic fiber mostly Correspondence prevent the fabric from getting wet. The water re- used in textiles. The most abundant source of cellu- sistance of the fabric mainly involves in textile fiber Trinh Thi Kim Hue, Department of Textile lose is wood, of which it constitutes about 50%. Reg- Garment Engineering, Faculty of properties and the density of the textile materials. The ular viscose is different from cotton in having non fib- Mechanical Engineering, Ho Chi Minh hydrophobicity of the fiber is evaluated by the dif- City University of Technology, rills, having no lumen, and having a much lower de- VNU-HCM, Vietnam ference in surface energy between fabric and liquid. gree of polymerisation. Viscose staple fibers are pro- It is reasonable to make difference between ”water- Email: ttkhue@hcmut.edu.vn duced in the types of linear densities ranging from 0.1 repellent” with ”waterproof”. ”Water-repellent fabric” History to 0.8 tex and lengths from 40 to 120 mm to suit the • Received: 02-11-2020 is a fabric with many holes and is capable of vent- • characteristics of other commonly used textile fibers ing and evaporating water. This fabric allows the wa- Accepted: 27-02-2021 1,2 • Published: 15-03-2021 such as cotton, silk . The fabric made from vis- ter to pass through it when the used pressure is high cose fibers will be soft, comfortable in hot and humid DOI : 10.32508/stdjet.v4i1.788 enough. ”Waterproof fabric” is water resistant fabric conditions, drape well, highly absorbent and easy to under hydrostatic pressure much higher than ”Water- dye. However, viscose fabrics have not so high dimen- repellent fabric”. This fabric has fewer holes and the sional stability in washing, creasing, and tend to very air permeability and water vapor is also worse 2,3. All strong stretch. Compared with cotton or the other cel- of those finishing methods must ensure the breatha- Copyright lulose such as lyocell, modal, viscose has the several bility and the comfort of the fabric. FC provides the © VNU-HCM Press. This is an open- disadvantages of much lower breaking strength, par- access article distributed under the lowest surface energie ... for 6–8 nology on 100% Viscose fabric . The three differ- 5 min. ent water repellent options used are Nuva 1811 com- bines acetic acid; Ruco Dry combines acetic acid and Table 1: The details of treatment method 1 FW-500D combines acetic acid. The repellency, ten- Recipe name Chemical concentrations sile strength, abrasion durability tests and SEM image Nuva 1811 Acetic acid analysis are used to characterize and compare the wa- (g/l) (ml/l) ter repellent performance of the three methods.where is citation 9? N40 40 3 MATERIALS AND METHODS N50 50 3 N60 60 3 Materials The plain woven 100% viscose fabric, , mass per unit area of fabric 2.05 g/m2, count of warp 65 threads − − Ruco Dry ECO with catalyst acetic acid cm 1, count of weft 50 threads cm 1, were scoured and supplied by Tam Xuan Company in Viet Nam. The samples were padded to 80% wet pickup approx- Samples were prepared with the size of 20 cm × 20 imately with prepared solutions. The padded fabrics ◦ ◦ cm. were dried at 110 C for 3 min, and cured at 150 C for The chemicals used to include Nuva 1811 (Archroma, 5 min. Switzerland); Ruco Dry ECO (Rudolf, Germany); Table 2: The details of treatment method 2 FW-500D (R.O.C, Taiwan); acetic acid (99.9%) were Recipe purchased from Xilong Chem Co. Ltd. (China). Chemical concentrations name Three kinds of chemicals are fluorocarbon- based Ruco Dry ECO Acetic acid (ml/l) acrylate polymer. Nuva 1811 is C6 based fluorocar- (g/l) bon. Ruco Dry ECO is made from FC wax. It has R40 40 3 proper characteristics as the cationic, water repellency is very good with monomers with the trend of sustain- R50 50 3 able developments. FW-500D is C8 based fluorocar- R60 60 3 bon. FW-500D with catalyst acetic acid The samples were padded to 80% wet pickup approx- imately with prepared solutions. The padded fabrics ◦ ◦ were dried at 110 C for 3 min, and cured at 150 C for 5 min. Table 3: The details of treatment method 3 Recipe name Chemical concentrations FW-500D (g/l) Acetic acid (ml/l) Figure 1: Chemical structure of perfluorinated acry- late. F40 40 3 F50 50 3 F60 60 3 Treatment methods Three treatment methods were applied. The sample code was marked as Xa where X is the type of chemi- Water repellent rating measurement cals, a is the code of different chemical concentrations Rating test was used AATCC-22 (Spray test). The wa- as described in Tables 1, 2 and 3. ter repellent rating was performed according to the 697 Science & Technology Development Journal – Engineering and Technology, 4(1):696-703 level from 0 to 5. Tensile strength and abrasion resistance measurements The tensile strength of the fabric was tested with ISO 13934-1:1999. Abrasion resistance test was deter- mined with ISO 12947-3. The tests were conducted at different cycles to check the weight loss of fabrics. Dimensional stability Dimensional stability test was determined with AATCC-135. Characterization The morphology of the fabric samples were charac- terized via using scanning electron microscopy (SEM, Zeiss Evo10). Washing Test The Washing procedure was performed following standard test method AATCC -135. The setting tem- ◦ perature for washing test was approximately 40 C. RESULTS AND DISCUSSION Repellent results The untreated viscose fabrics exhibited no water re- pellent. The drops of water will spread on the surface of fabric. The contact angle between the contact an- gle between the water drop and the fabric surface is ◦ smaller than 30 . Nuva1811 has revealed clearly an excellent improvement in making drops of water stay on the surface and drip off easily. The obtained test- ing value was level 4 at 60 g/l of the Nuva 1811 finish. The results were given in Table 4, Figure 2. Figure 2: Water repellent capacity of Viscose fabric treated with N60 (a), R60(b), F60(c) after 24h. Table 4: Repellency results (the best rating in each method) after finishing treatment on fabric Method Repellency rating Water clearly observed from Figure 2 that It is greater than ◦ No treatment 0 90 . This results show that the formation of FC layer N60 4 on viscose fiber which was responsible not to be wet or repel water. R60 3.5 The repellent washing fastness of the finishing vis- F60 3 cose fabric was greatly maximum to 10 washing. *‘0’ is zero; fabric sample is absolutely wet. Nuva 1811 is fluorocarbon polymer which is synthe- sized from acrylate monomers and can form sufficient The water on treated fabric will not spread on the sur- functional groups for binding and adhering on the face of fabric. The drops of water were not much con- surface of fibers or inter fibers in the viscose fabric. tacted with fabric surface. So mechanism can be that cross-linking of the cellu- In method 1,2,3 when dripping the water drops on lose and the Nuva 1811 (C-O-C) creates the linkage in the fabric surface, the contact angle between the wa- treating process is better and the washing fastness of ter drop and the fabric surface is much increased. It is samples were good. The results were given in Table 5. 698 Science & Technology Development Journal – Engineering and Technology, 4(1):696-703 Table 5: Effect of 10 washing cycles on the durability Table 6: Weight loss of viscose for different cycles of finish Recipe name Weight loss (%) Method Repellency rating Wa- 500 cycles 1000 cycles ter No treatment 0.9 1.4 No treatment 0 N40 0.42 0.73 N60 4 N50 0.49 0.56 R60 3 N60 0.3 0.42 F60 2 *‘0’ is zero; fabric sample is absolutely wet R40 0.38 0.67 R50 0.23 0.49 The washing test after finishing exhibited thatthe R60 0.39 0.46 treated fabric remained the repellent ability at level 2-4 and the droplet retaining time ensured at 4h. F40 0.42 0.6 The different methods strongly influenced on wash- F50 0.39 0.7 ing fastness of treated fabrics. F60 0.27 0.47 Regarding the tensile strength of fabric, it can be seen that the strength of all finished fabric increased compared to untreated fabric. The untreated viscose that the existence of Nuva 1811 layer adhered onto the has poor wet strength (70.4 for warp and 112.8 for viscose fibers after treating processes. There were no weft). Viscose has a higher water absorbency than samples with deformation in the fabric structure or cotton or the other cellulose. When penetrating wa- damages on fibre surface. It can be confirmed that the ter, the fabric will uptake more water and begin to chemical used in these treatment are safe and feasi- much swell. It is reasonable to make fiber to decrease ble for fabric. Surface of fabric is rough in case of us- breaking strength on it. After finishing process, the ing FW-500D. The reason can be that the presence of surface energy of the treated fiber will decrease ob- chemical coated on fabric surface is not uniform. viously. Therefore it can lead to absorb lower water and enhance the wet resistance. Finally, recipe viscose CONCLUSION treated with Nuva 1811 60g/l has showed the high- All testing results in this study confirmed that the wa- est wet strength (140.6 lbf for weft). The results were ter repellent finished fabric exhibited the good prop- shown in Figure 3. erties. The samples N60 of method 1 showed a mild As the results were presented in Figure 4, fabric be- water repellent ability with a concentration of 60 g/l. fore finishing has the low wet elongation (29.2 %for The samples finished with method 2 and 3 proved the warp and 31.2 % for weft). After the water repellent good repellent as they finished with FC chain C6 and finishing, elongation was improved (44.6% for warp C8. In general, the water repellent capacity of the fin- and 34.2% for weft). Recipe viscose treated with Nuva ished fabric is reduced, but not worth much after 10 1811 60g/l has showed the highest elongation. washing cycles. The aim in the study is to improve To durability, original viscose obtained 0.9% weight the disadvantages of viscose fabric including its wet loss in 500 cycles and 1.4% weight in 1000 cycles. Af- resistance and these physical properties were greatly ter padding finishing, the weight loss of viscose was changed by using of water repellent finishes. Elon- decreased (0.3 % and 0.42% at N60 for 500 cycles and gation at the wet condition was improved. Similarly, 1000 cycles). The results were presented in Table 6. fabric tensile strength was also increased after finish- As given in Table 6, we have found that fabric’s abra- ing with FC chemicals. Viscose fabric shrinks higher sion resistance has increased gradually after finishing than the other cellulose fabrics. Abrasion resistance with the water repellent agents. and dimensional stability of viscose were also consid- The coated viscose has shrinkage percentage (at N60- erably increased after utilizing the potential finishing 3%) compare to the untreated fabric (9.5%). The agent in textile industry. The results also showed that treated viscose fabric improved the shrink resistant of the sample with the best water repellent was N60 in fabric after washing. The results were shown in Fig- method 1. Therefore viscose has a very good sustain- ure 5. able development trend to replace the other cellulose SEM analysis images of samples as presented in Fig- fabrics after using different FC polymers to finish wa- ure 6 with 500x manification. SEM images confirmed ter repellent. 699 Science & Technology Development Journal – Engineering and Technology, 4(1):696-703 Figure 3: Changes in tensile strengh of treated viscose fabric compared to untreated fabric (wet condition) Figure 4: Changes in elongation % of treated viscose fabric compared to untreated fabric (wet condition) 700 Science & Technology Development Journal – Engineering and Technology, 4(1):696-703 Figure 5: Changes in shrinkage % of treated viscose fabric compared to untreated fabric (wet condition) Figure 6: SEM image of untreated viscose (a)and treated viscose fabric N60,R60,F60 (b,c,d) 701 Science & Technology Development Journal – Engineering and Technology, 4(1):696-703 ACKNOWLEDGMENT REFERENCES This research is funded by Ho Chi Minh City Univer- 1. Heywood D. Textile finishing, Chapter 1,2, Bradford, Eng.: Soci- ety of Dyers and Colourist. 2003;. sity of Technology-VNU-HCM under grant number 2. Williams JT. Waterproof and Water Repellent Textiles and Cloth- T-CK-2019-22. ing. Woodhead Publishing. 2018;. 3. Sato Y, et al. Effect of Crosslinking Agents on Water Repel- ABBREVIATIONS lency of Cotton Fabrics Treated with Fluorocarbon Resin. Textile Research Journal . 1994;64(6):316–320. Available from: https: FC: Fluorocarbon //doi.org/10.1177/004051759406400602. SEM: Scanning Electron Microscope 4. Castelvetro V, Francini G, Ciardelli G, Ceccato M. Evaluating Flu- orinated Acrylic Latices as Textile Water and Oil Repellent Fin- ishes. Textile Research Journal. 2001;7(5):399–406. Available CONFLICT OF INTERESTS from: https://doi.org/10.1177/004051750107100506. 5. Morton WE, Hearle JWS. Physical properties of textile fibres The author declares that there is no conflict of interests - Fourth edition. Woodhead Publishing. 2008;Available from: regarding the publication of this paper. https://doi.org/10.1201/9781439831830. 6. Schindler WD, Hauser PJ. Chemical Finishing of textiles. Wood- AUTHORS’ CONTRIBUTION head Publishing. 2004;Available from: https://doi.org/10.1201/ 9781439823477. Trinh Thi Kim Hue is in charge of all research content 7. Paul R. Functional Finishes for Textiles: Improving Comfort, Per- presented in the article. formance and Protection. Woodhead Publishing. 2014;. 8. Rowen JW, Gagliardi D. Properties of Water-Repellent Fabrics. Bui Mai Huong check and review the article. 1947;38. Available from: https://doi.org/10.6028/jres.038.002. 9. Choudhury AKR. Principles of Textile Finishing, Woodhead Pub- lishing. 2017;. 702 Tạp chí Phát triển Khoa học và Công nghệ – Kĩ thuật và Công nghệ, 4(1):696-703 Open Access Full Text Article Bài nghiên cứu Nghiên cứu cải thiện tính chất của vải viscose bằng phương pháp hoàn tất chống thấm Trịnh Thị Kim Huệ*, Bùi Mai Hương TÓM TẮT Viscose có nguồn gốc từ cellulose, loại vải rẻ nhất trong các loại vải gốc cellulose có thể là lựa chọn thay thế tốt nhất hiện nay. Viscose được sản xuất từ cellulose tái sinh. Viscose là một sản phẩm dệt Use your smartphone to scan this thân thiện với môi trường. Do đó, nhu cầu về các sản phẩm dệt thân thiện với môi trường tăng QR code and download this article sẽ làm tăng nhu cầu về sợi visco và giảm bớt sản lượng cotton như hiện nay. Vải viscose thể hiện một số tính chất tương tự như vải cotton ngoại trừ độ bền ướt kém do độ hồi ẩm cao hơn. Trong nghiên cứu này, hoàn tất hoá học bằng các chất liên kết ngang khác nhau đã được áp dụng để cải thiện độ bền ướt của vải viscose. Các polymer acrylate gốc fluorocarbon như Nuva1811, Ruco Dry ECO, FW-500D được đánh giá trên vải viscose. Vải được xử lý với Nuva 1811 60 g/l có kết quả chống thấm nước tốt trước khi giặt. Kết quả chống thấm trên vải đạt mức 4 sau khi xử lý. Tuy nhiên, mức chống thấm giảm sau khi giặt. Các chuỗi fluorocarbon của polyacrylate được định hướng ra ngoài bề mặt xơ và các nhóm –CF2CF3 hình thành một lớp chống thấm năng lượng thấp. Hoàn tất chống thấm nước giúp làm giảm lực cản giữa các phân tử xơ riêng lẻ và làm giảm sức căng bề mặt của vải. Nó làm giảm khả năng thấm hút của vải viscose dẫn đến làm tăng độ bền ướt. Vì vậy, vải viscose đã qua xử lý thể hiện độ bền ướt tốt hơn sau khi đã hoàn tất chống thấm lên nó. Độ bền kéo của vải viscose tăng lên 24.6 %. Độ co của vải viscose chỉ còn 3% sau khi xử lý với Nuva 1811 so với vải chưa xử lý có độ co là 9,5%. Độ mài mòn cũng đã giảm chỉ còn 0,42% cho trường hợp 1000 vòng sau khi xử lý với Nuva 1811 so với vải chưa xử lý là 1,4%. Kính hiển vi điện tử quét (SEM) được sử dụng để kiểm tra bề mặt của vải sau khi xử lý bằng hoá chất. Từ khoá: Viscose, độ bền ướt, chống thấm nước, hoàn tất hoá học, vải Bộ môn Kỹ thuật Dệt may, Khoa Cơ khí, Trường Đại học Bách khoa TP HCM, ĐHQG-HCM, Việt Nam Liên hệ Trịnh Thị Kim Huệ, Bộ môn Kỹ thuật Dệt may, Khoa Cơ khí, Trường Đại học Bách khoa TP HCM, ĐHQG-HCM, Việt Nam Email: ttkhue@hcmut.edu.vn Lịch sử • Ngày nhận: 02-11-2020 • Ngày chấp nhận: 27-02-2021 • Ngày đăng: 15-03-2021 DOI : 10.32508/stdjet.v4i1.788 Bản quyền © ĐHQG Tp.HCM. Đây là bài báo công bố mở được phát hành theo các điều khoản của the Creative Commons Attribution 4.0 International license. Trích dẫn bài báo này: Huệ T T K, Hương B M. Nghiên cứu cải thiện tính chất của vải viscose bằng phương pháp hoàn tất chống thấm. Sci. Tech. Dev. J. - Eng. Tech.; 4(1):696-703. 703

File đính kèm:

improving_properties_of_viscose_fabric_by_water_repellent_fi.pdf

improving_properties_of_viscose_fabric_by_water_repellent_fi.pdf