Antibacterial finishing on cotton 100 % and cvc fabrics with tannin from piper betle extract

Following the recent trend of using natural ingredients from bio-macromolecules,

biomaterials and plant extract in textile chain, this research aims to develop an antibacterial

textile finishing with tannin extracted from piper betle plant. The extracting processes were

carried out with different solvent: distilled water, ethanol 30 %, ethanol 50 %, ethanol 70 % for

60 minutes. Two important types of fabric, including cotton and CVC (Cotton/Polyester) were

padded with piper betle extracts, then dried at 60 oC for 5 minutes. The presence of tannin on

fabric after treatment was determined by FeCl3 test and FT-IR spectrum. The antibacterial effect

of finished fabrics was proved according to ASTM 2149-01 standard. The test was performed

with E. coli ATCC 25922 and S. aureus AATCC 6538. The final results exhibited good

antibacterial activity of 83.02 %, 65,33 % against the bacteria E. coli and 93.88 %, 85.14 %

against the bacteria S. aureus on cotton and then CVC fabrics.

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Trang 6

Trang 7

Trang 8

Trang 9

Trang 10

Tóm tắt nội dung tài liệu: Antibacterial finishing on cotton 100 % and cvc fabrics with tannin from piper betle extract

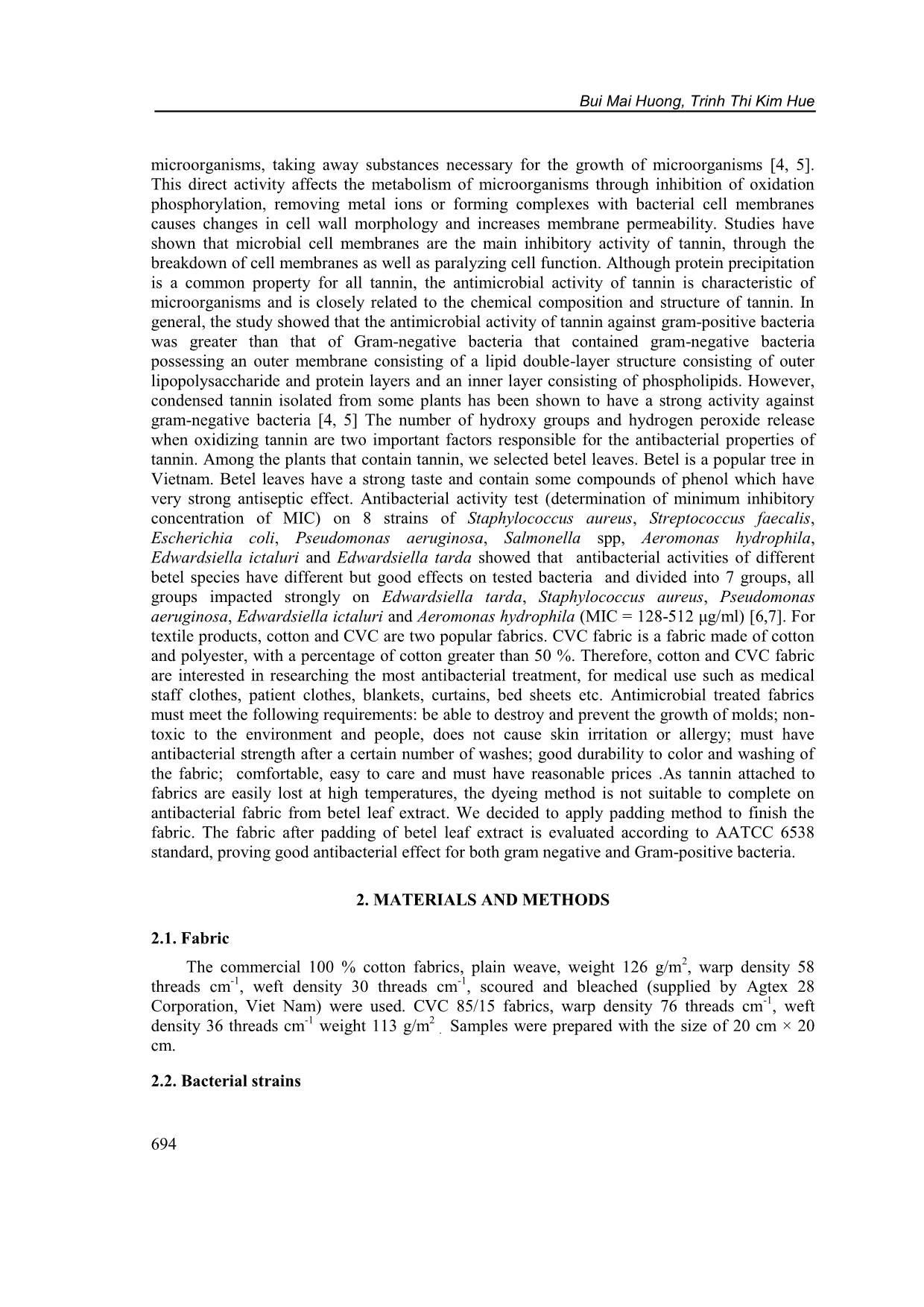

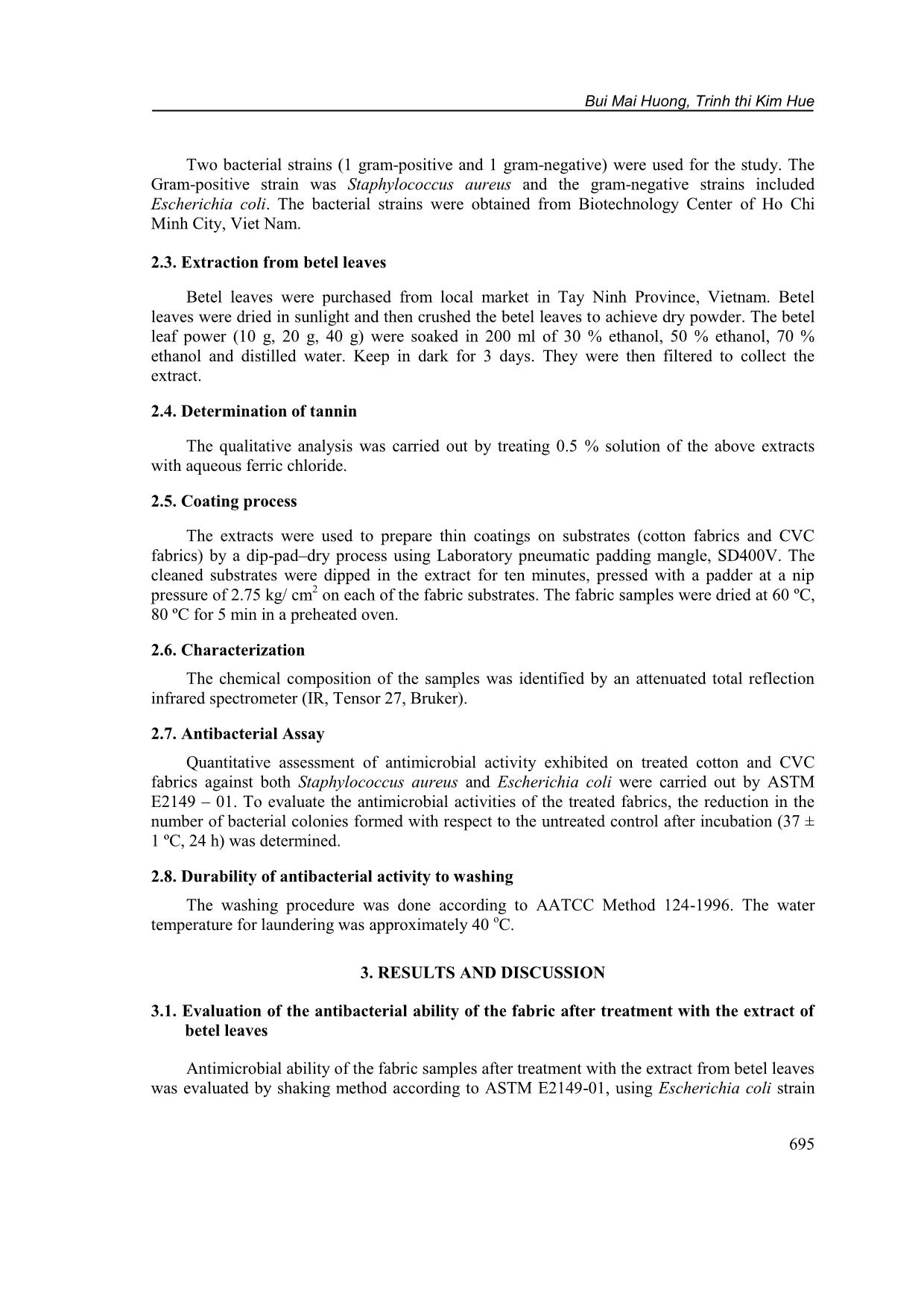

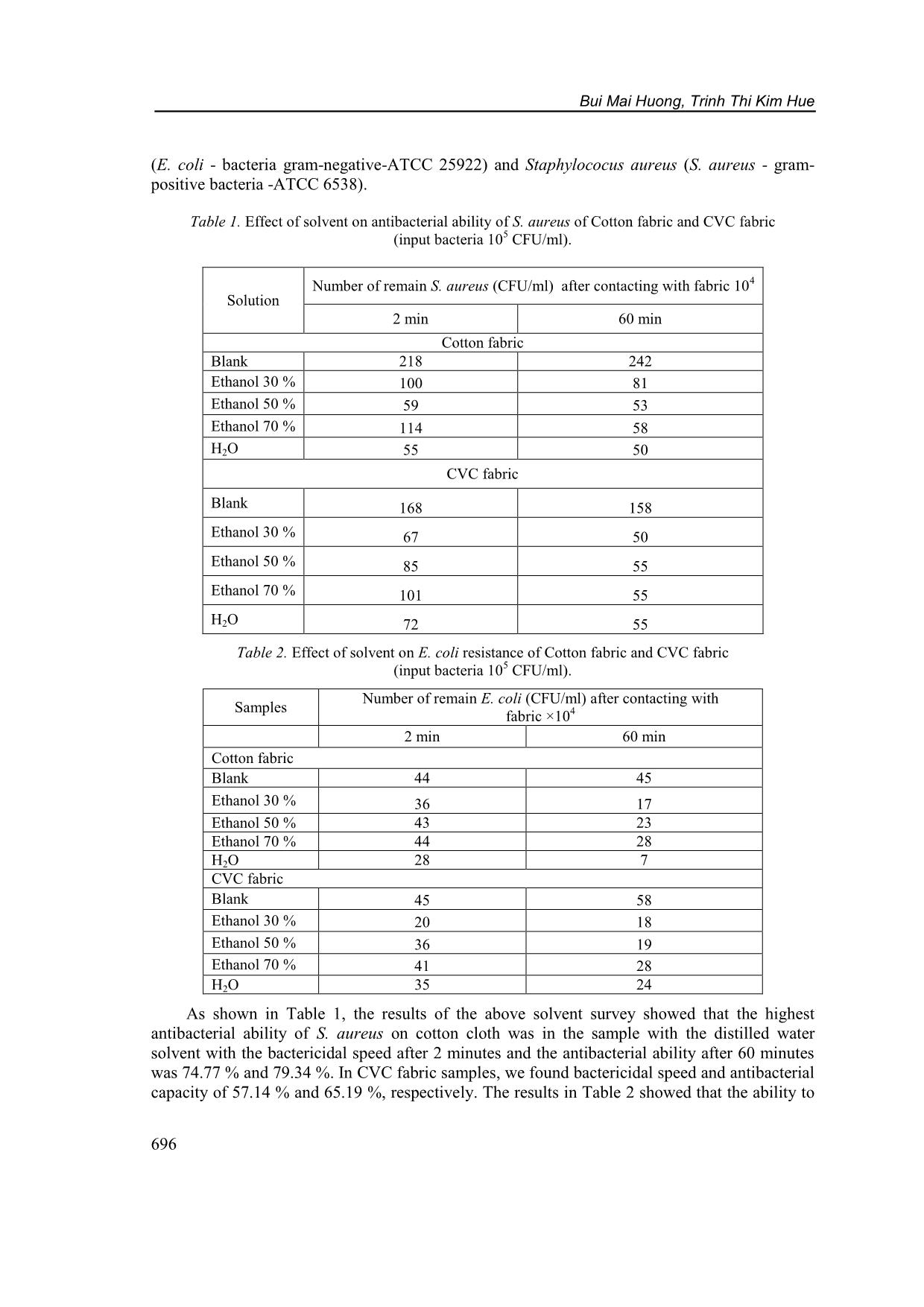

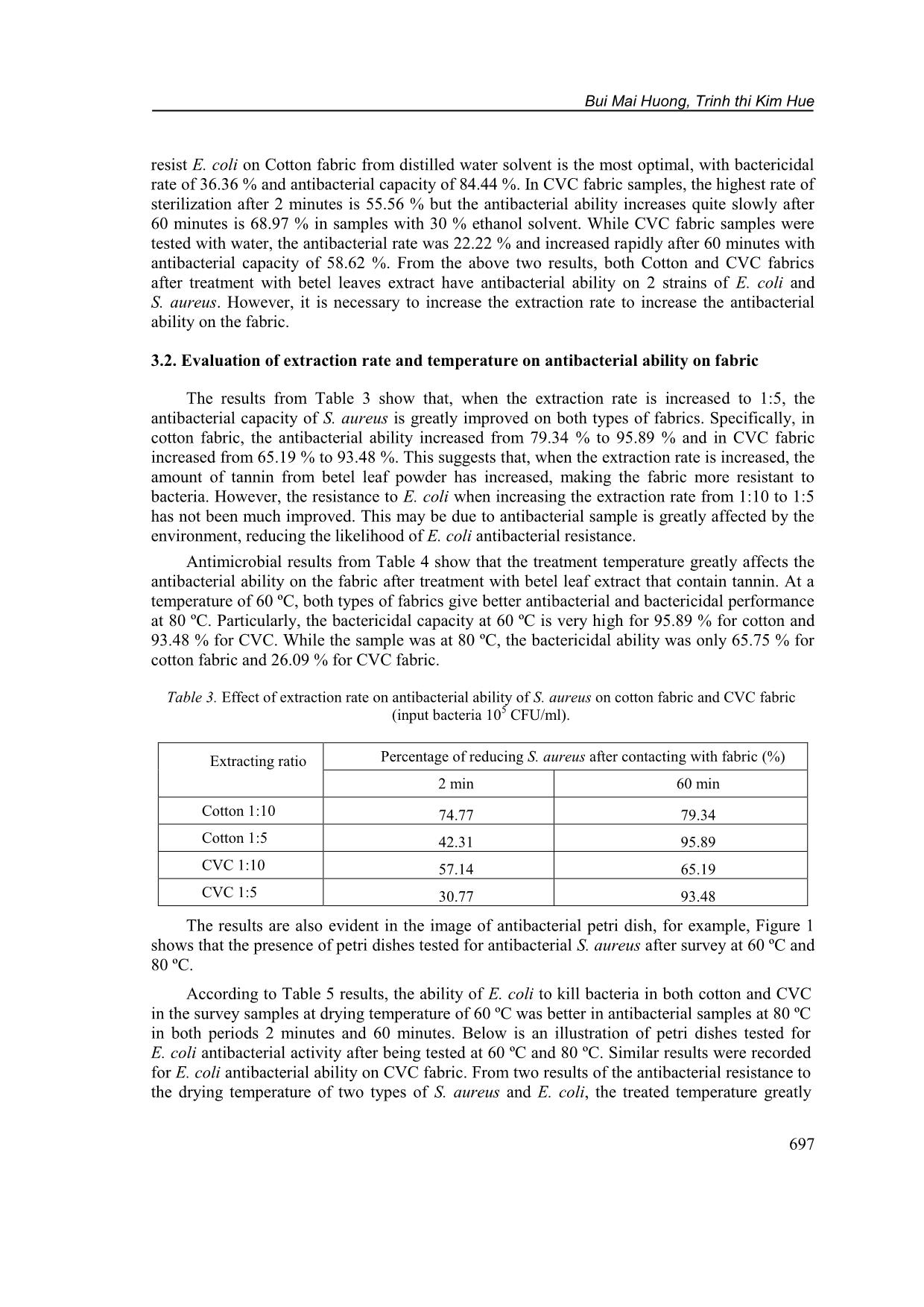

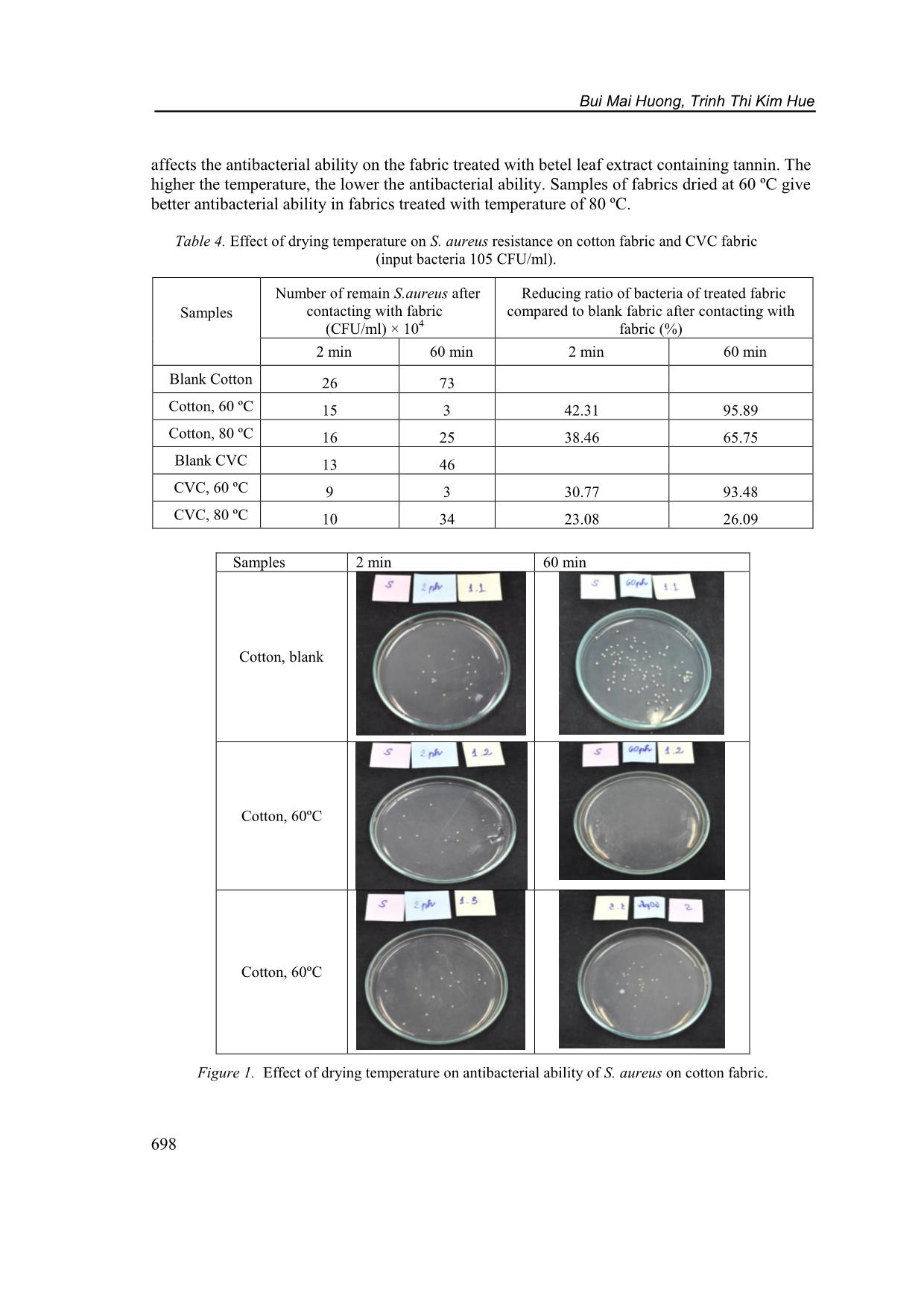

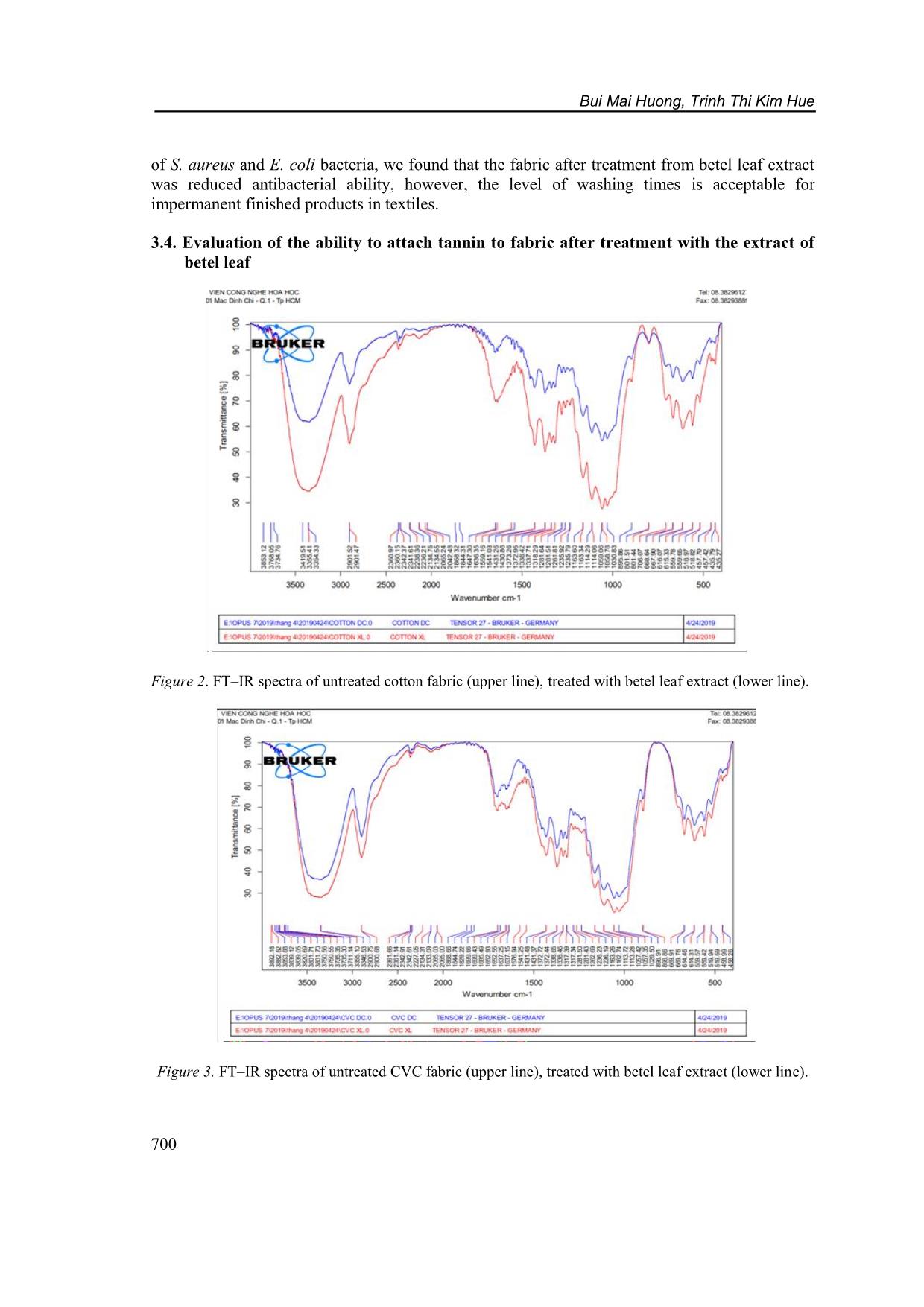

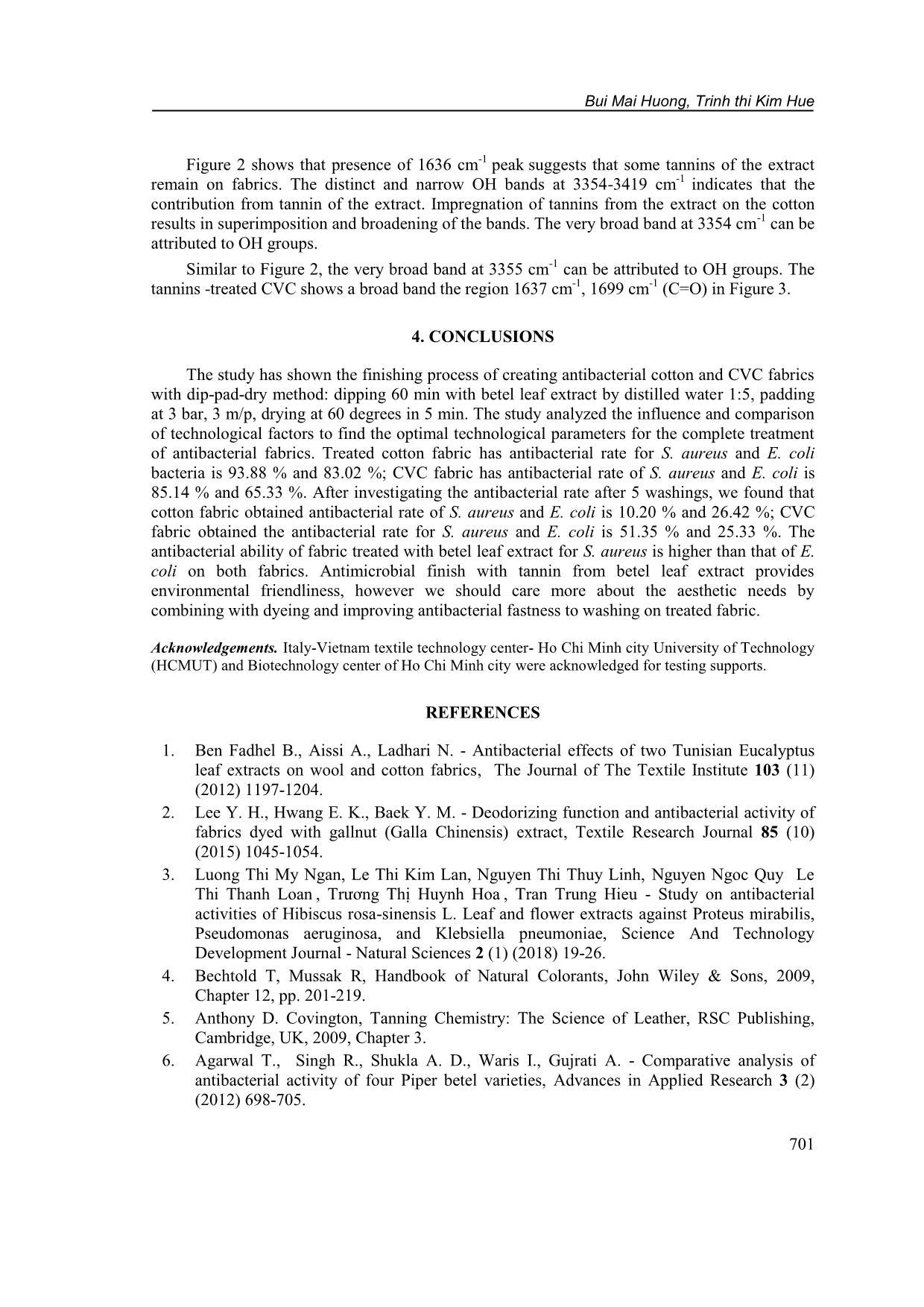

Vietnam Journal of Science and Technology 57 (6) (2019) 693-702 doi:10.15625/2525-2518/57/6/13953 ANTIBACTERIAL FINISHING ON COTTON 100 % AND CVC FABRICS WITH TANNIN FROM PIPER BETLE EXTRACT Bui Mai Huong * , Trinh Thi Kim Hue Department of Textile–Garment Engineering, Faculty of Mechanical Engineering, Ho Chi Minh City University of Technology (HCMUT–VNUHCM) 268 Ly Thuong Kiet, Ward 14, District 10, Ho Chi Minh City * Email: bmhuong@gmail.com Received: 15 July 2019; Accepted for publication: 5 September 2019 Abstract. Following the recent trend of using natural ingredients from bio-macromolecules, biomaterials and plant extract in textile chain, this research aims to develop an antibacterial textile finishing with tannin extracted from piper betle plant. The extracting processes were carried out with different solvent: distilled water, ethanol 30 %, ethanol 50 %, ethanol 70 % for 60 minutes. Two important types of fabric, including cotton and CVC (Cotton/Polyester) were padded with piper betle extracts, then dried at 60 o C for 5 minutes. The presence of tannin on fabric after treatment was determined by FeCl3 test and FT-IR spectrum. The antibacterial effect of finished fabrics was proved according to ASTM 2149-01 standard. The test was performed with E. coli ATCC 25922 and S. aureus AATCC 6538. The final results exhibited good antibacterial activity of 83.02 %, 65,33 % against the bacteria E. coli and 93.88 %, 85.14 % against the bacteria S. aureus on cotton and then CVC fabrics. Keywords: cotton, fabric, Piper betle, tannin, antibacterial. Classification numbers: 1.3.4, 2.7.1 1. INTRODUCTION Fabrics are an ideal environment for microorganisms such as bacteria and fungi to grow if they meet proper temperature and humidity. Many studies have demonstrated that microorganisms residing in textile products in hospitals are a source of hospital infections through endogenous, contact and air routes. In recent years, many antibacterial fabrics have been developed and proven to kill microorganisms, including bacteria, viruses and even fungi, reducing odors and safe to the skin and health. The use of antimicrobial fabrics has shown to be effective in reducing hospital infections, necessitating the need for finishing of antibacterial agents on fabrics, especially environmentally friendly antibacterial compounds [1, 2]. These compounds can be obtained from abundant plant resources in tropical countries such as tea leaves, neem leaves, aloe plants, pomegranate skin, mangosteen skin, hibiscus rosa-sinensis L. leaf and flower extracts, etc. [3]. They have been widely used in pharmaceuticals, cosmetics, however limited applications in textile products [3, 4]. Many studies show that tannin can be used as an effective antibacterial compound. Tannin causes enzyme inhibition of extracellular Bui Mai Huong, Trinh Thi Kim Hue 694 microorganisms, taking away substances necessary for the growth of microorganisms [4, 5]. This direct activity affects the metabolism of microorganisms through inhibition of oxidation phosphorylation, removing metal ions or forming complexes with bacterial cell membranes causes changes in cell wall morphology and increases membrane permeability. Studies have shown that microbial cell membranes are the main inhibitory activity of tannin, through the breakdown of cell membranes as well as paralyzing cell function. Although protein precipitation is a common property for all tannin, the antimicrobial activity of tannin is characteristic of microorganisms and is closely related to the chemical composition and structure of tannin. In general, the study showed that the antimicrobial activity of tannin against gram-positive bacteria was greater than that of Gram-negative bacteria that contained gram-negative bacteria possessing an outer membrane consisting of a lipid double-layer structure consisting of outer lipopolysaccharide and protein layers and an inner layer consisting of phospholipids. However, condensed tannin isolated from some plants has been shown to have a strong activity against gram-negative bacteria [4, 5] The number of hydroxy groups and hydrogen peroxide release when oxidizing tannin are two important factors responsible for the antibacterial properties of tannin. Among the plants that contain tannin, we selected betel leaves. Betel is a popular tree in Vietnam. Betel leaves have a strong taste and contain some compounds of phenol which have very strong antiseptic effect. Antibacterial activity test (determination of minimum inhibitory concentration of MIC) on 8 strains of Staphylococcus aureus, Streptococcus faecalis, Escherichia coli, Pseudomonas aeruginosa, Salmonella spp, Aeromonas hydrophila, Edwardsiella ictaluri and Edwardsiella tarda showed that antibacterial activities of different betel species have different but good effects on tested bacteria and divided i ... l 100 % cotton fabrics, plain weave, weight 126 g/m 2 , warp density 58 threads cm -1 , weft density 30 threads cm -1 , scoured and bleached (supplied by Agtex 28 Corporation, Viet Nam) were used. CVC 85/15 fabrics, warp density 76 threads cm -1 , weft density 36 threads cm -1 weight 113 g/m 2 . Samples were prepared with the size of 20 cm × 20 cm. 2.2. Bacterial strains Bui Mai Huong, Trinh thi Kim Hue 695 Two bacterial strains (1 gram-positive and 1 gram-negative) were used for the study. The Gram-positive strain was Staphylococcus aureus and the gram-negative strains included Escherichia coli. The bacterial strains were obtained from Biotechnology Center of Ho Chi Minh City, Viet Nam. 2.3. Extraction from betel leaves Betel leaves were purchased from local market in Tay Ninh Province, Vietnam. Betel leaves were dried in sunlight and then crushed the betel leaves to achieve dry powder. The betel leaf power (10 g, 20 g, 40 g) were soaked in 200 ml of 30 % ethanol, 50 % ethanol, 70 % ethanol and distilled water. Keep in dark for 3 days. They were then filtered to collect the extract. 2.4. Determination of tannin The qualitative analysis was carried out by treating 0.5 % solution of the above extracts with aqueous ferric chloride. 2.5. Coating process The extracts were used to prepare thin coatings on substrates (cotton fabrics and CVC fabrics) by a dip-pad–dry process using Laboratory pneumatic padding mangle, SD400V. The cleaned substrates were dipped in the extract for ten minutes, pressed with a padder at a nip pressure of 2.75 kg/ cm 2 on each of the fabric substrates. The fabric samples were dried at 60 ºC, 80 ºC for 5 min in a preheated oven. 2.6. Characterization The chemical composition of the samples was identified by an attenuated total reflection infrared spectrometer (IR, Tensor 27, Bruker). 2.7. Antibacterial Assay Quantitative assessment of antimicrobial activity exhibited on treated cotton and CVC fabrics against both Staphylococcus aureus and Escherichia coli were carried out by ASTM E2149 – 01. To evaluate the antimicrobial activities of the treated fabrics, the reduction in the number of bacterial colonies formed with respect to the untreated control after incubation (37 ± 1 ºC, 24 h) was determined. 2.8. Durability of antibacterial activity to washing The washing procedure was done according to AATCC Method 124-1996. The water temperature for laundering was approximately 40 o C. 3. RESULTS AND DISCUSSION 3.1. Evaluation of the antibacterial ability of the fabric after treatment with the extract of betel leaves Antimicrobial ability of the fabric samples after treatment with the extract from betel leaves was evaluated by shaking method according to ASTM E2149-01, using Escherichia coli strain Bui Mai Huong, Trinh Thi Kim Hue 696 (E. coli - bacteria gram-negative-ATCC 25922) and Staphylococus aureus (S. aureus - gram- positive bacteria -ATCC 6538). Table 1. Effect of solvent on antibacterial ability of S. aureus of Cotton fabric and CVC fabric (input bacteria 10 5 CFU/ml). Solution Number of remain S. aureus (CFU/ml) after contacting with fabric 10 4 2 min 60 min Cotton fabric Blank 218 242 Ethanol 30 % 100 81 Ethanol 50 % 59 53 Ethanol 70 % 114 58 H2O 55 50 CVC fabric Blank 168 158 Ethanol 30 % 67 50 Ethanol 50 % 85 55 Ethanol 70 % 101 55 H2O 72 55 Table 2. Effect of solvent on E. coli resistance of Cotton fabric and CVC fabric (input bacteria 10 5 CFU/ml). Samples Number of remain E. coli (CFU/ml) after contacting with fabric ×10 4 2 min 60 min Cotton fabric Blank 44 45 Ethanol 30 % 36 17 Ethanol 50 % 43 23 Ethanol 70 % 44 28 H2O 28 7 CVC fabric Blank 45 58 Ethanol 30 % 20 18 Ethanol 50 % 36 19 Ethanol 70 % 41 28 H2O 35 24 As shown in Table 1, the results of the above solvent survey showed that the highest antibacterial ability of S. aureus on cotton cloth was in the sample with the distilled water solvent with the bactericidal speed after 2 minutes and the antibacterial ability after 60 minutes was 74.77 % and 79.34 %. In CVC fabric samples, we found bactericidal speed and antibacterial capacity of 57.14 % and 65.19 %, respectively. The results in Table 2 showed that the ability to Bui Mai Huong, Trinh thi Kim Hue 697 resist E. coli on Cotton fabric from distilled water solvent is the most optimal, with bactericidal rate of 36.36 % and antibacterial capacity of 84.44 %. In CVC fabric samples, the highest rate of sterilization after 2 minutes is 55.56 % but the antibacterial ability increases quite slowly after 60 minutes is 68.97 % in samples with 30 % ethanol solvent. While CVC fabric samples were tested with water, the antibacterial rate was 22.22 % and increased rapidly after 60 minutes with antibacterial capacity of 58.62 %. From the above two results, both Cotton and CVC fabrics after treatment with betel leaves extract have antibacterial ability on 2 strains of E. coli and S. aureus. However, it is necessary to increase the extraction rate to increase the antibacterial ability on the fabric. 3.2. Evaluation of extraction rate and temperature on antibacterial ability on fabric The results from Table 3 show that, when the extraction rate is increased to 1:5, the antibacterial capacity of S. aureus is greatly improved on both types of fabrics. Specifically, in cotton fabric, the antibacterial ability increased from 79.34 % to 95.89 % and in CVC fabric increased from 65.19 % to 93.48 %. This suggests that, when the extraction rate is increased, the amount of tannin from betel leaf powder has increased, making the fabric more resistant to bacteria. However, the resistance to E. coli when increasing the extraction rate from 1:10 to 1:5 has not been much improved. This may be due to antibacterial sample is greatly affected by the environment, reducing the likelihood of E. coli antibacterial resistance. Antimicrobial results from Table 4 show that the treatment temperature greatly affects the antibacterial ability on the fabric after treatment with betel leaf extract that contain tannin. At a temperature of 60 ºC, both types of fabrics give better antibacterial and bactericidal performance at 80 ºC. Particularly, the bactericidal capacity at 60 ºC is very high for 95.89 % for cotton and 93.48 % for CVC. While the sample was at 80 ºC, the bactericidal ability was only 65.75 % for cotton fabric and 26.09 % for CVC fabric. Table 3. Effect of extraction rate on antibacterial ability of S. aureus on cotton fabric and CVC fabric (input bacteria 10 5 CFU/ml). Extracting ratio Percentage of reducing S. aureus after contacting with fabric (%) 2 min 60 min Cotton 1:10 74.77 79.34 Cotton 1:5 42.31 95.89 CVC 1:10 57.14 65.19 CVC 1:5 30.77 93.48 The results are also evident in the image of antibacterial petri dish, for example, Figure 1 shows that the presence of petri dishes tested for antibacterial S. aureus after survey at 60 ºC and 80 ºC. According to Table 5 results, the ability of E. coli to kill bacteria in both cotton and CVC in the survey samples at drying temperature of 60 ºC was better in antibacterial samples at 80 ºC in both periods 2 minutes and 60 minutes. Below is an illustration of petri dishes tested for E. coli antibacterial activity after being tested at 60 ºC and 80 ºC. Similar results were recorded for E. coli antibacterial ability on CVC fabric. From two results of the antibacterial resistance to the drying temperature of two types of S. aureus and E. coli, the treated temperature greatly Bui Mai Huong, Trinh Thi Kim Hue 698 affects the antibacterial ability on the fabric treated with betel leaf extract containing tannin. The higher the temperature, the lower the antibacterial ability. Samples of fabrics dried at 60 ºC give better antibacterial ability in fabrics treated with temperature of 80 ºC. Table 4. Effect of drying temperature on S. aureus resistance on cotton fabric and CVC fabric (input bacteria 105 CFU/ml). Samples Number of remain S.aureus after contacting with fabric (CFU/ml) × 10 4 Reducing ratio of bacteria of treated fabric compared to blank fabric after contacting with fabric (%) 2 min 60 min 2 min 60 min Blank Cotton 26 73 Cotton, 60 ºC 15 3 42.31 95.89 Cotton, 80 ºC 16 25 38.46 65.75 Blank CVC 13 46 CVC, 60 ºC 9 3 30.77 93.48 CVC, 80 ºC 10 34 23.08 26.09 Samples 2 min 60 min Cotton, blank Cotton, 60ºC Cotton, 60ºC Figure 1. Effect of drying temperature on antibacterial ability of S. aureus on cotton fabric. Bui Mai Huong, Trinh thi Kim Hue 699 Table 5. Effect of drying temperature on E. coli resistance on cotton fabric and CVC fabric (input bacteria 10 5 CFU/ml). Samples Number of remain E. coli after contacting with fabric (CFU/ml) × 10 4 Reducing ratio of bacteria of treated fabric compared to blank fabric after contacting with fabric (%) 2 min 60 min 2 min 60 min Blank cotton 34 42 Cotton, 60 ºC 14 10 66.67 76.19 Cotton, 90 ºC 19 28 54.76 33.33 Blank CVC 38 32 CVC, 60 ºC 30 14 21.05 56.25 CVC, 90 ºC 33 24 13.16 25.00 3.3. Evaluation of the effect of washing process on antibacterial ability on fabric The fabric samples after being treated with betel leaves extract are washed, tested for antibacterial and obtained the results shown in Table 6. Table 6. Effect of washing process on antibacterial ability of S. aureus on cotton fabric and CVC fabric (input bacteria 10 5 CFU/ml). Samples Number of remain S. aureus after contacting with fabric (CFU/ml) × 10 4 Reducing ratio of bacteria of treated fabric compared to blank fabric after contacting with fabric (%) 2 min 60 min 2 min 60 min Blank cotton 38 49 No washing cotton 25 3 34.21 93.88 Washing, cotton 33 44 13.16 10.20 Blank CVC 50 74 No washing CVC 14 11 72.00 85.14 Washing, CVC 42 36 16.00 51.35 Table 6 shows that the washing process reduces the antibacterial ability of S. aureus on both fabrics. Specifically, the antimicrobial ability decreased significantly after washing in cotton fabric from 93.88 % to 10.2 % and in CVC fabric decreased from 85.14 % to 51.35 %. E. coli resistance also decreases for fabric samples after performing the washing process. For cotton fabric, bactericidal ability is 83.02 % for newly processed samples from betel leaf extract and reduced to 26.42 % for samples after washing. Similarly, CVC fabric decreased from 65.33 % to 25.33 %. Through the investigation of antibacterial ability after washing on 2 types Bui Mai Huong, Trinh Thi Kim Hue 700 of S. aureus and E. coli bacteria, we found that the fabric after treatment from betel leaf extract was reduced antibacterial ability, however, the level of washing times is acceptable for impermanent finished products in textiles. 3.4. Evaluation of the ability to attach tannin to fabric after treatment with the extract of betel leaf Figure 2. FT–IR spectra of untreated cotton fabric (upper line), treated with betel leaf extract (lower line). Figure 3. FT–IR spectra of untreated CVC fabric (upper line), treated with betel leaf extract (lower line). Bui Mai Huong, Trinh thi Kim Hue 701 Figure 2 shows that presence of 1636 cm -1 peak suggests that some tannins of the extract remain on fabrics. The distinct and narrow OH bands at 3354-3419 cm -1 indicates that the contribution from tannin of the extract. Impregnation of tannins from the extract on the cotton results in superimposition and broadening of the bands. The very broad band at 3354 cm -1 can be attributed to OH groups. Similar to Figure 2, the very broad band at 3355 cm -1 can be attributed to OH groups. The tannins -treated CVC shows a broad band the region 1637 cm -1 , 1699 cm -1 (C=O) in Figure 3. 4. CONCLUSIONS The study has shown the finishing process of creating antibacterial cotton and CVC fabrics with dip-pad-dry method: dipping 60 min with betel leaf extract by distilled water 1:5, padding at 3 bar, 3 m/p, drying at 60 degrees in 5 min. The study analyzed the influence and comparison of technological factors to find the optimal technological parameters for the complete treatment of antibacterial fabrics. Treated cotton fabric has antibacterial rate for S. aureus and E. coli bacteria is 93.88 % and 83.02 %; CVC fabric has antibacterial rate of S. aureus and E. coli is 85.14 % and 65.33 %. After investigating the antibacterial rate after 5 washings, we found that cotton fabric obtained antibacterial rate of S. aureus and E. coli is 10.20 % and 26.42 %; CVC fabric obtained the antibacterial rate for S. aureus and E. coli is 51.35 % and 25.33 %. The antibacterial ability of fabric treated with betel leaf extract for S. aureus is higher than that of E. coli on both fabrics. Antimicrobial finish with tannin from betel leaf extract provides environmental friendliness, however we should care more about the aesthetic needs by combining with dyeing and improving antibacterial fastness to washing on treated fabric. Acknowledgements. Italy-Vietnam textile technology center- Ho Chi Minh city University of Technology (HCMUT) and Biotechnology center of Ho Chi Minh city were acknowledged for testing supports. REFERENCES 1. Ben Fadhel B., Aissi A., Ladhari N. - Antibacterial effects of two Tunisian Eucalyptus leaf extracts on wool and cotton fabrics, The Journal of The Textile Institute 103 (11) (2012) 1197-1204. 2. Lee Y. H., Hwang E. K., Baek Y. M. - Deodorizing function and antibacterial activity of fabrics dyed with gallnut (Galla Chinensis) extract, Textile Research Journal 85 (10) (2015) 1045-1054. 3. Luong Thi My Ngan, Le Thi Kim Lan, Nguyen Thi Thuy Linh, Nguyen Ngoc Quy Le Thi Thanh Loan , Trương Thị Huynh Hoa , Tran Trung Hieu - Study on antibacterial activities of Hibiscus rosa-sinensis L. Leaf and flower extracts against Proteus mirabilis, Pseudomonas aeruginosa, and Klebsiella pneumoniae, Science And Technology Development Journal - Natural Sciences 2 (1) (2018) 19-26. 4. Bechtold T, Mussak R, Handbook of Natural Colorants, John Wiley & Sons, 2009, Chapter 12, pp. 201-219. 5. Anthony D. Covington, Tanning Chemistry: The Science of Leather, RSC Publishing, Cambridge, UK, 2009, Chapter 3. 6. Agarwal T., Singh R., Shukla A. D., Waris I., Gujrati A. - Comparative analysis of antibacterial activity of four Piper betel varieties, Advances in Applied Research 3 (2) (2012) 698-705. Bui Mai Huong, Trinh Thi Kim Hue 702 7. Chakraborty D., Shah B. - Antimicrobial, Anti-Oxidative and Anti-Hemolytic activity of Piper betel leaf extracts, International Journal of Pharmacy and Pharmaceutical Sciences 3 (3) (2011) 192-199.

File đính kèm:

antibacterial_finishing_on_cotton_100_and_cvc_fabrics_with_t.pdf

antibacterial_finishing_on_cotton_100_and_cvc_fabrics_with_t.pdf