Ứng dụng chu trình PDCA tại doanh nghiệp nông sản đạt chuẩn hữu cơ USDA. Nghiên cứu tình huống tại công ty tnhh tiềm năng sinh thái Hòa Lạc

Bài viết này chỉ ra tầm quan trọng của các sản phẩm hữu cơ, qua đó giới thiệu một tiêu

chuẩn hữu cơ của Mỹ - USDA Organic, đồng thời thảo luận các vấn đề cốt lõi khi áp dụng tiêu

chuẩn USDA Organic. Nghiên cứu sử dụng cách tiếp cận 4M1E và sơ đồ xương cá Ishikawa để

phân tích các quy định cụ thể trong chứng nhận USDA Organic thông qua nghiên cứu thực

nghiệm tại Công ty TNHH Tiềm năng Sinh thái Hòa Lạc. Kết quả nghiên cứu chỉ ra rằng trong

quy trình sản xuất sản phẩm của Công ty TNHH Tiềm năng Sinh thái Hòa Lạc vẫn còn tồn tại

một số yếu tố hoạt động chưa hiệu quả. Do đó, nhóm tác giả đề xuất một số giải pháp cho doanh

nghiệp sản xuất Hòa Lạc nói riêng và các doanh nghiệp nông sản Việt Nam nói chung bằng cách

áp dụng chu trình PDCA trong vận hành doanh nghiệp để đáp ứng các tiêu chuẩn khắt khe của

chứng nhận hữu cơ USDA một cách hiệu quả.

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Trang 6

Trang 7

Trang 8

Trang 9

Trang 10

Tải về để xem bản đầy đủ

Tóm tắt nội dung tài liệu: Ứng dụng chu trình PDCA tại doanh nghiệp nông sản đạt chuẩn hữu cơ USDA. Nghiên cứu tình huống tại công ty tnhh tiềm năng sinh thái Hòa Lạc

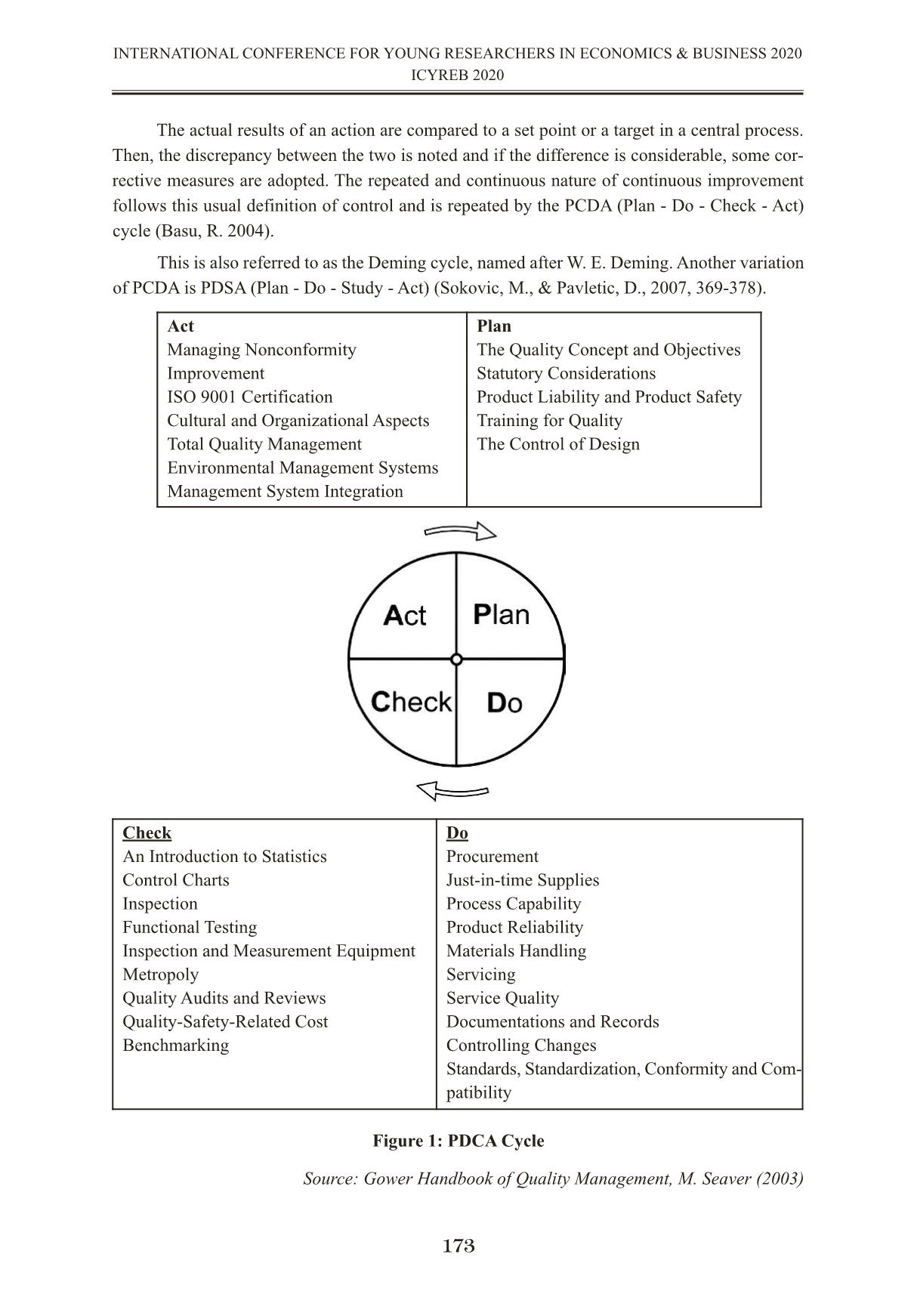

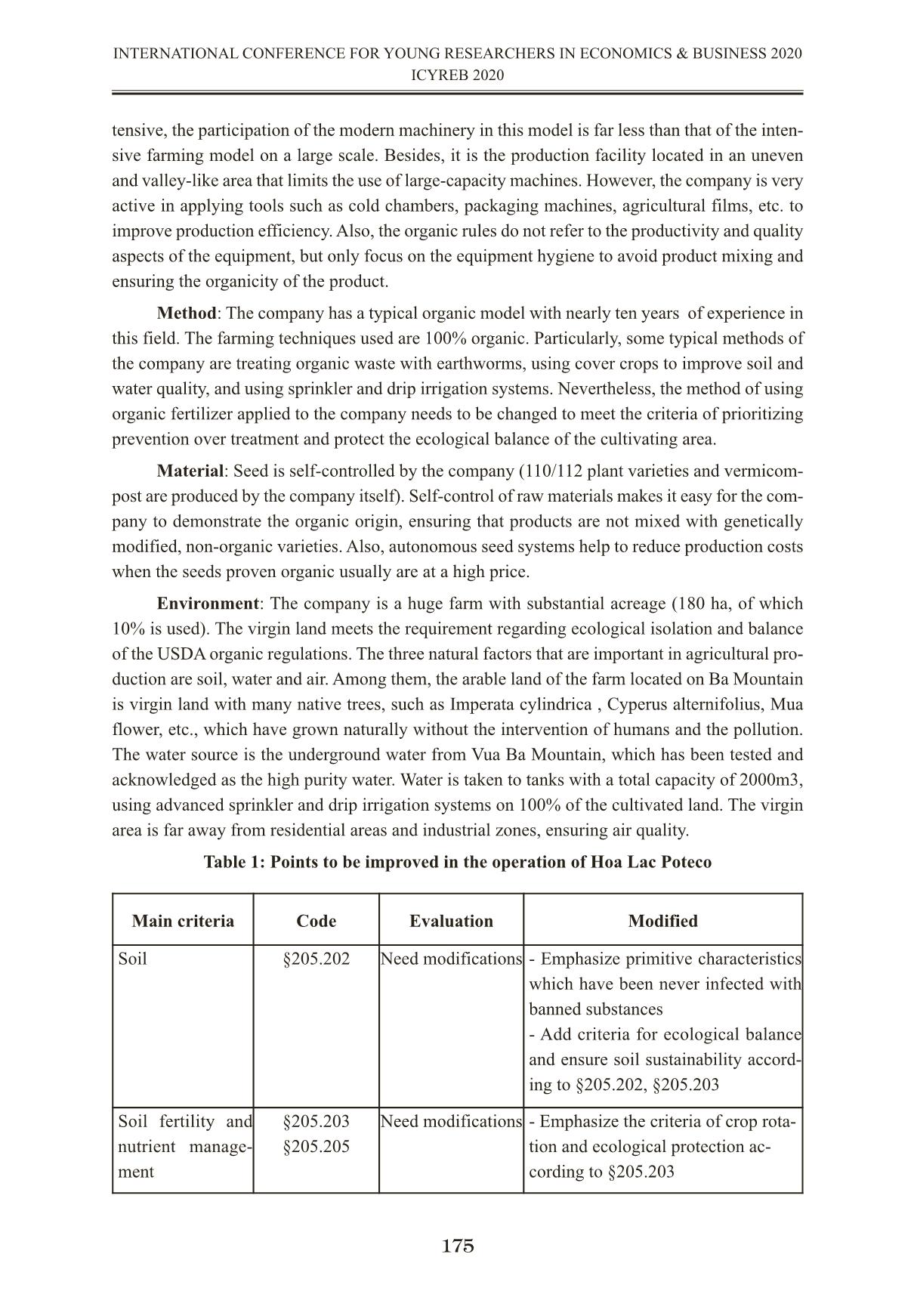

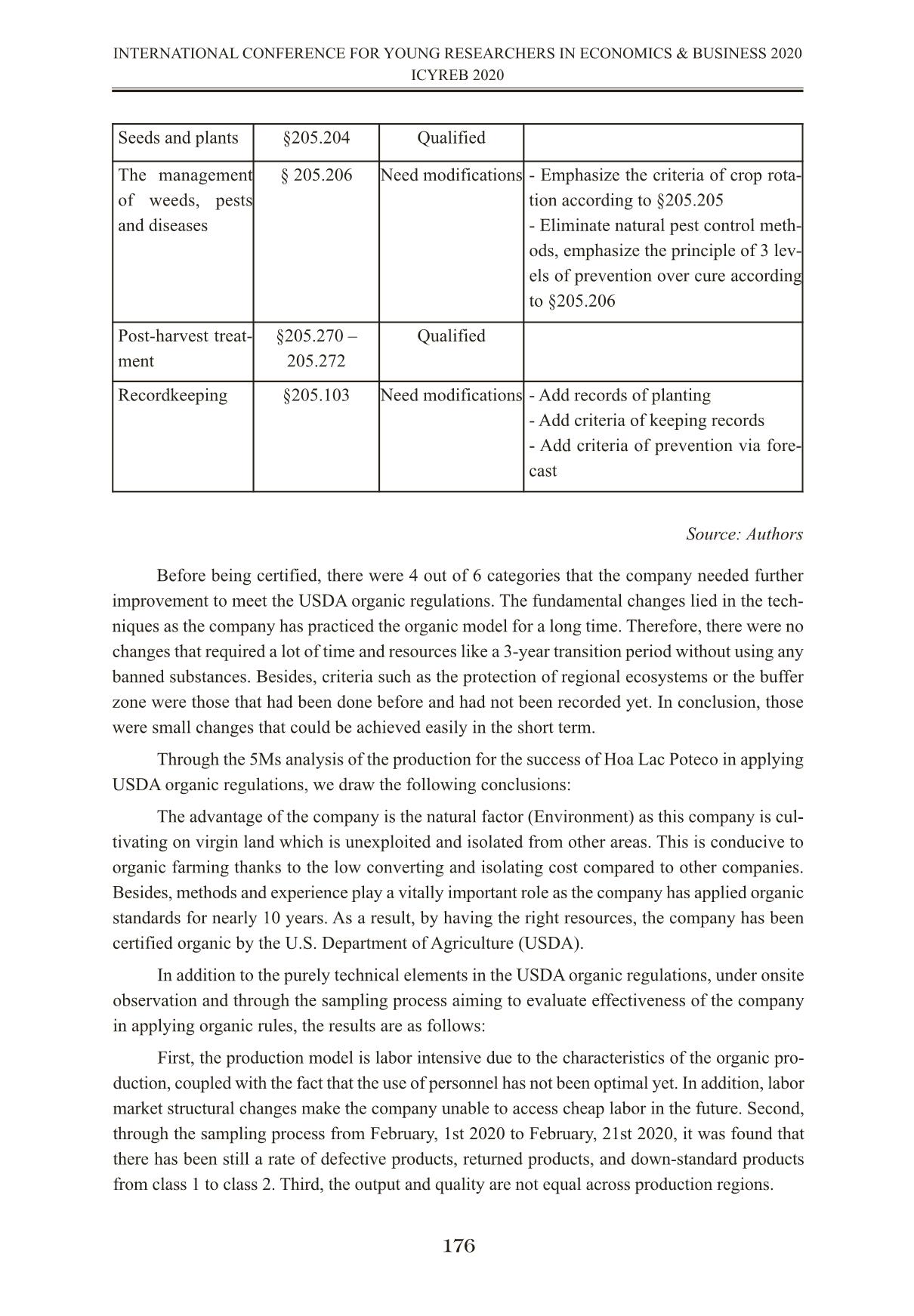

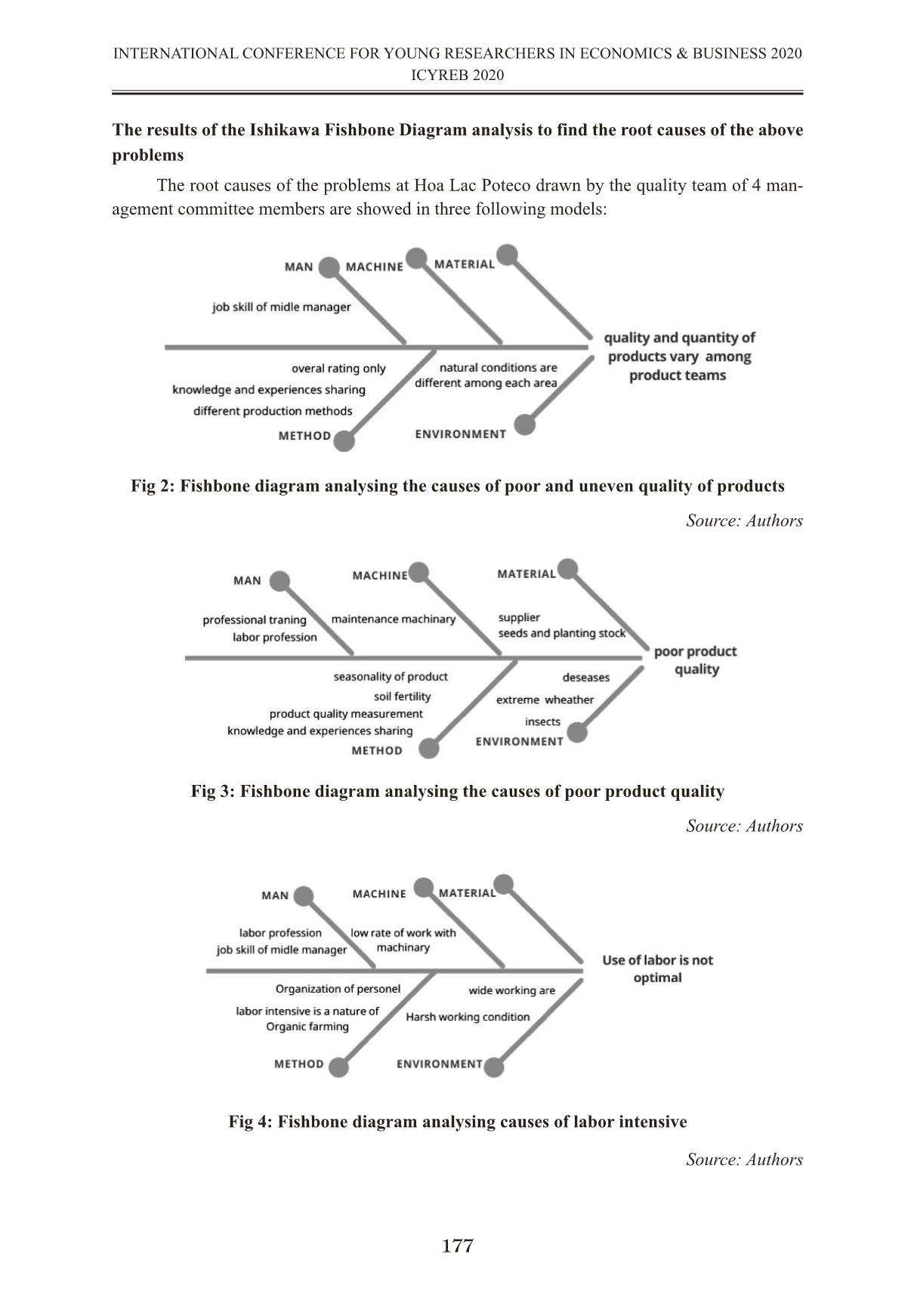

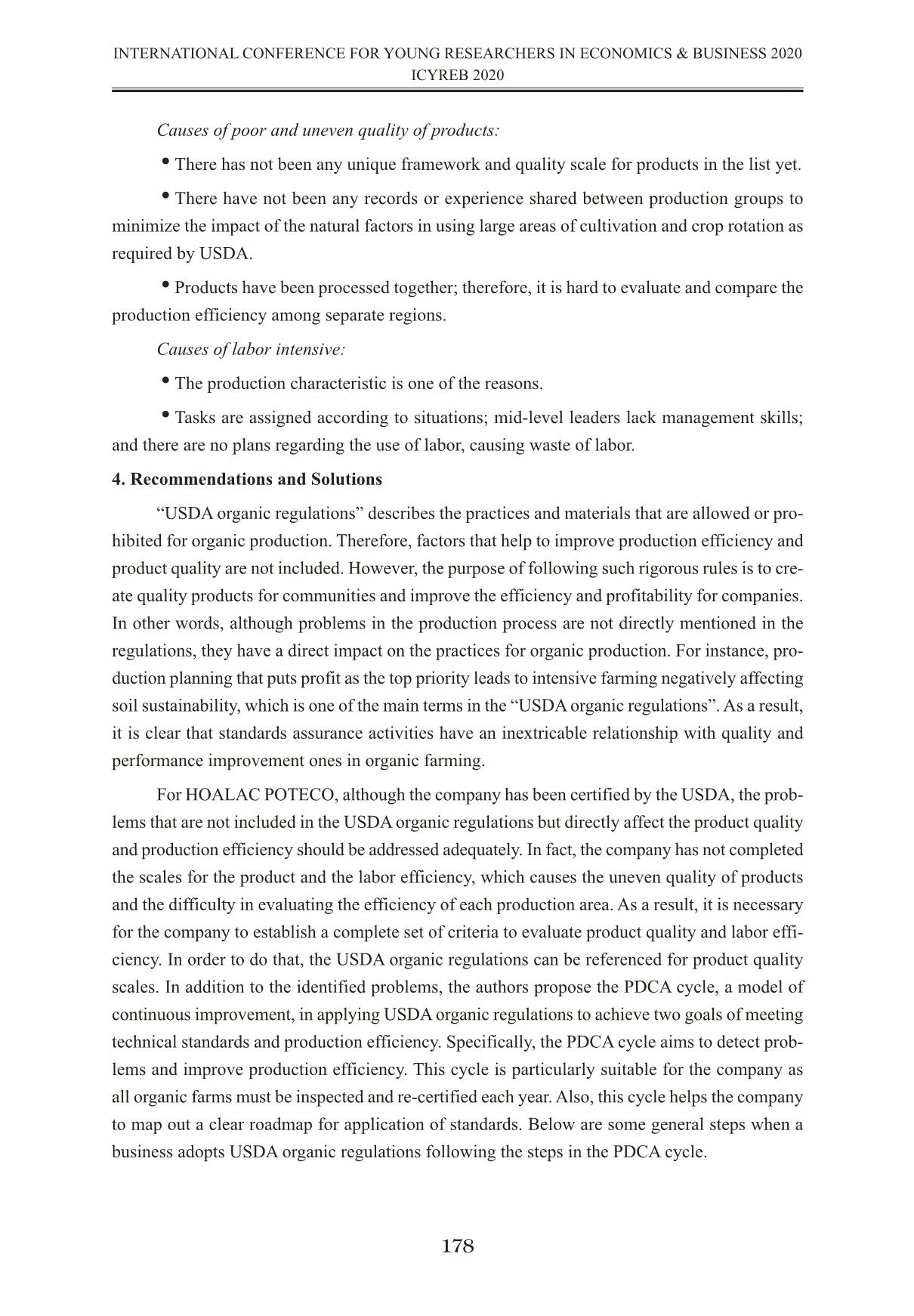

THE APPLICATION OF THE PDCA CYCLE IN AGRICULTURAL ENTERPRISES MEETING USDA ORGANIC CERTIFICATION A CASE STUDY OF HOALAC POTECO CO., LTD ỨNG DỤNG CHU TRÌNH PDCA TẠI DOANH NGHIỆP NÔNG SẢN ĐẠT CHUẨN HỮU CƠ USDA. NGHIÊN CỨU TÌNH HUỐNG TẠI CÔNG TY TNHH TIỀM NĂNG SINH THÁI HÒA LẠC Nguyễn Mạnh Tiến; Nguyễn Thị Thanh Huyền; Nguyễn Thị Chung Anh University of Economics and Business, VNU nguyenmanhtiend32@gmail.com Abstracts This paper presents the importance of organic products, introduces USDA Organic certi- fication and discuss some practical issues for Vietnamese organic producers to achieve this cer- tificate. This study uses the 4E1M concept and Ishikawa fishbone diagram to analyze the specific regulations being gained through the field study of Hoalac Poteco. The findings show that there are some ineffective points in the process of applying these standards in Hoalac Poteco. Thus, this paper suggests solutions for Hoalac Poteco in particular and Vietnamese agricultural en- terprises in general by applying the PDCA Cycle to meet standards of USDA Organic Certifica- tion effectively and efficiently. Keywords: organic food, USDA certification, PDCA cycle, 4E1M concept, Ishikawa diagram. Tóm tắt Bài viết này chỉ ra tầm quan trọng của các sản phẩm hữu cơ, qua đó giới thiệu một tiêu chuẩn hữu cơ của Mỹ - USDA Organic, đồng thời thảo luận các vấn đề cốt lõi khi áp dụng tiêu chuẩn USDA Organic. Nghiên cứu sử dụng cách tiếp cận 4M1E và sơ đồ xương cá Ishikawa để phân tích các quy định cụ thể trong chứng nhận USDA Organic thông qua nghiên cứu thực nghiệm tại Công ty TNHH Tiềm năng Sinh thái Hòa Lạc. Kết quả nghiên cứu chỉ ra rằng trong quy trình sản xuất sản phẩm của Công ty TNHH Tiềm năng Sinh thái Hòa Lạc vẫn còn tồn tại một số yếu tố hoạt động chưa hiệu quả. Do đó, nhóm tác giả đề xuất một số giải pháp cho doanh nghiệp sản xuất Hòa Lạc nói riêng và các doanh nghiệp nông sản Việt Nam nói chung bằng cách áp dụng chu trình PDCA trong vận hành doanh nghiệp để đáp ứng các tiêu chuẩn khắt khe của chứng nhận hữu cơ USDA một cách hiệu quả. Từ khóa: thực phẩm hữu cơ, chứng nhận hữu cơ USDA, chu trình PDCA, 4M1E, sơ đồ xương cá Ishikawa. 1. Introduction Vegetables play an irreplaceable role in human diet. According to the World Health Or- ganization (WHO), each person should consume 400g of vegetables and fruits per day (Kinder- sley, D. 2015). 169 INTERNATIONAL CONFERENCE FOR YOUNG RESEARCHERS IN ECONOMICS & BUSINESS 2020 ICYREB 2020 In recent decades, the demand for agricultural products and the prices of such products are on the rise under the shifts in the population structure and environmental factors. Indeed, the cur- rent world population is 7.4 billion and is projected to reach 9.5 billion by 2050 (United Nation, 2012). This is compounded by the fact that the world’s population is not only increasing, but also getting wealthier. Particularly, only 1.4 billion people in the world were middle class in 2000, but this figure is estimated to increase to 3.25 billion by 2020 (Kharas, H. & Gertz, G. 2010). Since the middle class consumes more and requires better-quality products, the agricultural sector is expected to grow considerably with a larger market. Besides, some factors regarding climate change, industrialization and urbanization have a substantial impact on the resources of this sector. Therefore, it can be seen that the new approach for food production needs to address the issues of quantity, quality and sustainability. Organic agriculture is one of the promising models meeting the above conditions. Organic foods are particularly appealing to health-conscious consumers as they are cultivated without the involvement of chemicals. The global organic food and beverages market is projected to reach $327 billion by 2022, about three times more than $115 billion in 2015 (Dwivedi, D. 2016). Sim- ilarly, the domestic market itself shares the same tendency as Vietnam’s economic growth is main- tained at a high level, averaging 6.5% per year (The World Bank, 2019). In addition, the growing concern over food contamination has been making fresh produce, especially organic food, gain more traction among customers. Vietnam is a tropical country with many favorable conditions to develop the agricultural industry. With geopolitical incentives, agriculture is considered a strategic sector of the country. In fact, 37.6% of Vietnamese laborers are involved in this sector (General Statistics Office of Vietnam, 2018). However, the prestige and quality of Vietnamese agricultural products have not been guaranteed because the production process focuses too much on productivity and crop in- tensification, and farmers’ awareness is still low. Consequently, those farmers may use toxic chemicals at their will, which adversely affects the health of consumers as well as the environ- ment. Gradually, customers will lose confidence in Vietnamese agricultural products. Current ... rticipation of the modern machinery in this model is far less than that of the inten- sive farming model on a large scale. Besides, it is the production facility located in an uneven and valley-like area that limits the use of large-capacity machines. However, the company is very active in applying tools such as cold chambers, packaging machines, agricultural films, etc. to improve production efficiency. Also, the organic rules do not refer to the productivity and quality aspects of the equipment, but only focus on the equipment hygiene to avoid product mixing and ensuring the organicity of the product. Method: The company has a typical organic model with nearly ten years of experience in this field. The farming techniques used are 100% organic. Particularly, some typical methods of the company are treating organic waste with earthworms, using cover crops to improve soil and water quality, and using sprinkler and drip irrigation systems. Nevertheless, the method of using organic fertilizer applied to the company needs to be changed to meet the criteria of prioritizing prevention over treatment and protect the ecological balance of the cultivating area. Material: Seed is self-controlled by the company (110/112 plant varieties and vermicom- post are produced by the company itself). Self-control of raw materials makes it easy for the com- pany to demonstrate the organic origin, ensuring that products are not mixed with genetically modified, non-organic varieties. Also, autonomous seed systems help to reduce production costs when the seeds proven organic usually are at a high price. Environment: The company is a huge farm with substantial acreage (180 ha, of which 10% is used). The virgin land meets the requirement regarding ecological isolation and balance of the USDA organic regulations. The three natural factors that are important in agricultural pro- duction are soil, water and air. Among them, the arable land of the farm located on Ba Mountain is virgin land with many native trees, such as Imperata cylindrica , Cyperus alternifolius, Mua flower, etc., which have grown naturally without the intervention of humans and the pollution. The water source is the underground water from Vua Ba Mountain, which has been tested and acknowledged as the high purity water. Water is taken to tanks with a total capacity of 2000m3, using advanced sprinkler and drip irrigation systems on 100% of the cultivated land. The virgin area is far away from residential areas and industrial zones, ensuring air quality. Table 1: Points to be improved in the operation of Hoa Lac Poteco 175 INTERNATIONAL CONFERENCE FOR YOUNG RESEARCHERS IN ECONOMICS & BUSINESS 2020 ICYREB 2020 Main criteria Code Evaluation Modified Soil §205.202 Need modifications - Emphasize primitive characteristics which have been never infected with banned substances - Add criteria for ecological balance and ensure soil sustainability accord- ing to §205.202, §205.203 Soil fertility and nutrient manage- ment §205.203 §205.205 Need modifications - Emphasize the criteria of crop rota- tion and ecological protection ac- cording to §205.203 Source: Authors Before being certified, there were 4 out of 6 categories that the company needed further improvement to meet the USDA organic regulations. The fundamental changes lied in the tech- niques as the company has practiced the organic model for a long time. Therefore, there were no changes that required a lot of time and resources like a 3-year transition period without using any banned substances. Besides, criteria such as the protection of regional ecosystems or the buffer zone were those that had been done before and had not been recorded yet. In conclusion, those were small changes that could be achieved easily in the short term. Through the 5Ms analysis of the production for the success of Hoa Lac Poteco in applying USDA organic regulations, we draw the following conclusions: The advantage of the company is the natural factor (Environment) as this company is cul- tivating on virgin land which is unexploited and isolated from other areas. This is conducive to organic farming thanks to the low converting and isolating cost compared to other companies. Besides, methods and experience play a vitally important role as the company has applied organic standards for nearly 10 years. As a result, by having the right resources, the company has been certified organic by the U.S. Department of Agriculture (USDA). In addition to the purely technical elements in the USDA organic regulations, under onsite observation and through the sampling process aiming to evaluate effectiveness of the company in applying organic rules, the results are as follows: First, the production model is labor intensive due to the characteristics of the organic pro- duction, coupled with the fact that the use of personnel has not been optimal yet. In addition, labor market structural changes make the company unable to access cheap labor in the future. Second, through the sampling process from February, 1st 2020 to February, 21st 2020, it was found that there has been still a rate of defective products, returned products, and down-standard products from class 1 to class 2. Third, the output and quality are not equal across production regions. 176 INTERNATIONAL CONFERENCE FOR YOUNG RESEARCHERS IN ECONOMICS & BUSINESS 2020 ICYREB 2020 Seeds and plants §205.204 Qualified The management of weeds, pests and diseases § 205.206 Need modifications - Emphasize the criteria of crop rota- tion according to §205.205 - Eliminate natural pest control meth- ods, emphasize the principle of 3 lev- els of prevention over cure according to §205.206 Post-harvest treat- ment §205.270 – 205.272 Qualified Recordkeeping §205.103 Need modifications - Add records of planting - Add criteria of keeping records - Add criteria of prevention via fore- cast The results of the Ishikawa Fishbone Diagram analysis to find the root causes of the above problems The root causes of the problems at Hoa Lac Poteco drawn by the quality team of 4 man- agement committee members are showed in three following models: Fig 2: Fishbone diagram analysing the causes of poor and uneven quality of products Source: Authors Fig 3: Fishbone diagram analysing the causes of poor product quality Source: Authors Fig 4: Fishbone diagram analysing causes of labor intensive Source: Authors 177 INTERNATIONAL CONFERENCE FOR YOUNG RESEARCHERS IN ECONOMICS & BUSINESS 2020 ICYREB 2020 Causes of poor and uneven quality of products: iThere has not been any unique framework and quality scale for products in the list yet. iThere have not been any records or experience shared between production groups to minimize the impact of the natural factors in using large areas of cultivation and crop rotation as required by USDA. iProducts have been processed together; therefore, it is hard to evaluate and compare the production efficiency among separate regions. Causes of labor intensive: iThe production characteristic is one of the reasons. iTasks are assigned according to situations; mid-level leaders lack management skills; and there are no plans regarding the use of labor, causing waste of labor. 4. Recommendations and Solutions “USDA organic regulations” describes the practices and materials that are allowed or pro- hibited for organic production. Therefore, factors that help to improve production efficiency and product quality are not included. However, the purpose of following such rigorous rules is to cre- ate quality products for communities and improve the efficiency and profitability for companies. In other words, although problems in the production process are not directly mentioned in the regulations, they have a direct impact on the practices for organic production. For instance, pro- duction planning that puts profit as the top priority leads to intensive farming negatively affecting soil sustainability, which is one of the main terms in the “USDA organic regulations”. As a result, it is clear that standards assurance activities have an inextricable relationship with quality and performance improvement ones in organic farming. For HOALAC POTECO, although the company has been certified by the USDA, the prob- lems that are not included in the USDA organic regulations but directly affect the product quality and production efficiency should be addressed adequately. In fact, the company has not completed the scales for the product and the labor efficiency, which causes the uneven quality of products and the difficulty in evaluating the efficiency of each production area. As a result, it is necessary for the company to establish a complete set of criteria to evaluate product quality and labor effi- ciency. In order to do that, the USDA organic regulations can be referenced for product quality scales. In addition to the identified problems, the authors propose the PDCA cycle, a model of continuous improvement, in applying USDA organic regulations to achieve two goals of meeting technical standards and production efficiency. Specifically, the PDCA cycle aims to detect prob- lems and improve production efficiency. This cycle is particularly suitable for the company as all organic farms must be inspected and re-certified each year. Also, this cycle helps the company to map out a clear roadmap for application of standards. Below are some general steps when a business adopts USDA organic regulations following the steps in the PDCA cycle. 178 INTERNATIONAL CONFERENCE FOR YOUNG RESEARCHERS IN ECONOMICS & BUSINESS 2020 ICYREB 2020 Figure 4: Four main steps in PCDA Cycle applying in agricultural companies Source: Authors Evaluating the organic system and planning the necessary changes are the prerequisites in pursuing an organic certification. This step helps the company find “gaps” between their existing operation system and requirements for accreditation. Finding these gaps is really important as it helps producers make informed decisions of whether they should pursue various certifications. This is simply because when the gap is too large, it means that producers have to invest a huge amount of money in technologies, infrastructure, etc. To illustrate, if a producer is going to im- plement organic practices on a normal farming area, she or he should take into account the enor- mous cost of creating the buffer zone and the isolation distance needed to prevent organic crop contamination with genetically modified (GM) pollen or prohibited substances. Therefore, the question for him or her should be whether he or she should cultivate that area or not. This is even more important for conventional farmers who are considering organic certification for their crops. As a result, once the producers decide to follow the rules, a clear roadmap should be put in place to implement necessary changes. After planning and identifying points that need to be changed, a business needs to broadly implement the plan. Since the typical characteristic of the organic sector is labor intensive, a large number of employees (most of them take on constantly changing tasks) is required. Therefore, it is necessary to make sure that all employees grasp the plan and the organic standards. This means the company has to have effective propaganda. Throughout the implementation, it is necessary to observe and find out ineffective points to change. In reality, controlling activities and adjustments are made right in the second stage to standardize the process. In the third stage, checking operation and continuous self-assessment are significant because this will help producers reduce the costs incurred when fixing the error (according to the correlation between the cost of the error and the fault location) and avoid un- necessary waste of resources. 179 INTERNATIONAL CONFERENCE FOR YOUNG RESEARCHERS IN ECONOMICS & BUSINESS 2020 ICYREB 2020 The final stage is testing and accrediting. For HOALAC POTECO, the detected problems are outside the USDA organic regulations, so the company needs to focus on the third stage “checking operation and continuous self-assessment” to address aforementioned problems. Since PDCA cycle is a cyclic process, companies could repeat the PCDA steps as many times as needed until being certain that the PDCA cycle is as efficient as it can be. REFERENCES 1. Bao, L., Introduction about 4Ms, 2019. 2. Basu, R. (2004). Implementing quality: a practical guide to tools and techniques: en- abling the power of operational excellence. Cengage Learning EMEA. 3. Dwivedi, D. (2016), Organic Food and Beverages Market by Organic Foods: Global Opportunity Analysis and Industry Forecast 2014-2022. 4. EU Agricultural Markets Briefs, Organic farming in the EU A fast growing sector, 2019. 5. Electronic Code of Federal Regulations, Title 7, Subtitle B, Chapter I, Subchapter M, Part 205. 6. Kharas, H., & Gertz, G. (2010). The new global middle class: A cross-over from West to East. Wolfensohn Center for Development at Brookings, 1-14. 7. Ian, M. (2014), The Business Book. 8. Ishikawa, K., & Loftus, J. H. (1990). Introduction to quality control Tokyo. Japan: 3A Corporation. 9. Kindersley, D. (2015), How food works. 10. Kotler, P., Armstrong, G., Brown, L., Adam, S (2006), Marketing, 7th Edition. 11. Liliana, L. (2016, June). A new model of Ishikawa diagram for quality assessment. In IOP Conference Series: Materials Science and Engineering (Vol. 161, No. 1, p. 012099). IOP Publishing. 12. Miller, A., Boehlje, M., & Dobbins, C. L. (1998), Positioning the farm business (No. 1239-2016-101545). 13. National Organic Program, U.S. Department of Agriculture, (2012), What is Organic Certification? 14. National Young Farmer Coalition, (2014), Vegetable farmer’s guide to organic certifi- cation. 15. Oakley, E., National Young Farmer Coalition (2014), Vegetable farmer’s guide to or- ganic certification. 16. Pamela Coleman National Center for Appropriate Technology (NCAT) Agriculture Specialist, Guide for Organic Crop Producers, 2012. 180 INTERNATIONAL CONFERENCE FOR YOUNG RESEARCHERS IN ECONOMICS & BUSINESS 2020 ICYREB 2020 17. Sokovic, M., & Pavletic, D. (2007), Quality Improvement- PDCA Cycle vs. DMAIC and DFSS. Strojniski Vestnik, 53(6), 369-378. 18. Schiraldi, M. M., Operations Management, 2013. 18. Tague, N. R. (2005). Plan–do–study–act cycle. The quality toolbox, 390-392. 20. Tổng Cục Thống Kê, 2018, Thông cáo báo chí về tình hình kinh tế - xã hội năm 2018. 21. United Nation, World Population Prospect, The 2012 Revision. 22. Yihua, M., & Tuo, X. (2011), Research of 4M1E’s effect on engineering quality based on structural equation model, Systems Engineering Procedia, 1, 213-220. 181 INTERNATIONAL CONFERENCE FOR YOUNG RESEARCHERS IN ECONOMICS & BUSINESS 2020 ICYREB 2020

File đính kèm:

ung_dung_chu_trinh_pdca_tai_doanh_nghiep_nong_san_dat_chuan.pdf

ung_dung_chu_trinh_pdca_tai_doanh_nghiep_nong_san_dat_chuan.pdf