Tensile properties of monocrystalline gold film using molecular dynamics simulation

In recent years, crystalline metals have

attracted intensive attention because of their

excellent mechanical properties. Many previous

studies investigated the mechanical properties

of crystalline metals by experimental methods.

However, as the size of the material decreases to

the nanoscale, the use of experimental methods is

not easy. With the rapid development of computer

technology, molecular dynamics (MD) simulations

have become more suitable than empirical methods

for studying the properties of nanomaterials.

Numerous processes have been investigated using

MD simulations, including nanoindentation [1],

nanoscratch formation [2], nanotension [3], and

nanowelding [4]. Among various test processes,

nanotension is commonly used to analyze the

deformation and mechanical properties of

nanocrystalline materials.

Crystalline gold is widely applied in

electronic industries, for instance, the fabrication

of semiconductor, superconductor are used in

electronic, optical, and magnetic applications.

Therefore, the understanding of the mechanical

properties of crystalline gold is very important and

necessary for fabrication processes.

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Tóm tắt nội dung tài liệu: Tensile properties of monocrystalline gold film using molecular dynamics simulation

ISSN 2354-0575

TENSILE PROPERTIES OF MONOCRYSTALLINE GOLD FILM

USING MOLECULAR DYNAMICS SIMULATION

The-Van Tran, Anh-Son Tran

Hung Yen University of Technology and Education

Received: 21/01/2019

Revised: 15/02/2019

Accepted for publication: 05/03/2019

Abstract:

In this paper, the tensile properties of the monocrystalline gold film are studied by using molecular

dynamics simulation. The stress-strain relation, crack growth behavior and effects of different temperature

are considered. The results show that the stress concentration is obviously distributed in the middle and

corners of the specimen, leading to the cracks are formed and propagated in these positions. Under the

tensile process, the transformation from the face-centered cubic (FCC) into hexagonal closest packed

(HCP) structures occurred. From the stress-strain diagram, the tensile strength and Young’s modulus

values decreased with increasing temperature. The RDF is decreased with a higher temperature.

Keywords: Molecular dynamics; tensile strength; monocrystalline gold.

1. Introduction 2. Methodology

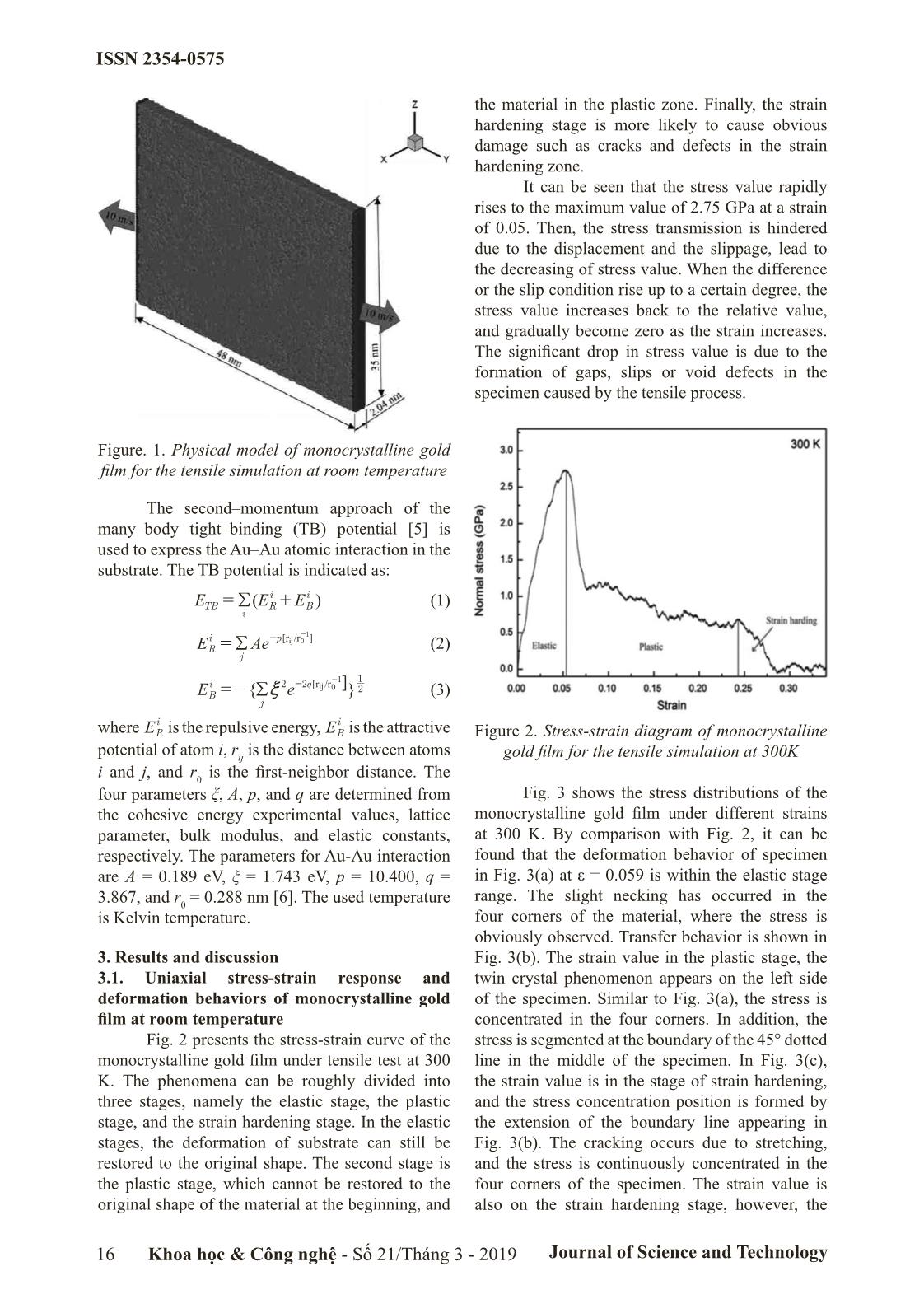

In recent years, crystalline metals have In this study, the effects of nanotension

attracted intensive attention because of their on monocrystalline gold film are studied by

excellent mechanical properties. Many previous using MD simulations. Fig. 1 shows the physical

studies investigated the mechanical properties sample of monocrystalline gold film used for the

of crystalline metals by experimental methods. tensile simulation. The crystalline unit of the face-

However, as the size of the material decreases to centered cubic (FCC) Au substrate comprises x,

the nanoscale, the use of experimental methods is y, and z-axes are directed along [100], [010], and

not easy. With the rapid development of computer [001], respectively. The geometric dimensions are

technology, molecular dynamics (MD) simulations approximately 2.04 nm (width) × 48 nm (length)

have become more suitable than empirical methods × 35 nm (height). The two-dimensional (2-D)

for studying the properties of nanomaterials. nanocrystalline nanomaterials are simulated in this

Numerous processes have been investigated using study. In a real situation, 2-D nanomaterials can be

MD simulations, including nanoindentation [1], patterned with different features at various scales.

nanoscratch formation [2], nanotension [3], and These 2-D patterns have different geometries from

nanowelding [4]. Among various test processes, three-dimensional (3-D) bulk nanomaterials. The

nanotension is commonly used to analyze the 2-D model has been selected because it is simple

deformation and mechanical properties of and nanofilms can be patterned. 2-D numerical

nanocrystalline materials. models can be used with good accuracy instead of

Crystalline gold is widely applied in 3-D models if the in-plane stresses are primarily of

electronic industries, for instance, the fabrication interest. It is expected to adequate for a qualitative

of semiconductor, superconductor are used in investigation of the nanocrystalline films. The fixed

electronic, optical, and magnetic applications. layers at the left and right sides of the sample along

Therefore, the understanding of the mechanical the y-axis direction are set to a fixed thickness

properties of crystalline gold is very important and of 6 Å. The lattice constant of gold is 4.08 Å,

necessary for fabrication processes. the total numbers of atoms of the substrates are

In this paper, the author prepared approximate: 194,520. The periodic boundary

monocrystalline gold film and focused to investigate condition is considered along the x-axis, while the

the stress-strain relationship, deformation behaviors free-boundary condition is assigned to the z-axis.

and crack nucleation of monocrystalline gold The tensile speed of the fixed layer in the y-axis

film at room temperature. Besides, the effects of is fixed given unilaterally at 10 m/s until the set of

different temperatures on the mechanical properties steps is completed. The movement is integrated by

and the radial distribution function (RDF) of the velocity–Verlet algorithm with a time step of 2

monocrystalline gold are also considered. fs.

Khoa học & Công nghệ - Số 21/Tháng 3 - 2019 Journal of Science and Technology 15

ISSN 2354-0575

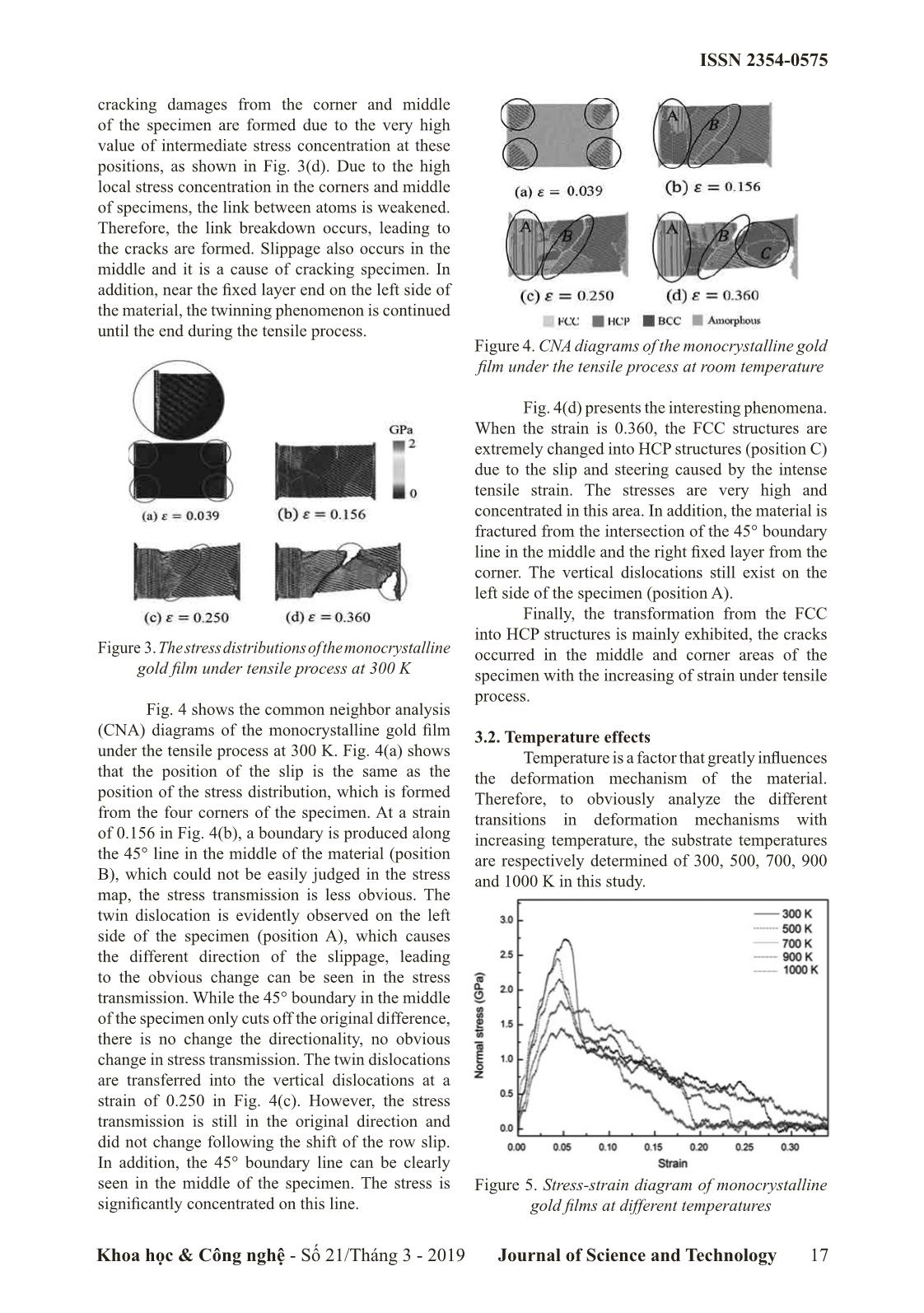

the material in the plastic zone. Finally, the strain

hardening stage is more likely to cause obvious

damage such as cracks and defects in the strain

hardening zone.

It can be seen that the stress value rapidly

rises to the maximum value of 2.75 GPa at a strain

of 0.05. Then, the stress transmission is hindered

due to the displacement and the slippage, lead to

the decreasing of stress value. When the difference

or the slip condition rise up to a certain degree, the

stress value increases back to the relative value,

and gradually become zero as the strain increases.

The significant drop in stress value is due tothe

formation of gaps, slips or void defects in the

specimen caused by the tensile process.

Figure. 1. Physical model of monocrystalline gold

film for the tensile simulation at room temperature

The second–momentum approach of the

many–body tight–binding (TB) potential [5] is

used to express the Au–Au atomic interaction in the

substrate. The TB potential is indicated as:

i i

EETB =+/ ()R EB (1)

i

-1

ip- [rij /r0 ]

EAR = / e (2)

j

-1 1

iq22- [rij/r0 ] 2

EeB =-{}/ p (3)

j

i i

where ER is the repulsive energy, EB is the attractive Figure 2. Stress-strain diagram of monocrystalline

potential of atom i, rij is the distance between atoms gold film for the tensile simulation at 300K

i and j, and r0 is the first-neighbor distance. The

four parameters ξ, A, p, and q are determined from Fig. 3 shows the stress distributions of the

the cohesive energy experimental values, lattice monocrystalline gold film under different strains

parameter, bulk modulus, and elastic constants, at 300 K. By comparison with Fig. 2, it can be

respectively. The parameters for Au-Au interaction found that the deformation behavior of specimen

are A = 0.189 eV, ξ = 1.743 eV, p = 10.400, q = in Fig. 3(a) at ε = 0.059 is within the elastic stage

range. The slight necking has occurred in the

3.867, and r0 = 0.288 nm [6]. The used temperature

is Kelvin temperature. four corners of the material, where the stress is

obviously observed. Transfer behavior is shown in

3. Results and discussion Fig. 3(b). The strain value in the plastic stage, the

3.1. Uniaxial stress-strain response and twin crystal phenomenon appears on the left side

deformation behaviors of monocrystalline gold of the specimen. Similar to Fig. 3(a), the stress is

film at room temperature concentrated in the four corners. In addition, the

Fig. 2 presents the stress-strain curve of the stress is segmented at the boundary of the 45° dotted

monocrystalline gold film under tensile test at 300 line in the middle of the specimen. In Fig. 3(c),

K. The phenomena can be roughly divided into the strain value is in the stage of strain hardening,

three stages, namely the elastic stage, the plastic and the stress concentration position is formed by

stage, and the strain hardening stage. In the elastic the extension of the boundary line appearing in

stages, the deformation of substrate can still be Fig. 3(b). The cracking occurs due to stretching,

restored to the original shape. The second stage is and the stress is continuously concentrated in the

the plastic stage, which cannot be restored to the four corners of the specimen. The strain value is

original shape of the material at the beginning, and also on the strain hardening stage, however, the

16 Khoa học & Công nghệ - Số 21/Tháng 3 - 2019 Journal of Science and Technology

ISSN 2354-0575

cracking damages from the corner and middle

of the specimen are formed due to the very high

value of intermediate stress concentration at these

positions, as shown in Fig. 3(d). Due to the high

local stress concentration in the corners and middle

of specimens, the link between atoms is weakened.

Therefore, the link breakdown occurs, leading to

the cracks are formed. Slippage also occurs in the

middle and it is a cause of cracking specimen. In

addition, near the fixed layer end on the left side of

the material, the twinning phenomenon is continued

until the end during the tensile process.

Figure 4. CNA diagrams of the monocrystalline gold

film under the tensile process at room temperature

Fig. 4(d) presents the interesting phenomena.

When the strain is 0.360, the FCC structures are

extremely changed into HCP structures (position C)

due to the slip and steering caused by the intense

tensile strain. The stresses are very high and

concentrated in this area. In addition, the material is

fractured from the intersection of the 45° boundary

line in the middle and the right fixed layer from the

corner. The vertical dislocations still exist on the

left side of the specimen (position A).

Finally, the transformation from the FCC

into HCP structures is mainly exhibited, the cracks

Figure 3. The stress distributions of the monocrystalline occurred in the middle and corner areas of the

gold film under tensile process at 300 K specimen with the increasing of strain under tensile

process.

Fig. 4 shows the common neighbor analysis

(CNA) diagrams of the monocrystalline gold film 3.2. Temperature effects

under the tensile process at 300 K. Fig. 4(a) shows Temperature is a factor that greatly influences

that the position of the slip is the same as the the deformation mechanism of the material.

position of the stress distribution, which is formed Therefore, to obviously analyze the different

from the four corners of the specimen. At a strain transitions in deformation mechanisms with

of 0.156 in Fig. 4(b), a boundary is produced along increasing temperature, the substrate temperatures

the 45° line in the middle of the material (position are respectively determined of 300, 500, 700, 900

B), which could not be easily judged in the stress and 1000 K in this study.

map, the stress transmission is less obvious. The

twin dislocation is evidently observed on the left

side of the specimen (position A), which causes

the different direction of the slippage, leading

to the obvious change can be seen in the stress

transmission. While the 45° boundary in the middle

of the specimen only cuts off the original difference,

there is no change the directionality, no obvious

change in stress transmission. The twin dislocations

are transferred into the vertical dislocations at a

strain of 0.250 in Fig. 4(c). However, the stress

transmission is still in the original direction and

did not change following the shift of the row slip.

In addition, the 45° boundary line can be clearly

seen in the middle of the specimen. The stress is Figure 5. Stress-strain diagram of monocrystalline

significantly concentrated on this line. gold films at different temperatures

Khoa học & Công nghệ - Số 21/Tháng 3 - 2019 Journal of Science and Technology 17

ISSN 2354-0575

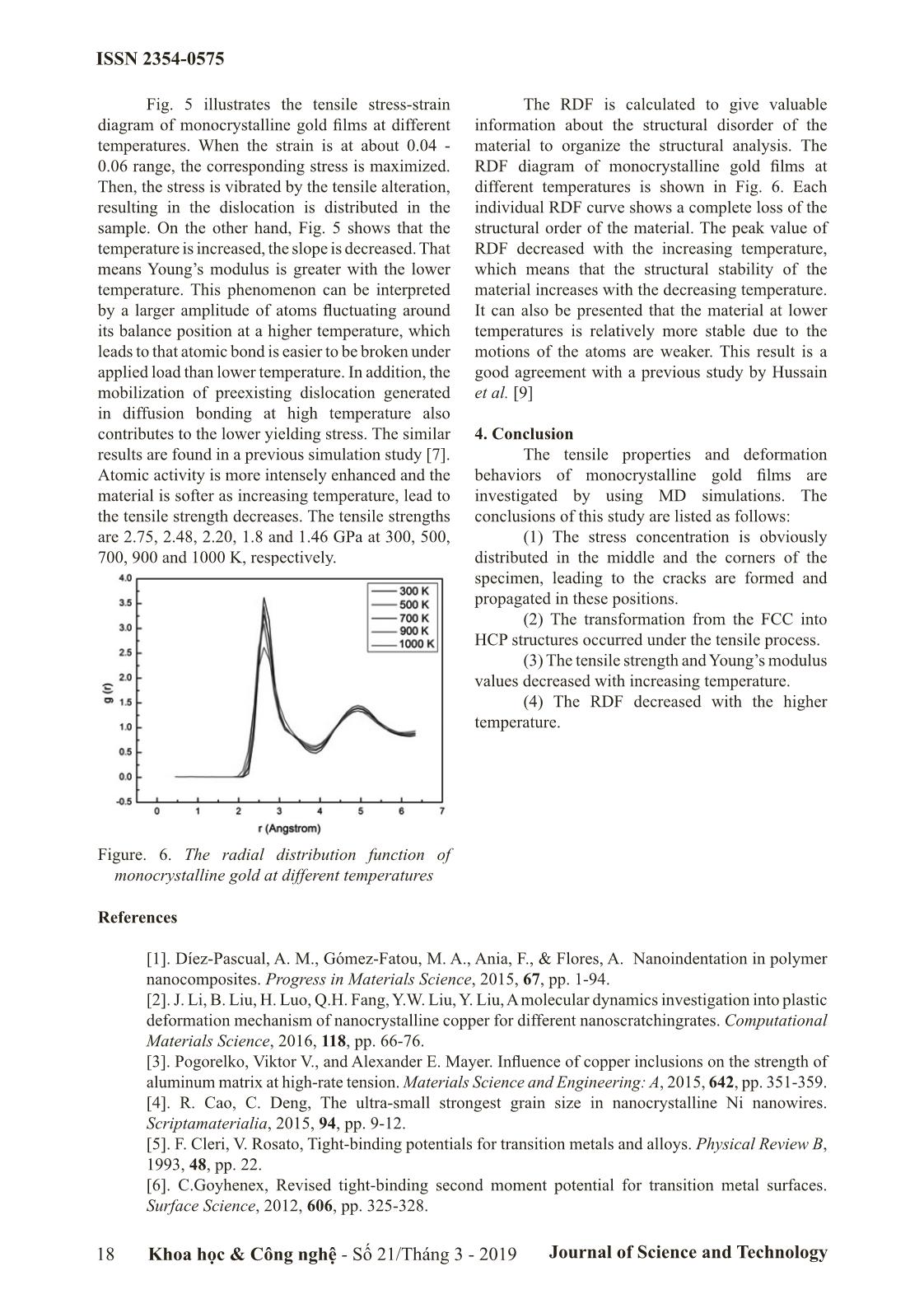

Fig. 5 illustrates the tensile stress-strain The RDF is calculated to give valuable

diagram of monocrystalline gold films at different information about the structural disorder of the

temperatures. When the strain is at about 0.04 - material to organize the structural analysis. The

0.06 range, the corresponding stress is maximized. RDF diagram of monocrystalline gold films at

Then, the stress is vibrated by the tensile alteration, different temperatures is shown in Fig. 6. Each

resulting in the dislocation is distributed in the individual RDF curve shows a complete loss of the

sample. On the other hand, Fig. 5 shows that the structural order of the material. The peak value of

temperature is increased, the slope is decreased. That RDF decreased with the increasing temperature,

means Young’s modulus is greater with the lower which means that the structural stability of the

temperature. This phenomenon can be interpreted material increases with the decreasing temperature.

by a larger amplitude of atoms fluctuating around It can also be presented that the material at lower

its balance position at a higher temperature, which temperatures is relatively more stable due to the

leads to that atomic bond is easier to be broken under motions of the atoms are weaker. This result is a

applied load than lower temperature. In addition, the good agreement with a previous study by Hussain

mobilization of preexisting dislocation generated et al. [9]

in diffusion bonding at high temperature also

contributes to the lower yielding stress. The similar 4. Conclusion

results are found in a previous simulation study [7]. The tensile properties and deformation

Atomic activity is more intensely enhanced and the behaviors of monocrystalline gold films are

material is softer as increasing temperature, lead to investigated by using MD simulations. The

the tensile strength decreases. The tensile strengths conclusions of this study are listed as follows:

are 2.75, 2.48, 2.20, 1.8 and 1.46 GPa at 300, 500, (1) The stress concentration is obviously

700, 900 and 1000 K, respectively. distributed in the middle and the corners of the

specimen, leading to the cracks are formed and

propagated in these positions.

(2) The transformation from the FCC into

HCP structures occurred under the tensile process.

(3) The tensile strength and Young’s modulus

values decreased with increasing temperature.

(4) The RDF decreased with the higher

temperature.

Figure. 6. The radial distribution function of

monocrystalline gold at different temperatures

References

[1]. Díez-Pascual, A. M., Gómez-Fatou, M. A., Ania, F., & Flores, A. Nanoindentation in polymer

nanocomposites. Progress in Materials Science, 2015, 67, pp. 1-94.

[2]. J. Li, B. Liu, H. Luo, Q.H. Fang, Y.W. Liu, Y. Liu, A molecular dynamics investigation into plastic

deformation mechanism of nanocrystalline copper for different nanoscratchingrates. Computational

Materials Science, 2016, 118, pp. 66-76.

[3]. Pogorelko, Viktor V., and Alexander E. Mayer. Influence of copper inclusions on the strength of

aluminum matrix at high-rate tension. Materials Science and Engineering: A, 2015, 642, pp. 351-359.

[4]. R. Cao, C. Deng, The ultra-small strongest grain size in nanocrystalline Ni nanowires.

Scriptamaterialia, 2015, 94, pp. 9-12.

[5]. F. Cleri, V. Rosato, Tight-binding potentials for transition metals and alloys. Physical Review B,

1993, 48, pp. 22.

[6]. C.Goyhenex, Revised tight-binding second moment potential for transition metal surfaces.

Surface Science, 2012, 606, pp. 325-328.

18 Khoa học & Công nghệ - Số 21/Tháng 3 - 2019 Journal of Science and Technology

ISSN 2354-0575

[7]. A.B. Lebedev, Y.A. Burenkov, A.E. Romanov, V.I. Kopylov, V.P. Filonenko, V.G. Gryaznov,

Softening of the elastic modulus in submicrocrystalline copper. Materials Science and Engineering:

A, 1995, 203, pp. 165-170.

[8]. Huang, S., Gao, Y., An, K., Zheng, L., Wu, W., Teng, Z., & Liaw, P. K. Deformation mechanisms

in a precipitation-strengthened ferritic superalloy revealed by in situ neutron diffraction studies at

elevated temperatures. Acta Materialia, 2015, 83, pp. 137-148.

[9]. F. Hussain, M. Imran, M. Rashid, H. Ullah, A. Shakoor, E. Ahmad, S.A. Ahmad, Molecular

dynamics simulation of mechanical characteristics of CuZr bulk metallic glasses using uni-axial

tensile loading technique. Physica Scripta, 2014, 89, 115701.

TÍNH CHẤT CHỊU KÉO CỦA MÀNG NANO VÀNG ĐƠN TINH THỂ

SỬ DỤNG MÔ PHỎNG ĐỘNG LỰC HỌC PHÂN TỬ

Tóm tắt:

Trong bài báo này tính chất chịu kéo của màng nano vàng đơn tinh thể được nghiên cứu sử dụng

mô phỏng động lực học phân tử. Mối quan hệ giữa sức căng và ứng suất, trạng thái mở rộng của vết nứt và

những ảnh hưởng của nhiệt độ khác nhau được điều tra. Kết quả cho thấy ứng suất tập trung được phân bố

chủ yếu ở giữa và tại các góc của mẫu, dẫn đến các vết nứt được hình thành và mở rộng tại các vị trí này.

Dưới ảnh hưởng của quá trình kéo, sự chuyển đổi từ cấu trúc nguyên tử FCC thành cấu trúc HCP đã xảy

ra. Từ biểu đồ sức căng và ứng suất, giá trị của độ bền kéo và mô đun đàn hồi giảm xuống khi nhiệt độ tăng

lên. Chức năng phân phối xuyên tâm (RDF) của vật liệu cũng giảm dần với nhiệt độ cao hơn.

Từ khóa: Động lực học phân tử; độ bền kéo; vàng đơn tinh thể.

Khoa học & Công nghệ - Số 21/Tháng 3 - 2019 Journal of Science and Technology 19File đính kèm:

tensile_properties_of_monocrystalline_gold_film_using_molecu.pdf

tensile_properties_of_monocrystalline_gold_film_using_molecu.pdf