Optimal weight design problem of spur gears

ABSTRACT

Gear is one of the most common and important components in machinery. Evaluation on durability

of gears plays crucial role in the assessment of the whole system reliability and service life. For other

parts like shafts, the gears also act as loads. Therefore, dimensions and weight of the gears should

be reduced as much as possible, contributing the size and weight reduction of the whole systems,

which is essential to be cost-effectiveness. The current research focuses on optimal weight design

problem of spur gears, such that the weight is minimized under the constraints taken from working

conditions. The weight is a function of six variables, i.e. face width, shaft diameter of pinion, shaft

diameter of gear, number of teeth on pinion, module and hardness. Constraints are derived based

on AGMA standard and engineering handbooks, including the bending strength, the surface fatigue strength, the interference condition, the condition for uniform load distribution, the torsional

strength of shaft on pinion and gear, and the center distance. The set of optimum design variables

is determined by the heuristic algorithm Grey Wolf Optimizer (GWO). The accuracy and efficiency

of the GWO in the optimal weight design problem of spur gears are assessed based on comparison

with other popular methods, such as Genetic Algorithm (GA), Particle Swarm Optimization (PSO)

and Simulated Annealing (SA). It is noted that in previous works, some of the constraints are still

violated. Therefore, a penalty term is taken into the objective function, such that any set of design

variables that violates constraints will be considered as ``unfit'' by the algorithm. It is demonstrated

that using the proposed approach by current work, the optimal weight and the corresponding set

of design variable are very close to reference data. Yet the ad

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Trang 6

Trang 7

Trang 8

Trang 9

Tóm tắt nội dung tài liệu: Optimal weight design problem of spur gears

Science & Technology Development Journal – Engineering and Technology, 4(1):670-678

Open Access Full Text Article Research Article

Optimal weight design problem of spur gears

Nguyen Anh My1,2, Le Quang Phu Vinh1,2, Vo Thanh Binh1,2, Nguyen Ngoc Minh1,2,*

ABSTRACT

Gear is one of the most common and important components in machinery. Evaluation on durability

of gears plays crucial role in the assessment of the whole system reliability and service life. For other

Use your smartphone to scan this parts like shafts, the gears also act as loads. Therefore, dimensions and weight of the gears should

QR code and download this article be reduced as much as possible, contributing the size and weight reduction of the whole systems,

which is essential to be cost-effectiveness. The current research focuses on optimal weight design

problem of spur gears, such that the weight is minimized under the constraints taken from working

conditions. The weight is a function of six variables, i.e. face width, shaft diameter of pinion, shaft

diameter of gear, number of teeth on pinion, module and hardness. Constraints are derived based

on AGMA standard and engineering handbooks, including the bending strength, the surface fa-

tigue strength, the interference condition, the condition for uniform load distribution, the torsional

strength of shaft on pinion and gear, and the center distance. The set of optimum design variables

is determined by the heuristic algorithm Grey Wolf Optimizer (GWO). The accuracy and efficiency

of the GWO in the optimal weight design problem of spur gears are assessed based on comparison

with other popular methods, such as Genetic Algorithm (GA), Particle Swarm Optimization (PSO)

and Simulated Annealing (SA). It is noted that in previous works, some of the constraints are still

violated. Therefore, a penalty term is taken into the objective function, such that any set of design

variables that violates constraints will be considered as ``unfit'' by the algorithm. It is demonstrated

that using the proposed approach by current work, the optimal weight and the corresponding set

of design variable are very close to reference data. Yet the advantage of the proposed approach is

exhibited in the fact that all of the constraints are satisfied.

1Department of Engineering Mechanics, Key words: Spur gear, optimal weight design, constrained optimization, Grey Wolf Optimizer

Faculty of Applied Science, Ho Chi Minh

city University of Technology

2

Vietnam National University Ho Chi 3

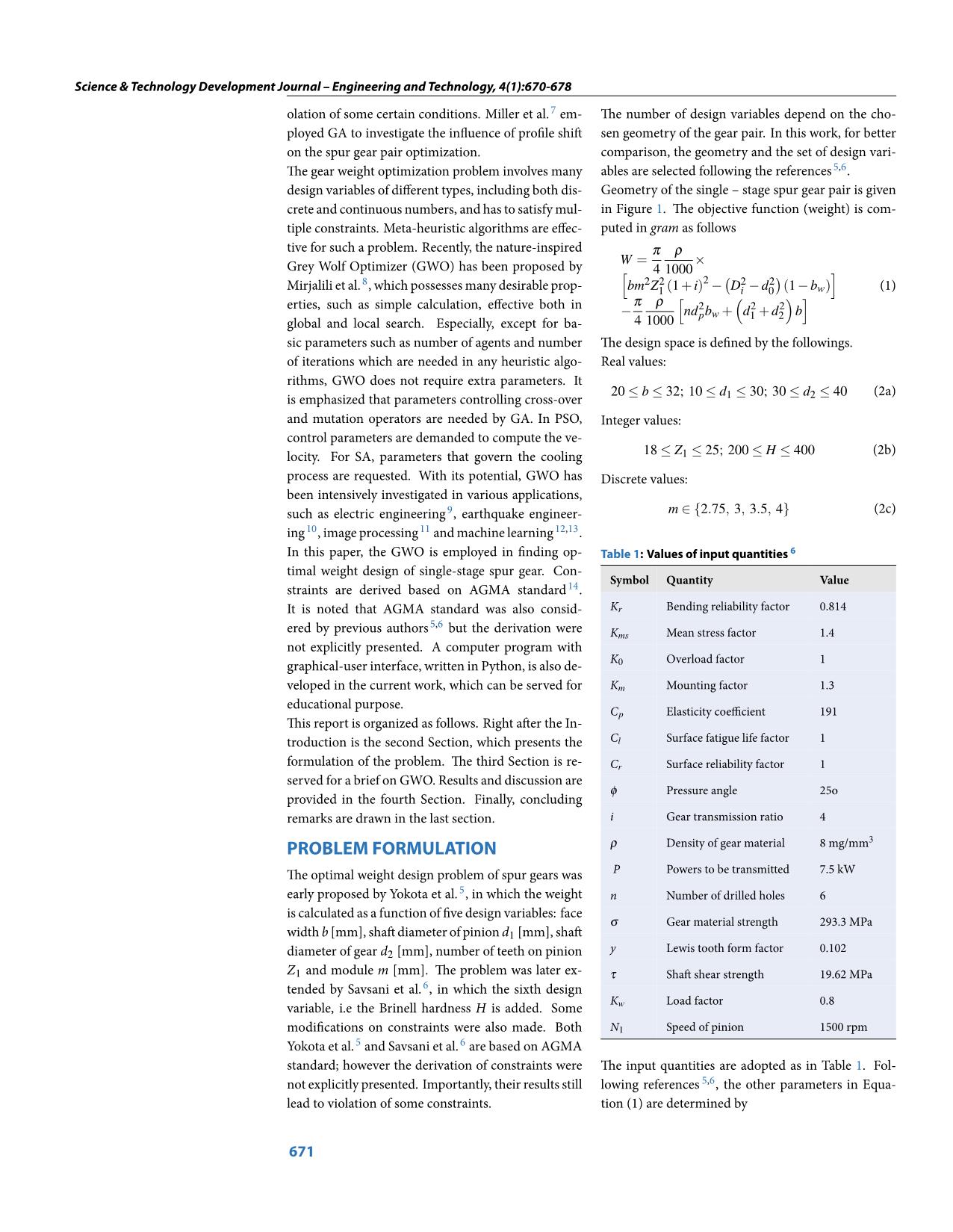

Minh city INTRODUCTION Walton focused on minimization of the centre dis-

tance or gear volume (separately) for internal gears,

Gears are widely found in mechanical power trans-

Correspondence

mission systems, which in turn are essential in many using three design variables. Zarefar and Muthukr-

Nguyen Ngoc Minh, Department of ishnan 4 proposed an adaptive random-search algo-

Engineering Mechanics, Faculty of fields of applications such as cars, motorbikes, air-

Applied Science, Ho Chi Minh city planes and machines. Traditionally, the gear design rithm to minimize the weight of helical gear weight

University of Technology process involves lots of empirical formulas for tooth with four variables (module, helix angle, umber of

Vietnam National University Ho Chi Minh bending strength, tooth surface fatigue strength, in- pinion teeth and face width). The problem of op-

city

terference, etc. According to handbooks and guide- timal weight design of spur gears under constraints

Email: nguyenngocminh@hcmut.edu.vn

lines, e.g. see references 1,2, the designer firstly such as bending strength of gear, torsional strength

5

History chooses the values of some certain parameters, then of shafts was formulated and solved by Yokota et al. ,

• Received: 16-11-2020 with the aid of Genetic Algorithm (GA), in which the

• the conditions are verified one by one. If any of the

Accepted: 02-3-2021 objective function (weight) is calculated based on five

• Published: 15-3-2021 conditions (e.g. tooth bending strength or tooth sur-

face fatigue strength) is not satisfied, the process has to variables (module, face width, shaft diameter of pin-

DOI :

10.32508/stdjet.v4i1.792 be repeated with new choice of parameters. Although ion, shaft diameter of gear, and the number of pinion

6

the computation can be much accelerated with the teeth). Savsani et al. further extended the problem

aid of computers, the traditional procedure is limited by considering the sixth design variable (hardness).

in the sense that the outcome is an admissible de- In fact, the hardness is not involved in the calculation

Copyright

sign but may not be an optimum one. Therefore, an of objective function (i.e. weight), but contributes in

© VNU-HCM Press. This is an open-

the computation of constraints. Two heuristic algo-

access article distributed under the optimization-based process is required to determine

ter ... al random values from 0 to

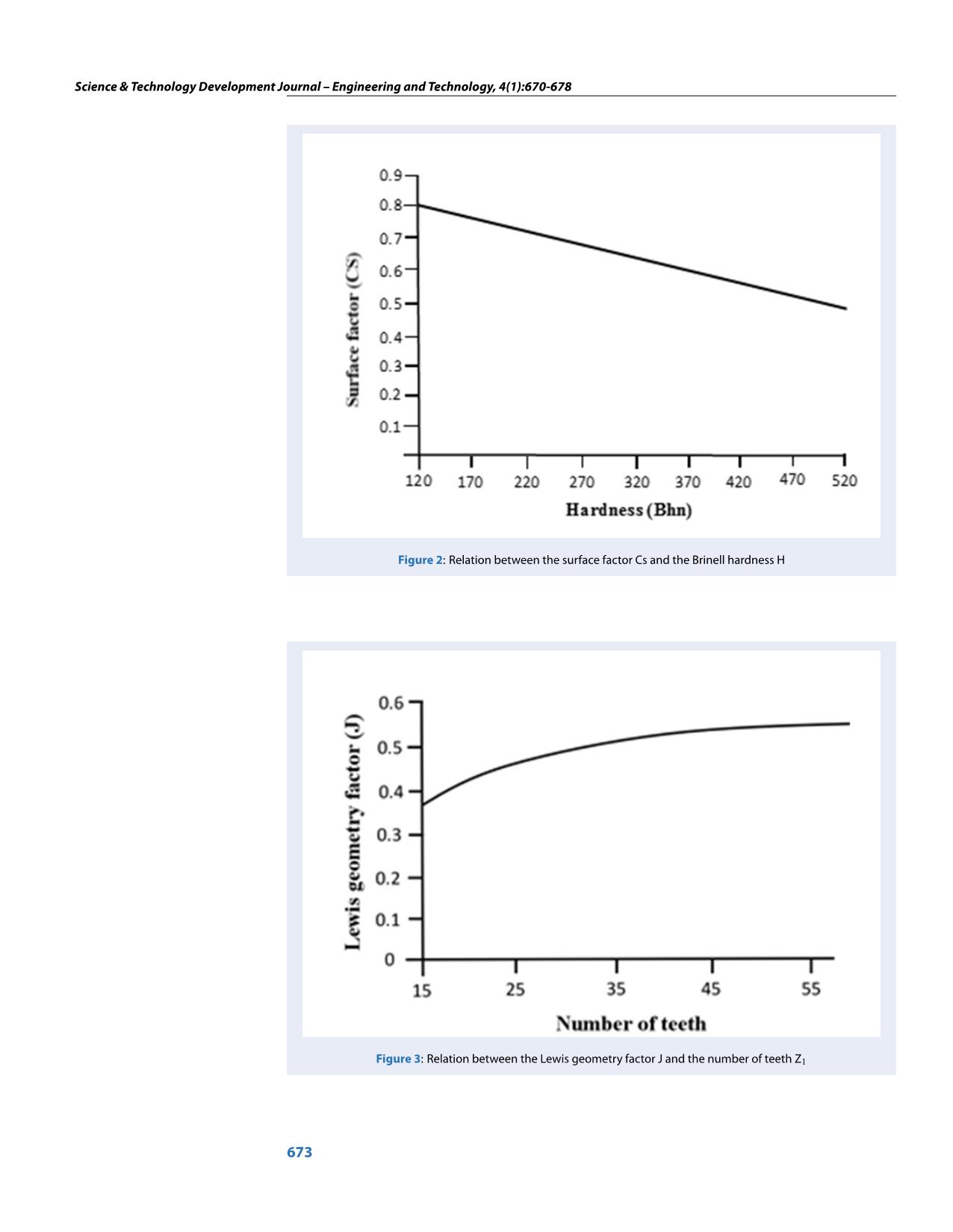

Substitute Equation (13) into (12), the condition for 1. The value of s gradually decreases from 2 to zero

( )

the shaft diameter of pinion is obtained t

s = 2 1 − , (22)

× 7 tmax

3 ≥ 4.78 10 P

G5 = d1 . (15)

τN1 in which tmax is the maximum number of iteration. It

should be emphasized that if |aα | < 1, the omega wolf

The condition for the shaft diameter of gear is deter-

will tend to join with the dominant ones to attack the

mined analogously prey (i.e. local search). On the other hand, if |aα | >

× 7 1, the omega runs away, hopefully to discover a more

3 4.78 10

G6 = d ≥ . (16) attractive prey (i.e. global search).

2 τN2

The points X2, X3 are determined using the same

•Center distance manner as mentioned in Equations (19-20).

The above algorithm of GWO 8 is for un-constrained

The distance between centers of the gear pairs is cal- problems. In order to take the constraints into ac-

culated by count, the penalty method is employed. If a con-

straint is violated, the fitness function (see Equation

D1 + D2 (1 + i)mZ1

a = = (17) (1)) is added by a penalty term, which should be a

2 2

large value. By doing so, any set of design variables

It is recommended that this value should be larger that leads to violation of constraint will be considered

than a lower bound 1 as “not fitted” by the algorithm. It is crucial to select a

large value for the penalty term. If the penalty term is

(1 + i)mZ1

G7 = ≥ 100m. (18) small, it is useless. A possible strategy is that at first,

2

the penalty term is set to zero. It is very likely that the

It is remarked that the seven constraints presented in obtained solution will violate some of the constraints.

Equations (8, 9, 11, 12, 15, 16, 18) were also consid- Let us call the corresponding weight in this case as

6

ered by reference , although the derivation was not “f 0”, the penalty term then can be estimated by mul-

explicitly mentioned. tiplying “f 0” with a factor of 1000.

674

Science & Technology Development Journal – Engineering and Technology, 4(1):670-678

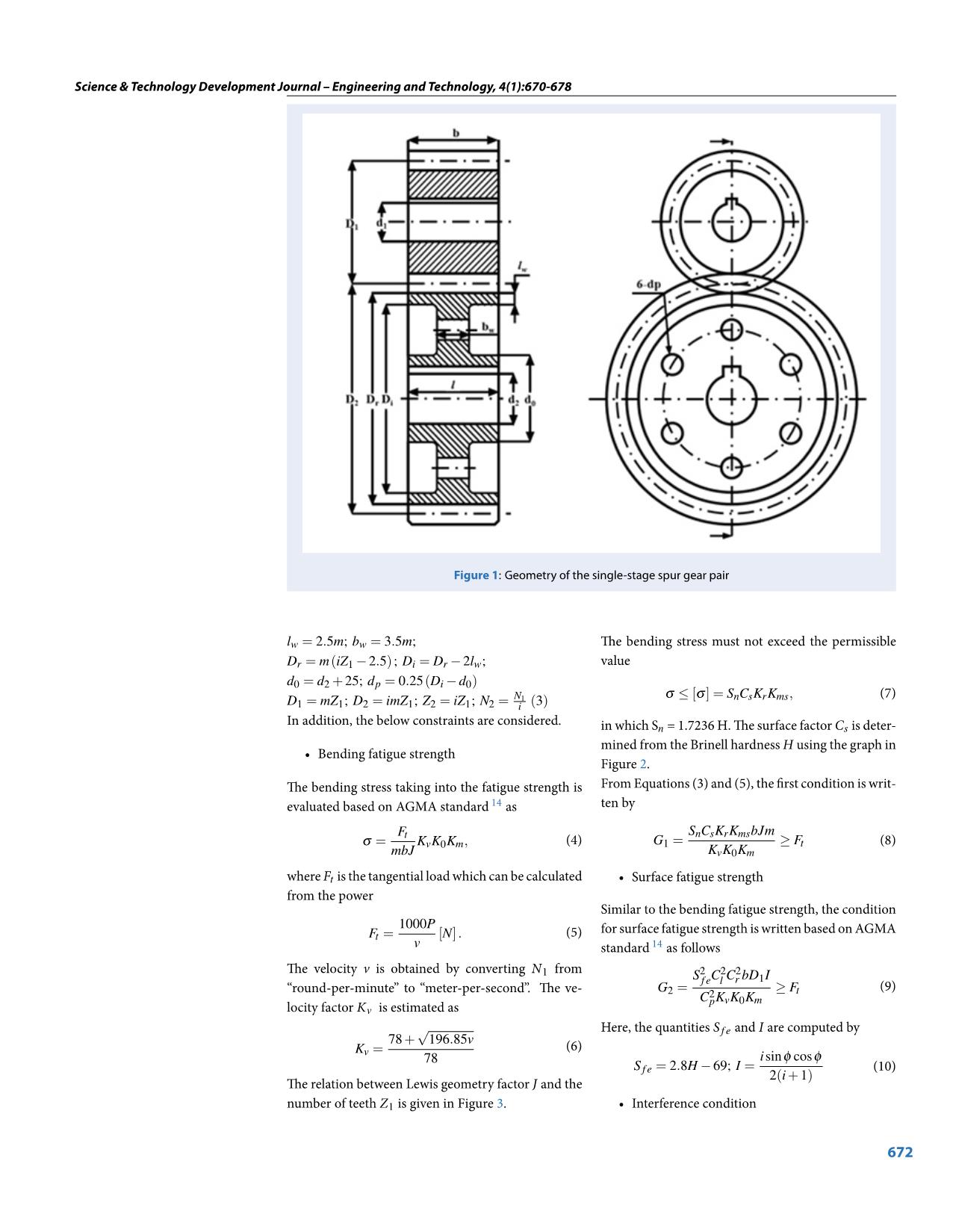

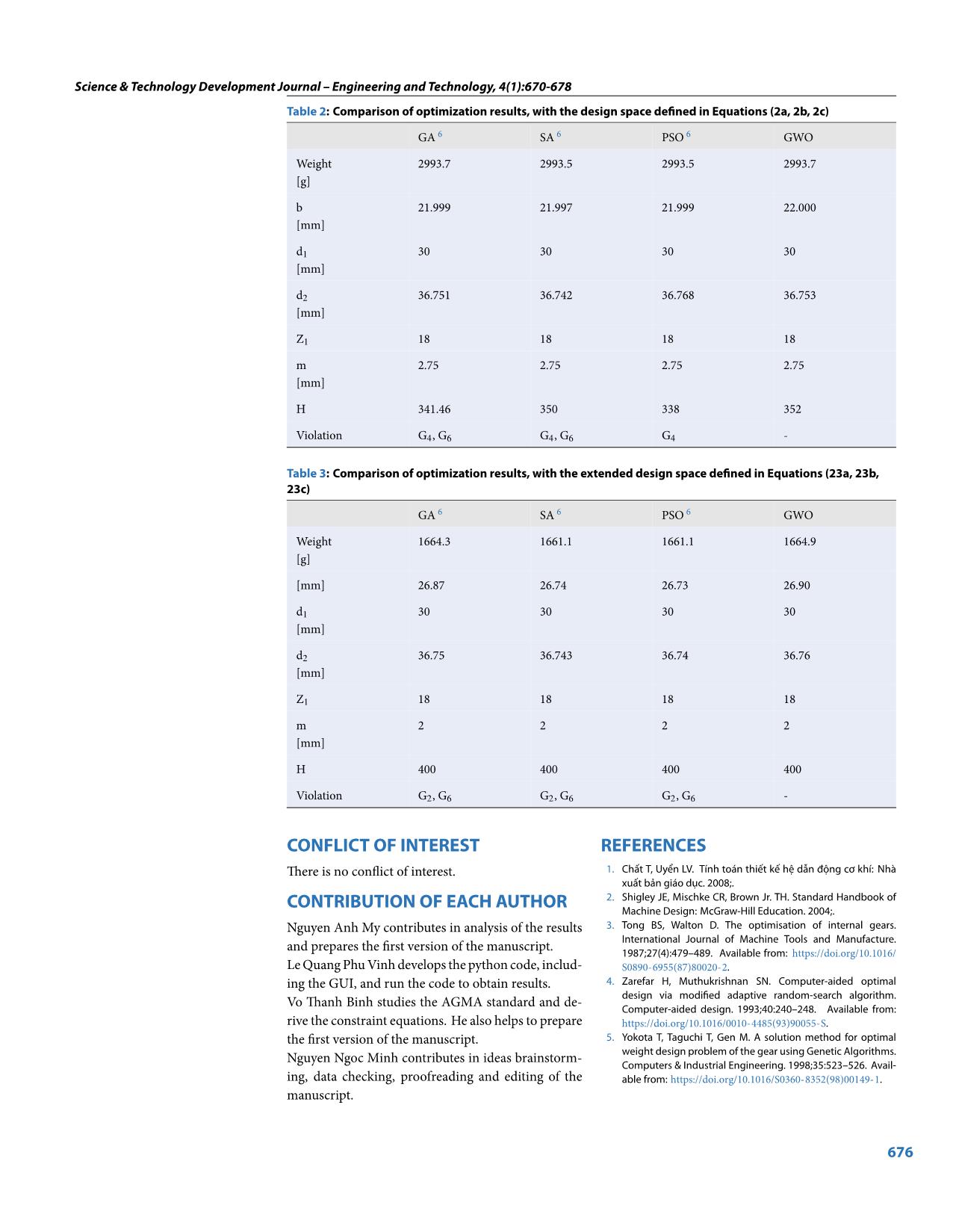

RESULTS AND DISCUSSION CONCLUSION

The proposed GWO algorithm for constrained op- The meta-heuristic GWO algorithm has been success-

timization (the third Section) is implemented in fully applied to the constrained optimization problem

Python to solve the problem of finding the optimal of finding optimal weight design of spur gear. The

weight design of spur gears (the second Section). constraints are derived from working conditions with

Results obtained by the present GWO algorithm are reference to AGMA standard and engineering hand-

displayed in Table 2, showing a comparison with those books. The problem is challenging, as results reported

obtained by GA, SA and PSO 6, for the design space in previous works by other authors still encounter vi-

defined in Equations (2a, 2b, 2c). The population olation of constraints. The current results show that

size and the maximum number iteration are chosen an optimal set of design variables that satisfy all the

exactly the same with Savsani et al. 6, i.e. 20 wolves constraints can be obtained.

and 300 iterations. It is observed that both the weight All of the six design variables have their roles. The

and the corresponding “optimized” set of design vari- first five variables are geometry parameters, which di-

rectly contribute to the weight (objective function).

ables are quite similar to those reported in reference 6.

Although the hardness H does not contribute to the

However, the notable difference is that the set of de-

weight, it represents the material strength. Indeed,

sign variables determined by GWO satisfy all the con-

H is required during evaluation of bending fatigue

straints. All the results by Savsani et al. 6, regardless

strength (constraint G ) and surface fatigue strength

GA, SA or PSO algorithm, still encounter violation of 1

(constraint G2). Loosely speaking, higher value of

some constraints.

hardness H leads to higher strength, which allows the

For further demonstration, the ranges of design vari-

reduction of geometry parameters. Therefore, H in-

ables are extended as follows

directly affects the total weight. However the manu-

Real values:

facturing cost may increase as well. For practical pur-

pose, additional constraint on manufacturing cost can

10 ≤ b ≤ 35; 10 ≤ d1 ≤ 30; 10 ≤ d2 ≤ 40 (23a)

be included.

Integer values: In GWO algorithm, the position of each wolf is up-

dated based on the information of the three best

18 ≤ Z ≤ 25; 200 ≤ H ≤ 400 (23b)

1 wolves, i.e. the alpha, the beta, and the delta. Al-

Discrete values: though the technique may enhance the exploitation, it

requires more calculation and more storage space. It

∈ { }

m 1, 1.25, 1.5, 2, 2.75, 3, 3.5, 4 (23c) is noted that in GA, the update of each chromosome

does not involve information of the best solution. In

Due to broader ranges of variables, the maximum

PSO, two special solutions, i.e. the current best and

number of iteration is also increased to 500. Opti-

worst ones, are required. Furthermore, it is argued by

mized results for the extended design space are pre-

Gao and Zhao 16 that the role of alpha, the beta, and

sented in Table 3. In this case, the weight obtained by

the delta should not be the same as in Equation (19).

GWO is slightly higher than that by GA, SA, and PSO

Equation (19) should be rewritten as a weighted aver-

as reported in Savsani et al. 6. However, again it is im-

age, in which the influence will be assigned from high-

portant that some constraints are violated in Savsani

est to lowest value to the alpha, the beta and the delta,

6

et al. , while no violation is encountered by the pro- respectively. However, the task of improving GWO is

posed GWO. not within the scope of the current work.

20 wolves and 300 iterations are used to obtain the re-

sults in Table 2. By using a computer with Intel(R) ACKNOWLEDGEMENT

Core(TM) i7-10750H CPU @ 2.60GHz and 8.00 GB This work is financially supported by the Ho Chi Minh

RAM, the computational time is approximately 15 city University of Technology under the grant SVCQ-

minutes (no parallel computing is involved). For the 2020-KHUD-48.

example presented in Table 3, 20 wolves and 500 it-

erations are used. The elapsed time in this case is LIST OF ABBREVIATIONS

nearly 20 minutes. Unfortunately, there is no in- AGMA: American gear manufacturers association

formation available on the computational cost in the GWO: Grey Wolf Optimizer

references 5,6. Nevertheless, it is reasonable to con- GA: Genetic Algorithm

sider that the current approach is more efficient be- SA: Simulated Annealing

cause the solution is achieved without any violation PSO: Particle Swarm Optimization

of constraints. GUI: Graphical User Interface

675

Science & Technology Development Journal – Engineering and Technology, 4(1):670-678

Table 2: Comparison of optimization results, with the design space defined in Equations (2a, 2b, 2c)

GA 6 SA 6 PSO 6 GWO

Weight 2993.7 2993.5 2993.5 2993.7

[g]

b 21.999 21.997 21.999 22.000

[mm]

d1 30 30 30 30

[mm]

d2 36.751 36.742 36.768 36.753

[mm]

Z1 18 18 18 18

m 2.75 2.75 2.75 2.75

[mm]

H 341.46 350 338 352

Violation G4, G6 G4, G6 G4 -

Table 3: Comparison of optimization results, with the extended design space defined in Equations (23a, 23b,

23c)

GA 6 SA 6 PSO 6 GWO

Weight 1664.3 1661.1 1661.1 1664.9

[g]

[mm] 26.87 26.74 26.73 26.90

d1 30 30 30 30

[mm]

d2 36.75 36.743 36.74 36.76

[mm]

Z1 18 18 18 18

m 2 2 2 2

[mm]

H 400 400 400 400

Violation G2, G6 G2, G6 G2, G6 -

CONFLICT OF INTEREST REFERENCES

There is no conflict of interest. 1. Chất T, Uyển LV. Tính toán thiết kế hệ dẫn động cơ khí: Nhà

xuất bản giáo dục. 2008;.

2. Shigley JE, Mischke CR, Brown Jr. TH. Standard Handbook of

CONTRIBUTION OF EACH AUTHOR Machine Design: McGraw-Hill Education. 2004;.

Nguyen Anh My contributes in analysis of the results 3. Tong BS, Walton D. The optimisation of internal gears.

International Journal of Machine Tools and Manufacture.

and prepares the first version of the manuscript. 1987;27(4):479–489. Available from: https://doi.org/10.1016/

Le Quang Phu Vinh develops the python code, includ- S0890-6955(87)80020-2.

ing the GUI, and run the code to obtain results. 4. Zarefar H, Muthukrishnan SN. Computer-aided optimal

design via modified adaptive random-search algorithm.

Vo Thanh Binh studies the AGMA standard and de- Computer-aided design. 1993;40:240–248. Available from:

rive the constraint equations. He also helps to prepare https://doi.org/10.1016/0010-4485(93)90055-S.

the first version of the manuscript. 5. Yokota T, Taguchi T, Gen M. A solution method for optimal

Nguyen Ngoc Minh contributes in ideas brainstorm- weight design problem of the gear using Genetic Algorithms.

Computers & Industrial Engineering. 1998;35:523–526. Avail-

ing, data checking, proofreading and editing of the able from: https://doi.org/10.1016/S0360-8352(98)00149-1.

manuscript.

676

Science & Technology Development Journal – Engineering and Technology, 4(1):670-678

6. Savsani V, Rao RV, Vakharia DP. Optimal weight design of 11. Zhang S, Zhou Y. Template matching using grey wolf op-

a gear train using particle swarm optimization and simu- timizer with lateral inhibition. Optik. 2017;130:1229–1243.

lated annealing algorithms. Mechanism and Machine Theory. Available from: https://doi.org/10.1016/j.ijleo.2016.11.173.

2009;45:531–541. Available from: https://doi.org/10.1016/j. 12. Emary E, Zawbaa HM, Grosan C, Hassenian AE. Binary grey

mechmachtheory.2009.10.010. wolf optimization approaches for feature selection. Neuro-

7. Miler D, Loncar A, ZD, and Domitran Z. Influence of profile computing. 2016;172(8):371–381. Available from: https://doi.

shift on the spur gear optimization. Mechanism and Machine org/10.1016/j.neucom.2015.06.083.

Theory. 2017;117:189–197. Available from: https://doi.org/10. 13. Eswaramoorthy S, Sivakumaran N, Sekaran S. Grey wolf opti-

1016/j.mechmachtheory.2017.07.001. mization based parameter selection for support vector ma-

8. Mirjalili S, Mirjalili SM, Lewis A. Grey Wolf Optimizer. Advances chines. COMPEL - The international journal for computation

in Engineering Software. 2014;69:46–61. Available from: and mathematics in electrical and electronic engineering.

https://doi.org/10.1016/j.advengsoft.2013.12.007. 2016;35(5):1513–1523. Available from: https://doi.org/10.

9. Lakum A, Mahajan V. Optimal placement and sizing of mul- 1108/COMPEL-09-2015-0337.

tiple active power filters in radial distribution system using 14. American National Standard: Fundamental Rating Factors

grey wolf optimizer in presence of nonlinear distributed gen- and Calculation Mehods for Involute Spur and Helical Gear

eration. Electric Power System Research. 2019;173:281–290. Teeth: American Gear Manufacturers Association. 2001;.

Available from: https://doi.org/10.1016/j.epsr.2019.04.001. 15. Norton RL. Machine Design - An integrated approach: Pear-

10. Song X, Tang L, Zhao S, Zhang X, Li L, Huang J, et al. Grey Wolf son. 2020;.

Optimizer for parameter estimation in surface waves. Soil Dy- 16. Gao ZM, Zhao J. An improved Grey Wolf Optimization algo-

namics and Earthquake Engineering. 2015;75:147–157. Avail- rithm with variable weights. Computational Intelligence and

able from: https://doi.org/10.1016/j.soildyn.2015.04.004. Neuroscience. 2019;2019:2981282. PMID: 31281334. Avail-

able from: https://doi.org/10.1155/2019/2981282.

677

Tạp chí Phát triển Khoa học và Công nghệ – Kĩ thuật và Công nghệ, 4(1):670-678

Open Access Full Text Article Bài nghiên cứu

Tối ưu hóa khối lượng của cặp bánh răng trụ răng thẳng

Nguyễn Anh Mỹ1,2, Lê Quang Phú Vinh1,2, Võ Thanh Bình1,2, Nguyễn Ngọc Minh1,2,*

TÓM TẮT

Bánh răng là chi tiết phổ biến và quan trọng trong máy móc. Việc đánh giá độ bền của bánh răng

vì thế có ý nghĩa thiết yếu đối với độ tin cậy và tuổi thọ làm việc của toàn hệ thống. Đối với các chi

Use your smartphone to scan this tiết khác, chẳng hạn như trục, bánh răng còn đóng vai trò là tải. Vì vậy, kích thước và khối lượng

QR code and download this article bánh răng cần được hết sức tiết giảm, nhằm làm thu gọn kích thước và khối lượng của toàn hệ

thống, từ đó giảm được chi phí. Nghiên cứu hiện tại tập trung vào tối ưu hóa khối lượng của cặp

bánh răng trụ răng thẳng, xét đến những ràng buộc xuất phát từ điều kiệ làm việc. Các biến thiết

kế được lựa chọn là bề rộng răng, đường kính trục ở bánh răng chủ động, đường kính trục ở bánh

răng bị động, số răng ở bánh răng chủ động, mô-đun và độ cứng. Các ràng buộc được xây dựng

với tham khảo từ tiêu chuẩn AGMA và sổ tay thiết kế, bao gồm độ bền uốn, độ bền mỏi tiếp xúc,

điều kiện ăn khớp, điều kiện phân bố tải trọng khi tiếp xúc, độ bền xoắn trục tại vị trí lắp bánh răng

và khoảng cách trục. Bộ giá trị biến thiết kế tối ưu được xác định thông qua giải thuật tìm kiếm

sói xám (Grey Wolf Optimizer – GWO). Tính chính xác và hiệu quả của GWO được so sánh với các

phương pháp khác như giải thuật di truyền (Genetic Algorithm – GA), giải thuật bầy đàn (Particle

Swarm Optimization - PSO) và giải thuật mô phỏng luyện kim (Simulated Annealing – SA). Kết quả

thu được từ các nghiên cứu trước đều ghi nhận sự vi phạm đối với một vài điều kiện ràng buộc.

Trong nghiên cứu hiện tại, hàm mục tiêu được cộng thêm thành phần ``phạt'' để đảm bảo bất kỳ

tập hợp biến thiết kế nào vi phạm điều kiện ràng buộc đều bị thuật toán coi là không phù hợp.

Kết quả cho thấy, lời giải thu được từ phương pháp đề xuất trong nghiên cứu hiện tại có sự tương

đồng tốt với các tài liệu tham khảo, cả về khối lượng bánh răng và các giá trị biến thiết kế tương

ứng. Ưu điểm của nghiên cứu hiện tại được thể hiện qua việc tất cả các điều kiện ràng buộc đều

được thỏa mãn.

Từ khoá: Bánh răng trụ răng thẳng, thiết kế tối ưu khối lượng, tối ưu hóa có ràng buộc, Grey Wolf

1Bộ môn Cơ kỹ thuật, Khoa Khoa học Optimizer

Ứng dụng, Trường Đại học Bách khoa

Thành phố Hồ Chí Minh

2Đại học Quốc gia Thành phố Hồ Chí

Minh

Liên hệ

Nguyễn Ngọc Minh, Bộ môn Cơ kỹ thuật,

Khoa Khoa học Ứng dụng, Trường Đại học

Bách khoa Thành phố Hồ Chí Minh

Đại học Quốc gia Thành phố Hồ Chí Minh

Email: nguyenngocminh@hcmut.edu.vn

Lịch sử

• Ngày nhận: 16-11-2020

• Ngày chấp nhận: 02-3-2021

• Ngày đăng: 15-3-2021

DOI : 10.32508/stdjet.v4i1.792

Bản quyền

© ĐHQG Tp.HCM. Đây là bài báo công bố

mở được phát hành theo các điều khoản của

the Creative Commons Attribution 4.0

International license.

Trích dẫn bài báo này: Mỹ N A, Vinh L Q P, Bình V T, Minh N N. Tối ưu hóa khối lượng của cặp bánh

răng trụ răng thẳng. Sci. Tech. Dev. J. - Eng. Tech.; 4(1):670-678.

678File đính kèm:

optimal_weight_design_problem_of_spur_gears.pdf

optimal_weight_design_problem_of_spur_gears.pdf