On the balance between magnetization and coercivity of mnbi green powders and magnets prepared thereof

Last time, numerous works were done for searching a processing route to prepare high-performance

MnBi bulk magnets with the energy product higher the record of 8.4 MGOe reported in [1, 2]. The value

of 10 MGOe or more is waited to be reached in short coming time to expand the potential of MnBi

magnets in high-temperature magnet applications.

Excluding some magnet applications, for example, in the magnetophysical therapy, the most

applications of permanent magnets are based on the magnetic circuits utilizing the maximal energy

product (BH)max. In comparison with the widely used magnets, MnBi magnets own a high and raised-

with-temperature coercivity iHc which is very attractive feature for high-temperature magnet

applications. Unfortunately, the magnetism of MnBi based alloys yields the moderate spontaneous

magnetization Ms. This circumstance causes the balance between remanent magnetization Mr and

coercivity bHc to be very important for MnBi magnets in order to improve (BH)max of MnBi magnets

and make them being a new potential product in the world permanent magnet market.

In this paper we analyze the role of this balance and the technique of regulating it to improve the

(BH)max of green powders and thus of the bulk magnets prepared thereof.

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Trang 6

Trang 7

Trang 8

Trang 9

Trang 10

Tóm tắt nội dung tài liệu: On the balance between magnetization and coercivity of mnbi green powders and magnets prepared thereof

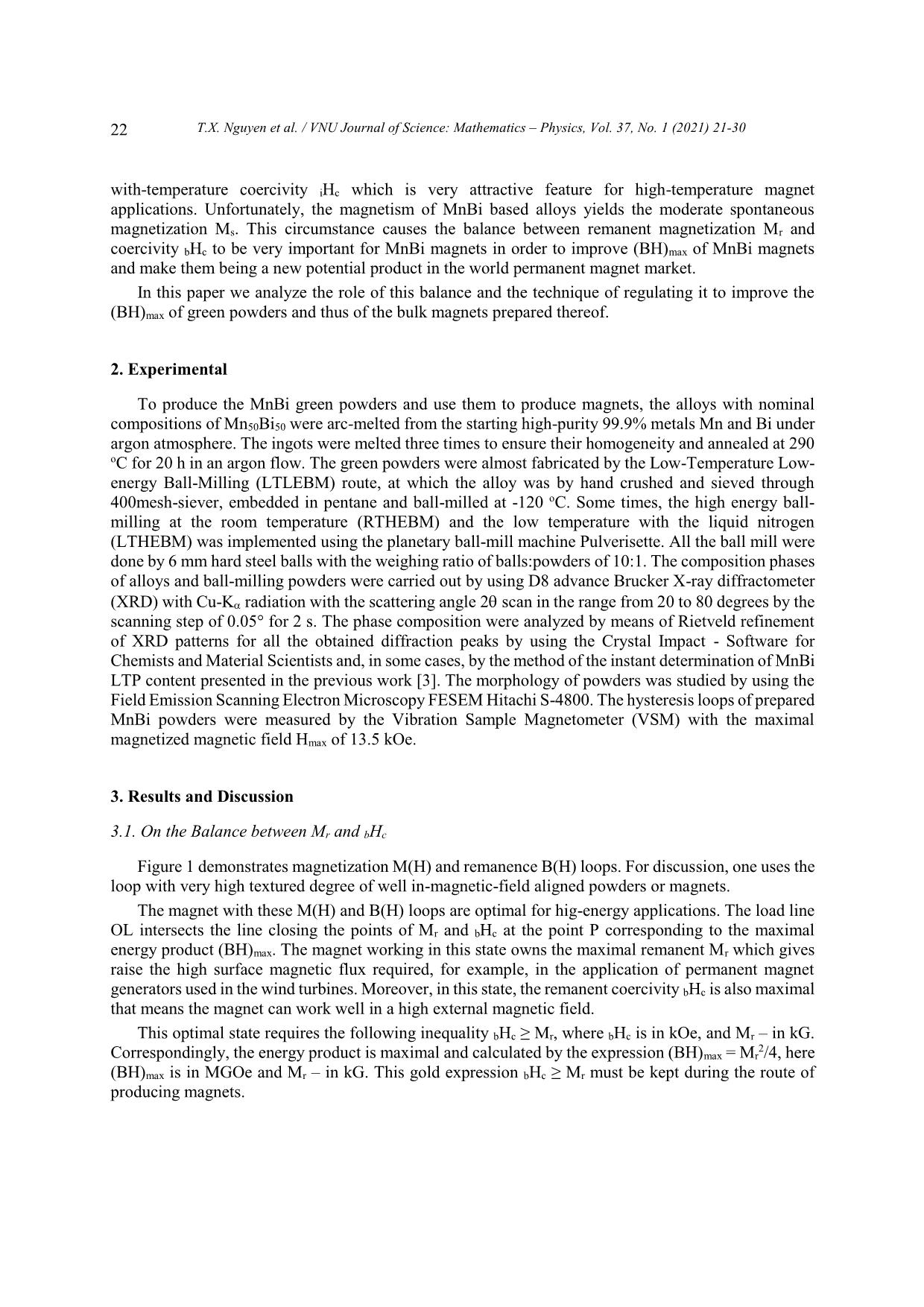

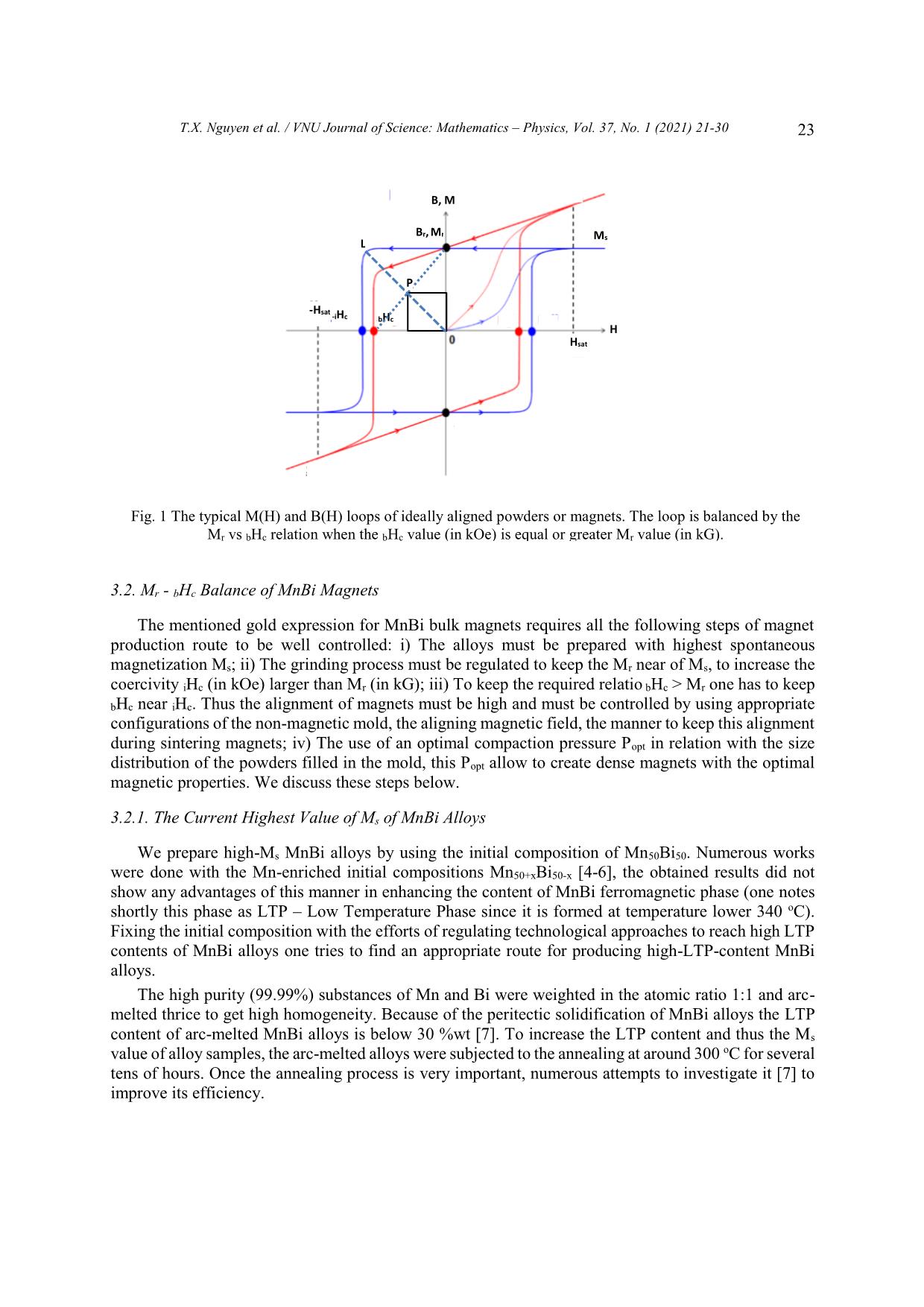

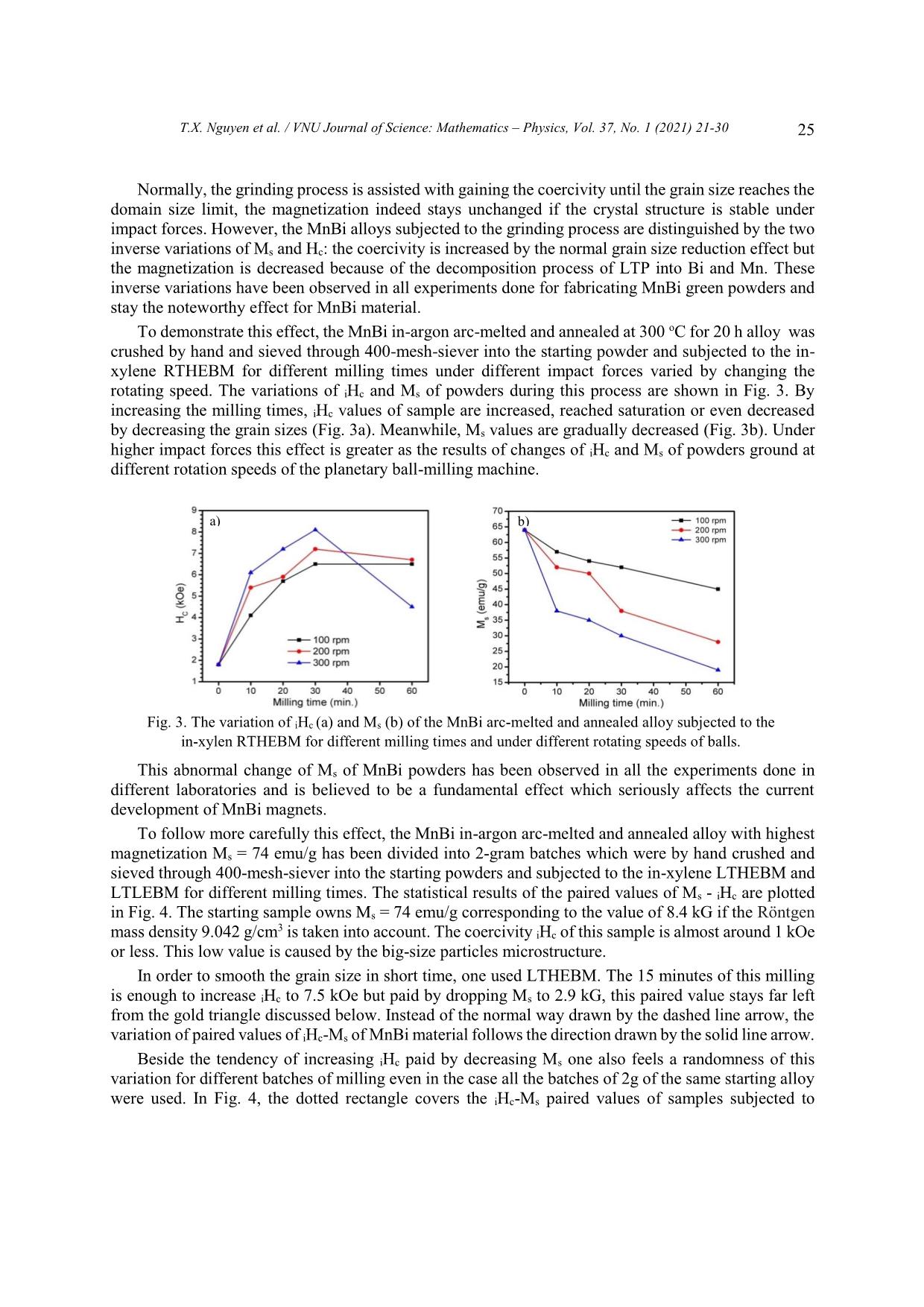

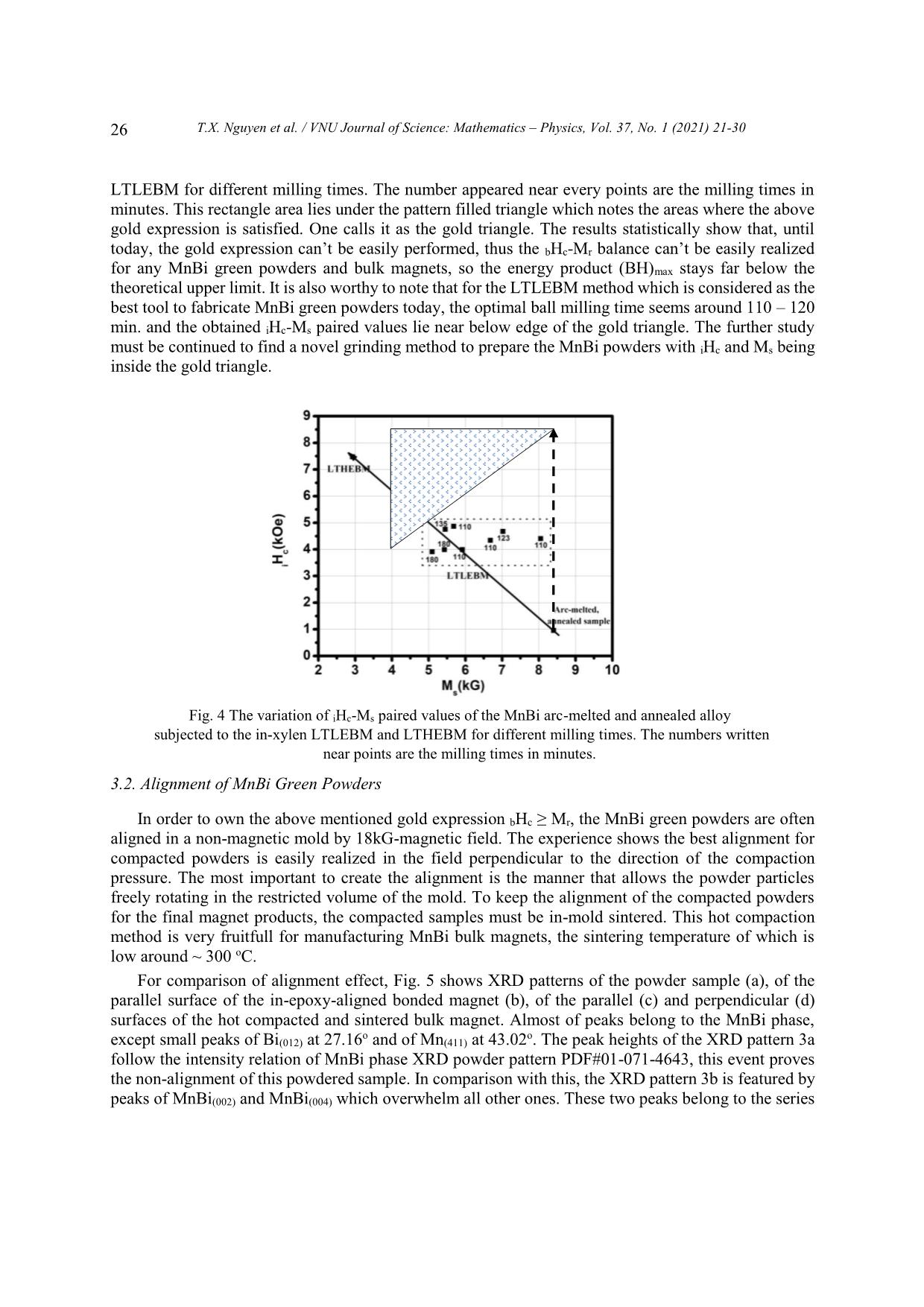

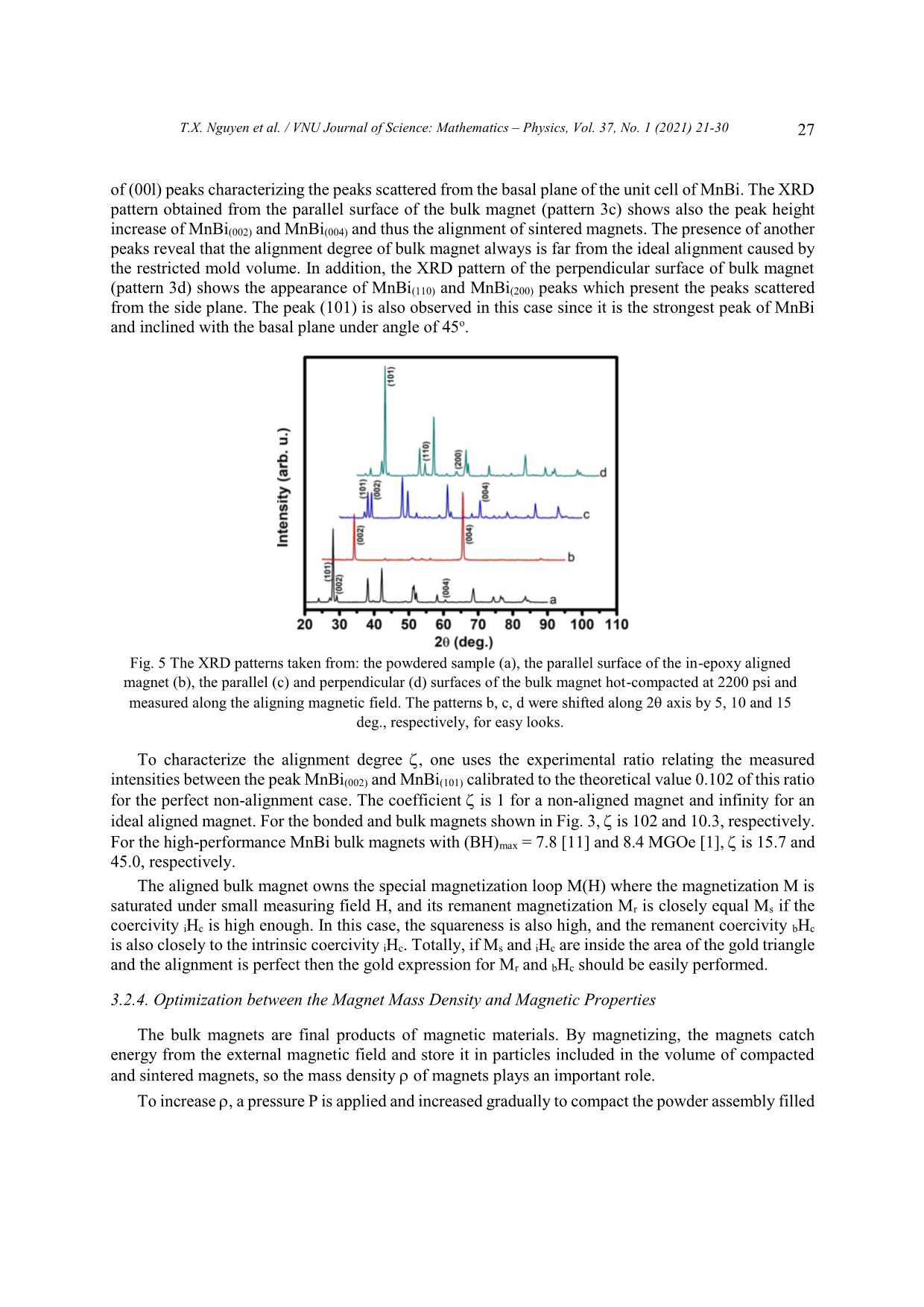

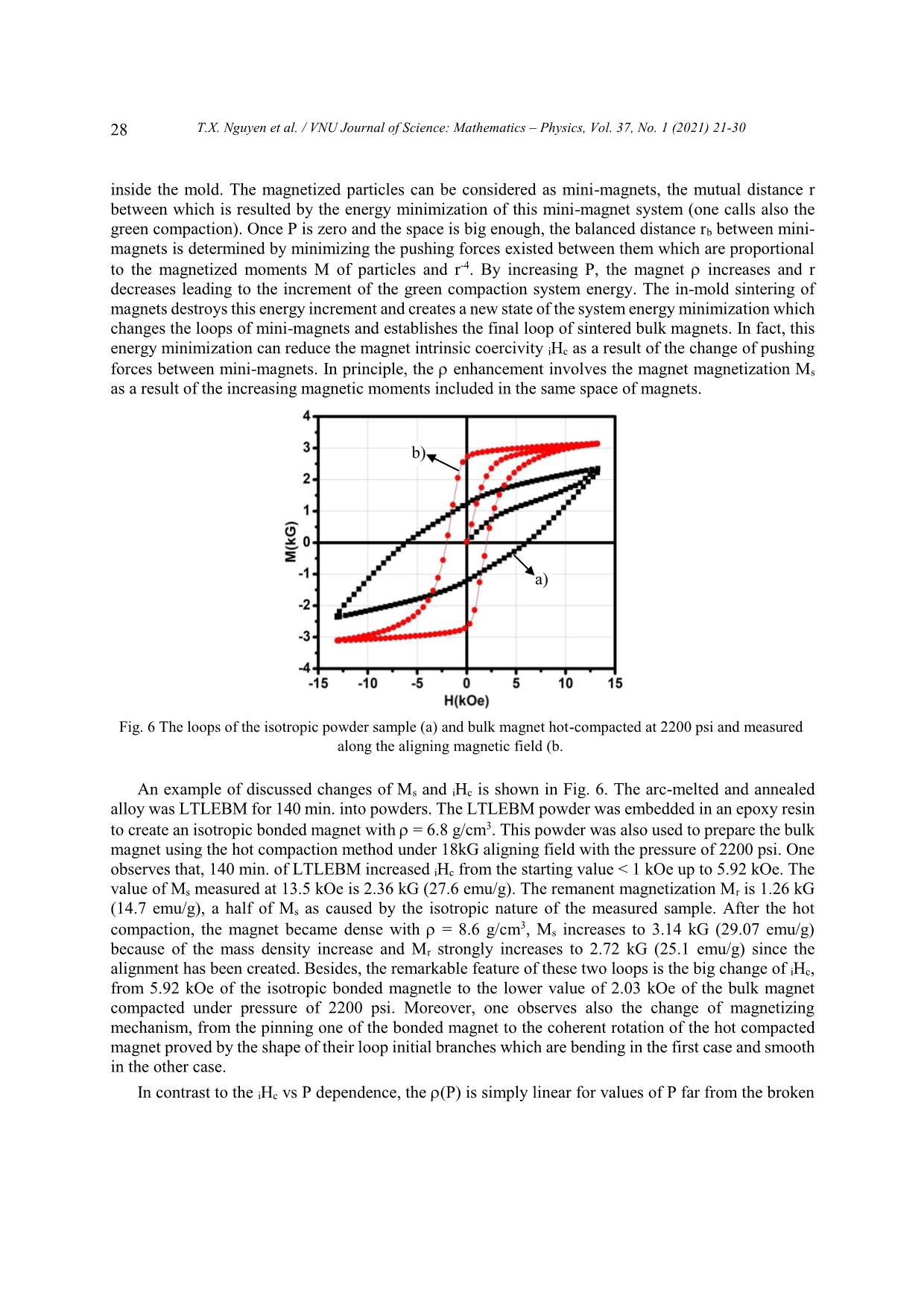

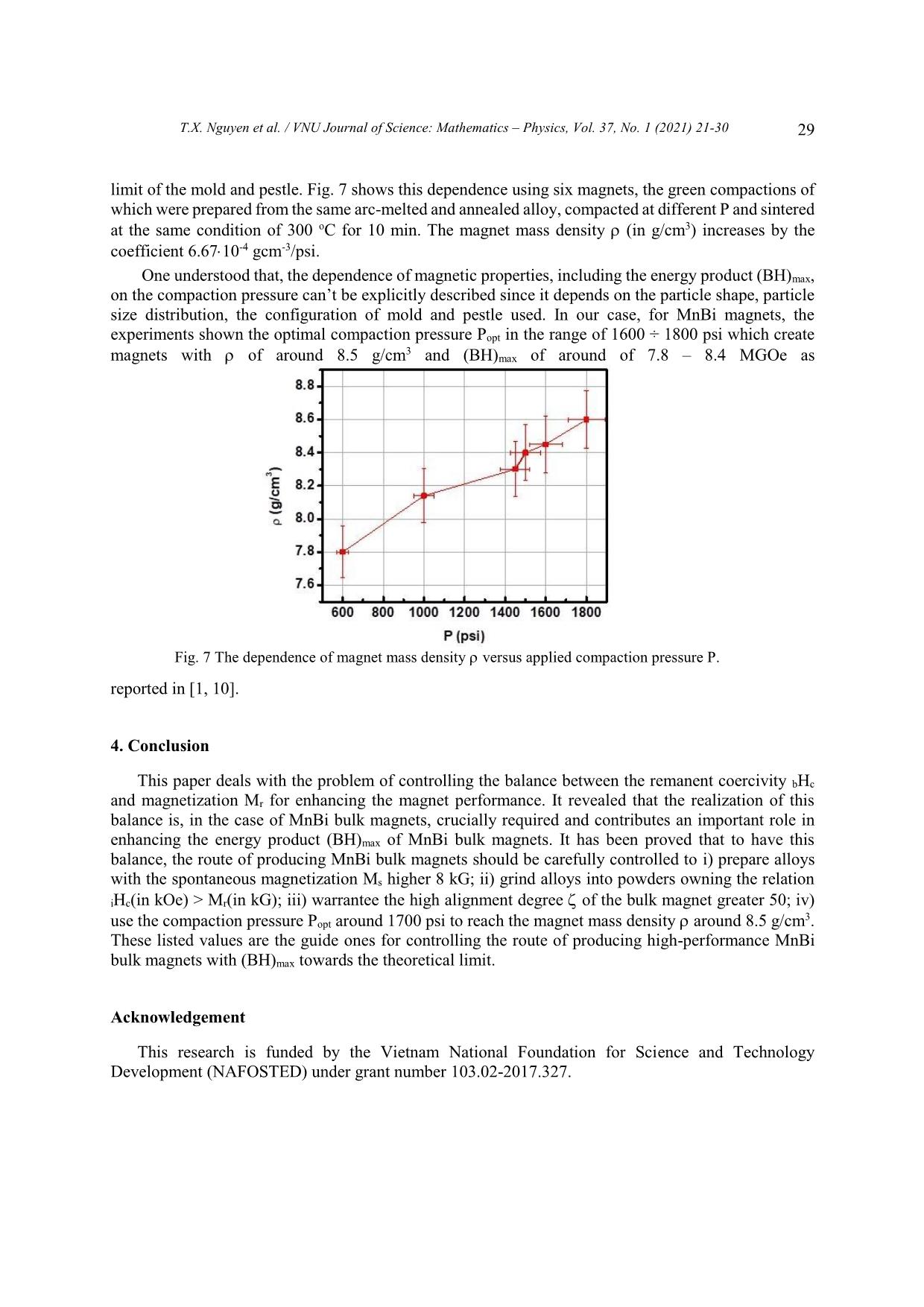

VNU Journal of Science: Mathematics – Physics, Vol. 37, No. 1 (2021) 21-30 Original Article On the Balance between Magnetization and Coercivity of MnBi Green Powders and Magnets Prepared Thereof * Truong Xuan Nguyen, Ky Hong Vu, Vuong Van Nguyen Institute of Materials Science, Vietnam Academy of Science and Technology 18 Hoang Quoc Viet, Cau Giay, Hanoi, Vietnam Received 07 February 2020 Revised 21 July 2020; Accepted 15 August 2020 Abstract: Currently, MnBi magnetic material is promising to be very potential for low-cost high- temperature permanent magnetic applications. The most attractive parameters are the high magnetocrystalline anisotropy energy and its positive thermal coefficient which allow a high coercivity of MnBi magnets working even at 150 – 200 oC. This advantage is paid by the moderate value of magnetization, so the high energy product of MnBi magnets depends on how one can keep a good balance between the remanent magnetization Mr and the coercivity bHc. The paper considers this problem and discusses how to regulate the processing route to keep this balance to enhance the performance of MnBi green powders and MnBi bulk magnets prepared thereof. Keywords: Magnetization, coercivity, balance between magnetization and coercivity, energy product. 1. Introduction Last time, numerous works were done for searching a processing route to prepare high-performance MnBi bulk magnets with the energy product higher the record of 8.4 MGOe reported in [1, 2]. The value of 10 MGOe or more is waited to be reached in short coming time to expand the potential of MnBi magnets in high-temperature magnet applications. Excluding some magnet applications, for example, in the magnetophysical therapy, the most applications of permanent magnets are based on the magnetic circuits utilizing the maximal energy product (BH)max. In comparison with the widely used magnets, MnBi magnets own a high and raised- ________ Corresponding author. Email address: vuongnv@ims.vast.ac.vn https//doi.org/ 10.25073/2588-1124/vnumap.4462 21 22 T.X. Nguyen et al. / VNU Journal of Science: Mathematics – Physics, Vol. 37, No. 1 (2021) 21-30 with-temperature coercivity iHc which is very attractive feature for high-temperature magnet applications. Unfortunately, the magnetism of MnBi based alloys yields the moderate spontaneous magnetization Ms. This circumstance causes the balance between remanent magnetization Mr and coercivity bHc to be very important for MnBi magnets in order to improve (BH)max of MnBi magnets and make them being a new potential product in the world permanent magnet market. In this paper we analyze the role of this balance and the technique of regulating it to improve the (BH)max of green powders and thus of the bulk magnets prepared thereof. 2. Experimental To produce the MnBi green powders and use them to produce magnets, the alloys with nominal compositions of Mn50Bi50 were arc-melted from the starting high-purity 99.9% metals Mn and Bi under argon atmosphere. The ingots were melted three times to ensure their homogeneity and annealed at 290 oC for 20 h in an argon flow. The green powders were almost fabricated by the Low-Temperature Low- energy Ball-Milling (LTLEBM) route, at which the alloy was by hand crushed and sieved through 400mesh-siever, embedded in pentane and ball-milled at -120 oC. Some times, the high energy ball- milling at the room temperature (RTHEBM) and the low temperature with the liquid nitrogen (LTHEBM) was implemented using the planetary ball-mill machine Pulverisette. All the ball mill were done by 6 mm hard steel balls with the weighing ratio of balls:powders of 10:1. The composition phases of alloys and ball-milling powders were carried out by using D8 advance Brucker X-ray diffractometer (XRD) with Cu-K radiation with the scattering angle 2 scan in the range from 20 to 80 degrees by the scanning step of 0.05° for 2 s. The phase composition were analyzed by means of Rietveld refinement of XRD patterns for all the obtained diffraction peaks by using the Crystal Impact - Software for Chemists and Material Scientists and, in some cases, by the method of the instant determination of MnBi LTP content presented in the previous work [3]. The morphology of powders was studied by using the Field Emission Scanning Electron Microscopy FESEM Hitachi S-4800. The hysteresis loops of prepared MnBi powders were measured by the Vibration Sample Magnetometer (VSM) with the maximal magnetized magnetic field Hmax of 13.5 kOe. 3. Results and Discussion 3.1. On the Balance between Mr and bHc Figure 1 demonstrates magnetization M(H) and remanence B(H) loops. For discussion, one uses the loop with very high textured degree of well in-magnetic-field aligned powders or magnets. The magnet with these M(H) and B(H) loops are optimal for hig-energy applications. The load line O ... all-milling machine. a) b) Fig. 3. The variation of iHc (a) and Ms (b) of the MnBi arc-melted and annealed alloy subjected to the in-xylen RTHEBM for different milling times and under different rotating speeds of balls. This abnormal change of Ms of MnBi powders has been observed in all the experiments done in different laboratories and is believed to be a fundamental effect which seriously affects the current development of MnBi magnets. To follow more carefully this effect, the MnBi in-argon arc-melted and annealed alloy with highest magnetization Ms = 74 emu/g has been divided into 2-gram batches which were by hand crushed and sieved through 400-mesh-siever into the starting powders and subjected to the in-xylene LTHEBM and LTLEBM for different milling times. The statistical results of the paired values of Ms - iHc are plotted in Fig. 4. The starting sample owns Ms = 74 emu/g corresponding to the value of 8.4 kG if the Röntgen 3 mass density 9.042 g/cm is taken into account. The coercivity iHc of this sample is almost around 1 kOe or less. This low value is caused by the big-size particles microstructure. In order to smooth the grain size in short time, one used LTHEBM. The 15 minutes of this milling is enough to increase iHc to 7.5 kOe but paid by dropping Ms to 2.9 kG, this paired value stays far left from the gold triangle discussed below. Instead of the normal way drawn by the dashed line arrow, the variation of paired values of iHc-Ms of MnBi material follows the direction drawn by the solid line arrow. Beside the tendency of increasing iHc paid by decreasing Ms one also feels a randomness of this variation for different batches of milling even in the case all the batches of 2g of the same starting alloy were used. In Fig. 4, the dotted rectangle covers the iHc-Ms paired values of samples subjected to 26 T.X. Nguyen et al. / VNU Journal of Science: Mathematics – Physics, Vol. 37, No. 1 (2021) 21-30 LTLEBM for different milling times. The number appeared near every points are the milling times in minutes. This rectangle area lies under the pattern filled triangle which notes the areas where the above gold expression is satisfied. One calls it as the gold triangle. The results statistically show that, until today, the gold expression can’t be easily performed, thus the bHc-Mr balance can’t be easily realized for any MnBi green powders and bulk magnets, so the energy product (BH)max stays far below the theoretical upper limit. It is also worthy to note that for the LTLEBM method which is considered as the best tool to fabricate MnBi green powders today, the optimal ball milling time seems around 110 – 120 min. and the obtained iHc-Ms paired values lie near below edge of the gold triangle. The further study must be continued to find a novel grinding method to prepare the MnBi powders with iHc and Ms being inside the gold triangle. Fig. 4 The variation of iHc-Ms paired values of the MnBi arc-melted and annealed alloy subjected to the in-xylen LTLEBM and LTHEBM for different milling times. The numbers written near points are the milling times in minutes. 3.2. Alignment of MnBi Green Powders In order to own the above mentioned gold expression bHc ≥ Mr, the MnBi green powders are often aligned in a non-magnetic mold by 18kG-magnetic field. The experience shows the best alignment for compacted powders is easily realized in the field perpendicular to the direction of the compaction pressure. The most important to create the alignment is the manner that allows the powder particles freely rotating in the restricted volume of the mold. To keep the alignment of the compacted powders for the final magnet products, the compacted samples must be in-mold sintered. This hot compaction method is very fruitfull for manufacturing MnBi bulk magnets, the sintering temperature of which is low around ~ 300 oC. For comparison of alignment effect, Fig. 5 shows XRD patterns of the powder sample (a), of the parallel surface of the in-epoxy-aligned bonded magnet (b), of the parallel (c) and perpendicular (d) surfaces of the hot compacted and sintered bulk magnet. Almost of peaks belong to the MnBi phase, o o except small peaks of Bi(012) at 27.16 and of Mn(411) at 43.02 . The peak heights of the XRD pattern 3a follow the intensity relation of MnBi phase XRD powder pattern PDF#01-071-4643, this event proves the non-alignment of this powdered sample. In comparison with this, the XRD pattern 3b is featured by peaks of MnBi(002) and MnBi(004) which overwhelm all other ones. These two peaks belong to the series T.X. Nguyen et al. / VNU Journal of Science: Mathematics – Physics, Vol. 37, No. 1 (2021) 21-30 27 of (00l) peaks characterizing the peaks scattered from the basal plane of the unit cell of MnBi. The XRD pattern obtained from the parallel surface of the bulk magnet (pattern 3c) shows also the peak height increase of MnBi(002) and MnBi(004) and thus the alignment of sintered magnets. The presence of another peaks reveal that the alignment degree of bulk magnet always is far from the ideal alignment caused by the restricted mold volume. In addition, the XRD pattern of the perpendicular surface of bulk magnet (pattern 3d) shows the appearance of MnBi(110) and MnBi(200) peaks which present the peaks scattered from the side plane. The peak (101) is also observed in this case since it is the strongest peak of MnBi and inclined with the basal plane under angle of 45o. Fig. 5 The XRD patterns taken from: the powdered sample (a), the parallel surface of the in-epoxy aligned magnet (b), the parallel (c) and perpendicular (d) surfaces of the bulk magnet hot-compacted at 2200 psi and measured along the aligning magnetic field. The patterns b, c, d were shifted along 2 axis by 5, 10 and 15 deg., respectively, for easy looks. To characterize the alignment degree , one uses the experimental ratio relating the measured intensities between the peak MnBi(002) and MnBi(101) calibrated to the theoretical value 0.102 of this ratio for the perfect non-alignment case. The coefficient is 1 for a non-aligned magnet and infinity for an ideal aligned magnet. For the bonded and bulk magnets shown in Fig. 3, is 102 and 10.3, respectively. For the high-performance MnBi bulk magnets with (BH)max = 7.8 [11] and 8.4 MGOe [1], is 15.7 and 45.0, respectively. The aligned bulk magnet owns the special magnetization loop M(H) where the magnetization M is saturated under small measuring field H, and its remanent magnetization Mr is closely equal Ms if the coercivity iHc is high enough. In this case, the squareness is also high, and the remanent coercivity bHc is also closely to the intrinsic coercivity iHc. Totally, if Ms and iHc are inside the area of the gold triangle and the alignment is perfect then the gold expression for Mr and bHc should be easily performed. 3.2.4. Optimization between the Magnet Mass Density and Magnetic Properties The bulk magnets are final products of magnetic materials. By magnetizing, the magnets catch energy from the external magnetic field and store it in particles included in the volume of compacted and sintered magnets, so the mass density of magnets plays an important role. To increase , a pressure P is applied and increased gradually to compact the powder assembly filled 28 T.X. Nguyen et al. / VNU Journal of Science: Mathematics – Physics, Vol. 37, No. 1 (2021) 21-30 inside the mold. The magnetized particles can be considered as mini-magnets, the mutual distance r between which is resulted by the energy minimization of this mini-magnet system (one calls also the green compaction). Once P is zero and the space is big enough, the balanced distance rb between mini- magnets is determined by minimizing the pushing forces existed between them which are proportional to the magnetized moments M of particles and r-4. By increasing P, the magnet increases and r decreases leading to the increment of the green compaction system energy. The in-mold sintering of magnets destroys this energy increment and creates a new state of the system energy minimization which changes the loops of mini-magnets and establishes the final loop of sintered bulk magnets. In fact, this energy minimization can reduce the magnet intrinsic coercivity iHc as a result of the change of pushing forces between mini-magnets. In principle, the enhancement involves the magnet magnetization Ms as a result of the increasing magnetic moments included in the same space of magnets. b) a) Fig. 6 The loops of the isotropic powder sample (a) and bulk magnet hot-compacted at 2200 psi and measured along the aligning magnetic field (b. An example of discussed changes of Ms and iHc is shown in Fig. 6. The arc-melted and annealed alloy was LTLEBM for 140 min. into powders. The LTLEBM powder was embedded in an epoxy resin to create an isotropic bonded magnet with = 6.8 g/cm3. This powder was also used to prepare the bulk magnet using the hot compaction method under 18kG aligning field with the pressure of 2200 psi. One observes that, 140 min. of LTLEBM increased iHc from the starting value < 1 kOe up to 5.92 kOe. The value of Ms measured at 13.5 kOe is 2.36 kG (27.6 emu/g). The remanent magnetization Mr is 1.26 kG (14.7 emu/g), a half of Ms as caused by the isotropic nature of the measured sample. After the hot 3 compaction, the magnet became dense with = 8.6 g/cm , Ms increases to 3.14 kG (29.07 emu/g) because of the mass density increase and Mr strongly increases to 2.72 kG (25.1 emu/g) since the alignment has been created. Besides, the remarkable feature of these two loops is the big change of iHc, from 5.92 kOe of the isotropic bonded magnetle to the lower value of 2.03 kOe of the bulk magnet compacted under pressure of 2200 psi. Moreover, one observes also the change of magnetizing mechanism, from the pinning one of the bonded magnet to the coherent rotation of the hot compacted magnet proved by the shape of their loop initial branches which are bending in the first case and smooth in the other case. In contrast to the iHc vs P dependence, the (P) is simply linear for values of P far from the broken T.X. Nguyen et al. / VNU Journal of Science: Mathematics – Physics, Vol. 37, No. 1 (2021) 21-30 29 limit of the mold and pestle. Fig. 7 shows this dependence using six magnets, the green compactions of which were prepared from the same arc-melted and annealed alloy, compacted at different P and sintered at the same condition of 300 oC for 10 min. The magnet mass density (in g/cm3) increases by the coefficient 6.6710-4 gcm-3/psi. One understood that, the dependence of magnetic properties, including the energy product (BH)max, on the compaction pressure can’t be explicitly described since it depends on the particle shape, particle size distribution, the configuration of mold and pestle used. In our case, for MnBi magnets, the experiments shown the optimal compaction pressure Popt in the range of 1600 ÷ 1800 psi which create 3 magnets with of around 8.5 g/cm and (BH)max of around of 7.8 – 8.4 MGOe as Fig. 7 The dependence of magnet mass density versus applied compaction pressure P. reported in [1, 10]. 4. Conclusion This paper deals with the problem of controlling the balance between the remanent coercivity bHc and magnetization Mr for enhancing the magnet performance. It revealed that the realization of this balance is, in the case of MnBi bulk magnets, crucially required and contributes an important role in enhancing the energy product (BH)max of MnBi bulk magnets. It has been proved that to have this balance, the route of producing MnBi bulk magnets should be carefully controlled to i) prepare alloys with the spontaneous magnetization Ms higher 8 kG; ii) grind alloys into powders owning the relation iHc(in kOe) > Mr(in kG); iii) warrantee the high alignment degree of the bulk magnet greater 50; iv) 3 use the compaction pressure Popt around 1700 psi to reach the magnet mass density around 8.5 g/cm . These listed values are the guide ones for controlling the route of producing high-performance MnBi bulk magnets with (BH)max towards the theoretical limit. Acknowledgement This research is funded by the Vietnam National Foundation for Science and Technology Development (NAFOSTED) under grant number 103.02-2017.327. 30 T.X. Nguyen et al. / VNU Journal of Science: Mathematics – Physics, Vol. 37, No. 1 (2021) 21-30 References [1] N. Poudyal , X. Liu, W. Wang, V. V. Nguyen. Y. Ma. K. Gandha, K. Elkins, J. P. Liu, K. Sun, M. J. Kramer and J. Cui, Processing of MnBi bulk magnets with enhanced energy product, AIP Advances 6 (2016) 056004, [2] V. V. Nguyen, T. X. Nguyen, Effects of microstructures on the performance of rare-earth-free MnBi magnetic materials and magnets, Physica B 532 (2018) 103–107. https://doi.org/10.1016/j.physb.2017.06.018. [3] T. X. Nguyen and V. V. Nguyen, Preparation and Magnetic Properties of MnBi Alloy and its Hybridization with NdFeB, Journal of Magnetics 20(4) (2015) 336-341. https://doi.org/10.4283/JMAG.2015.20.4.336. [4] J. Cui, J. P. Choi, E. Polikarpov, M. E. Bowden, W. Xiea, G. Li, Z. Nie, N. Zarkevich, M. J. Kramer, D. Johnson, Effect of composition and heat treatment on MnBi magnetic materials, Acta Materialia 79 (2014) 374–381. https://doi.org/10.1016/j.actamat.2014.07.034. [5] Y. C. Chen, G. Gregori, A. Leineweber, F. Qu, C. C. Chen, T. Tietze, H. Kronmüller, G. Schüt, E. Goering, Unique high-temperature performance of highly condensed MnBi, Scripta Materialia 107 (2015) 131–135. https://doi.org/10.1016/j.scriptamat.2015.06.003. [6] S. Kim, H. Moon, H. Jung, S. M. Kim, H. S. Lee, H. Choi-Yim, W. Lee, Magnetic properties of large-scaled MnBi bulk magnets, J. Alloys and Compd. 708 (2017) 1245 -1249. https://doi.org/10.1016/j.jallcom.2017.03.067. [7] T. X. Nguyen, V. V. Nguyen, Fabrication of MnBi alloys with high ferromagnetic phase content: effects of heat treatment regimes and dopants, Journal of Materials Science: Materials in Electronics 30 (2019) 6888–6894. 10.1007/s10854-019-01003-x. [8] K. Oikawa, Y. Mitsui, K. Koyama and K. Anzai, Thermodynamic assessment of the Bi-Mn system, Materials Transactions 52 (2011) 2032-2039. https://doi.org/10.2320/matertrans.M2011229. [9] V. V. Nguyen, T. X. Nguyen, Low temperature phase of the rare-earth-free MnBi magnetic material, Journal of Science and Technology 54 (1A) (2016) 50-57. https://doi.org/10.15625/2525-2518/54/1A/11805. [10] V. V. Nguyen, N. Poudyal, X. Liu, J. P. Liu, K. Sun, M. J. Kramer, and J. Cui, High-performance MnBi alloy prepared using profiled heat treatment, IEEE Transactions on magnetics, 50 (2015) 2105506.

File đính kèm:

on_the_balance_between_magnetization_and_coercivity_of_mnbi.pdf

on_the_balance_between_magnetization_and_coercivity_of_mnbi.pdf