Numerical modelization of the oil film pressure for a hydrodynamic tilting - pad thrust bearing

Tilting pad thrust bearings are used in rotary

machineries, allow for the thrust load operation at the

average of rotation and support a heavy load.

Hydrodynamic thrust bearing based on hydrodynamic

lubrication.

In 2012, D. V. Srikanth et. al. [1] studied a large

tilting pad thrust bearing angular stiffness. In 2014,

Najar and Harmain [2] performed a numerical study on

pressure profiles in the hydrodynamic thrust bearing.

Annan Guo et.al [3] experiment static and dynamic

characteristics of tilting pad thrust bearing in the same

year. In 2018, Mostefa K. et al. [4] analyzed the effect

of dimple geometries on textured tilting pad thrust

bearing using a finite difference method.

In Vietnam, studies about hydrodynamic tilting

pad bearing are few. Most recently, Hai T.T.T et al [5]

compared a numerical calculation of a hydrodynamic

fixed pad thrust bearing with experiment results.

Besides Dung Le Anh et al. [6] perform a numerical

modelization of oil film pressure in hydrodynamic

journal bearing under a steady load.

This research analyzes the pressure and oil film

thickness of a pivot tilting pad thrust bearing at

hydrodynamic lubrication.

2. Thrust bearing and the equations

2.1. Tilting pad thrust bearing

*Corresponding author: Tel.: (+84) 978263926

Email: hai.tranthithanh@hust.edu.vn

Fig.1 shows the diagram of a pad in pivot tilting

pad thrust bearing. Here, the pad is placed onto a pivot

that is eccentric from the middle of the pad, to form the

oil wedge as hydrodynamic theory. The pressure in the

wedge generates the force onto the pad surface making

the pad to tilt at an angle respected to the r-axis and the

θ -axis. r and θ are two directions of polar

coordinates. The inner and outer radius of the pad are

r1 and r2, θ pad is the pad angle, θ p and rp are the

position of the pivot, hp is the film thickness at pivot

location, αr and αθ are the inclinations of the pad

along the radial and circumferential direction, ω is

the angular velocity of the collar.

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Trang 6

Tóm tắt nội dung tài liệu: Numerical modelization of the oil film pressure for a hydrodynamic tilting - pad thrust bearing

Journal of Science & Technology 146 (2020) 025-030

Numerical Modelization of the Oil Film Pressure for a Hydrodynamic

Tilting-Pad Thrust Bearing

Le Anh Dung, Tran Thi Thanh Hai *

Hanoi University of Science and Technology, No.1 Dai Co Viet str., Hai Ba Trung dist., Hanoi, Vietnam

Received: June 17, 2020; Accepted: November 12, 2020

Abstract

This study analyses the hydrodynamic characteristic of the tilting pad thrust bearing. Research content is

simultaneously solving the Reynolds equation, force equilibrium equation, and momentum equilibrium

equations. Reynolds equation is solved by utilizing the finite element method with Galerkin weighted residual,

thereby determines the pressure at each discrete node of the film. Force and momentums are integrated from

pressure nodes by Gaussian integral. Finally, force and momentum equilibrium equations are solved using

Newton-Raphson iterative to achieve film thickness and inclination angles of the pad at the equilibrium

position. The results yielded the film thickness, the pressure distribution on the whole pad and different

sections of the bearing respected to the radial direction. The high-pressure zone is located at the low film

thickness zone and near the pivot location.

Keywords: Hydrodynamic tilting-pad thrust bearing, equilibrium position, finite element method.

1. Introduction1 Fig.1 shows the diagram of a pad in pivot tilting

pad thrust bearing. Here, the pad is placed onto a pivot

Tilting pad thrust bearings are used in rotary

that is eccentric from the middle of the pad, to form the

machineries, allow for the thrust load operation at the

oil wedge as hydrodynamic theory. The pressure in the

average of rotation and support a heavy load.

wedge generates the force onto the pad surface making

Hydrodynamic thrust bearing based on hydrodynamic

the pad to tilt at an angle respected to the r-axis and the

lubrication.

θ -axis. r and θ are two directions of polar

In 2012, D. V. Srikanth et. al. [1] studied a large coordinates. The inner and outer radius of the pad are

tilting pad thrust bearing angular stiffness. In 2014,

r1 and r2, θ pad is the pad angle, θ p and rp are the

Najar and Harmain [2] performed a numerical study on

position of the pivot, hp is the film thickness at pivot

pressure profiles in the hydrodynamic thrust bearing.

location, α and α are the inclinations of the pad

Annan Guo et.al [3] experiment static and dynamic r θ

characteristics of tilting pad thrust bearing in the same along the radial and circumferential direction, ω is

year. In 2018, Mostefa K. et al. [4] analyzed the effect the angular velocity of the collar.

of dimple geometries on textured tilting pad thrust

bearing using a finite difference method.

In Vietnam, studies about hydrodynamic tilting

pad bearing are few. Most recently, Hai T.T.T et al [5]

compared a numerical calculation of a hydrodynamic

fixed pad thrust bearing with experiment results.

Besides Dung Le Anh et al. [6] perform a numerical

modelization of oil film pressure in hydrodynamic

journal bearing under a steady load.

This research analyzes the pressure and oil film

thickness of a pivot tilting pad thrust bearing at

hydrodynamic lubrication.

2. Thrust bearing and the equations

2.1. Tilting pad thrust bearing

Fig. 1. Diagram of a pivot tilting pad thrust bearing.

*Corresponding author: Tel.: (+84) 978263926

Email: hai.tranthithanh@hust.edu.vn

25

Journal of Science & Technology 146 (2020) 025-030

2.2. The equations 33∂∂WWii∂∂∂pph1

∬ −−rh h − Wi .6µω r dS +

2.2.1 The Reynolds equation: S ∂∂rrr ∂∂θθ ∂ θ

33∂∂pp1

Obtained from the Naviers-Stockes and ++∮Wir rh n dττ W i.0 h nθ d =

∮b

continuity equations for an incompressible, isoviscous, ∂∂rrθ

steady-state and laminar flow fluid, the Reynolds (5)

equation is written in polar coordinates [7]: n

= =

p can be expressed as: p∑ Npii N.{ p}

∂ ∂p 1 ∂∂ ph ∂ =

rh33+=h 6µωr (1) i 1

∂ ∂ ∂∂θθ ∂ θ

r rr where n is the total number of mesh points, N is the

where p is oil film pressure, r is radial direction, θ is global polynomials function vector.

circumferential direction, h is oil film thickness, µ is

dynamic viscosity, ω is angular velocity of the shaft.

The boundary condition chosen for the Reynolds

equation is:

pr(θ =0,) = 0 ; pr(θθ=pad ,0) =

p(θ,0 rr=1 ) = ; p(θ,0 rr=2 ) =

2.2.2 Oil film thickness equation:

=+−θθ − α +

h hpp r rcos( p) sin( θ ) Fig. 2. Diagram of a tilting pad thrust bearing

+−rsin(θθpr) sin( α) (2) With Galerkin weight residual, the weighting

function Wi is chosen equal to the shape function Ni .

2.2.3 Force and momentum equilibrium equations:

Combined with boundary condition, we have:

The pressure distribution is integrated over the

∂ ∂

pad area to give the resulting force and the moments in 3 p 1 3 p

∮Wir rh n dτ = 0 and ∮ Whi .0 ndθ τ =

two perpendicular directions around the pivot point. ∂r b r ∂θ

Equation (5) becomes:

Fzp h ,,ααθ r= prd θ dr= W

( ) ∬S

∂∂∂∂NN

33{NNii} { jj} 1 { } { }

2 ∬ rh + h dS{ p}

Mxp h ,,ααθ r= pr sin θθ −=pd θ dr 0 (3) S

( ) ∬S ( ) ∂∂r rr ∂∂θθ

∂

αα =θθ −− θ = h

Myp( h ,,θ r) ∬ p( r.cos( p) r p) rd dr 0 =∬ −{Ni }.6µω r dS (6)

S S ∂θ

3. Algorithm Rewrite the left side of equation (4) as a matrix

3.1 Solving Reynolds equation form:

The pad domain is discreted into a 4-node finite ∂∂NNii

3 ∂∂NNin

element mesh as Fig. 2. Here coordinates in polar form ∂∂θ r h

0 ∂∂θθ

is change to the reference coordinates ξη, . Using ∬ r .{ pi } rdθ dr

( ) S ∂∂

3 NNin

∂∂NN0 rh

finite element method, integrate equation (1) over the nn ∂∂rr

domain S: ∂∂θ r

∂ ∂p 1 ∂ ∂ ph ∂ (7)

33+−=µω

∬ W i rh h60 r dS

S ∂r ∂ rr ∂∂θθ ∂ θ The conversion from polar coordinates to

(4) reference coordinate system is featured by Jacobi

matrix J:

where Wi is weight functions.

Integrate by part equation (4), we have:

26

Journal of Science & Technology 146 (2020) 025-030

∂∂θ r nn∂∂NNjj ∂∂∂

θ FFFzzz

∑∑= ii= r

∂∂ξξii11 ∂ ξ ∂ ξ ∂∂∂h αα

J = = (8) prθ

∂∂θ ∂ ∂

rNnnjj N ∂∂∂

θ r MMMxxx

∑∑ii=11ii= D = − (14)

∂∂ηη∂∂ηη ∂∂∂h αα

prθ

Thus (7) becomes: ∂∂∂MMMyyy

∂∂∂αα

hprθ

∂∂NNii

∂∂θ 3

r h Substitute (13) to (14), we have:

−1 0

∬ ××J r ×

S ttt

3

Sp... Spαα Sp

∂∂NN 0 rh hprθ

nn

ttt

∂∂θ r D= − Rp...h Rpαα Rp

prθ

ttt

Tp...h Tpαα Tp

∂∂NNin prθ

− ∂∂θθ t

××J1 ×pr × S

{ i }

∂∂NNin (9) t

= − Rp pαα p (15)

hprθ

∂∂rr t

T

×det( J) ×=× dξη d[ K] { pi }

∂p ∂p ∂p

where p = , p = , p =

The right side of the equation (6) becomes: hp αθ αr

∂hp ∂αθ ∂αr

∂h

{F} = −{ Ni }.6µω r rd θ dr

∬S p , p , p are calculated as follows:

∂θ hp αθ αr

(10)

∂h

= −∬ { Ni }.6µω r r . det( J) . dξ d η Derive equation (11) respected to h , α , α :

S ∂θ p θ r

Thus, equation (6) is rewritten as: ∂[K ] ∂∂{ pFi } { }

{ pK} +=[ ] (16)

∂∂∂kkki

[Kp].{ i } = { F} (11)

with kh= , α , α .

Solve the above equation with boundary p θ r

condition, we can get pressure value at all nodes.

∂∂{ pF} 1 { } ∂[K ]

Thus, i = − p (17)

3.2 Solve force and momentum equation { i }

∂kKk[ ] ∂∂ k

Let:

where:

= θ

S∬ rd dr ∂[K ] ∂h

S = 3h2 ×

∬S

∂∂kk

2

R=∬ r sin (θθ− p )d θ dr (12)

S ∂∂{NN} ∂∂{NNjj} 1 { } { }

×+r iirdθ dr

∂∂ ∂∂θθ

r rr

T=∬ ( r.cos(θθ −−pp) r) rd θ dr

S (18)

αα = t

We get:. Fhzp( ,,θ r) S{ p i} ∂{F} ∂∂h

= −{Ni }.6µω r rdθ dr (19)

∬S

t ∂kk∂∂θ

Mhxp( ,,ααθ r) = Rp{ i} (13)

In order to solve the nonlinear equation, Newton-

t

Mhyp( ,,ααθ r) = Tp{ i} Raphson method is commonly used due to its rapid

convergence and highly accurate approximation. Let

The Jacobian matrix related to the equilibrium t

= αα

position is: uhpr, θ , be the present step of the equilibrium

position, unew be the new guess value for the new step.

Thus, the iterative process is given by:

27

Journal of Science & Technology 146 (2020) 025-030

t

=−− −− 4. Results

unew u D\ Fz WM ,x 0, M y 0

The present study bearing is a large tilting pad

This iteration process ends when the following bearing and its parameters are described in Table 1.

error bound condition err is satisfied: The program is written in MATLAB 2019a.

kk+1 Table 2 illustrates the iteration process of a

uunew − FWz −

≤ err & ≤ err & Mx ≤ err 100x100 elements mesh grid. The result shows with a

k +1 F

u z good initial guess, high accuracy can be achieved after

-5 a few iterative steps due to the high convergence rate

& My ≤ err with err=10 .

of the Newton-Raphson method. The circumferential

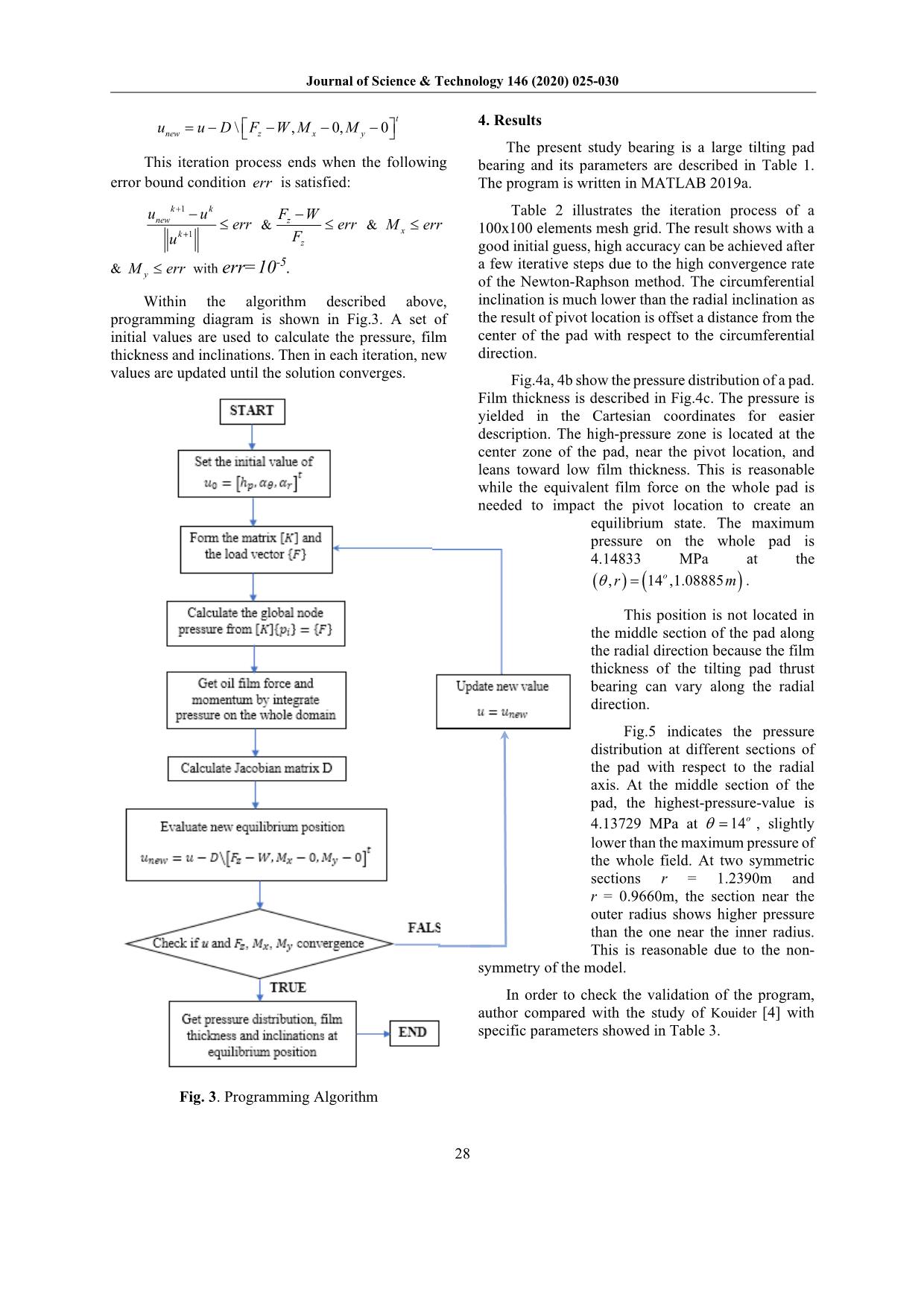

Within the algorithm described above, inclination is much lower than the radial inclination as

programming diagram is shown in Fig.3. A set of the result of pivot location is offset a distance from the

initial values are used to calculate the pressure, film center of the pad with respect to the circumferential

thickness and inclinations. Then in each iteration, new direction.

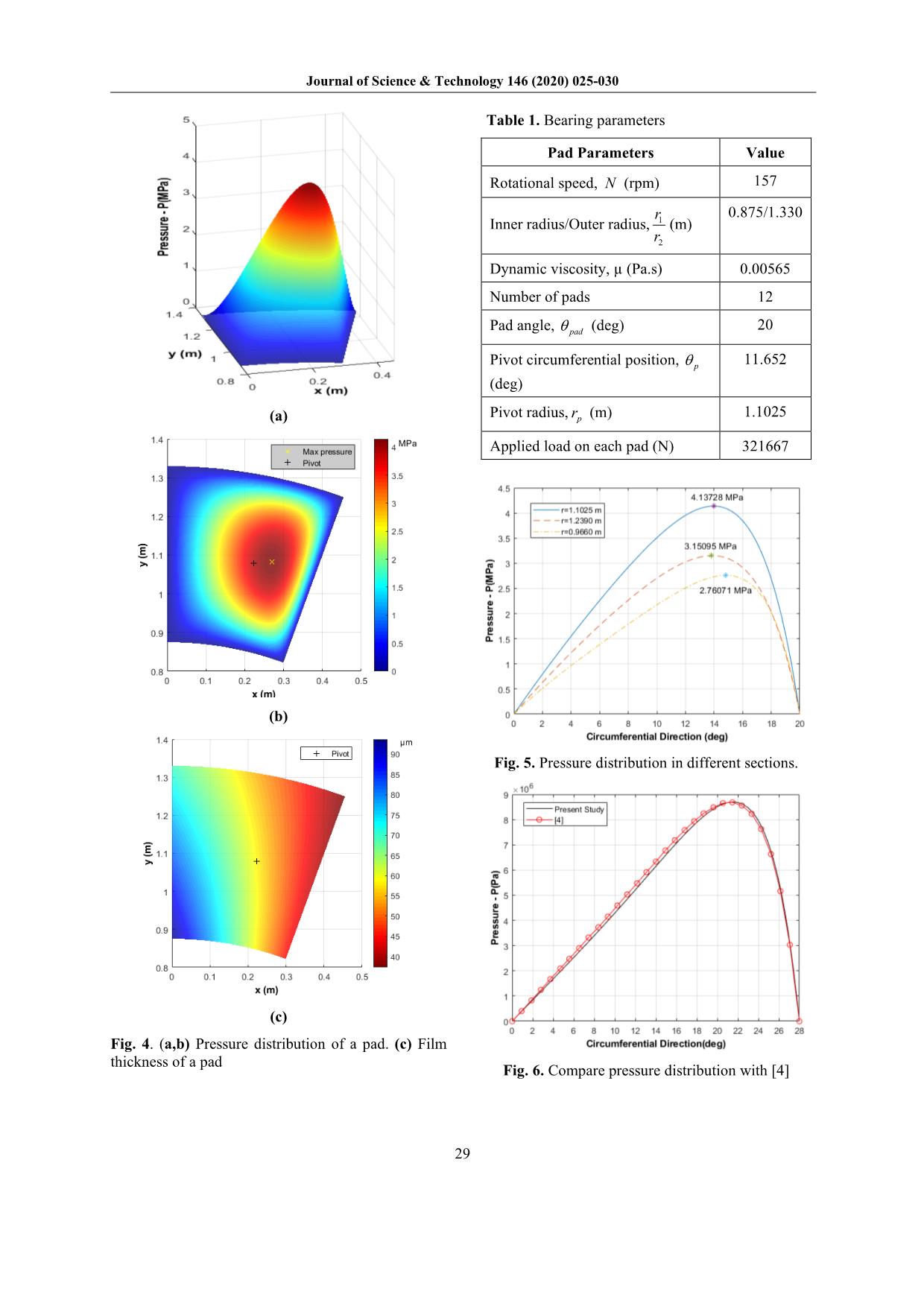

values are updated until the solution converges. Fig.4a, 4b show the pressure distribution of a pad.

Film thickness is described in Fig.4c. The pressure is

yielded in the Cartesian coordinates for easier

description. The high-pressure zone is located at the

center zone of the pad, near the pivot location, and

leans toward low film thickness. This is reasonable

while the equivalent film force on the whole pad is

needed to impact the pivot location to create an

equilibrium state. The maximum

pressure on the whole pad is

4.14833 MPa at the

(θ,rm) = ( 14o ,1.08885 ) .

This position is not located in

the middle section of the pad along

the radial direction because the film

thickness of the tilting pad thrust

bearing can vary along the radial

direction.

Fig.5 indicates the pressure

distribution at different sections of

the pad with respect to the radial

axis. At the middle section of the

pad, the highest-pressure-value is

4.13729 MPa at θ = 14o , slightly

lower than the maximum pressure of

the whole field. At two symmetric

sections r = 1.2390m and

r = 0.9660m, the section near the

outer radius shows higher pressure

than the one near the inner radius.

This is reasonable due to the non-

symmetry of the model.

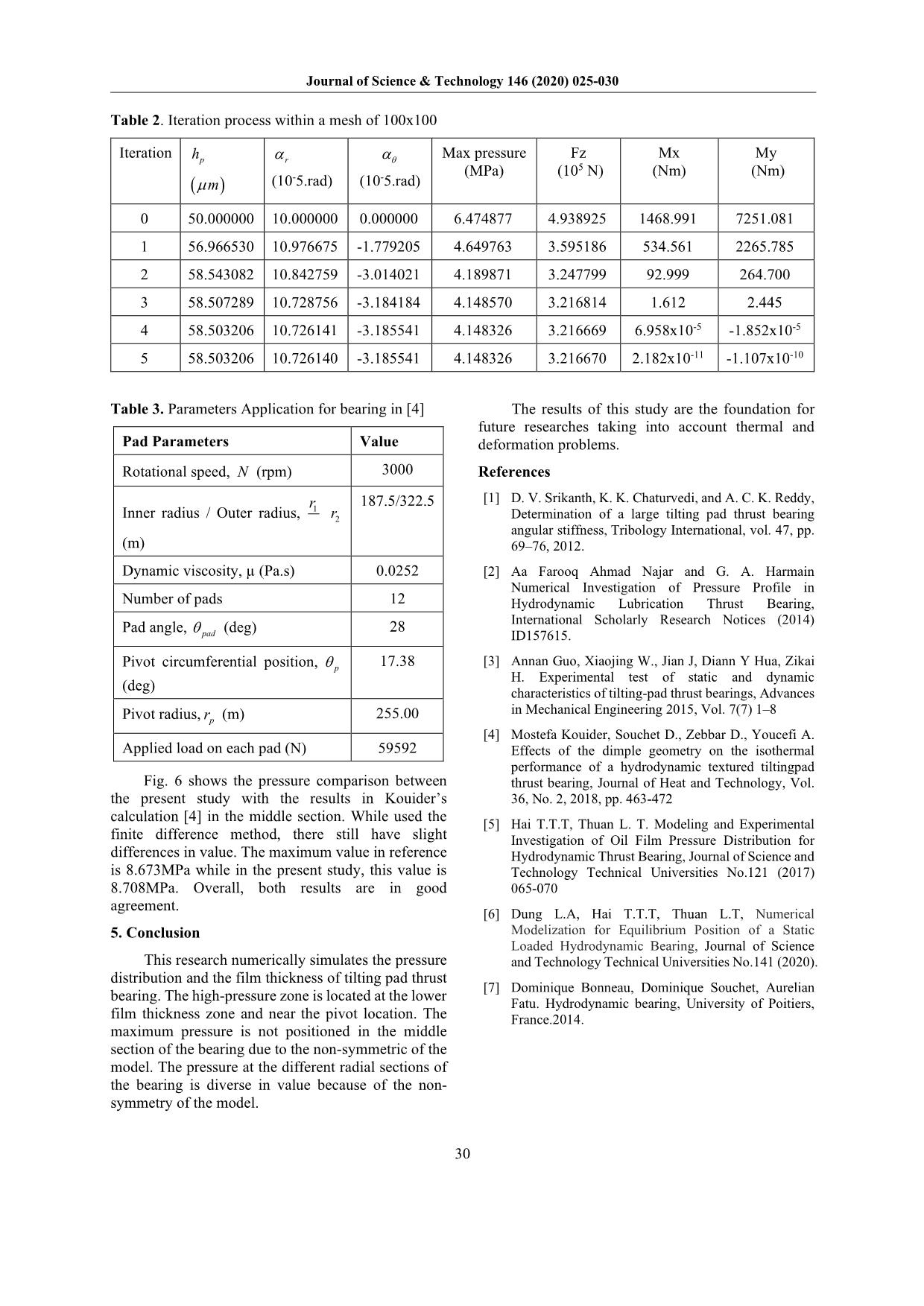

In order to check the validation of the program,

author compared with the study of Kouider [4] with

specific parameters showed in Table 3.

Fig. 3. Programming Algorithm

28

Journal of Science & Technology 146 (2020) 025-030

Table 1. Bearing parameters

Pad Parameters Value

Rotational speed, N (rpm) 157

r 0.875/1.330

Inner radius/Outer radius, 1 (m)

r2

Dynamic viscosity, µ (Pa.s) 0.00565

Number of pads 12

Pad angle, θ pad (deg) 20

Pivot circumferential position, θ p 11.652

(deg)

(a) Pivot radius, rp (m) 1.1025

Applied load on each pad (N) 321667

(b)

Fig. 5. Pressure distribution in different sections.

(c)

Fig. 4. (a,b) Pressure distribution of a pad. (c) Film

thickness of a pad

Fig. 6. Compare pressure distribution with [4]

29

Journal of Science & Technology 146 (2020) 025-030

Table 2. Iteration process within a mesh of 100x100

Iteration hp αr αθ Max pressure Fz Mx My

5

- - (MPa) (10 N) (Nm) (Nm)

(µm) (10 5.rad) (10 5.rad)

0 50.000000 10.000000 0.000000 6.474877 4.938925 1468.991 7251.081

1 56.966530 10.976675 -1.779205 4.649763 3.595186 534.561 2265.785

2 58.543082 10.842759 -3.014021 4.189871 3.247799 92.999 264.700

3 58.507289 10.728756 -3.184184 4.148570 3.216814 1.612 2.445

4 58.503206 10.726141 -3.185541 4.148326 3.216669 6.958x10-5 -1.852x10-5

5 58.503206 10.726140 -3.185541 4.148326 3.216670 2.182x10-11 -1.107x10-10

Table 3. Parameters Application for bearing in [4] The results of this study are the foundation for

future researches taking into account thermal and

Pad Parameters Value deformation problems.

Rotational speed, N (rpm) 3000 References

[1] D. V. Srikanth, K. K. Chaturvedi, and A. C. K. Reddy,

r1 187.5/322.5

Inner radius / Outer radius, r2 Determination of a large tilting pad thrust bearing

angular stiffness, Tribology International, vol. 47, pp.

(m) 69–76, 2012.

Dynamic viscosity, µ (Pa.s) 0.0252 [2] Aa Farooq Ahmad Najar and G. A. Harmain

Numerical Investigation of Pressure Profile in

Number of pads 12 Hydrodynamic Lubrication Thrust Bearing,

Pad angle, θ (deg) 28 International Scholarly Research Notices (2014)

pad ID157615.

Pivot circumferential position, θ p 17.38 [3] Annan Guo, Xiaojing W., Jian J, Diann Y Hua, Zikai

H. Experimental test of static and dynamic

(deg) characteristics of tilting-pad thrust bearings, Advances

in Mechanical Engineering 2015, Vol. 7(7) 1–8

Pivot radius, rp (m) 255.00

[4] Mostefa Kouider, Souchet D., Zebbar D., Youcefi A.

Applied load on each pad (N) 59592 Effects of the dimple geometry on the isothermal

performance of a hydrodynamic textured tiltingpad

Fig. 6 shows the pressure comparison between thrust bearing, Journal of Heat and Technology, Vol.

the present study with the results in Kouider’s 36, No. 2, 2018, pp. 463-472

calculation [4] in the middle section. While used the

[5] Hai T.T.T, Thuan L. T. Modeling and Experimental

finite difference method, there still have slight Investigation of Oil Film Pressure Distribution for

differences in value. The maximum value in reference Hydrodynamic Thrust Bearing, Journal of Science and

is 8.673MPa while in the present study, this value is Technology Technical Universities No.121 (2017)

8.708MPa. Overall, both results are in good 065-070

agreement.

[6] Dung L.A, Hai T.T.T, Thuan L.T, Numerical

5. Conclusion Modelization for Equilibrium Position of a Static

Loaded Hydrodynamic Bearing, Journal of Science

This research numerically simulates the pressure and Technology Technical Universities No.141 (2020).

distribution and the film thickness of tilting pad thrust

[7] Dominique Bonneau, Dominique Souchet, Aurelian

bearing. The high-pressure zone is located at the lower Fatu. Hydrodynamic bearing, University of Poitiers,

film thickness zone and near the pivot location. The France.2014.

maximum pressure is not positioned in the middle

section of the bearing due to the non-symmetric of the

model. The pressure at the different radial sections of

the bearing is diverse in value because of the non-

symmetry of the model.

30 File đính kèm:

numerical_modelization_of_the_oil_film_pressure_for_a_hydrod.pdf

numerical_modelization_of_the_oil_film_pressure_for_a_hydrod.pdf