Large displacements of fgsw beams in thermal environment using a finite element formulation

Abstract. The large displacements of functionally graded sandwich (FGSW) beams in

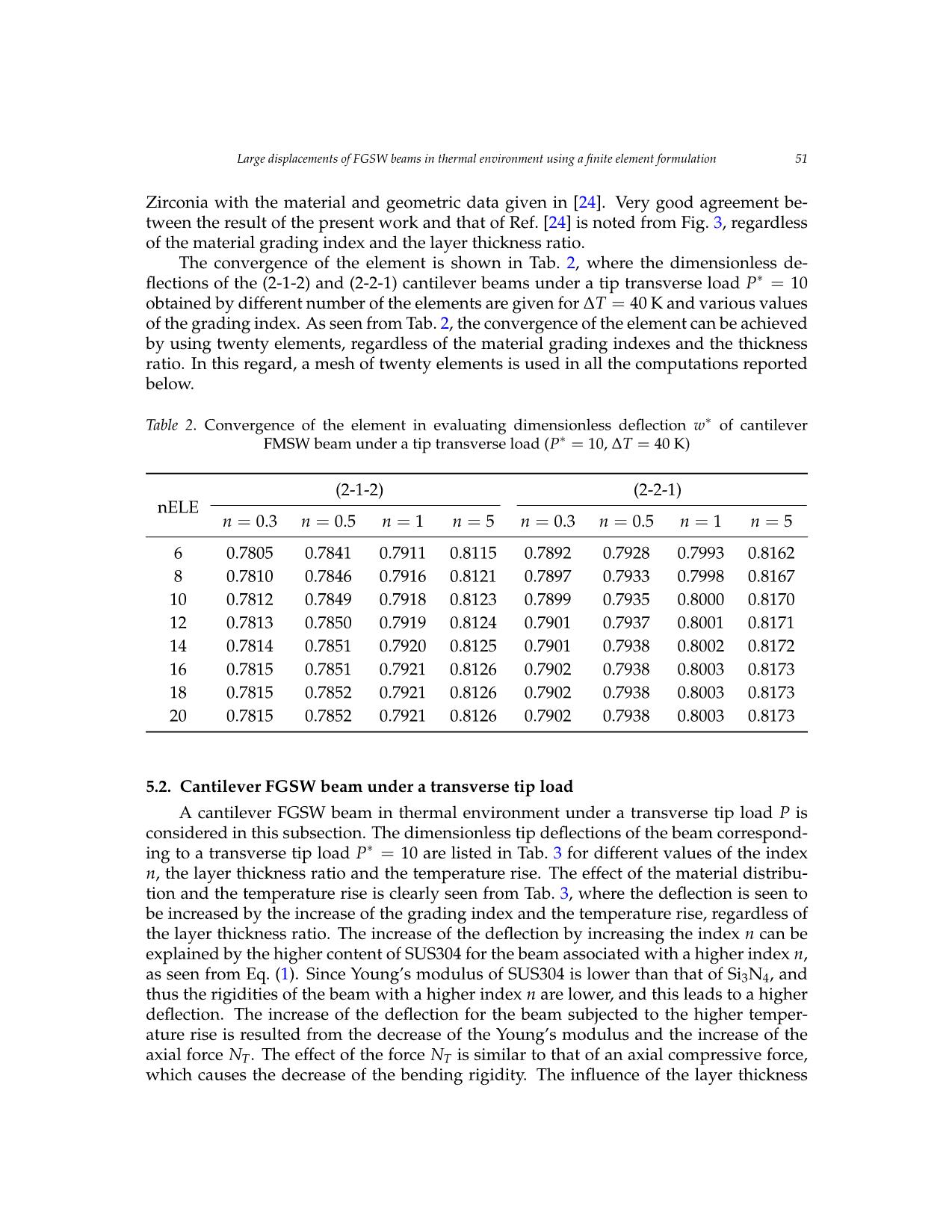

thermal environment are studied using a finite element formulation. The beams are composed of three layers, a homogeneous core and two functionally graded face sheets with

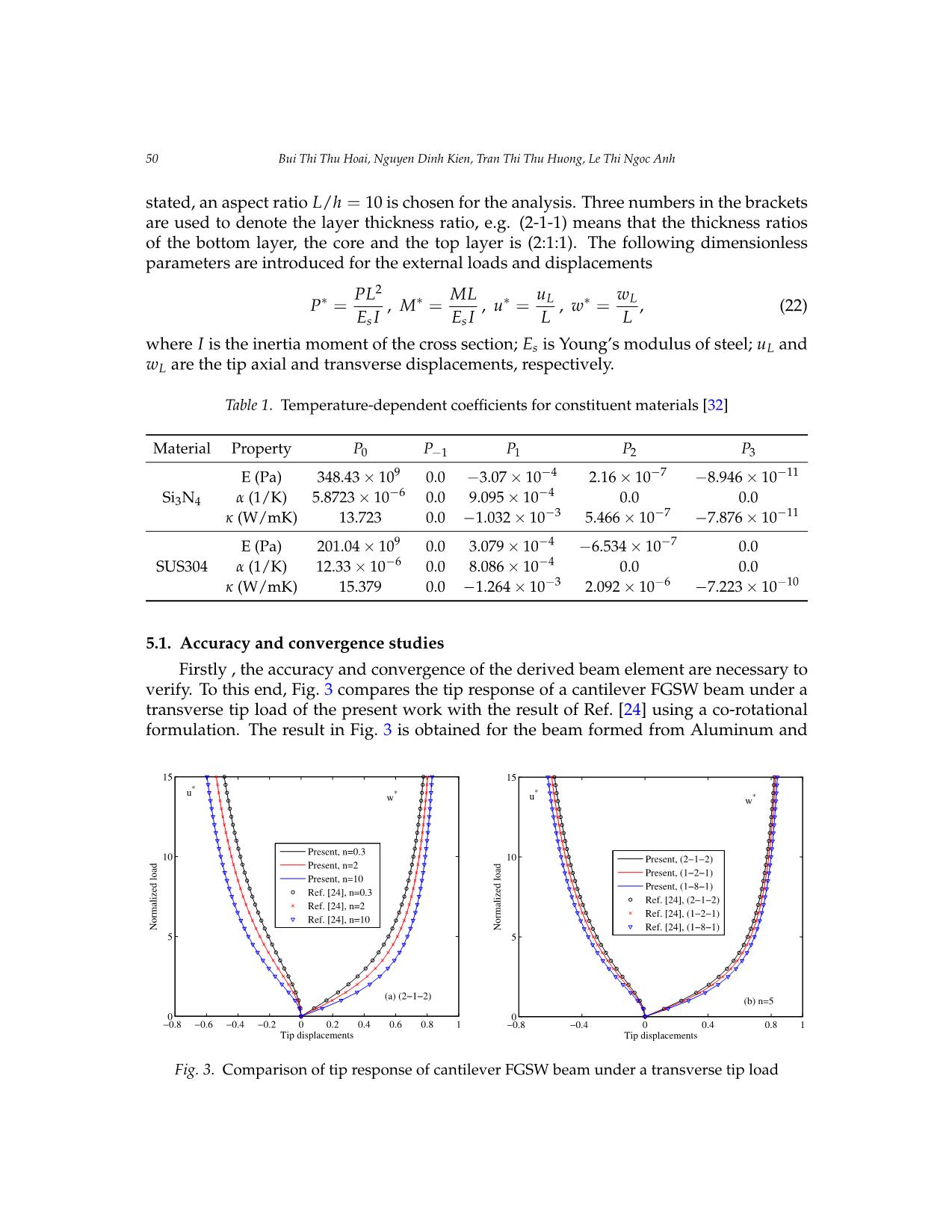

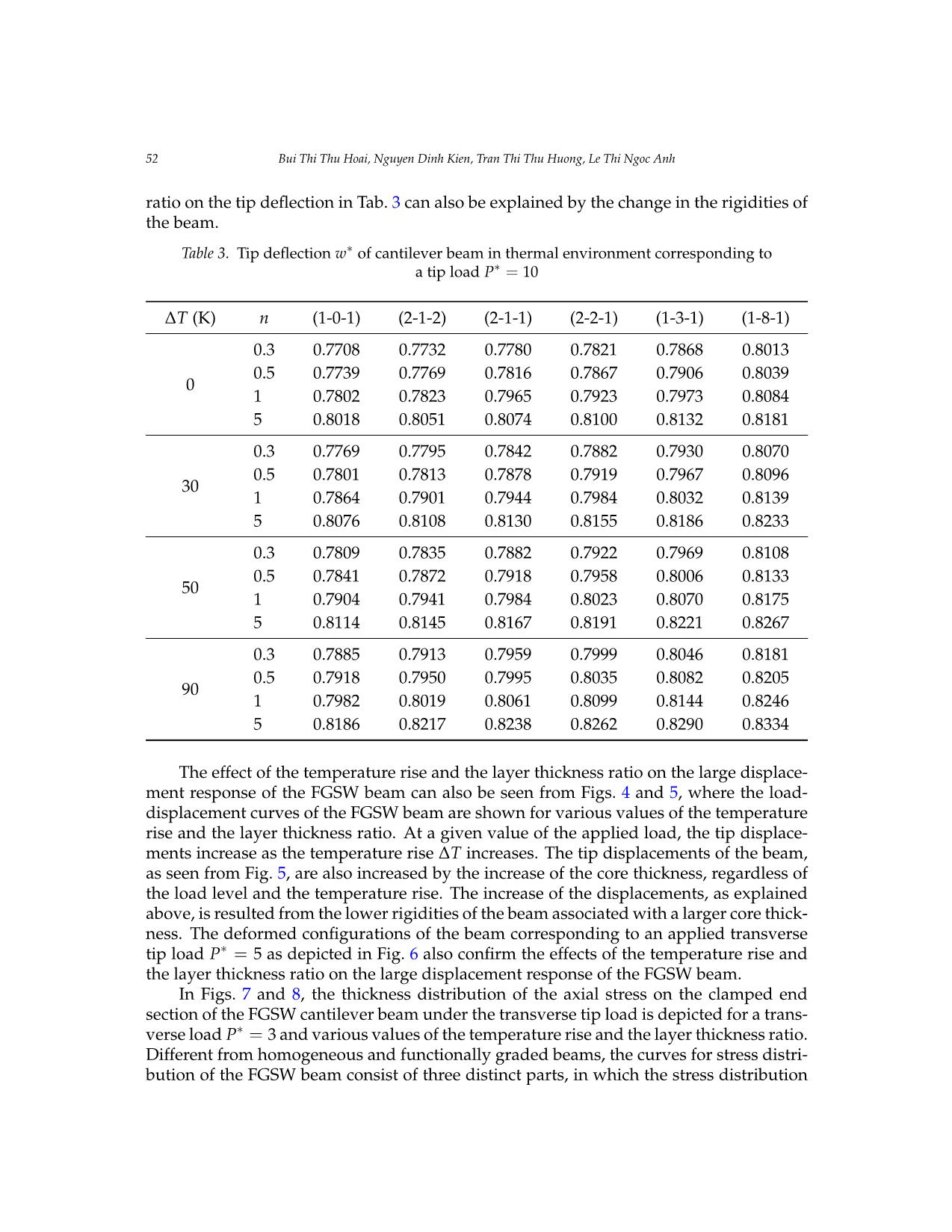

volume fraction of constituents following a power gradation law. The material properties of the beams are considered to be temperature-dependent. Based on Antman beam

model and the total Lagrange formulation, a two-node nonlinear beam element taking the

effect of temperature rise into account is formulated and employed in the study. The element with explicit expressions for the internal force vector and tangent stiffness matrix is

derived using linear interpolations and reduced integration technique to avoid the shear

locking. Newton-Raphson based iterative algorithm is employed in combination with

the arc-length control method to compute the large displacement response of a cantilever

FGSW beam subjected to end forces. The accuracy of the formulated element is confirmed

through a comparison study. The effects of the material inhomogeneity, temperature rise

and layer thickness ratio on the large deflection response of the beam are examined and

highlighted.

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Trang 6

Trang 7

Trang 8

Trang 9

Trang 10

Tải về để xem bản đầy đủ

Tóm tắt nội dung tài liệu: Large displacements of fgsw beams in thermal environment using a finite element formulation

Vietnam Journal of Mechanics, VAST, Vol.42, No. 1 (2020), pp. 43 – 61

DOI: https://doi.org/10.15625/0866-7136/14628

LARGE DISPLACEMENTS OF FGSW BEAMS

IN THERMAL ENVIRONMENT USING A FINITE ELEMENT

FORMULATION

Bui Thi Thu Hoai1,2,∗, Nguyen Dinh Kien1,2, Tran Thi Thu Huong3, Le Thi Ngoc Anh4

1Institute of Mechanics, VAST, Hanoi, Vietnam

2Graduate University of Science and Technology, VAST, Hanoi, Vietnam

3Phenikaa University, Hanoi, Vietnam

4Institute of Applied Mechanics and Informatics, VAST, Ho Chi Minh city, Vietnam

E-mail: thuhoaihus@gmail.com

Received: 18 December 2019 / Published online: 20 March 2020

Abstract. The large displacements of functionally graded sandwich (FGSW) beams in

thermal environment are studied using a finite element formulation. The beams are com-

posed of three layers, a homogeneous core and two functionally graded face sheets with

volume fraction of constituents following a power gradation law. The material proper-

ties of the beams are considered to be temperature-dependent. Based on Antman beam

model and the total Lagrange formulation, a two-node nonlinear beam element taking the

effect of temperature rise into account is formulated and employed in the study. The ele-

ment with explicit expressions for the internal force vector and tangent stiffness matrix is

derived using linear interpolations and reduced integration technique to avoid the shear

locking. Newton-Raphson based iterative algorithm is employed in combination with

the arc-length control method to compute the large displacement response of a cantilever

FGSW beam subjected to end forces. The accuracy of the formulated element is confirmed

through a comparison study. The effects of the material inhomogeneity, temperature rise

and layer thickness ratio on the large deflection response of the beam are examined and

highlighted.

Keywords: FGSW beam, total Lagrange formulation, reduced integration, thermal environ-

ment, large deflection analysis.

1. INTRODUCTION

Large displacement analysis of structures has drawn much attention from researchers

since the recent invention of new materials allows structures to undergo large deforma-

tion during their service. The finite element method, a powerful tool in solving nonlinear

problems, is a preferable choice in dealing with this problem. In the context of finite

element analysis, two types of nonlinear formulation for analyzing beams undergoing

large displacement, namely the co-rotational formulation [1,2] and the total Lagrange

c 2020 Vietnam Academy of Science and Technology

44 Bui Thi Thu Hoai, Nguyen Dinh Kien, Tran Thi Thu Huong, Le Thi Ngoc Anh

one [3,4], are the most often used. The main difference between these two formulations

is the choice of reference frames, which leads to different expressions of the element for-

mulation.

Functionally graded materials (FGMs), a new type of composites initiated by Japan-

ese scientists in mid-1980 [5], are increasing used to fabricate structural elements for use

in severe environment. Investigations on nonlinear behaviour of FGM beam structure

have been extensively reported in the last two decades. In this line of works, Kang and

Li [6,7] derived the large displacement solutions for cantilever FGM beams subjected to

a transverse tip load or a tip moment. The position of the neutral axis has been taken into

account in the derivation, which eliminates the axial deformation and bending coupling

effect. Kocaturk¨ et al. [8] formulated a total Lagrange formulation for studying large

displacement behaviour of FGM beams due to distributed load. Also using the total La-

grange formulation, Almeida et al. [9] investigated geometrically nonlinear behaviour of

FGM beams under mechanical loads. Levyakov [10, 11] adopted the neutral surface as

reference plane to derive the elastic solutions for FGM beams under the thermal loading.

Based on the third-order shear deformation beam theory, Zhang [12] derived the consti-

tutive equations for studying the nonlinear bending of FGM beams. Nguyen et al. [13–17]

derived the co-rotational beam elements for large displacement analysis of FGM beams

and frames. The effect of plastic deformation on buckling and nonlinear bending of FGM

beams is considered using the finite element method [18,19]. A geometrically exact beam

model with fully intrinsic formulation is employed by Masjedi et al. [20] to study the

large deflection behaviour of functionally graded beams under conservative and non-

conservative loading.

With the development of advanced manufacturing methods [21], FGMs can now be

incorporated into sandwich construction to improve the performance of structures. Func-

tionally graded sandwich (FGSW) structures can be designed to have a smooth variation

of material properties, and this helps to avoid the interface delaminating problem as often

seen in the conventional sandwich structures. Several investigations, mainl ... 25 −0.25

*

(a) (2−1−1), n=3, P =3 (b) (1−2−1), n=3, P*=3

−0.5 −0.5

−1.2 −0.8 −0.4 0 0.4 0.8 1 −1.2 −0.8 −0.4 0 0.4 0.8 1.2

σ /109 (N/m) σ /109 (N/m)

x x

Fig. 7. Effect of temperature rise on thickness distribution of axial stress at clamped section

of FGSW cantilever beam corresponding to a transverse tip load P∗ = 3

Large displacements of FGSW beams in thermal environment using a finite element formulation 55

0.5 0.5

(1−0−1) (1−0−1)

(2−2−1) (2−2−1)

(1−8−1) (1−8−1)

0.25 0.25

0

z/h 0

z/h

−0.25 −0.25

*

(a) n=3, ∆T=0, P =3 (b) n=3, ∆T=50K, P*=3

−0.5 −0.5

−1.2 −0.8 −0.4 0 0.4 0.8 1.2 −1.2 −0.8 −0.4 0 0.4 0.8 1.2

9

σ /10 (N/m) σ /109 (N/m)

x x

Fig. 8. Effect of layer thickness ratio on thickness distribution of axial stress at clamped section

of FGSW cantilever beam corresponding to a transverse tip load P∗ = 3

5.3. Roll-up of cantilever beam due to a tip moment

The roll-up of a cantilever FGSW beam subjected to a tip moment M is studied in this

sub-section. In Figs.9 and 10, the equilibrium paths of the beam are respectively depicted

for different values of the temperature rise and the layer thickness ratio. The temperature

rise and the layer thickness ratio, as seen from the figures, play an important role on the

large displacement behaviour of the beam. The effect of the layer thickness ratio on the

response of the beam is more significant in the large displacement region than that of

6 6

* *

u* w* u w

5 5

4 4

3 3

Normalized moment

2 Normalized moment 2

(a) n=5, ∆T=50K (b) n=5, ∆T=90K

∆ T=0K ∆ T=0K

1 ∆ T=30K 1 ∆ T=30K

∆ T=60K ∆ T=60K

∆ T=90K ∆ T=90K

0 0

−1.5 −1 −0.5 0 0.5 1 −1.5 −1 −0.5 0 0.5 1

Tip displacements Tip displacements

Fig. 9. Equilibrium paths of cantilever FGSW beam under a tip moment

for different temperature rise

56 Bui Thi Thu Hoai, Nguyen Dinh Kien, Tran Thi Thu Huong, Le Thi Ngoc Anh

6 6

* *

u w u* w*

5 5

4 4

3 3

Normalized moment

2 Normalized moment 2

(a) n=5, ∆ T=50K (b) n=5 ∆ T=90K

(8−1−8) (8−1−8)

1 (2−2−1) 1 (2−2−1)

(1−3−1) (1−3−1)

(1−8−1) (1−8−1)

0 0

−1.5 −1 −0.5 0 0.5 1 −1.5 −1 −0.5 0 0.5 1

Tip displacements Tip displacements

Fig. 10. Equilibrium paths of cantilever FGSW beam under a tip moment

for different layer thickness ratio

0.4 0.4

0.3 0.3

0.2 ∆T=0K 0.2

w*

w* (1−0−1)

∆T=50K (2−1−1)

∆T=90K (1−8−1)

*

0.1 (a) (2−1−1), n=2, M*=7 0.1 (b) n=5, ∆T=50K, M =7

0 0

−0.2 −0.1 0 0.1 0.2 −0.2 −0.1 0 0.1 0.2

x/L x/L

Fig. 11. Deformed configurations of FGSW beam subjected to a tip moment

the temperature rise. The significant influence of the layer thickness ratio on the large

displacement behaviour of the FGSW beam can be seen more clearly from Fig. 11, where

the deformed configurations of the beam are displayed for M∗ = 7 and different values

of the temperature rise and layer thickness ratio. At the applied moment M∗ = 7, the

(1-8-1) beam has already rolled up to a circle while the (1-0-1) beam has not yet. Noting

that due to the snap-back of the equilibrium paths, the arc-length control method must

be employed to trace the paths in Figs.9 and 10.

Large displacements of FGSW beams in thermal environment using a finite element formulation 57

6. CONCLUSIONS

The large displacement behaviour of FGSW beams in thermal environment has been

investigated by a finite element formulation. The beams are considered to be composed

of three layers, a homogeneous core and two functionally graded skin layers with the

temperature-dependent material properties. Based on the Antman beam model, a first-

order shear deformable nonlinear beam element taking the effect of temperature rise into

account was formulated in the context of the total Lagrange formulation. The element

with explicit expressions for the internal force vector and tangent stiffness matrix has

been derived using the reduced integration technique to avoid the shear locking. Using

the derived beam element, the large displacement response of a cantilever FGSW beam

under the end forces has been computed, and the effects of the material inhomogeneity,

temperature rise and layer thickness ratio have been examined. The obtained numerical

results reveal that, in addition to the material inhomogeneity, the temperature rise and

the layer thickness ratio also play an important role on the large displacement behaviour

of the beam. It has been shown that the effect of the layer thickness ratio on the behaviour

of the FGSW beams in the large displacement region is more significant than that of the

temperature rise. It is necessary to note that though the numerical investigation in the

present paper has been carried out for the cantilever beam only, the element formulation

formulated herein can be used to analyze the FGSW beams with other boundary con-

ditions as well. Additionally, the present beam formulation is simple, and its extension

to the large displacement analysis of beams made of other materials, e.g., functionally

graded carbon nanotube reinforced composite beams, is straightforward.

ACKNOWLEDGEMENTS

The work presented in this article was supported by National Foundation for Science

and Technology Development (NAFOSTED), grant number 107.02-2018.23 and Vietnam

Academy of Science and Technology, grant number QTRU01.07/20-21.

REFERENCES

[1] D. K. Nguyen. A non-linear element for analysing elastic frame structures at large deflec-

tions. Vietnam Journal of Mechanics, 22, (1), (2000), pp. 19–28. https://doi.org/10.15625/0866-

7136/9959.

[2] D. K. Nguyen and Q. Q. Do. Large deflection analysis of frames by elements con-

taining higher-order terms. Vietnam Journal of Mechanics, 25, (4), (2003), pp. 243–254.

https://doi.org/10.15625/0866-7136/25/4/6595.

[3] R. D. Wood and O. C. Zienkiewicz. Geometrically nonlinear finite element analysis of beams,

frames, arches and axisymmetric shells. Computers & Structures, 7, (6), (1977), pp. 725–735.

https://doi.org/10.1016/0045-7949(77)90027-x.

[4] D. K. Nguyen. Postbuckling behavior of beams on two-parameter elastic foundation.

International Journal of Structural Stability and Dynamics, 4, (01), (2004), pp. 21–43.

https://doi.org/10.1142/s0219455404001082.

[5] M. Koizumi. FGM activities in Japan. Composites Part B: Engineering, 28, (1-2), (1997), pp. 1–4.

https://doi.org/10.1016/s1359-8368(96)00016-9.

58 Bui Thi Thu Hoai, Nguyen Dinh Kien, Tran Thi Thu Huong, Le Thi Ngoc Anh

[6] Y. A. Kang and X. F. Li. Bending of functionally graded cantilever beam with power-law

non-linearity subjected to an end force. International Journal of Non-Linear Mechanics, 44, (6),

(2009), pp. 696–703. https://doi.org/10.1016/j.ijnonlinmec.2009.02.016.

[7] Y. A. Kang and X. F. Li. Large deflections of a non-linear cantilever functionally

graded beam. Journal of Reinforced Plastics and Composites, 29, (12), (2010), pp. 1761–1774.

https://doi.org/10.1177/0731684409103340.

[8] T. Kocaturk,¨ M. S¸ims¸ek, and S¸. D. Akbas¸. Large displacement static analysis of a cantilever

Timoshenko beam composed of functionally graded material. Science and Engineering of Com-

posite Materials, 18, (1-2), (2011), pp. 21–34. https://doi.org/10.1515/secm.2011.005.

[9] C. A. Almeida, J. C. R. Albino, I. F. M. Menezes, and G. H. Paulino. Geomet-

ric nonlinear analyses of functionally graded beams using a tailored Lagrangian

formulation. Mechanics Research Communications, 38, (8), (2011), pp. 553–559.

https://doi.org/10.1016/j.mechrescom.2011.07.006.

[10] S. V. Levyakov. Elastica solution for thermal bending of a functionally graded beam. Acta

Mechanica, 224, (8), (2013), pp. 1731–1740. https://doi.org/10.1007/s00707-013-0834-1.

[11] S. V. Levyakov. Thermal elastica of shear-deformable beam fabricated of functionally graded

material. Acta Mechanica, 226, (3), (2015), pp. 723–733. https://doi.org/10.1007/s00707-014-

1218-x.

[12] D. G. Zhang. Nonlinear bending analysis of FGM beams based on physical neutral sur-

face and high order shear deformation theory. Composite Structures, 100, (2013), pp. 121–126.

https://doi.org/10.1016/j.compstruct.2012.12.024.

[13] D. K. Nguyen. Large displacement response of tapered cantilever beams made of axi-

ally functionally graded material. Composites Part B: Engineering, 55, (2013), pp. 298–305.

https://doi.org/10.1016/j.compositesb.2013.06.024.

[14] D. K. Nguyen. Large displacement behaviour of tapered cantilever Euler–Bernoulli beams

made of functionally graded material. Applied Mathematics and Computation, 237, (2014),

pp. 340–355. https://doi.org/10.1016/j.amc.2014.03.104.

[15] D. K. Nguyen, T. H. Trinh, and T. H. Le. A co-rotational beam element for geometrically

nonlinear analysis of plane frames. Vietnam Journal of Mechanics, 35, (1), (2013), pp. 51–65.

https://doi.org/10.15625/0866-7136/35/1/2892.

[16] D. K. Nguyen and B. S. Gan. Large deflections of tapered functionally graded beams sub-

jected to end forces. Applied Mathematical Modelling, 38, (11-12), (2014), pp. 3054–3066.

[17] D. K. Nguyen, B. S. Gan, and T. H. Trinh. Geometrically nonlinear analysis of planar beam

and frame structures made of functionally graded material. Structural Engineering and Me-

chanics, 49, (6), (2014), pp. 727–743. https://doi.org/10.12989/sem.2014.49.6.727.

[18] T. H. Trinh, D. K. Nguyen, B. S. Gan, and S. Alexandrov. Post-buckling responses of elasto-

plastic FGM beams on nonlinear elastic foundation. Structural Engineering and Mechanics, 58,

(3), (2016), pp. 515–532. https://doi.org/10.12989/sem.2016.58.3.515.

[19] D. K. Nguyen, K. V. Nguyen, B. S. Gan, and S. Alexandrov. Nonlinear bend-

ing of elastoplastic functionally graded ceramic-metal beams subjected to nonuni-

form distributed loads. Applied Mathematics and Computation, 333, (2018), pp. 443–459.

https://doi.org/10.1016/j.amc.2018.03.100.

[20] P. K. Masjedi, A. Maheri, and P. M. Weaver. Large deflection of functionally graded porous

beams based on a geometrically exact theory with a fully intrinsic formulation. Applied Math-

ematical Modelling, 76, (2019), pp. 938–957. https://doi.org/10.1016/j.apm.2019.07.018.

Large displacements of FGSW beams in thermal environment using a finite element formulation 59

[21] Y. Watanabe, Y. Inaguma, H. Sato, and E. Miura-Fujiwara. A novel fabrication method

for functionally graded materials under centrifugal force: The centrifugal mixed-powder

method. Materials, 2, (4), (2009), pp. 2510–2525. https://doi.org/10.3390/ma2042510.

[22] T. P. Vo, H. T. Thai, T. K. Nguyen, A. Maheri, and J. Lee. Finite element

model for vibration and buckling of functionally graded sandwich beams based on

a refined shear deformation theory. Engineering Structures, 64, (2014), pp. 12–22.

https://doi.org/10.1016/j.engstruct.2014.01.029.

[23] T. P. Vo, H. T. Thai, T. K. Nguyen, F. Inam, and J. Lee. A quasi-3D theory for vibration and

buckling of functionally graded sandwich beams. Composite Structures, 119, (2015), pp. 1–12.

https://doi.org/10.1016/j.compstruct.2014.08.006.

[24] D. K. Nguyen and T. T. Tran. A corotational formulation for large displacement analysis of

functionally graded sandwich beam and frame structures. Mathematical Problems in Engineer-

ing, 2016, (2016). https://doi.org/10.1155/2016/5698351.

[25] Y. S. Touloukian. Thermophysical properties of high temperature solid materials. Macmillan, New

York, USA, (1967).

[26] S. S. Antman. Nonlinear problems of elasticity. Springer-Verlag, New York, (1995).

[27] C. Pacoste and A. Eriksson. Beam elements in instability problems. Computer Methods in Ap-

plied Mechanics and Engineering, 144, (1-2), (1997), pp. 163–197. https://doi.org/10.1016/s0045-

7825(96)01165-6.

[28] E. N. Lages, G. H. Paulino, I. F. M. Menezes, and R. R. Silva. Nonlinear finite el-

ement analysis using an object-oriented philosophy–application to beam elements and

to the cosserat continuum. Engineering with Computers, 15, (1), (1999), pp. 73–89.

https://doi.org/10.1007/s003660050006.

[29] A. Mahi, E. A. A. Bedia, A. Tounsi, and I. Mechab. An analytical method for

temperature-dependent free vibration analysis of functionally graded beams with

general boundary conditions. Composite Structures, 92, (8), (2010), pp. 1877–1887.

https://doi.org/10.1016/j.compstruct.2010.01.010.

[30] R. D. Cook, D. S. Malkus, and M. E. Plesha. Concepts and applications of finite element analysis.

John Wiley & Sons, New York, USA, 3rd edition, (1989).

[31] M. A. Crisfield. Non-linear finite element analysis of solids and structures, Vol. 1: Essentials. John

Wiley & Sons, Chichester, (1991).

[32] H. S. Shen and Z. X. Wang. Nonlinear analysis of shear deformable FGM beams resting on

elastic foundations in thermal environments. International Journal of Mechanical Sciences, 81,

(2014), pp. 195–206. https://doi.org/10.1016/j.ijmecsci.2014.02.020.

60 Bui Thi Thu Hoai, Nguyen Dinh Kien, Tran Thi Thu Huong, Le Thi Ngoc Anh

APPENDIX

This Appendix presents detail expressions for the nodal forces and the tangent stiff-

ness matrices in Eq. (19). The following notations are used

s = sin θ¯ , c = cos θ¯,

2

a1 = (sε¯ − cγ¯) , a2 = (cε¯ + sγ¯) , a3 = γ¯ − ε¯ (1 + ε¯) , (23)

2 2

a4 = cγ¯ − s (1 + ε¯) , a5 = sγ¯ + c (1 + ε¯) , a6 = (1 + ε¯) − γ¯ .

The internal force vector

l l T

f = A ε¯ −c − s γ¯ c s γ¯ , f = A κ¯{0 0 1 0 0 − 1}T,

a 11 2 2 b 22

l l T

f = A ε¯{0 0 1 0 0 − 1}T + A κ¯ −c − s γ¯ c s γ¯ ,

c 12 12 2 2

(24)

l l T

f = ψA γ¯ s − c − (1 + ε¯) − s c − (1 + ε¯) ,

s 33 2 2

(w − w ) (w − w ) T

f = 0 − 2 1 N 0 0 2 1 N 0 ,

T l T l T

c2

sc s2 sym.

2

l l l

a1 − a2 a3

2 2 4

1 l

ka = A 2 2 , (25)

l 11 −c −sc − a1 c

2

l

− − 2 2

sc s a5 sc s

2

l l l2 l l l2

a − a a − a a a

2 1 2 2 4 3 2 1 2 2 4 3

0

0 0 sym.

1 0 0 1

k = A , (26)

b l 22 0 0 0 0

0 0 0 0 0

0 0 −1 0 0 1

Large displacements of FGSW beams in thermal environment using a finite element formulation 61

0 0 s 0 0 s 0 0 −c 0 0 c

0 0 −c 0 0 −c 0 0 −s 0 0 s

s c l s c l l l

− − (1 + ε¯) − (1 + ε¯) 0 0 γ¯ 0 0 − γ¯

2 2 2 2 2 2 2 2 2

kc = A12κ¯ + A12 ,

0 0 −s 0 0 −s l 0 0 c 0 0 −c

0 0 c 0 0 c 0 0 s 0 0 −s

1 1 l 1 1 l l l

s − c − (1 + ε¯) − s c (1 + ε¯) 0 0 γ¯ 0 0 − γ¯

2 2 2 2 2 2 2 2

(27)

s2

−sc c2 sym.

2

l l l

a4 a5 a6

2 2 4

ψ l

ks = A33 2 2 , (28)

l −s sc − a4 s

2

l

− 2 − − 2

sc c a5 sc c

2

l l l2 l l l2

a a a − a − a a

2 4 2 5 4 6 2 4 2 5 4 6

0

0 1 sym.

0 0 0

NT

k = . (29)

T l 0 0 0 0

0 −1 0 0 1

0 0 0 0 0 0

File đính kèm:

large_displacements_of_fgsw_beams_in_thermal_environment_usi.pdf

large_displacements_of_fgsw_beams_in_thermal_environment_usi.pdf