Experiments and optimization for the wedm process: A trade-off analysis between surface quality and production rate

Abstract. This work addressed a parameter optimization to simultaneously decrease the

root mean square roughness (Rq) as well as the thickness of the white layer (TW) and improve the material removal rate (MRR) for the wire electro-discharge machining (WEDM)

of a stainless steel 304 (SS304). The factors considered are the discharge current (C), the

gap voltage (VO), the pulse on time (POT), and the wire drum speed (SP). The interpolative radius basic function (RBF) is applied to show the correlation between the varied

factors and WEDM performances measured. The optimal selection is chosen using the

multi-objective particle swarm optimization (MOPSO). Moreover, a traditional one using

the response surface method (RSM) and desirability approach (DA) is adopted to compare the working efficiency of two optimization techniques. The results showed that the

optimal findings of the C, POT, VO, and SP are 5.0 A, 1.0 µs, 61.0 V, and 8.0 m/min, respectively. The values of the Rq and TW are decreased by approximately 33.33% and 23.53%,

respectively, while the MRR enhances 47.42% at the optimal selection, as compared to the

common values used. The BRF-MOPSO can provide better performance than the RSMDA.

Keywords: WEDM, white layer, root mean square roughness, material removal rate, RBF,

stainless steel.

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Trang 6

Trang 7

Trang 8

Trang 9

Trang 10

Tải về để xem bản đầy đủ

Tóm tắt nội dung tài liệu: Experiments and optimization for the wedm process: A trade-off analysis between surface quality and production rate

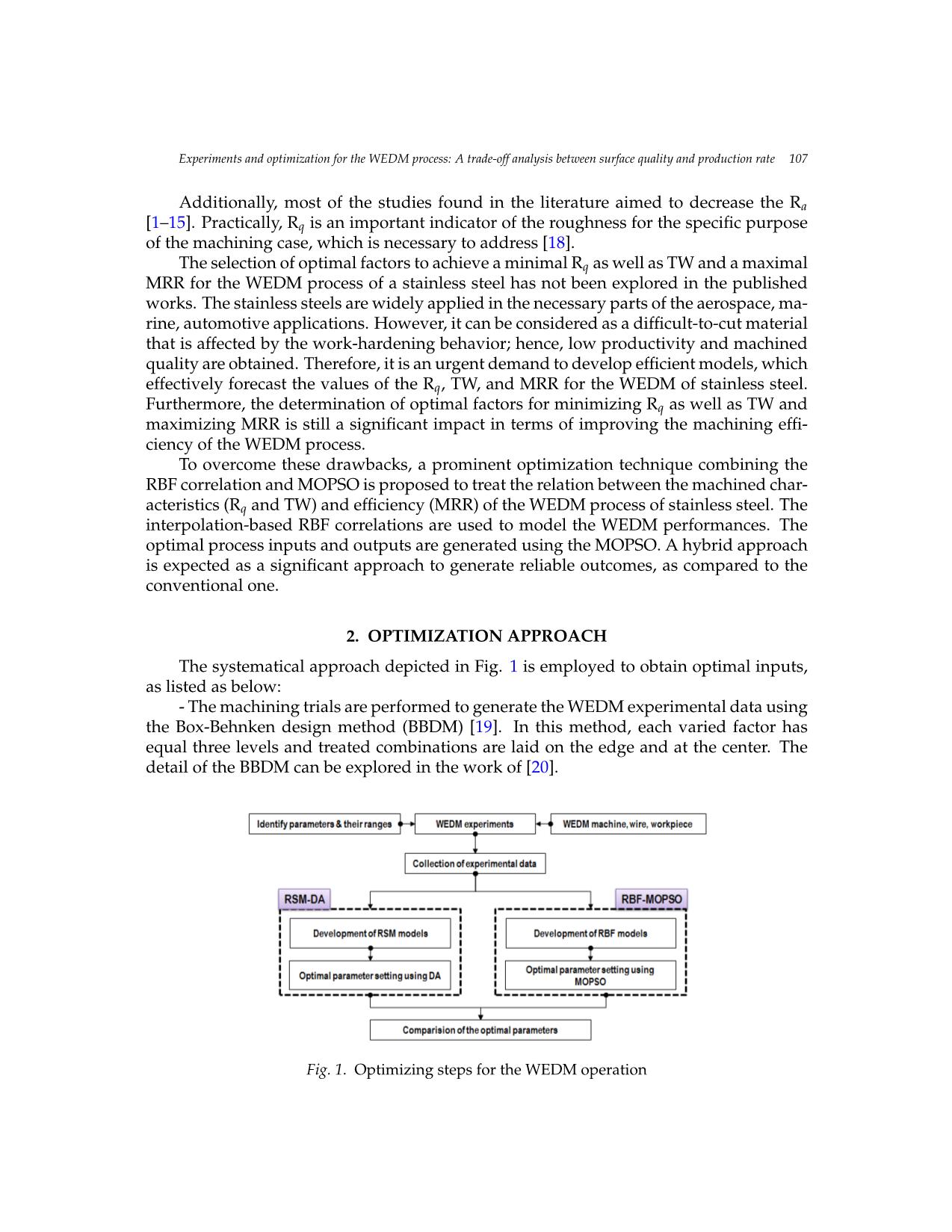

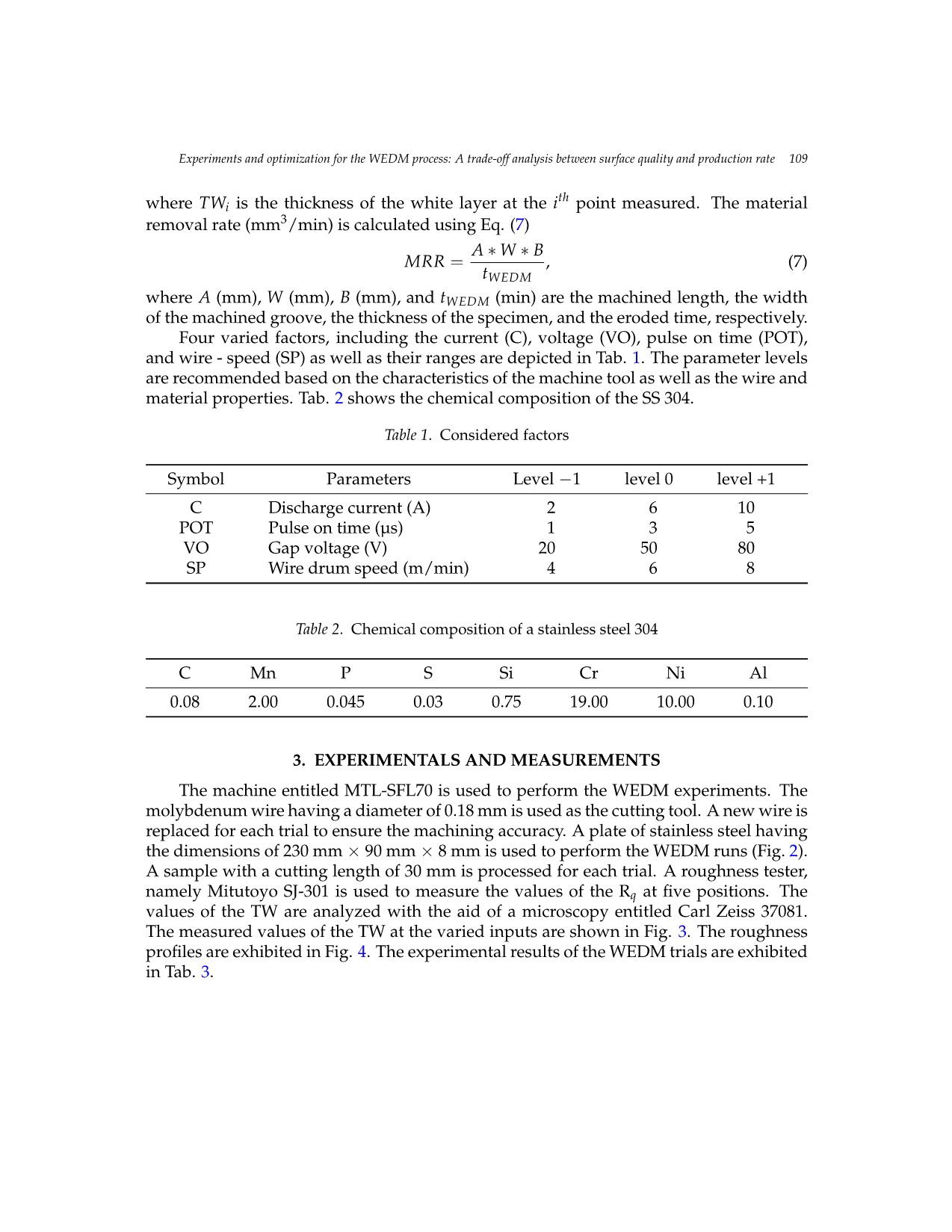

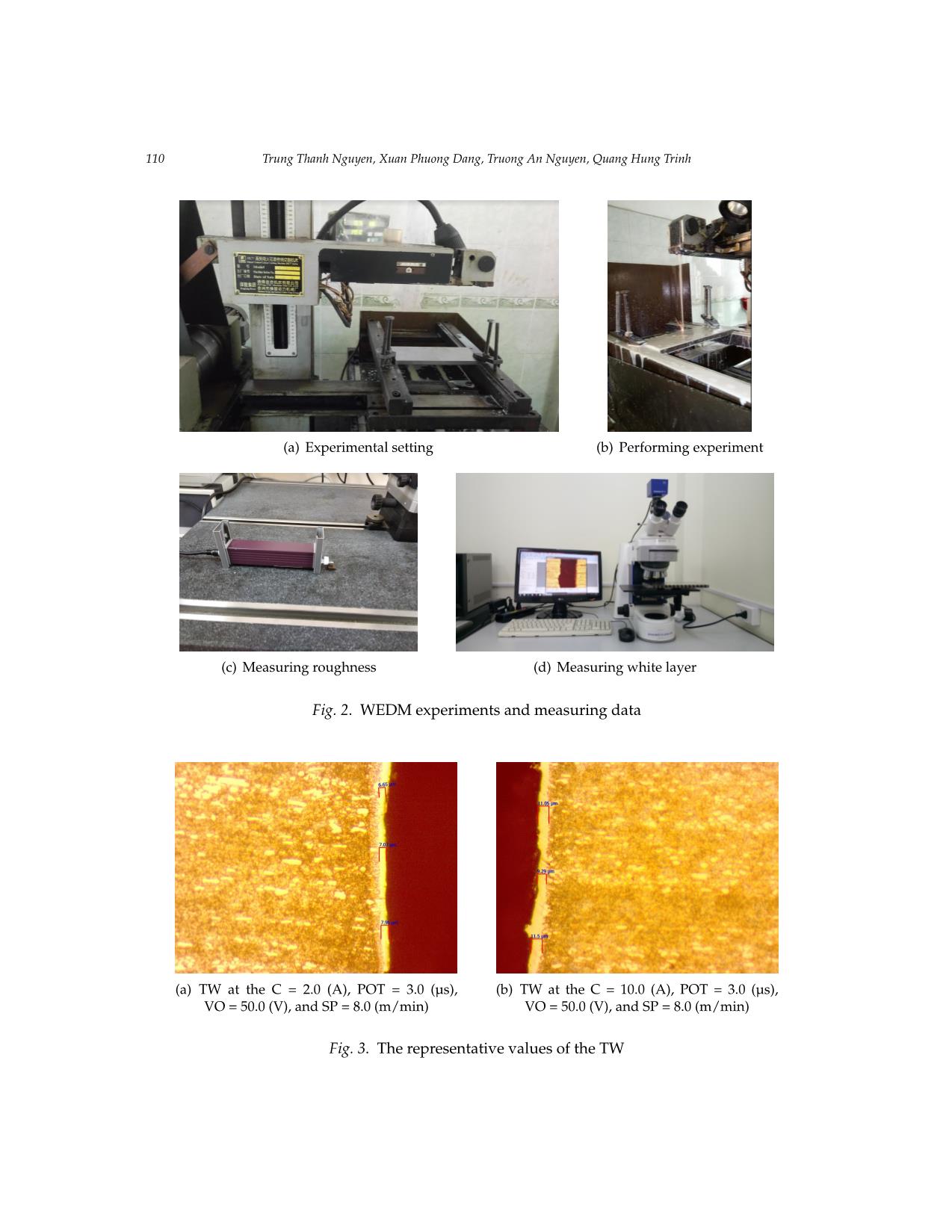

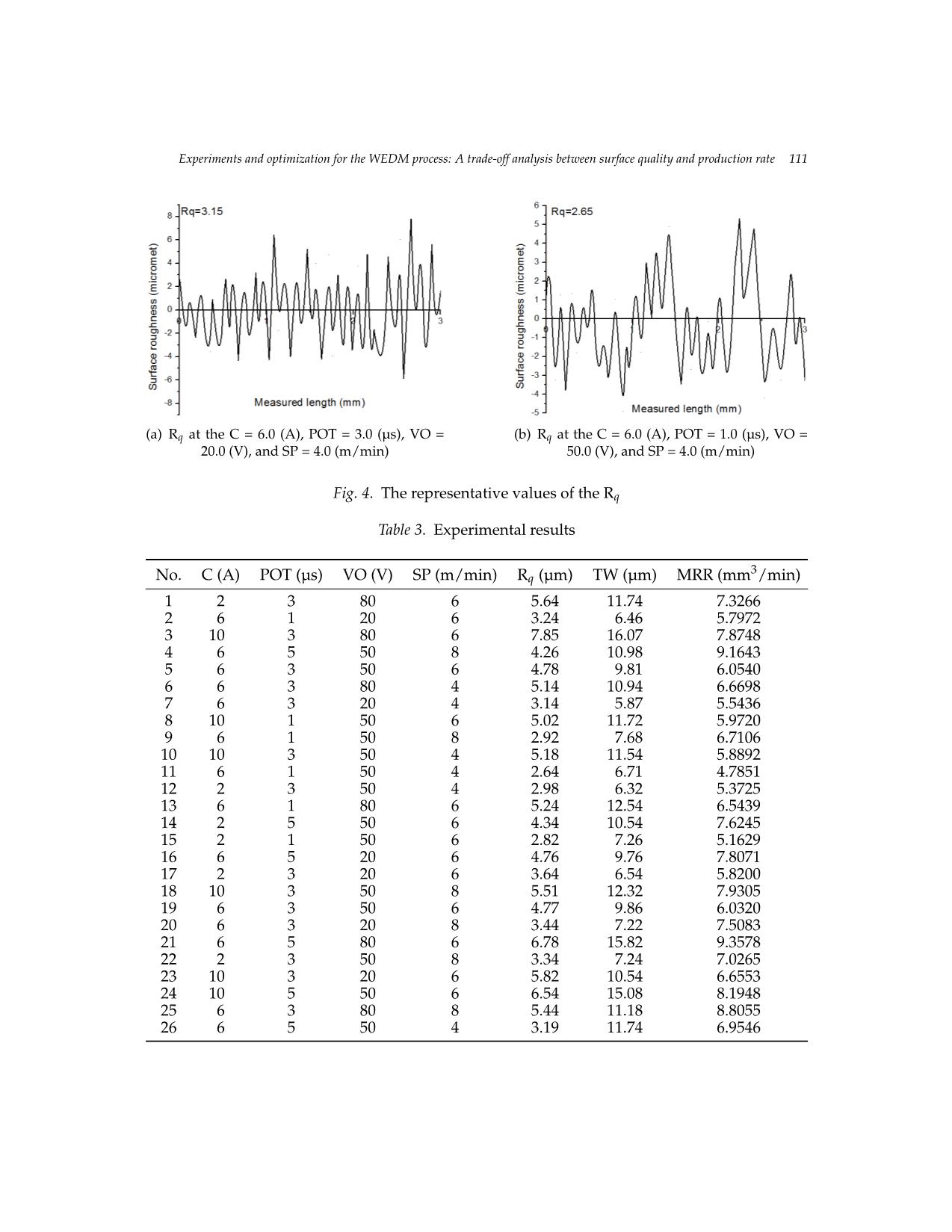

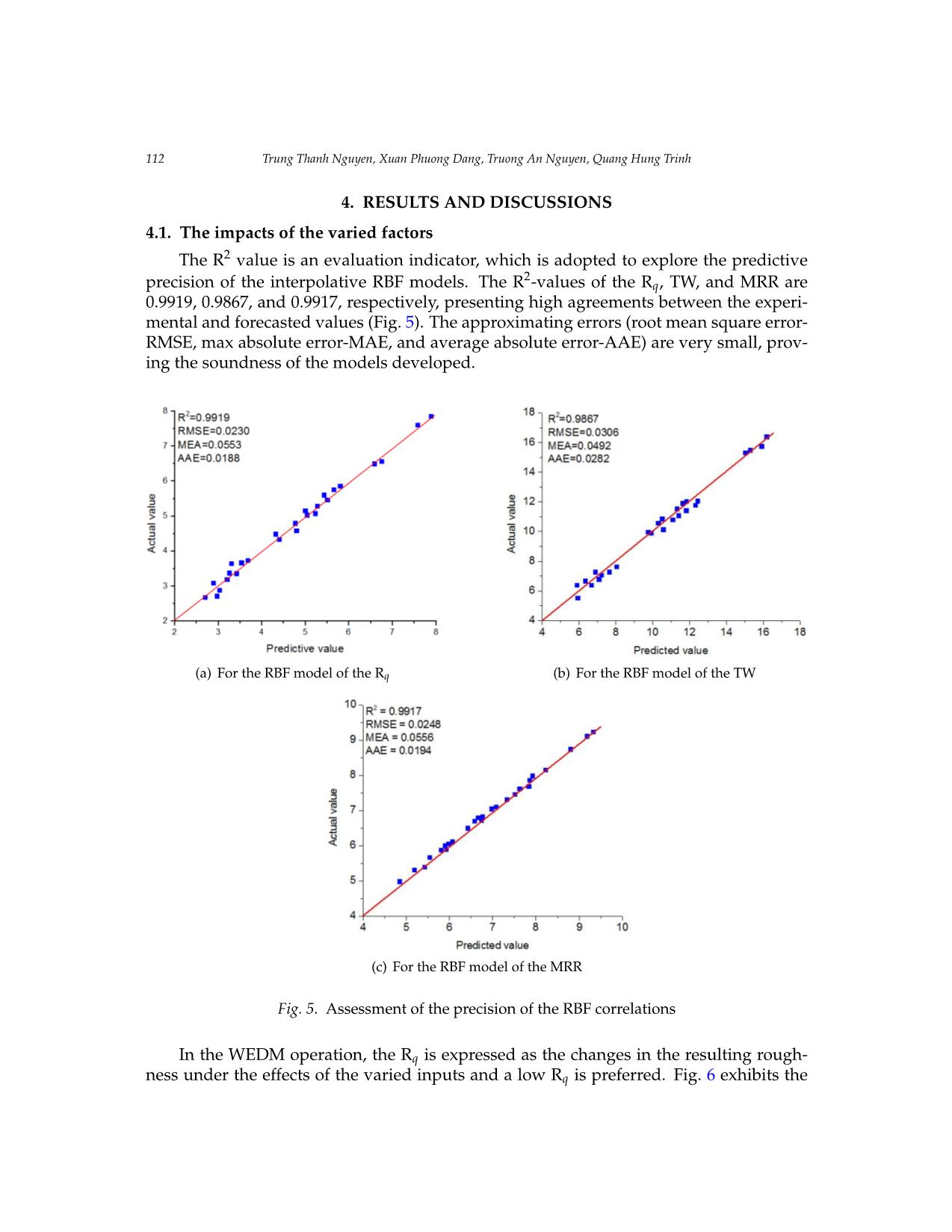

Vietnam Journal of Mechanics, VAST, Vol.42, No. 2 (2020), pp. 105 – 121 DOI: https://doi.org/10.15625/0866-7136/14663 EXPERIMENTS AND OPTIMIZATION FOR THE WEDM PROCESS: A TRADE-OFF ANALYSIS BETWEEN SURFACE QUALITY AND PRODUCTION RATE Trung Thanh Nguyen1, Xuan Phuong Dang2, Truong An Nguyen1, Quang Hung Trinh1,∗ 1Le Quy Don Technical University, Hanoi, Vietnam 2Nha Trang University, Vietnam E-mail: quanghung1020@gmail.com Received: 04 December 2019 / Published online: 07 April 2020 Abstract. This work addressed a parameter optimization to simultaneously decrease the root mean square roughness (Rq) as well as the thickness of the white layer (TW) and im- prove the material removal rate (MRR) for the wire electro-discharge machining (WEDM) of a stainless steel 304 (SS304). The factors considered are the discharge current (C), the gap voltage (VO), the pulse on time (POT), and the wire drum speed (SP). The interpola- tive radius basic function (RBF) is applied to show the correlation between the varied factors and WEDM performances measured. The optimal selection is chosen using the multi-objective particle swarm optimization (MOPSO). Moreover, a traditional one using the response surface method (RSM) and desirability approach (DA) is adopted to com- pare the working efficiency of two optimization techniques. The results showed that the optimal findings of the C, POT, VO, and SP are 5.0 A, 1.0 µs, 61.0 V, and 8.0 m/min, respec- tively. The values of the Rq and TW are decreased by approximately 33.33% and 23.53%, respectively, while the MRR enhances 47.42% at the optimal selection, as compared to the common values used. The BRF-MOPSO can provide better performance than the RSM- DA. Keywords: WEDM, white layer, root mean square roughness, material removal rate, RBF, stainless steel. 1. INTRODUCTION Wire electro-discharge machining (WEDM) is an efficient method, which is used to produce complicated products with high accuracy and quality. WEDM processes are widely applied in manufacturing conductive materials like titanium, copper, aluminum, graphite, tool steel, and polycrystalline diamond (PCD). In this process, the high energy intensity is used to cut and vaporize the specimen in the high-temperature environment, c 2020 Vietnam Academy of Science and Technology 106 Trung Thanh Nguyen, Xuan Phuong Dang, Truong An Nguyen, Quang Hung Trinh which causes the defects on the machined surface, such as high surface roughness, ten- sile residual stresses, recast layers, and cracks. Therefore, improving technological per- formances in the WEDM process is an urgent demand and an important research area. The impacts of the inputs on the technical responses in the WEDM operation have been explored. The response surface model (RSM) was used to describe the variations of the thickness of the white layer (TW) regarding the pulse on time (POT), the wire off- set (WO), and wire drum speed (SP). The authors stated that the explored correlation could be effectively adopted to estimate the objective outcome [1]. Similarly, the RSM technique was applied to design the correlated model of the average surface roughness (Ra) with respect to the POT, pulse off time (POFT), gap voltage (VO), and discharge current (C) [2]. The findings revealed the proposed model ensured an acceptable pre- cision. The genetic algorithm was used to decrease the Ra and TW for machining DIN 1.4542 [3]. The obtained reductions of the Ra and TW are 52% and 67%, as compared to the common values used. Shabgard et al. developed a simulation model to calculate the Ra, TW, and heat-affected zone (HAZ) [4]. The good agreement between simulated and experimental outcomes indicated the soundness of the simulation model. Shen et al. at- tempted to decrease the microscopic characteristics, such as the Ra, TW, hardness (MH), crack (MC), and void (MV) for the WEDM operation of Inconel 718 [5]. The primary out- comes revealed that the machined surface properties have been significantly enhanced with the aid of the high-speed EDM. Similarly, the Taguchi method was employed to decrease the Ra, WEDM speed, and taper error (TE) for the tapper component [6]. The authors presented that the WEDM performances were primarily affected by the POT and tapper angle. The empirical correlations of the TW and the surface crack density (SCD) were proposed in terms of the POT, POFT, VO, and C, respectively [7]. The RSM was ap- plied to minimize WEDM responses. The outcomes revealed that the WEDM responses were influenced by the POT, POFT, and CA, respectively. Additionally, the Ra, one of the most important indicators of the surface integrity was optimized in conjunction with other factors, including the cutting speed (CS) [8], wire wear ratio (WWR) [9], kerf width (KW) [10–12], and material removal rate (MRR) [13–15]. As a result, the effects of the varied conditions on machining responses for differe ... pulse of time and wire speed (volt- = 3 µs and wire speed = 6 m/min) age = 20 V and current = 6 A) Fig. 9. Impacts of varied parameters on the MRR 116 Trung Thanh Nguyen, Xuan Phuong Dang, Truong An Nguyen, Quang Hung Trinh causes more melted and evaporated material. Therefore, a higher amount of material is removed. The MRR value is enhanced by 11.94% when the C increased from 2.0 to 8.0 A. The MRR value is enhanced by 20.09% when the VO increased from 20.0 to 80.0 V. At a higher value of the POT, higher discharge energy generated; hence more ma- terial is melted and evaporated (Fig. 9(b)). Therefore, a higher amount of material is processed and the evaporating productivity is enhanced. The MRR value is enhanced by 43.49% when the POT increased from 1.0 to 5.0 µs. The similar effect of the SP on the MRR can be found in Fig. 9(b). The MRR value is enhanced by 36.93% when the SP increased from 4.0 to 8.0 m/min. The ANOVA analysis having a confidence level of 95% is used to analyze the contri- butions of the process inputs. The varied factor having a p-value less than 0.05 is listed as the effective term. The varied factor having the p-value greater than 0.05 is considered as an insignificant input. (a) The contributions of the processing conditions (b) The contributions of the processing conditions for Rq for TW (c) The contributions of the processing conditions for MRR Fig. 10. Parameters’ contributions Experiments and optimization for the WEDM process: A trade-off analysis between surface quality and production rate 117 The contributed percentage of the varied factors for the Rq is illustrated in Fig. 10(a). The VO is the most effective term (28.92%), followed by C (23.96%), POT (13.82%), and SP (2.21%). Especially, SP2 is the highest quadratic term (11.61%), followed by C2 (8.57%), VO2 (3.79%), and POT2 (3.49%). The contributed percentage of the varied factors for the TW is illustrated in Fig. 10(b). The VO is the most affected term with the contribution of 24.19%, followed by C (20.96%), POT (15.08%), and SP (3.92%). The SP2 has an effective effect on the TW with the highest percentage of 13.63%, followed by CO2 (7.80%), VO2 (5.26%), and POT2 (5.20%). The contributed percentage of the varied factors for the MRR is illustrated in Fig. 10(c). The explored contributions of the VO, C, SP, and POT are 21.51%, 15.12%, 13.86%, and 13.34%, respectively. The VO2 has the greatest contribution to the quadratic factor (11.24%). This is followed by POT2 (7.42%), C2 (5.24%), and SP2 (4.15%). 4.2. Optimization results of the varied factors and WEDM responses The optimal selection is determined using the interpolative RBF correlations and the MOPSO. The graphs generated by the MOPSO are exhibited in Fig. 11, in which the point no. 522 is a proper selection. Tab.4 presents the optimum outcomes of the varied factors and objectives. The reductions in the Rq and TW are 33.3% and 23.53%, respectively, while the MRR improves by 47.42% in comparison with the common values used. (a) Rq versus TW (b) MRR versus TW Fig. 11. Pareto fonts generated by MOPSO Table 4. Optimization results generated by RBF-MOPSO Optimization parameters Responses Method C POT VO SP Rq TW MRR (A) (µs) (V) (m/min) (µm) (µm) (mm3/min) Initial 6.0 3.0 50.0 6.0 4.77 9.86 6.0320 RBF-MOPSO 5.0 1.0 61.0 8.0 3.18 7.54 8.8925 Improvement (%) 33.33 23.53 47.42 118 Trung Thanh Nguyen, Xuan Phuong Dang, Truong An Nguyen, Quang Hung Trinh The mathematical models of the Rq, TW, and MRR generated by the RSM are ex- pressed as Rq = − 7.00497 − 0.031771C + 0.71500POT + 0.03299VO + 3.04625SP + 0.00006CVO − 0.00094CASP + 0.00008POTVO + 0.04938POTSP (8) + 0.0257C2 − 0.11375POT2 + 0.00066VO2 − 0.25656SP2, TW = − 12.31674 − 0.030625C + 0.47083POT + 0.05596VO + 4.80396SP + 0.0025CPOT + 0.00068CVO − 0.00438CSP − 0.00008POTVO (9) − 0.10812POTSP − 0.00463VSP + 0.04922C2 + 0.1775POT2 + 0.00056VO2 − 0.33969SP2, MRR = + 7.58714 − 0.04369C − 0.46617POT − 0.07393VO − 0.67296SP − 0.00746CPOT − 0.00059CVO + 0.0121CSP + 0.00335POTVO (10) + 0.01776POTSP + 0.00071VOSP + 0.00921C2 + 0.13761POT2 + 0.00084VO2 + 0.08404SP2. The R2 value is adopted to explore the adequacy of the developed regressions. The 2 R -values of the Rq, TW, and MRR are 0.9572, 0.9587, and 0.9612, denoting an accept- able correlation between experimental and predicted data. Consequently, the developed regressions can be applied in the optimizing step. The DA is used to select the optimal inputs, as shown in Tab.5. The optimal values of the C, POT, VO, and SP are 2.0 A, 5.0 µs, 20.0 V, and 8.0 m/min. The values of the Rq, TW, and MRR are 3.28 µm, 7.56 µm, and 8.7478 mm3/min (Fig. 12). Table 5. Optimization results generated by RSM-DA Optimization parameters Responses Method C POT VO SP Rq TW MRR (A) (µs) (V) (m/min) (µm) (µm) (mm3/min) Initial 6.0 3.0 50.0 6.0 4.77 9.86 6.0320 RSM-DA 2.0 5.0 20.0 8.0 3.29 7.57 8.7478 Improvement (%) 31.24 23.33 45.02 The improvements in the Rq, TW, and MRR generated by the RBF-MOPSO are higher than the RSM-DA due to the selection of the global solution. It can be stated that the RBF- MOPSO can be used to generate a reliable solution, as compared to the RSM-DA. In this paper, a combined optimization technique using the RBF model and MOPSO is proposed to select the optimal process inputs for minimal Rq as well as TW and maxi- mize MRR of the WEDM process of stainless. The relation between the economic aspect (MRR) and the social aspect (Rq and TW) of the WEDM process is addressed. The predic- tion of the WEDM responses measured can be implemented using the RBF correlations. Experiments and optimization for the WEDM process: A trade-off analysis between surface quality and production rate 119 Fig. 12. The ramp graph generated by the DA for the optimal values The Pareto graphs analyzed can be used to select the optimal values of the process in- puts and responses. The explored findings can be considered as a prominent solution in industrial machining. The proposed technique is useful for the optimization of various machining operations. The obtained outcomes can be applied in the expert system and further investigations of the WEDM process. 5. CONCLUSIONS An efficient optimization of the WEDM process of a stainless steel has been con- sidered to decrease the TW as well as the Rq and to improve the MRR. The nonlinear correlations of the machining targets were developed using RBF models. The optimal process inputs and WEDM technical performances were obtained using the MOPSO. The explored findings are summarized: - The rough surface was observed due to the high values of the inputs. The Rq of SS304 is most influenced by the C, followed by the VO, POT, and SP, respectively. The average value for Rq of SS304 has a variation of 2.64–7.85 µm. - The white layer is formed on the machined WEDM surface due to high energy intensity. The voltage and the current are found to be the most influencing factors on the TW. The wire speed has been found to be a less significant factor. The average value for the TW of SS304 was in a range of 5.87 to 16.07 µm. - The high MRR is observed due to the high values of the inputs. The MRR of SS304 is most influenced by the VO, followed by the C, SP, and POT, respectively. The average value for the MRR of SS304 ranges from 4.78508 to 9.35775 mm3/min. 120 Trung Thanh Nguyen, Xuan Phuong Dang, Truong An Nguyen, Quang Hung Trinh - The obtained improvements in the Rq, TW, and MRR are 33.33%, 23.53%, and 47.42% at the optimum selection, as compared to the common values used. The RBF- MOPSO performs a higher efficiency than the RSM-DA with the experimental data of the WEDM operation. ACKNOWLEDGMENT This research is funded by Vietnam National Foundation for Science and Technology Development (NAFOSTED) under grant number 107.04-2020.02. REFERENCES [1] A. B. Puri and B. Bhattacharyya. Modeling and analysis of white layer depth in a wire-cut EDM process through response surface methodology. The International Journal of Advanced Manufacturing Technology, 25, (3-4), (2005), pp. 301–307. https://doi.org/10.1007/s00170-003- 2045-8. [2] H. Kumar, A. Manna, and R. Kumar. Modeling and desirability approach-based multi- response optimization of WEDM parameters in machining of aluminum metal matrix com- posite. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 40, (9), (2018). https://doi.org/10.1007/s40430-018-1368-1. [3] H. Shahali, M. R. S. Yazdi, A. Mohammadi, and E. Iimanian. Optimization of surface rough- ness and thickness of white layer in wire electrical discharge machining of DIN 1.4542 stain- less steel using micro-genetic algorithm and signal to noise ratio techniques. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 226, (5), (2012), pp. 803–812. https://doi.org/10.1177/0954405411434234. [4] M. Shabgard, S. N. B. Oliaei, M. Seyedzavvar, and A. Najadebrahimi. Experimental investi- gation and 3D finite element prediction of the white layer thickness, heat affected zone, and surface roughness in EDM process. Journal of mechanical science and technology, 25, (12), (2011), pp. 3173–3183. https://doi.org/10.1007/s12206-011-0905-y. [5] Y. Shen, Y. Liu, H. Dong, K. Zhang, L. Lv, X. Zhang, X. Wu, C. Zheng, and R. Ji. Surface in- tegrity of Inconel 718 in high-speed electrical discharge machining milling using air dielec- tric. The International Journal of Advanced Manufacturing Technology, 90, (1-4), (2017), pp. 691– 698. https://doi.org/10.1007/s00170-016-9332-7. [6] G. Selvakumar, K. B. Jiju, and R. Veerajothi. Experimental study on wire electrical dis- charge machining of tapered parts. Arabian Journal for Science and Engineering, 41, (11), (2016), pp. 4431–4439. https://doi.org/10.1007/s13369-016-2145-z. [7] A. Kumar, V. Kumar, and J. Kumar. Surface crack density and recast layer thickness analysis in WEDM process through response surface methodology. Machining Science and Technology, 20, (2), (2016), pp. 201–230. https://doi.org/10.1080/10910344.2016.1165835. [8] M. P. Garg, A. Jain, and G. Bhushan. Multi-objective optimization of process parameters in wire electric discharge machining of Ti-6-2-4-2 alloy. Arabian Journal for Science and Engineer- ing, 39, (2), (2014), pp. 1465–1476. https://doi.org/10.1007/s13369-013-0715-x. [9] A. S. Shivade and V. D. Shinde. Multi-objective optimization in WEDM of D3 tool steel using integrated approach of Taguchi method & Grey relational analysis. Journal of Industrial Engi- neering International, 10, (4), (2014), pp. 149–162. https://doi.org/10.1007/s40092-014-0081-7. [10] D. V. S. S. S. V. Prasad and A. G. Krishna. Empirical modeling and optimization of kerf and wire wear ratio in wire electrical discharge machining. The International Journal of Advanced Experiments and optimization for the WEDM process: A trade-off analysis between surface quality and production rate 121 Manufacturing Technology, 77, (1-4), (2015), pp. 427–441. https://doi.org/10.1007/s00170-014- 6445-8. [11] H. Majumder and K. P. Maity. Predictive analysis on responses in WEDM of titanium grade 6 using general regression neural network (GRNN) and multiple regression analysis (MRA). Silicon, 10, (4), (2018), pp. 1763–1776. https://doi.org/10.1007/s12633-017-9667-1. [12] K. Chopra, A. Payla, and E. K. Mussada. Detailed experimental investigations on machin- ability of EN31 steel by WEDM. Transactions of the Indian Institute of Metals, 72, (4), (2019), pp. 919–927. https://doi.org/10.1007/s12666-018-1552-0. [13] V. Kumar, V. Kumar, and K. K. Jangra. An experimental analysis and optimization of ma- chining rate and surface characteristics in WEDM of Monel-400 using RSM and desir- ability approach. Journal of Industrial Engineering International, 11, (3), (2015), pp. 297–307. https://doi.org/10.1007/s40092-015-0103-0. [14] T. B. Rao and A. G. Krishna. Simultaneous optimization of multiple performance character- istics in WEDM for machining ZC63/SiCp MMC. Advances in Manufacturing, 1, (3), (2013), pp. 265–275. https://doi.org/10.1007/s40436-013-0029-y. [15] A. Kumar, T. Soota, and J. Kumar. Optimisation of wire-cut EDM process parameter by Grey- based response surface methodology. Journal of Industrial Engineering International, 14, (4), (2018), pp. 821–829. https://doi.org/10.1007/s40092-018-0264-8. [16] B. Keshtegar, C. Mert, and O. Kisi. Comparison of four heuristic regression techniques in solar radiation modeling: Kriging method vs RSM, MARS and M5 model tree. Renewable and sustainable energy reviews, 81, (2018), pp. 330–341. https://doi.org/10.1016/j.rser.2017.07.054. [17] A. Azadeh, M. H. Farahani, S. S. Kalantari, and M. Zarrin. Solving a multi-objective open shop problem for multi-processors under preventive maintenance. The Interna- tional Journal of Advanced Manufacturing Technology, 78, (5-8), (2015), pp. 707–722. https://doi.org/10.1007/s00170-014-6660-3. [18] T. T. Nguyen and X. B. Le. Optimization of roller burnishing process using Krig- ing model to improve surface properties. Proceedings of the Institution of Mechanical En- gineers, Part B: Journal of Engineering Manufacture, 233, (12), (2019), pp. 2264–2282. https://doi.org/10.1177/0954405419835295. [19] N. L. Thien, N. T. The, and T. N. Quyet. Manufacturing and evaluation of elastic properties of glass fiber reinforced polymers material. Vietnam Journal of Mechanics, 41, (3), (2019), pp. 243– 255. https://doi.org/10.15625/0866-7136/13721. [20] M. Watson, H. Long, and B. Lu. Investigation of wrinkling failure mechanics in metal spinning by Box-Behnken design of experiments using finite element method. The In- ternational Journal of Advanced Manufacturing Technology, 78, (5-8), (2015), pp. 981–995. https://doi.org/10.1007/s00170-014-6694-6. [21] G. Fu, H. Gong, H. Gao, T. Gu, and Z. Cao. Integrated thermal error modeling of machine tool spindle using a chicken swarm optimization algorithm-based radial basic function neural network. The International Journal of Advanced Manufacturing Technology, 105, (5-6), (2019), pp. 2039–2055. https://doi.org/10.1007/s00170-019-04388-5. [22] G. Z. Quan, Z. H. Zhang, X. Wang, A. Mao, and Y. Xia. Parameter optimization of cool- ing system in U-shape hot stamping mold for high strength steel sheet based on MOPSO. The International Journal of Advanced Manufacturing Technology, 90, (1-4), (2017), pp. 887–906. https://doi.org/10.1007/s00170-016-9446-y. [23] T. T. Huan and H. P. H. Anh. Comparative stable walking gait optimization for small-sized biped robot using meta-heuristic optimization algorithms. Vietnam Journal of Mechanics, 40, (4), (2018), pp. 407–424. https://doi.org/10.15625/0866-7136/12294.

File đính kèm:

experiments_and_optimization_for_the_wedm_process_a_trade_of.pdf

experiments_and_optimization_for_the_wedm_process_a_trade_of.pdf