Effects of indenter radius on mechanical properties and deformation behavior of cu₅₀zr₅₀ metallic glasses in indentation and scratching process

Mechanical properties and deformation

mechanisms are very typical and exceedingly

important factors used to evaluate the characteristics

of the materials. These factors directly influence

the workability of the materials. Therefore, the

investigation and evaluation on the mechanistic

characteristics of materials are very necessary.

Many experimental studies have been conducted

to investigate the mechanical properties and the

deformation mechanism of materials with different

testing methods [1,2]. However, the sizes of the

samples in the experimental studies are still quite

large, in the microscale or macroscale. In order

to assess the properties of materials more deeply

and more accurately, the size of the material has

been reduced to nanoscale. The nanoscale is a

major barrier for the performing of experimental

studies, requiring an alternative method. With

the strong development of computer technology,

molecular dynamics (MD) simulation method is

an appropriate choice in simulating and evaluating

the properties of nanomaterials. MD simulation

method is simple and accurate in conducting the

simulations with the testing processes are diverse

such as shear, compression, indentation, tension,

scratching, cutting, and so on.

In the modern industrial age today, MGs

are widely used [3]. One of the most popular

MGs systems is copper MGs type. Many systems

of copper MGs have been created to study the

structural, dynamic properties such as Cu-Mg [4],

Cu-Zr [5], Cu-Ta [6], Cu-Ni [7]. Among these

copper MGs systems, Cu–Zr MGs has emerged

as the promising immiscible alloy systems for

applications in electrical engineering, magneticsensing, chemical, and structural materials. The

indentation and scratching processes are usually

performed to study the mechanical properties and

deformation mechanisms of materials, however,

the combination of these two processes is scarce,

especially with Cu-Zr MGs.

In this work, the mechanical properties and

deformation mechanisms of Cu

50Zr50 MGs systems

are analyzed and evaluated through the combination

of indentation and scratching processes using MD

simulation. The machining processes are simulated

with different indenter radius. The results will

supply a more penetrating understanding of the

mechanistic abilities of Cu

50Zr50 MGs.

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Trang 6

Tóm tắt nội dung tài liệu: Effects of indenter radius on mechanical properties and deformation behavior of cu₅₀zr₅₀ metallic glasses in indentation and scratching process

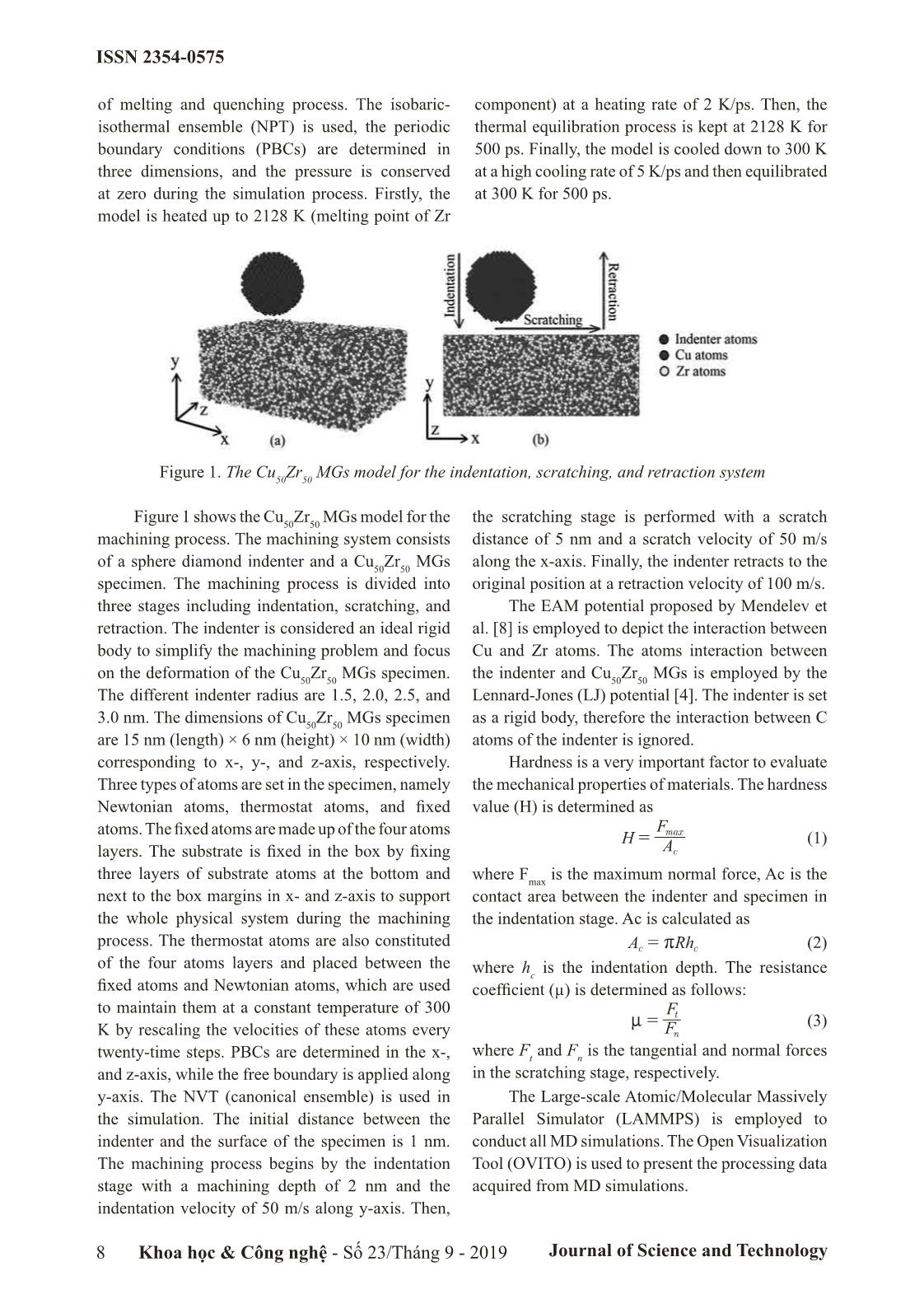

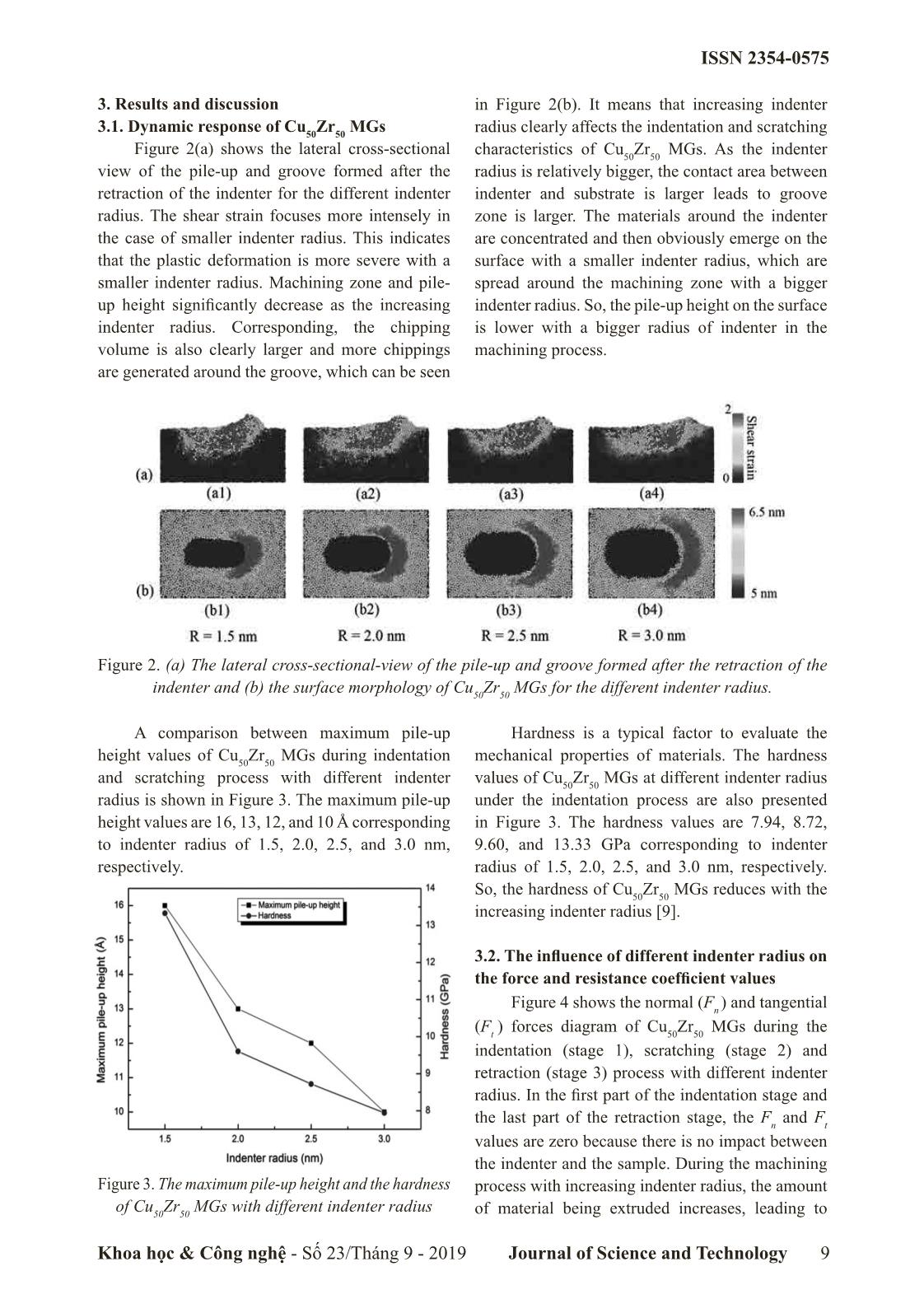

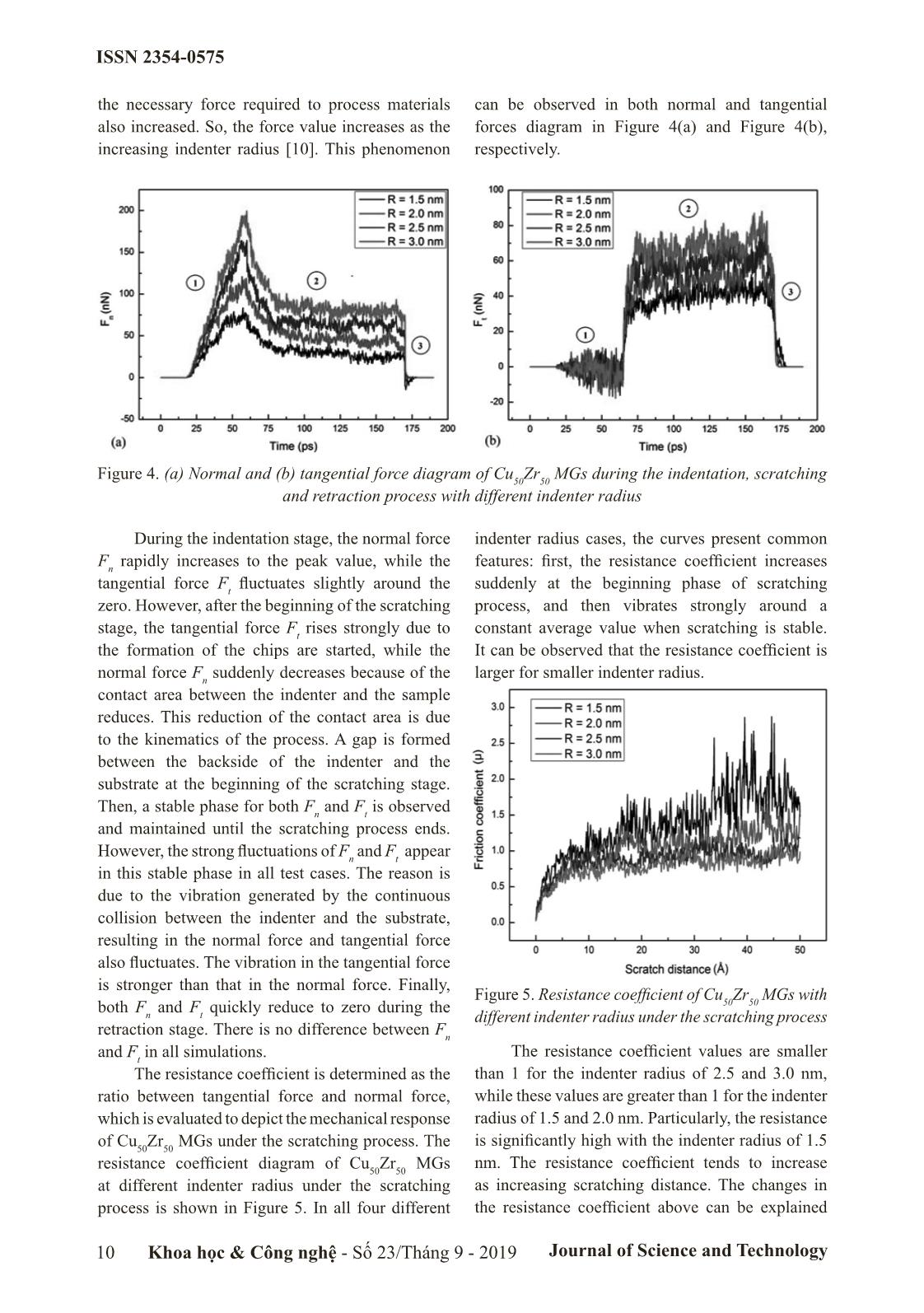

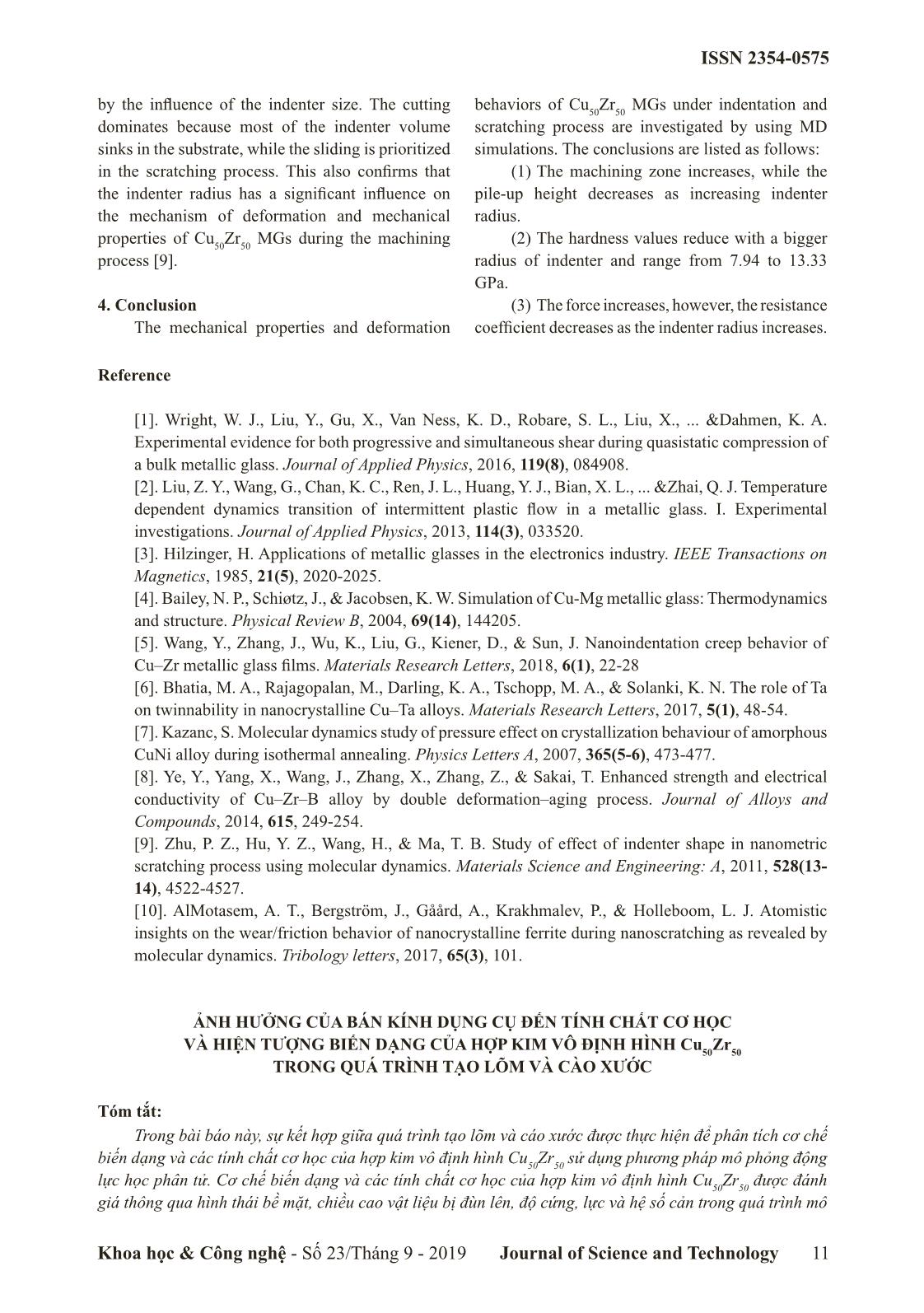

ISSN 2354-0575 EFFECTS OF INDENTER RADIUS ON MECHANICAL PROPERTIES AND DEFORMATION BEHAVIOR OF Cu50Zr50 METALLIC GLASSES IN INDENTATION AND SCRATCHING PROCESS Anh-Son Tran1, Phan Thi Ha Linh1, 2* 1 Hung Yen University of Technology and Education 2 Hanoi University of Science and Technology * Email: halinhcokhi@gmail.com Received: 02/08/2019 Revised: 22/08/2019 Accepted for publication: 10/09/2019 Abstract: In this paper, a combination between the indentation and scratching process was developed to analyze the deformation mechanisms and mechanical properties of Cu50Zr50 metallic glasses (MGs) using molecular dynamics (MD) simulation. The deformation mechanisms and mechanical properties of Cu50Zr50 MGs are appraised through the surface morphology, pile-up height, hardness, machining forces, and resistance coefficient. The influences of different indenter radius are clearly investigated. The results exhibit that the machining zone increases as increasing indenter radius. The pile-up height and hardness reduce with a bigger radius of the indenter. The hardness values range from 7.94 to 13.33 GPa. The forces increase, however, the resistance coefficient decreases as the indenter radius increases. Keywords: Cu50Zr50 MGs; indentation; scratching; resistance coefficient. 1. Introduction In the modern industrial age today, MGs Mechanical properties and deformation are widely used [3]. One of the most popular mechanisms are very typical and exceedingly MGs systems is copper MGs type. Many systems important factors used to evaluate the characteristics of copper MGs have been created to study the of the materials. These factors directly influence structural, dynamic properties such as Cu-Mg [4], the workability of the materials. Therefore, the Cu-Zr [5], Cu-Ta [6], Cu-Ni [7]. Among these investigation and evaluation on the mechanistic copper MGs systems, Cu–Zr MGs has emerged characteristics of materials are very necessary. as the promising immiscible alloy systems for Many experimental studies have been conducted applications in electrical engineering, magnetic- to investigate the mechanical properties and the sensing, chemical, and structural materials. The deformation mechanism of materials with different indentation and scratching processes are usually testing methods [1,2]. However, the sizes of the performed to study the mechanical properties and samples in the experimental studies are still quite deformation mechanisms of materials, however, large, in the microscale or macroscale. In order the combination of these two processes is scarce, to assess the properties of materials more deeply especially with Cu-Zr MGs. and more accurately, the size of the material has In this work, the mechanical properties and been reduced to nanoscale. The nanoscale is a deformation mechanisms of Cu50Zr50 MGs systems major barrier for the performing of experimental are analyzed and evaluated through the combination studies, requiring an alternative method. With of indentation and scratching processes using MD the strong development of computer technology, simulation. The machining processes are simulated molecular dynamics (MD) simulation method is with different indenter radius. The results will an appropriate choice in simulating and evaluating supply a more penetrating understanding of the the properties of nanomaterials. MD simulation mechanistic abilities of Cu50Zr50 MGs. method is simple and accurate in conducting the simulations with the testing processes are diverse 2. Methodology such as shear, compression, indentation, tension, The structure of a Cu50Zr50 MGs model at scratching, cutting, and so on. room temperature is created from the simulation Khoa học & Công nghệ - Số 23/Tháng 9 - 2019 Journal of Science and Technology 7 ISSN 2354-0575 of melting and quenching process. The isobaric- component) at a heating rate of 2 K/ps. Then, the isothermal ensemble (NPT) is used, the periodic thermal equilibration process is kept at 2128 K for boundary conditions (PBCs) are determined in 500 ps. Finally, the model is cooled down to 300 K three dimensions, and the pressure is conserved at a high cooling rate of 5 K/ps and then equilibrated at zero during the simulation process. Firstly, the at 300 K for 500 ps. model is heated up to 2128 K (melting point of Zr Figure 1. The Cu50Zr50 MGs model for the indentation, scratching, and retraction system Figure 1 shows the Cu50Zr50 MGs model for the the scratching stage is performed with a scratch machining process. The machining system consists distance of 5 nm and a scratch velocity of 50 m/s of a sphere diamond indenter and a Cu50Zr50 MGs along the x-axis. Finally, the indenter retracts to the specimen. The machining process is divided into original position at a retraction velocity of 100 m/s. three stages including indentation, scratching, and The EAM potential proposed by Mendelev et retraction. The indenter is considered an ideal rigid al. [8] is employed to depict the interaction between body to simplify the machining problem and focus Cu and Zr atoms. The atoms interaction between on the deformation of the Cu50Zr50 MGs specimen. the indenter and Cu50Zr50 MGs is employed by the The different indenter radius are 1.5, 2.0, 2.5, and Lennard-Jones (LJ) potential [4]. The indenter is set 3.0 nm. The dimensions of Cu50Zr50 MGs specimen as a rigid body, therefore the interaction between C are 15 nm (length) × 6 nm (height) × 10 nm (width) atoms of the indenter is ignored. corresponding to x-, y-, and z-axis, respectively. Hardness is a very important factor to evaluate Three types of atoms are set in the specimen, namely the mechanical properties of materials. The hardness Newtonian atoms, thermostat atoms, and fixed value (H) is determined as atoms. The fixed atoms are made up of the four atoms Fmax H = (1) layers. The substrate is fixed in the box by fixing Ac three layers of substrate atoms at the bottom and where Fmax is the maximum normal force, Ac is the next to the box margins in x- and z-axis to support contact area between the indenter and specimen in the whole physical system during the machining the indentation stage. Ac is calculated as process. The thermostat atoms are also constituted ARcc= r h (2) of the four atoms layers and placed between the where hc is the indentation depth. The resistance fixed atoms and Newtonian atoms, which are used coefficient (µ) is determined as follows: to maintain them at a constant temperature of 300 F n = t (3) K by rescaling the velocities of these atoms every Fn twenty-time steps. PBCs are determined in the x-, where Ft and Fn is the tangential and normal forces and z-axis, while the free boundary is applied along in the scratching stage, respectively. y-axis. The NVT (canonical ensemble) is used in The Large-scale Atomic/Molecular Massively the simulation. The initial distance between the Parallel Simulator (LAMMPS) is employed to indenter and the surface of the specimen is 1 nm. conduct all MD simulations. The Open Visualization The machining process begins by the indentation Tool (OVITO) is used to present the processing data stage with a machining depth of 2 nm and the acquired from MD simulations. indentation velocity of 50 m/s along y-axis. Then, 8 Khoa học & Công nghệ - Số 23/Tháng 9 - 2019 Journal of Science and Technology ISSN 2354-0575 3. Results and discussion in Figure 2(b). It means that increasing indenter 3.1. Dynamic response of Cu50Zr50 MGs radius clearly affects the indentation and scratching Figure 2(a) shows the lateral cross-sectional characteristics of Cu50Zr50 MGs. As the indenter view of the pile-up and groove formed after the radius is relatively bigger, the contact area between retraction of the indenter for the different indenter indenter and substrate is larger leads to groove radius. The shear strain focuses more intensely in zone is larger. The materials around the indenter the case of smaller indenter radius. This indicates are concentrated and then obviously emerge on the that the plastic deformation is more severe with a surface with a smaller indenter radius, which are smaller indenter radius. Machining zone and pile- spread around the machining zone with a bigger up height significantly decrease as the increasing indenter radius. So, the pile-up height on the surface indenter radius. Corresponding, the chipping is lower with a bigger radius of indenter in the volume is also clearly larger and more chippings machining process. are generated around the groove, which can be seen Figure 2. (a) The lateral cross-sectional-view of the pile-up and groove formed after the retraction of the indenter and (b) the surface morphology of Cu50Zr50 MGs for the different indenter radius. A comparison between maximum pile-up Hardness is a typical factor to evaluate the height values of Cu50Zr50 MGs during indentation mechanical properties of materials. The hardness and scratching process with different indenter values of Cu50Zr50 MGs at different indenter radius radius is shown in Figure 3. The maximum pile-up under the indentation process are also presented height values are 16, 13, 12, and 10 Å corresponding in Figure 3. The hardness values are 7.94, 8.72, to indenter radius of 1.5, 2.0, 2.5, and 3.0 nm, 9.60, and 13.33 GPa corresponding to indenter respectively. radius of 1.5, 2.0, 2.5, and 3.0 nm, respectively. So, the hardness of Cu50Zr50 MGs reduces with the increasing indenter radius [9]. 3.2. The influence of different indenter radius on the force and resistance coefficient values Figure 4 shows the normal (Fn ) and tangential (Ft ) forces diagram of Cu50Zr50 MGs during the indentation (stage 1), scratching (stage 2) and retraction (stage 3) process with different indenter radius. In the first part of the indentation stage and the last part of the retraction stage, the Fn and Ft values are zero because there is no impact between the indenter and the sample. During the machining Figure 3. The maximum pile-up height and the hardness process with increasing indenter radius, the amount of Cu50Zr50 MGs with different indenter radius of material being extruded increases, leading to Khoa học & Công nghệ - Số 23/Tháng 9 - 2019 Journal of Science and Technology 9 ISSN 2354-0575 the necessary force required to process materials can be observed in both normal and tangential also increased. So, the force value increases as the forces diagram in Figure 4(a) and Figure 4(b), increasing indenter radius [10]. This phenomenon respectively. Figure 4. (a) Normal and (b) tangential force diagram of Cu50Zr50 MGs during the indentation, scratching and retraction process with different indenter radius During the indentation stage, the normal force indenter radius cases, the curves present common Fn rapidly increases to the peak value, while the features: first, the resistance coefficient increases tangential force Ft fluctuates slightly around the suddenly at the beginning phase of scratching zero. However, after the beginning of the scratching process, and then vibrates strongly around a stage, the tangential force Ft rises strongly due to constant average value when scratching is stable. the formation of the chips are started, while the It can be observed that the resistance coefficient is normal force Fn suddenly decreases because of the larger for smaller indenter radius. contact area between the indenter and the sample reduces. This reduction of the contact area is due to the kinematics of the process. A gap is formed between the backside of the indenter and the substrate at the beginning of the scratching stage. Then, a stable phase for both Fn and Ft is observed and maintained until the scratching process ends. However, the strong fluctuations ofF n and Ft appear in this stable phase in all test cases. The reason is due to the vibration generated by the continuous collision between the indenter and the substrate, resulting in the normal force and tangential force also fluctuates. The vibration in the tangential force is stronger than that in the normal force. Finally, Figure 5. Resistance coefficient of Cu Zr MGs with both F and F quickly reduce to zero during the 50 50 n t different indenter radius under the scratching process retraction stage. There is no difference between Fn and Ft in all simulations. The resistance coefficient values are smaller The resistance coefficient is determined as the than 1 for the indenter radius of 2.5 and 3.0 nm, ratio between tangential force and normal force, while these values are greater than 1 for the indenter which is evaluated to depict the mechanical response radius of 1.5 and 2.0 nm. Particularly, the resistance of Cu50Zr50 MGs under the scratching process. The is significantly high with the indenter radius of 1.5 resistance coefficient diagram of50 Cu Zr50 MGs nm. The resistance coefficient tends to increase at different indenter radius under the scratching as increasing scratching distance. The changes in process is shown in Figure 5. In all four different the resistance coefficient above can be explained 10 Khoa học & Công nghệ - Số 23/Tháng 9 - 2019 Journal of Science and Technology ISSN 2354-0575 by the influence of the indenter size. The cutting behaviors of Cu50Zr50 MGs under indentation and dominates because most of the indenter volume scratching process are investigated by using MD sinks in the substrate, while the sliding is prioritized simulations. The conclusions are listed as follows: in the scratching process. This also confirms that (1) The machining zone increases, while the the indenter radius has a significant influence on pile-up height decreases as increasing indenter the mechanism of deformation and mechanical radius. properties of Cu50Zr50 MGs during the machining (2) The hardness values reduce with a bigger process [9]. radius of indenter and range from 7.94 to 13.33 GPa. 4. Conclusion (3) The force increases, however, the resistance The mechanical properties and deformation coefficient decreases as the indenter radius increases. Reference [1]. Wright, W. J., Liu, Y., Gu, X., Van Ness, K. D., Robare, S. L., Liu, X., ... &Dahmen, K. A. Experimental evidence for both progressive and simultaneous shear during quasistatic compression of a bulk metallic glass. Journal of Applied Physics, 2016, 119(8), 084908. [2]. Liu, Z. Y., Wang, G., Chan, K. C., Ren, J. L., Huang, Y. J., Bian, X. L., ... &Zhai, Q. J. Temperature dependent dynamics transition of intermittent plastic flow in a metallic glass. I. Experimental investigations. Journal of Applied Physics, 2013, 114(3), 033520. [3]. Hilzinger, H. Applications of metallic glasses in the electronics industry. IEEE Transactions on Magnetics, 1985, 21(5), 2020-2025. [4]. Bailey, N. P., Schiøtz, J., & Jacobsen, K. W. Simulation of Cu-Mg metallic glass: Thermodynamics and structure. Physical Review B, 2004, 69(14), 144205. [5]. Wang, Y., Zhang, J., Wu, K., Liu, G., Kiener, D., & Sun, J. Nanoindentation creep behavior of Cu–Zr metallic glass films.Materials Research Letters, 2018, 6(1), 22-28 [6]. Bhatia, M. A., Rajagopalan, M., Darling, K. A., Tschopp, M. A., & Solanki, K. N. The role of Ta on twinnability in nanocrystalline Cu–Ta alloys. Materials Research Letters, 2017, 5(1), 48-54. [7]. Kazanc, S. Molecular dynamics study of pressure effect on crystallization behaviour of amorphous CuNi alloy during isothermal annealing. Physics Letters A, 2007, 365(5-6), 473-477. [8]. Ye, Y., Yang, X., Wang, J., Zhang, X., Zhang, Z., & Sakai, T. Enhanced strength and electrical conductivity of Cu–Zr–B alloy by double deformation–aging process. Journal of Alloys and Compounds, 2014, 615, 249-254. [9]. Zhu, P. Z., Hu, Y. Z., Wang, H., & Ma, T. B. Study of effect of indenter shape in nanometric scratching process using molecular dynamics. Materials Science and Engineering: A, 2011, 528(13- 14), 4522-4527. [10]. AlMotasem, A. T., Bergström, J., Gåård, A., Krakhmalev, P., & Holleboom, L. J. Atomistic insights on the wear/friction behavior of nanocrystalline ferrite during nanoscratching as revealed by molecular dynamics. Tribology letters, 2017, 65(3), 101. ẢNH HƯỞNG CỦA BÁN KÍNH DỤNG CỤ ĐẾN TÍNH CHẤT CƠ HỌC VÀ HIỆN TƯỢNG BIẾN DẠNG CỦA HỢP KIM VÔ ĐỊNH HÌNH Cu50Zr50 TRONG QUÁ TRÌNH TẠO LÕM VÀ CÀO XƯỚC Tóm tắt: Trong bài báo này, sự kết hợp giữa quá trình tạo lõm và cáo xước được thực hiện để phân tích cơ chế biến dạng và các tính chất cơ học của hợp kim vô định hình Cu50Zr50 sử dụng phương pháp mô phỏng động lực học phân tử. Cơ chế biến dạng và các tính chất cơ học của hợp kim vô định hình Cu50Zr50 được đánh giá thông qua hình thái bề mặt, chiều cao vật liệu bị đùn lên, độ cứng, lực và hệ số cản trong quá trình mô Khoa học & Công nghệ - Số 23/Tháng 9 - 2019 Journal of Science and Technology 11 ISSN 2354-0575 phỏng. Các ảnh hưởng của giá trị bán kính dụng cụ khác nhau được phân tích rất rõ ràng. Kết quả cho thấy rằng vùng biến dạng tăng lên với bán kính dụng cụ lớn hơn. Chiều cao vật liệu bị đùn lên và độ cứng giảm khi bán kính dụng cụ tăng lên. Giá trị độ cứng đạt được trong khoảng từ 7.94 đến 13.33 GPa. Lực tác dụng tăng lên, tuy nhiên, hệ số cản giảm xuống khi bán kính dụng cụ tăng lên. Từ khóa: Hợp kim vô định hình Cu50Zr50 ; quá trình tạo lõm; quá trình cào xước; hệ số cản. 12 Khoa học & Công nghệ - Số 23/Tháng 9 - 2019 Journal of Science and Technology

File đính kèm:

effects_of_indenter_radius_on_mechanical_properties_and_defo.pdf

effects_of_indenter_radius_on_mechanical_properties_and_defo.pdf