Effect of x-ray irradiation on the physical properties of polyvinyl chloride

In this investigation, the MBR-1618R-BE (Hitachi, Japan) machine is used to generate X-rays.

Low energy X-rays vary with energies 0.5 kGy, 1.0 kGy, 5 kGy, and 10 kGy radiation level, and time

is 7.83 minutes, 15.75 minutes, 78.73 minutes, and 157.46 minutes respectively. This research

investigates the effect of X-ray irradiation doses on the physico-chemical properties of PVC. PVC

samples before and after irradiation are transferred in liquid form by using microwave digestion

Mars 6 and then X-ray Powder Diffraction (XRD) to determine the structural morphological

characteristics of PVC samples. XRD results show that the change of PVC polymer structure depends

significantly on a radiation dose. At the diffraction peaks of angles 17.670 and 26.170, the count at

the peak region decreases sharply at a low projection dose at 0.5 kGy and 1 kGy, and in this region,

the structural change according to the projection dose takes the form of a linear superlative function.

With higher energy from 1 kGy to 10 kGy, the effect on the PVC structure changes gradually. The

study results show that the application of radiation in PVC destruction can be applied to reduce the

decomposition time. It also results in less waste disposal to the environment.

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Trang 6

Trang 7

Trang 8

Tóm tắt nội dung tài liệu: Effect of x-ray irradiation on the physical properties of polyvinyl chloride

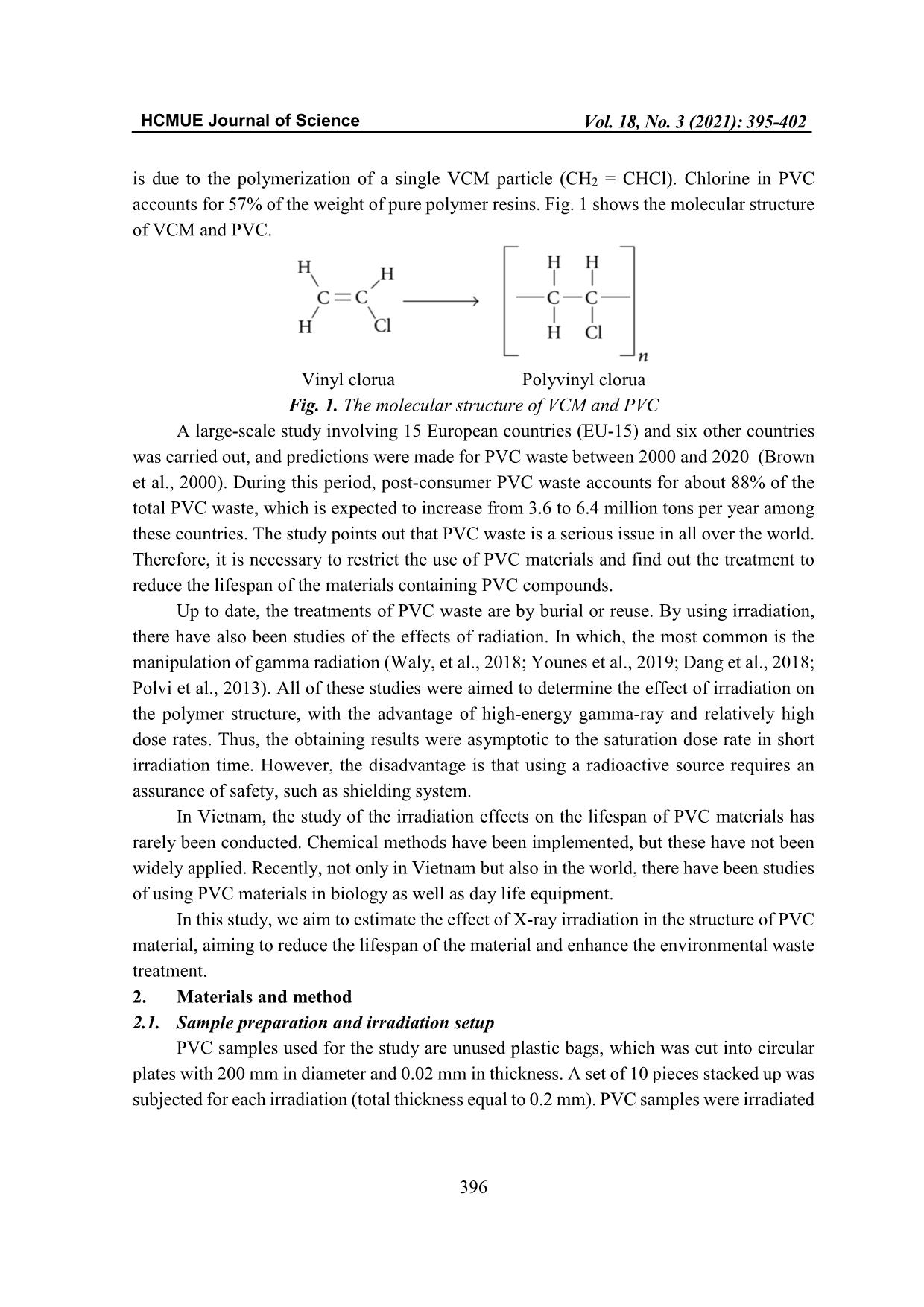

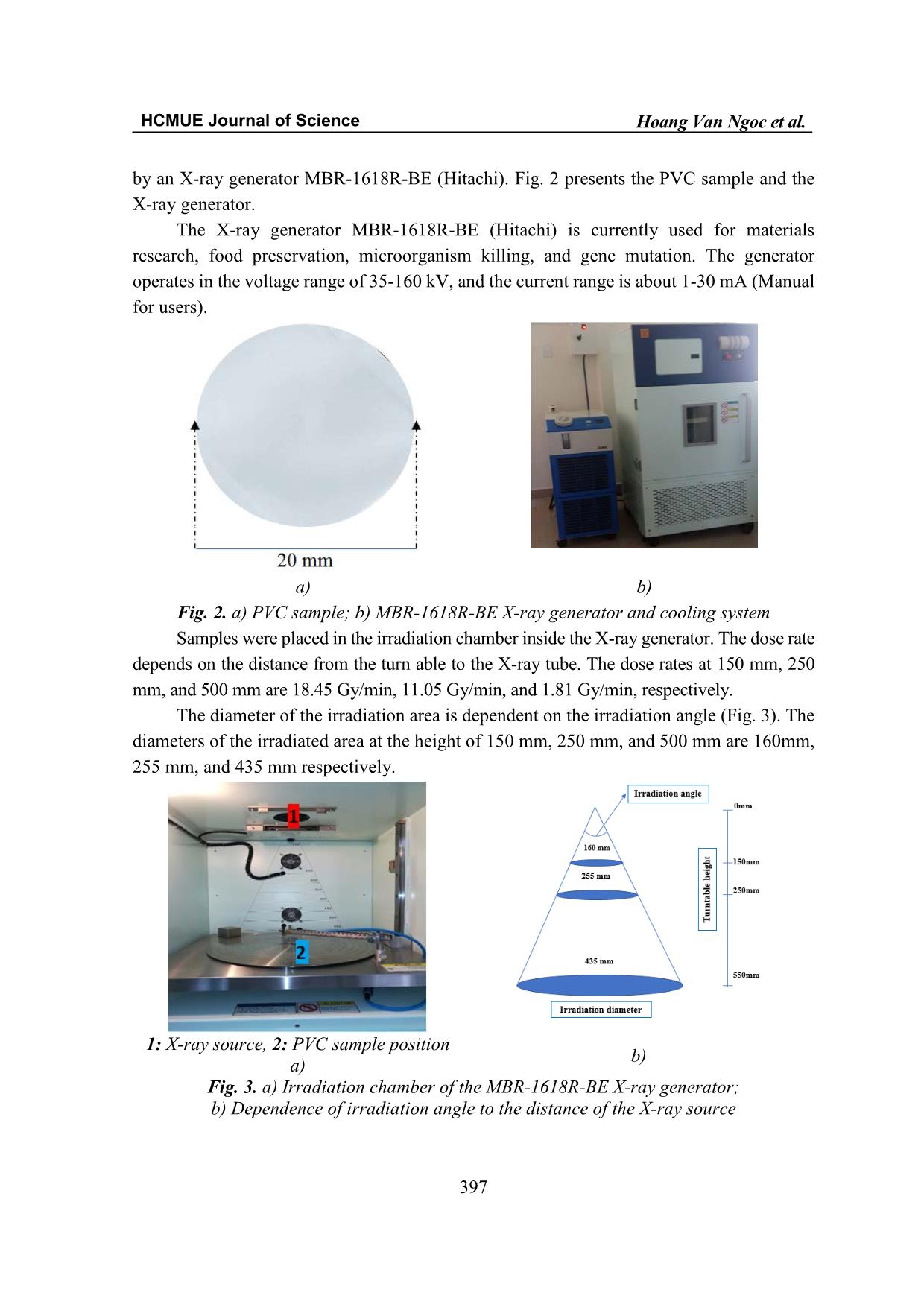

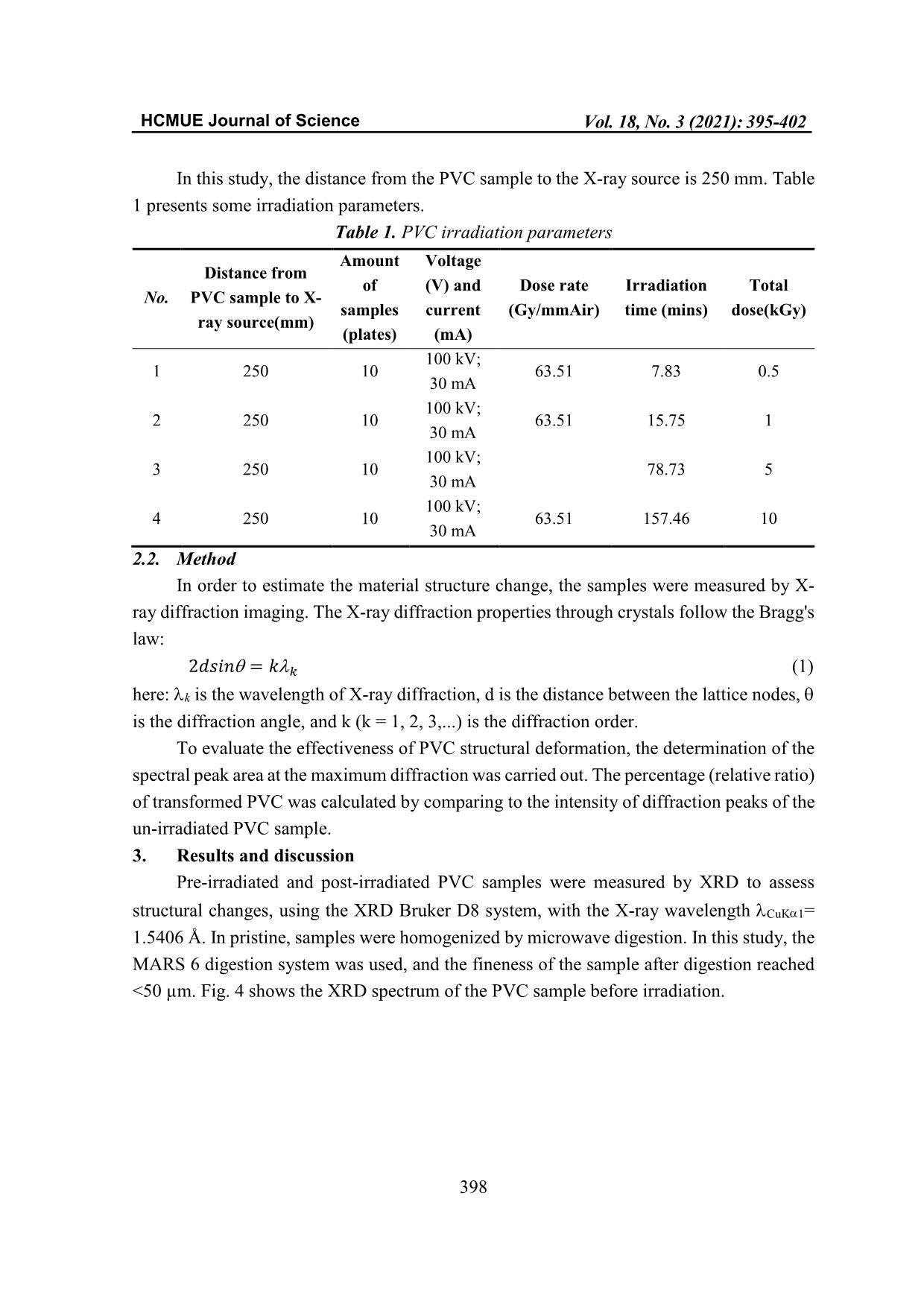

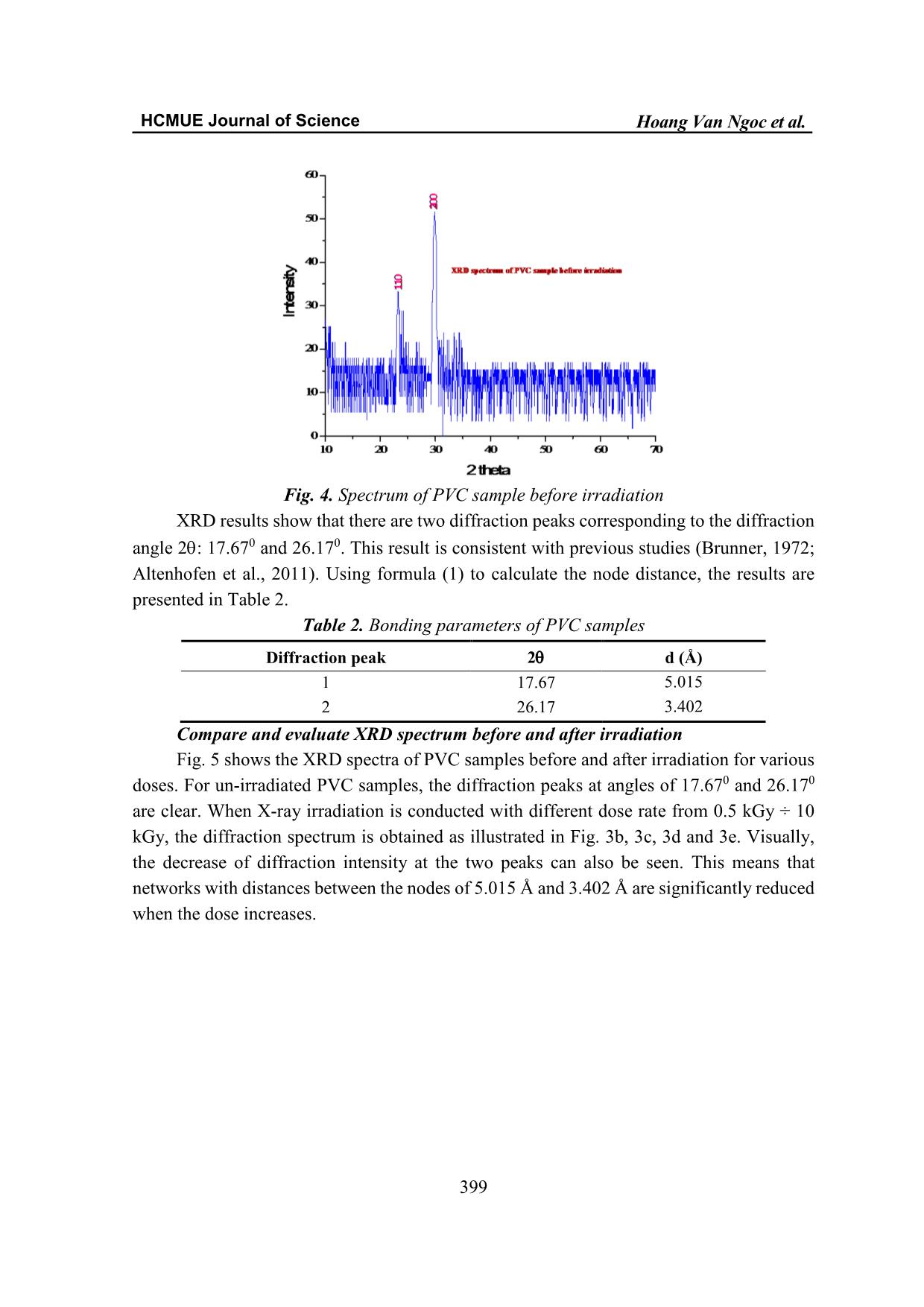

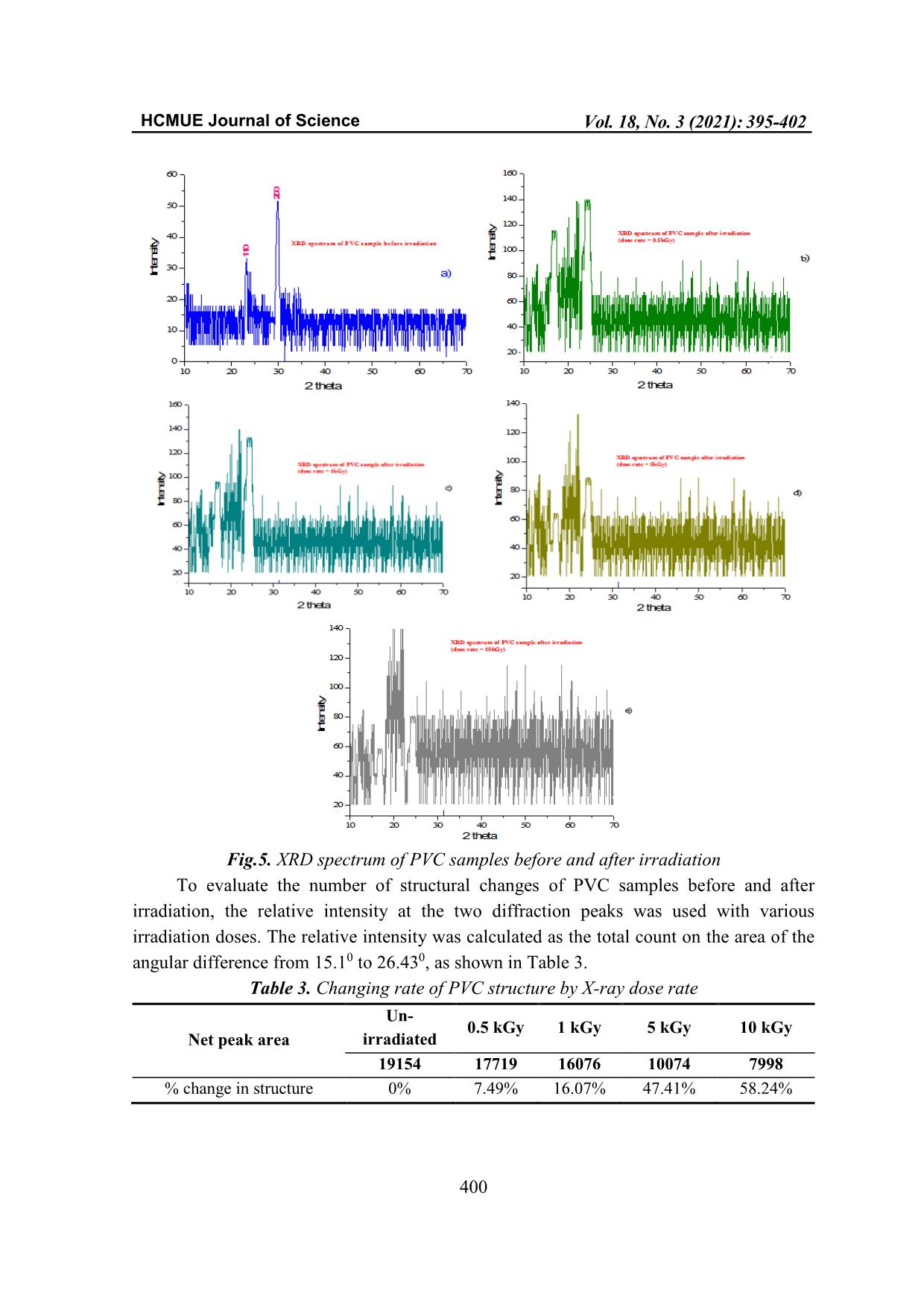

TẠP CHÍ KHOA HỌC HO CHI MINH CITY UNIVERSITY OF EDUCATION TRƯỜNG ĐẠI HỌC SƯ PHẠM TP HỒ CHÍ MINH JOURNAL OF SCIENCE Tập 18, Số 3 (2021): 395-402 Vol. 18, No. 3 (2021): 395-402 ISSN: 1859-3100 Website: Research Article* EFFECT OF X-RAY IRRADIATION ON THE PHYSICAL PROPERTIES OF POLYVINYL CHLORIDE Hoang Van Ngoc1, Nguyen An Son2*, Le Viet Huy2, Nguyen Thi Minh Sang2, Le Thi Thanh Tran2, Do Thi Le2 and Nguyen Thi Phuc2 1Thu Dau Mot University, Vietnam 2Dalat University, Vietnam *Corresponding author: Nguyen An Son – Email: sonna@dlu.edu.vn Received: October 17, 2020; Revised: December 23, 2020; Accepted: December 30, 2020 ABSTRACT In this investigation, the MBR-1618R-BE (Hitachi, Japan) machine is used to generate X-rays. Low energy X-rays vary with energies 0.5 kGy, 1.0 kGy, 5 kGy, and 10 kGy radiation level, and time is 7.83 minutes, 15.75 minutes, 78.73 minutes, and 157.46 minutes respectively. This research investigates the effect of X-ray irradiation doses on the physico-chemical properties of PVC. PVC samples before and after irradiation are transferred in liquid form by using microwave digestion Mars 6 and then X-ray Powder Diffraction (XRD) to determine the structural morphological characteristics of PVC samples. XRD results show that the change of PVC polymer structure depends significantly on a radiation dose. At the diffraction peaks of angles 17.670 and 26.170, the count at the peak region decreases sharply at a low projection dose at 0.5 kGy and 1 kGy, and in this region, the structural change according to the projection dose takes the form of a linear superlative function. With higher energy from 1 kGy to 10 kGy, the effect on the PVC structure changes gradually. The study results show that the application of radiation in PVC destruction can be applied to reduce the decomposition time. It also results in less waste disposal to the environment. Keywords: Polyvinyl Chloride (PVC); X-ray irradiation; X-ray dose; XRD 1. Introduction In recent years, Polyvinyl Chloride (PVC) has become one of the most widely used resins. Such plastic materials as packaging, home furnishings, children's toys, auto parts, construction materials, and hospital supplies are made from PVC. PVC is flexible, easy to manipulate, and cheap. However, PVC plastic is one of the biggest pollutants for the environment. PVC has a lifespan of more than 50 years when buried underground. PVC was firstly produced in 1872 by Baumann et al. (1872). When the tube containing vinyl chloride (VCM) was exposed under sunlight, it was resulted in a white powder, which Cite this article as: Hoang Van Ngoc, Nguyen An Son, Le Viet Huy, Nguyen Thi Minh Sang, Le Thi Thanh Tran, Do Thi Le, & Nguyen Thi Phuc (2021). Effect of X-ray irradiation on the physical properties of Polyvinyl Chloride. Ho Chi Minh City University of Education Journal of Science, 18(3), 395-402. 395 HCMUE Journal of Science Vol. 18, No. 3 (2021): 395-402 is due to the polymerization of a single VCM particle (CH2 = CHCl). Chlorine in PVC accounts for 57% of the weight of pure polymer resins. Fig. 1 shows the molecular structure of VCM and PVC. Vinyl clorua Polyvinyl clorua Fig. 1. The molecular structure of VCM and PVC A large-scale study involving 15 European countries (EU-15) and six other countries was carried out, and predictions were made for PVC waste between 2000 and 2020 (Brown et al., 2000). During this period, post-consumer PVC waste accounts for about 88% of the total PVC waste, which is expected to increase from 3.6 to 6.4 million tons per year among these countries. The study points out that PVC waste is a serious issue in all over the world. Therefore, it is necessary to restrict the use of PVC materials and find out the treatment to reduce the lifespan of the materials containing PVC compounds. Up to date, the treatments of PVC waste are by burial or reuse. By using irradiation, there have also been studies of the effects of radiation. In which, the most common is the manipulation of gamma radiation (Waly, et al., 2018; Younes et al., 2019; Dang et al., 2018; Polvi et al., 2013). All of these studies were aimed to determine the effect of irradiation on the polymer structure, with the advantage of high-energy gamma-ray and relatively high dose rates. Thus, the obtaining results were asymptotic to the saturation dose rate in short irradiation time. However, the disadvantage is that using a radioactive source requires an assurance of safety, such as shielding system. In Vietnam, the study of the irradiation effects on the lifespan of PVC materials has rarely been conducted. Chemical methods have been implemented, but these have not been widely applied. Recently, not only in Vietnam but also in the world, there have been studies of using PVC materials in biology as well as day life equipment. In this study, we aim to estimate the effect of X-ray irradiation in the structure of PVC material, aiming to reduce the lifespan of the material and enhance the environmental waste treatment. 2. Materials and method 2.1. Sample preparation and irradiation setup PVC samples used for the study are unused plastic bags, which was cut into circular plates with 200 mm in diameter and 0.02 mm in thickness. A set of 10 pieces stacked up was subjected for each irradiation (total thickness equal to 0.2 mm). PVC samples were irradiated 396 HCMUE Journal of Science Hoang Van Ngoc et al. by an X-ray generator MBR-1618R-BE (Hitachi). Fig. 2 presents the PVC sample and the X-ray generator. The X-ray generator MBR-1618R-BE (Hitachi) is currently used for materials research, food preservation, microorganism killing, and gene mutation. The generator operates in the voltage range of 35-160 kV, and the current range is about 1-30 mA (Manual for users). a) b) Fig. 2. a) PVC sample; b) MBR-1618R-BE X-ray generator and cooling system Samples were placed in the irradiation chamber inside the X-ray generator. The dose rate depends on the distance from the turn able to the X-ray tube. The dose rates at 150 mm, 250 mm, and 500 mm are 18.45 Gy/min, 11.05 Gy/min, and 1.81 Gy/min, respectively. The diameter of the irradiation area is dependent on the irradiation angle (Fig. 3). The diameters of the irradiated area at the height of 150 mm, 250 mm, and 500 mm are 160mm, 255 mm, and 435 mm respectively. 1: X-ray source, 2: PVC sample position b) a) Fig. 3. a) Irradiation chamber of the MBR-1618R-BE X-ray generator; b) Dependence of irradiation angle to the distance of the X-ray source 397 HCMUE Journal of Science Vol. 18, No. 3 (2021): 395-402 In this study, the distance from the PVC sample to the X-ray source is 250 mm. Table 1 presents some irradiation parameters. Table 1. PVC irradiation parameters Amount Voltage Distance from of (V) and Dose rate Irradiation Total No. PVC sample to X- samples current (Gy/mmAir) time (mins) dose(kGy) ray source(mm) (plates) (mA) 100 kV; 1 250 10 63.51 7.83 0.5 30 mA 100 kV; 2 250 10 63.51 15.75 1 30 mA 100 kV; 3 250 10 78.73 5 30 mA 100 kV; 4 250 10 63.51 157.46 10 30 mA 2.2. Method In order to estimate the material structure change, the samples were measured by X- ray diffraction imaging. The X-ray diffraction properties through crystals follow the Bragg's law: 2 θ = λ (1) here: λk is the wavelength of X-ray diffraction, d is the distance between the lattice nodes, θ 𝑑𝑑𝑑𝑑𝑑𝑑𝑑𝑑 𝑘𝑘 𝑘𝑘 is the diffraction angle, and k (k = 1, 2, 3,...) is the diffraction order. To evaluate the effectiveness of PVC structural deformation, the determination of the spectral peak area at the maximum diffraction was carried out. The percentage (relative ratio) of transformed PVC was calculated by comparing to the intensity of diffraction peaks of the un-irradiated PVC sample. 3. Results and discussion Pre-irradiated and post-irradiated PVC samples were measured by XRD to assess structural changes, using the XRD Bruker D8 system, with the X-ray wavelength λCuKα1= 1.5406 Å. In pristine, samples were homogenized by microwave digestion. In this study, the MARS 6 digestion system was used, and the fineness of the sample after digestion reached <50 µm. Fig. 4 shows the XRD spectrum of the PVC sample before irradiation. 398 HCMUE Journal of Science Hoang Van Ngoc et al. Fig. 4. Spectrum of PVC sample before irradiation XRD results show that there are two diffraction peaks corresponding to the diffraction angle 2θ: 17.670 and 26.170. This result is consistent with previous studies (Brunner, 1972; Altenhofen et al., 2011). Using formula (1) to calculate the node distance, the results are presented in Table 2. Table 2. Bonding parameters of PVC samples Diffraction peak 2θ d (Å) 1 17.67 5.015 2 26.17 3.402 Compare and evaluate XRD spectrum before and after irradiation Fig. 5 shows the XRD spectra of PVC samples before and after irradiation for various doses. For un-irradiated PVC samples, the diffraction peaks at angles of 17.670 and 26.170 are clear. When X-ray irradiation is conducted with different dose rate from 0.5 kGy ÷ 10 kGy, the diffraction spectrum is obtained as illustrated in Fig. 3b, 3c, 3d and 3e. Visually, the decrease of diffraction intensity at the two peaks can also be seen. This means that networks with distances between the nodes of 5.015 Å and 3.402 Å are significantly reduced when the dose increases. 399 HCMUE Journal of Science Vol. 18, No. 3 (2021): 395-402 Fig.5. XRD spectrum of PVC samples before and after irradiation To evaluate the number of structural changes of PVC samples before and after irradiation, the relative intensity at the two diffraction peaks was used with various irradiation doses. The relative intensity was calculated as the total count on the area of the angular difference from 15.10 to 26.430, as shown in Table 3. Table 3. Changing rate of PVC structure by X-ray dose rate Un- 0.5 kGy 1 kGy 5 kGy 10 kGy Net peak area irradiated 19154 17719 16076 10074 7998 % change in structure 0% 7.49% 16.07% 47.41% 58.24% 400 HCMUE Journal of Science Hoang Van Ngoc et al. The results show that the changing rate of PVC structure is dependent on the irradiation dose. At low doses, there are less variation. However, the change of PVC structure is not followed the linearity rule, for example, when the dose was increased from 0.5 kGy to 1 kGy (increased by 2 times), the PVC structure changes increased by ~ 2.145 times. However, when the dose was continuously increased from 1 kGy to 5 kGy and 10 kGy (5 times and 10 times, respectively), the structure of PVC changed 2.95 times and 3.624 times, respectively. 4. Conclusion In this study, the modification in PVC structure was implemented by using low-energy X-ray radiation, with the range of 0.5 kGy to 10 kGy. The diffraction imaging was applied to assess the changes in PVC structure with respect to irradiation dose. From the XRD results, there was a sharp change in PVC structure in the dynamic survey dose range. This result can be applied to polymer waste treatment, by reducing its decomposition time, thus contributing for environmental protection. The study has met two main objectives: - Study of irradiation effect on PVC polymers: the breakdown of polymer bonding structure using low energy X-rays. - Quantitative assessment of the degree of irradiation effect on the structure of PVC. In addition, the experimental data with mean dose rate and irradiation time of X-ray irradiation will also bring economic benefits to the future commercial irradiation process. Conflict of Interest: Authors have no conflict of interest to declare. Acknowledgement: The authors wish to thank Thu Dau Mot University for the fund to this work. We also wish to thank the Faculty of Physics and Nuclear Engineering – Dalat University, for the operation of X-rays irradiator MBR-1618R-BE (Hitachi Power Solutions, Japan). REFERENCES Altenhofen da Silva, M., Adeodato Vieira, M. G., Gomes Maçumoto, A. C., & Beppu, M. M. (2011). Polyvinylchloride (PVC) and natural rubber films plasticized with a natural polymeric plasticizer obtained through polyesterification of rice fatty acid. Polymer Testing, 30(5), 478- 484. https://doi.org/10.1016/j.polymertesting.2011.03.008 Baumann, E., Ann (1872). Ueber einige Vinylverbindungen. In: Ann. Chem. Pharm., 163(3), 308-322 Brown, K. A., Holland, Boyd, M. R., Thresh, S., Jones, H., & Ogilvie, S. M. (2000). Economic Evaluation of PVC Waste Management. AEA Technology Brunner, A. J. (1972). X-ray diffraction pattern of poly(vinyl chloride). Journal of Polymer Science Part B: Polymer Letters, 10(5), 379-383. https://doi.org/10.1002/pol.1972.110100509 Dang, W., Liu, J., Huang, X., Liang, J., Wang, C., Miao, P., An, Y., & Wang, X. (2018). Effects of γ-ray irradiation on the radial structure heterogeneity in Polyacrylonitrile fibers during thermal stabilization. Polymers, 10(9), 943. https://doi.org/10.3390/polym10090943 401 HCMUE Journal of Science Vol. 18, No. 3 (2021): 395-402 Manual for user “Operation manual X-rays irradiation system MBR-1618R-BE” Polvi, J., & Nordlund, K. (2013). Irradiation effects in high-density polyethylene. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms, 312, 54-59. https://doi.org/10.1016/j.nimb.2013.07.002 Waly, S., Shehata, M., & Mahmoud, H. (2018). Effect of gamma irradiation on the physical and chemical properties of copper-poly vinyl Pyrolidone composite films. Arab Journal of Nuclear Sciences and Applications, 51(4), 1-10. https://doi.org/10.21608/ajnsa.2018.13517 Younes, M., Abdel-Rahman H. A., & Hamed, E. (2019). Effect of Gamma-Irradiation on Properties of Polymer/Fibrous/Nanomaterials Particleboard Composites, J. Chem. Soc. Pak., 41(6), 966-974. ẢNH HƯỞNG CỦA CHIẾU XẠ TIA X LÊN CÁC TÍNH CHẤT VẬT LÍ CỦA VẬT LIỆU POLYVINYL CHLORIDE Hoàng Văn Ngọc1, Nguyễn An Sơn2*, Lê Viết Huy2, Nguyễn Thị Minh Sang2, Lê Thị Thanh Trân2, Đỗ Thị Lệ2, Nguyễn Thị Phúc2 1Trường Đại học Thủ Dầu Một, Việt Nam 2Trường Đại học Đà Lạt, Việt Nam *Tác giả liên hệ: Nguyễn An Sơn – Email: sonna@dlu.edu.vn Ngày nhận bài: 17-10-2020; ngày nhận bài sửa: 23-12-2020, ngày chấp nhận đăng: 30-12-2020 TÓM TẮT Trong nghiên cứu này, chúng tôi sử dụng máy phát tia X MBR-1618R-BE (Hitachi) phát tia X năng lượng thấp với liều chiếu 0.5 kGy, 1.0 kGy, 5 kGy và 10 kGy tương ứng thời gian chiếu 7.83 phút, 15.75 phút, 78.73 phút và 157.46 phút để khảo sát ảnh hưởng của liều chiếu xạ tia X lên tính chất hóa lí trên vật liệu PVC. Các mẫu trước và sau chiếu xạ được hóa lỏng bằng phá mẫu vi sóng Mars 6 và chụp ảnh nhiễu xạ tia X (XRD) để xác định đặc điểm hình thái cấu trúc của mẫu PVC. Kết quả chụp XRD cho thấy sự thay đổi của cấu trúc polymer PVC phụ thuộc mạnh vào liều chiếu xạ. Tại các đỉnh cực đại nhiễu xạ của các góc 17.670 và 26.170, số đếm tại vùng đỉnh suy giảm mạnh ở liều chiếu thấp tại 0.5 kGy và 1 kGy. Trong vùng này, sự thay đổi cấu trúc theo liều chiếu có dạng hàm tuyến tính bậc nhất. Trong vùng liều chiếu lớn hơn (từ 1 kGy đến 10 kGy), ảnh hưởng lên sự thay đổi cấu trúc PVC giảm dần. Kết quả nghiên cứu cho thấy, việc ứng dụng bức xạ trong phá hủy PVC có thể được ứng dụng để giảm thời gian phân hủy và ứng dụng trong xử lí rác thải ra môi trường. Từ khóa: Polyvinyl Clorua (PVC); chiếu xạ tia X; liều chiếu tia X; XRD 402

File đính kèm:

effect_of_x_ray_irradiation_on_the_physical_properties_of_po.pdf

effect_of_x_ray_irradiation_on_the_physical_properties_of_po.pdf