Determination of the refractive index of optical ceramics by using transmission data in the mid - wave infrared region

In the design and fabrication of an optical system, the refractive indexes of the

constitutive materials are important parameters to determine. Towards such a

characterization, many methods have been proposed in the past, ranging from classical

to newer techniques [1-4]. These can be grouped into two main categories: prism

methods and spectral methods. Regarding the prism methods, the deflection of a beam

entering and leaving a prism is measured. The advantage of these methods (e.g.

measurement of deviation, or minimum deviation angle, by refractometry, for which a

variety of different techniques have been developed historically [1]) is that an accurate

value of refractive index can be obtained at a fixed wavelength. This implies the use of

an expensive refractometer and the fabrication of a prism with high accuracy [1].

Unfortunately, these methods app

wide range of wavelengths. Hence spectral methods using transmission and reflection

data have increasingly been applied to determine the refractive index of materials with a

good accuracy. In this case, however, each time a new kind of materials is studied,

special care is required to ensure that the proposed model is in adequation with the

experimental data [5, 6].

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Trang 6

Trang 7

Trang 8

Trang 9

Tóm tắt nội dung tài liệu: Determination of the refractive index of optical ceramics by using transmission data in the mid - wave infrared region

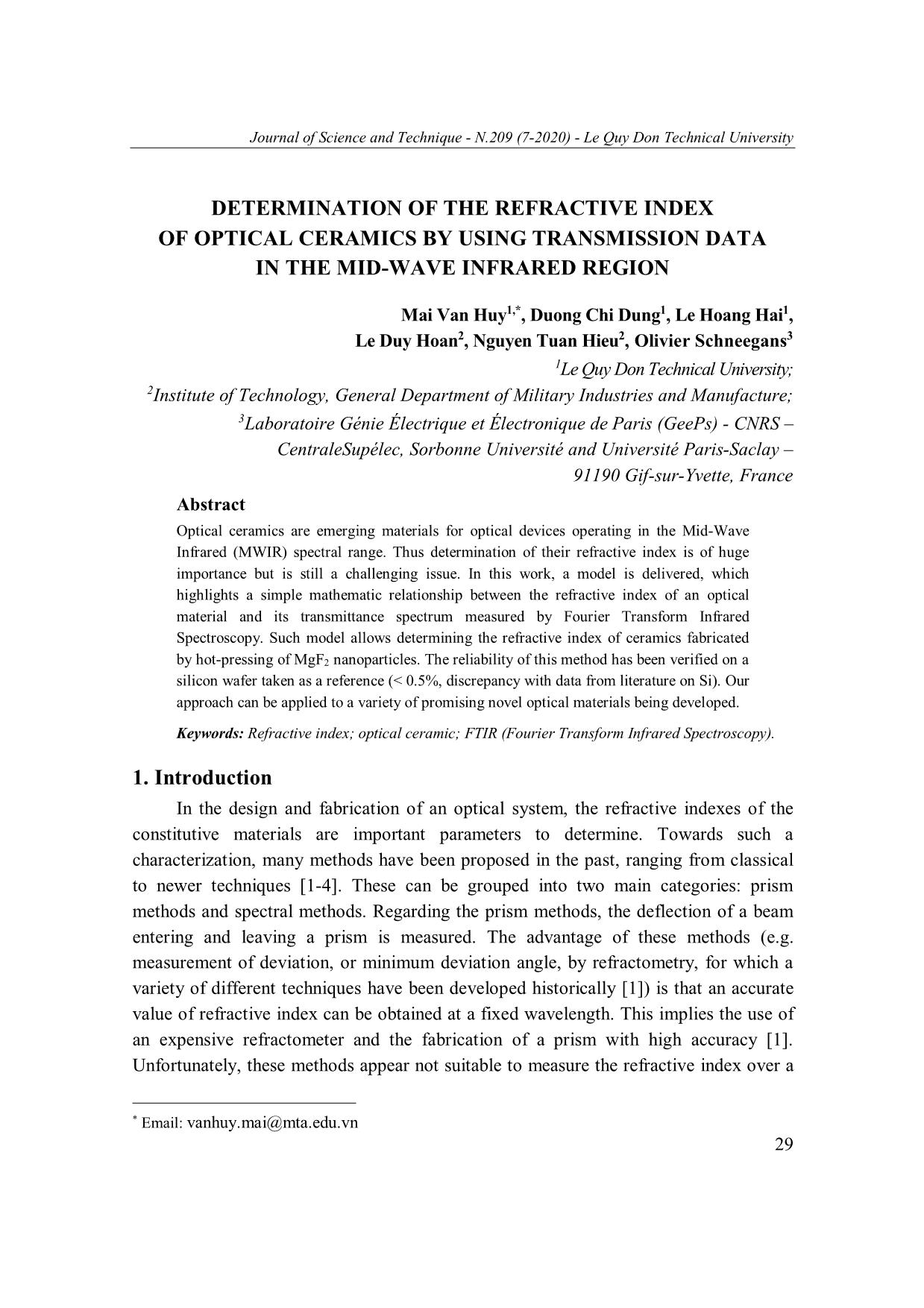

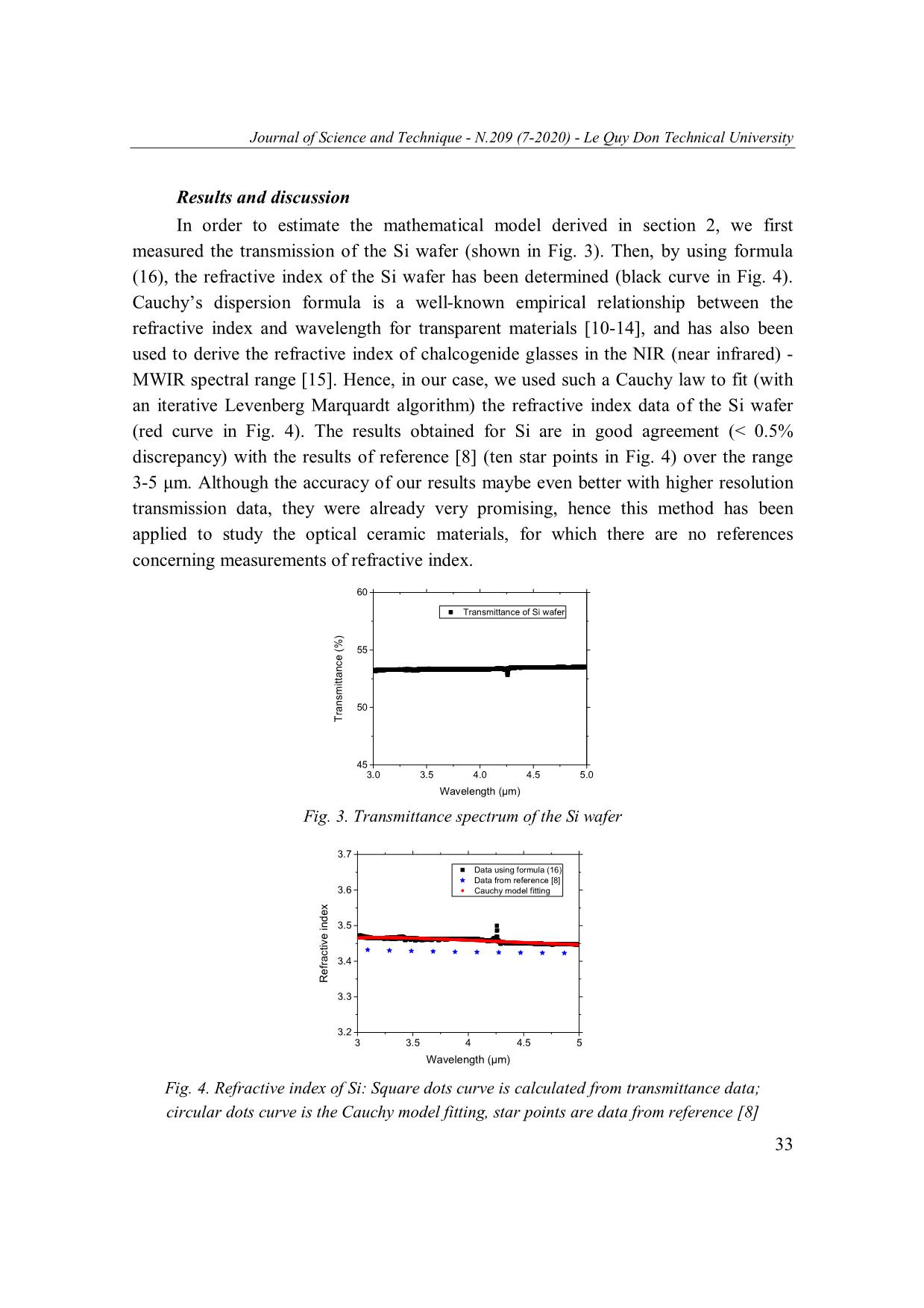

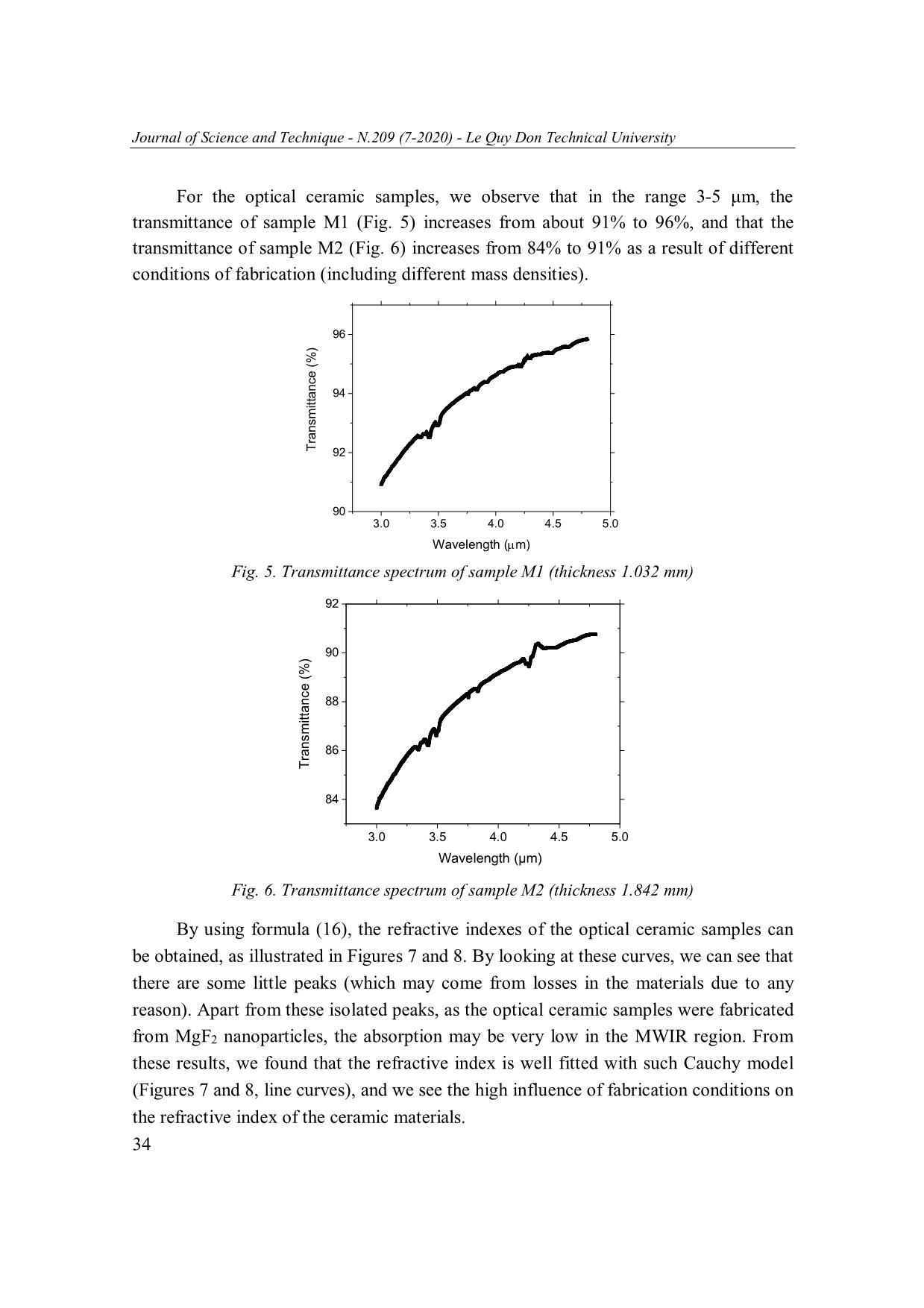

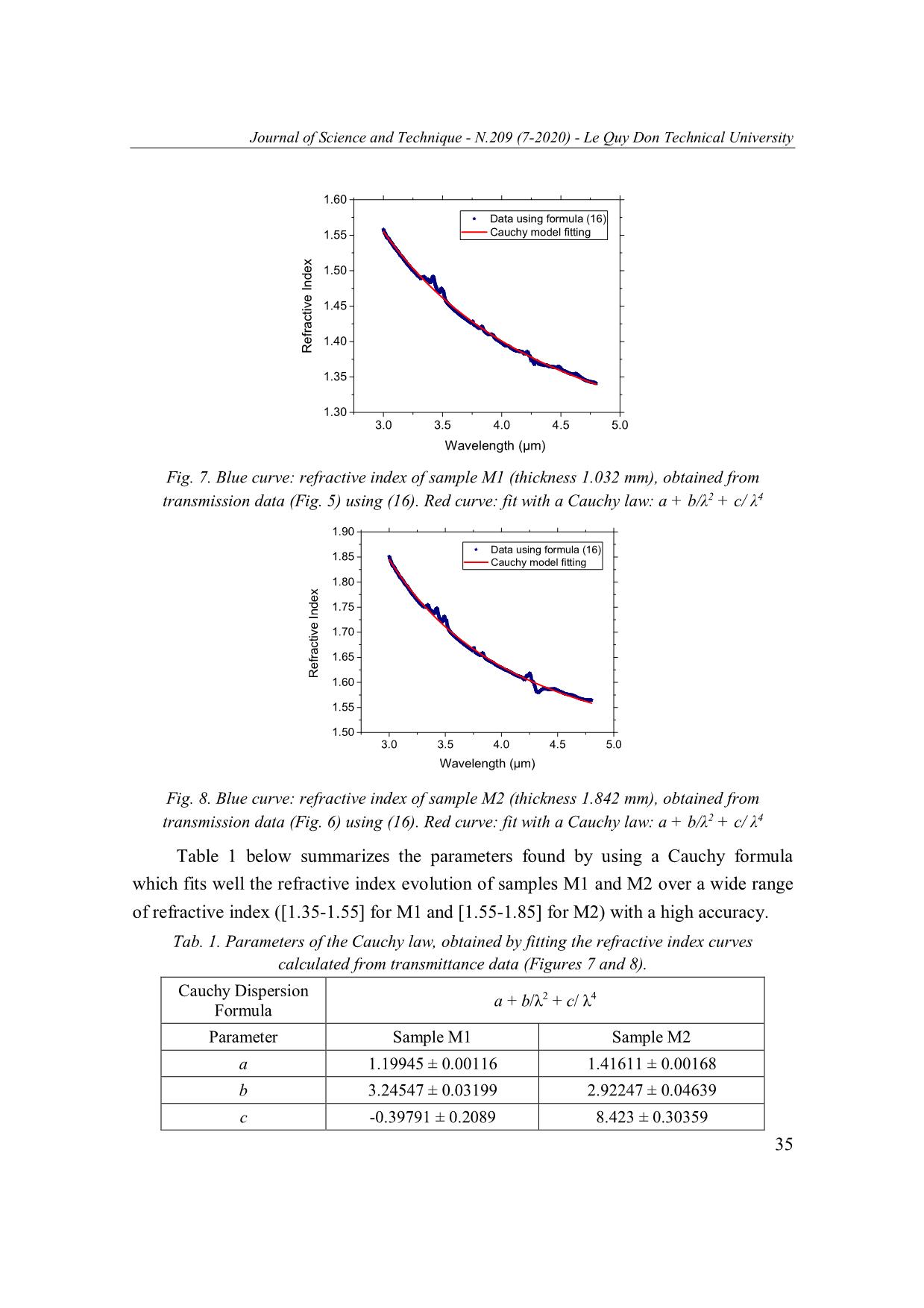

Journal of Science and Technique - N.209 (7-2020) - Le Quy Don Technical University DETERMINATION OF THE REFRACTIVE INDEX OF OPTICAL CERAMICS BY USING TRANSMISSION DATA IN THE MID-WAVE INFRARED REGION Mai Van Huy1,*, Duong Chi Dung1, Le Hoang Hai1, Le Duy Hoan2, Nguyen Tuan Hieu2, Olivier Schneegans3 1Le Quy Don Technical University; 2Institute of Technology, General Department of Military Industries and Manufacture; 3Laboratoire Génie Électrique et Électronique de Paris (GeePs) - CNRS – CentraleSupélec, Sorbonne Université and Université Paris-Saclay – 91190 Gif-sur-Yvette, France Abstract Optical ceramics are emerging materials for optical devices operating in the Mid-Wave Infrared (MWIR) spectral range. Thus determination of their refractive index is of huge importance but is still a challenging issue. In this work, a model is delivered, which highlights a simple mathematic relationship between the refractive index of an optical material and its transmittance spectrum measured by Fourier Transform Infrared Spectroscopy. Such model allows determining the refractive index of ceramics fabricated by hot-pressing of MgF2 nanoparticles. The reliability of this method has been verified on a silicon wafer taken as a reference (< 0.5%, discrepancy with data from literature on Si). Our approach can be applied to a variety of promising novel optical materials being developed. Keywords: Refractive index; optical ceramic; FTIR (Fourier Transform Infrared Spectroscopy). 1. Introduction In the design and fabrication of an optical system, the refractive indexes of the constitutive materials are important parameters to determine. Towards such a characterization, many methods have been proposed in the past, ranging from classical to newer techniques [1-4]. These can be grouped into two main categories: prism methods and spectral methods. Regarding the prism methods, the deflection of a beam entering and leaving a prism is measured. The advantage of these methods (e.g. measurement of deviation, or minimum deviation angle, by refractometry, for which a variety of different techniques have been developed historically [1]) is that an accurate value of refractive index can be obtained at a fixed wavelength. This implies the use of an expensive refractometer and the fabrication of a prism with high accuracy [1]. Unfortunately, these methods appear not suitable to measure the refractive index over a * Email: vanhuy.mai@mta.edu.vn 29 Journal of Science and Technique - N.209 (7-2020) - Le Quy Don Technical University wide range of wavelengths. Hence spectral methods using transmission and reflection data have increasingly been applied to determine the refractive index of materials with a good accuracy. In this case, however, each time a new kind of materials is studied, special care is required to ensure that the proposed model is in adequation with the experimental data [5, 6]. Single-crystal magnesium fluoride (MgF2) is a positive uniaxial crystal whose useful optical transmission is in the range of between 0.11 and 7.5 μm [3]. An optical ceramic, composed of polycrystalline high density MgF2, is elaborated by a hot-pressing technique; in the MWIR, its high transmittance interval lies in the range 2.5 to 6 μm [7]. This material has been widely used in the field of optics, especially for missiles domes. By traditional methods, the refractive index of this material is difficult to determine in the MWIR. In this paper, we first present the calculation and experiments carried out to determine the refractive index of a Si substrate by using FTIR. Our results were in good agreement (< 0.5% discrepancy) with published results in the 3-5 μm spectral range [8], hence we then applied this method to determine the refractive index of an optical ceramic, using parallel plate samples. 2. Methods and Experiments Mathematical model for calculation of refractive index Towards calculation of the refractive index, we first assume that a flat parallel plate sample has been polished on both sides (the surface roughness may thus be neglected), and that the sample is surrounded by ambient air (conditions to measure the transmission data), as illustrated in Fig. 1. The light beam reaches the sample at normal incidence, the sample thickness is such as both interference and absorption can be neglected. For each interface (air/substrate and substrate/air, respectively), we denote the transmittance and reflectance: T1, R1 and T2, R2 respectively. For a light (of intensity I0) coming from the left (Fig. 1), we can calculate the intensity at each interface by using the following equations [9]: ITI1 1 0 (1) ITITTI2 2 1 1 2 0 (2) IRIRTI3 2 1 2 1 0 (3) IRIRRTI4 1 3 1 2 1 0 (4) ITITTRRI5 2 4 1 2 1 2 0 (5) 30 Journal of Science and Technique - N.209 (7-2020) - Le Quy Don Technical University 2 IRIRRTI6 2 4 1 2 1 0 (6) 2 2 IRIRRTI7 1 6 1 2 1 0 (7) 2 ITITTRRI8 2 7 1 2 1 2 0 (8) IIIItot 2 5 8 (9) ITTRRRRRRI 1 2 3 (10) tot 1 2 1 2 1 2 1 2 0 Since R1 and R2 are both inferior to 1, we can re-calculate: 2 3 1 1 RRRRRR1 2 1 2 1 2 (11) 1 RR1 2 Therefore, expression (10) becomes: TT1 2 ITIItot 0 0 (12) 1 RR1 2 where the total transmittance T is: TT T 1 2 (13) 1 RR1 2 Fig. 1. Schematics of the light transmission through a parallel plate substrate in air. The light (intensity I0) comes from the left. The resulting total transmitted light (Itot) depends on T1, R1, T2 and R2 If we assume that both sides of the sample have undergone the same polishing, then both interfaces (air/substrate and substrate/air) are completely symmetric, hence T1 = T2 and R1 = R2. Besides, for a transparent sample (absorbance A = 0), we have T1 = 1 – R1. 31 Journal of Science and Technique - N.209 (7-2020) - Le Quy Don Technical University Thus the total transmittance T of the sample can be retrieved from (13): 2 (1 R1 ) T 2 (14) 1 R1 where R1 is the reflectance which comes from the Fresnel equations: 2 n 1 R1 (15) n 1 Finally, as the transmittance T is a function of wavelength , the refractive index n() is obtained from the transmittance T() using (14) and (15): 2 1 1 T ( ) n() (16) T () Fabrication of the IR optical ceramics The experiments have been carried out on two kinds of samples: - A Si wafer (diameter 1 inch, thickness 2 mm, polished on both sides), with the objective of comparing our results with published data. This kind of wafer is almost used in the field of optical thin film coating. - Two optical ceramic parallel plate samples which were fabricated at the Institute of Technology, General Department of Military Industries and Manufacture. The samples were fabricated by hot pressing of MgF2 nano particles (size 70-90 nm), in an annealing furnace at a pressure of 10-2 bar. The optical ceramic parallel plate samples M1 and M2 have been polished on both sides (resulting roughness < 0.05 µm). Sample M1 (thickness 1.032 mm) was annealed at a temperature of 640.9oC during 33 minutes at a pressure of 231.4 MPa, and sample M2 (thickness 1.842 mm) has been annealed at a temperature of 651oC during 35 minutes at a pressure of 240.5 MPa. The mass density of samples M1 and M2 are 3.17 and 3.18 g/cm3 respectively. The transmittance of the samples was measured in the MWIR region by using a FTIR spectrometer “Nicolet Summit Pro” of Thermo Scientific. Fig. 2. Optical photos of the optical ceramic samples: the thickness of M1 (left) is 1.032 mm, the thickness of M2 (right) is 1.842 mm 32 Journal of Science and Technique - N.209 (7-2020) - Le Quy Don Technical University Results and discussion In order to estimate the mathematical model derived in section 2, we first measured the transmission of the Si wafer (shown in Fig. 3). Then, by using formula (16), the refractive index of the Si wafer has been determined (black curve in Fig. 4). Cauchy’s dispersion formula is a well-known empirical relationship between the refractive index and wavelength for transparent materials [10-14], and has also been used to derive the refractive index of chalcogenide glasses in the NIR (near infrared) - MWIR spectral range [15]. Hence, in our case, we used such a Cauchy law to fit (with an iterative Levenberg Marquardt algorithm) the refractive index data of the Si wafer (red curve in Fig. 4). The results obtained for Si are in good agreement (< 0.5% discrepancy) with the results of reference [8] (ten star points in Fig. 4) over the range 3-5 μm. Although the accuracy of our results maybe even better with higher resolution transmission data, they were already very promising, hence this method has been applied to study the optical ceramic materials, for which there are no references concerning measurements of refractive index. 60 Transmittance of Si wafer 55 50 Transmittance (%) 45 3.0 3.5 4.0 4.5 5.0 Wavelength (µm) Fig. 3. Transmittance spectrum of the Si wafer 3.7 Data using formula (16) Data from reference [8] 3.6 Cauchy model fitting 3.5 3.4 Refractive index Refractive 3.3 3.2 3 3.5 4 4.5 5 Wavelength (µm) Fig. 4. Refractive index of Si: Square dots curve is calculated from transmittance data; circular dots curve is the Cauchy model fitting, star points are data from reference [8] 33 Journal of Science and Technique - N.209 (7-2020) - Le Quy Don Technical University For the optical ceramic samples, we observe that in the range 3-5 μm, the transmittance of sample M1 (Fig. 5) increases from about 91% to 96%, and that the transmittance of sample M2 (Fig. 6) increases from 84% to 91% as a result of different conditions of fabrication (including different mass densities). 96 94 Transmittance (%) Transmittance 92 90 3.0 3.5 4.0 4.5 5.0 Wavelength (m) Fig. 5. Transmittance spectrum of sample M1 (thickness 1.032 mm) 92 90 88 86 Transmittance (%) Transmittance 84 3.0 3.5 4.0 4.5 5.0 Wavelength (µm) Fig. 6. Transmittance spectrum of sample M2 (thickness 1.842 mm) By using formula (16), the refractive indexes of the optical ceramic samples can be obtained, as illustrated in Figures 7 and 8. By looking at these curves, we can see that there are some little peaks (which may come from losses in the materials due to any reason). Apart from these isolated peaks, as the optical ceramic samples were fabricated from MgF2 nanoparticles, the absorption may be very low in the MWIR region. From these results, we found that the refractive index is well fitted with such Cauchy model (Figures 7 and 8, line curves), and we see the high influence of fabrication conditions on the refractive index of the ceramic materials. 34 Journal of Science and Technique - N.209 (7-2020) - Le Quy Don Technical University 1.60 Data using formula (16) 1.55 Cauchy model fitting 1.50 1.45 1.40 Refractive Index Refractive 1.35 1.30 3.0 3.5 4.0 4.5 5.0 Wavelength (µm) Fig. 7. Blue curve: refractive index of sample M1 (thickness 1.032 mm), obtained from transmission data (Fig. 5) using (16). Red curve: fit with a Cauchy law: a + b/λ2 + c/ λ4 1.90 Data using formula (16) 1.85 Cauchy model fitting 1.80 1.75 1.70 1.65 Refractive Index Refractive 1.60 1.55 1.50 3.0 3.5 4.0 4.5 5.0 Wavelength (µm) Fig. 8. Blue curve: refractive index of sample M2 (thickness 1.842 mm), obtained from transmission data (Fig. 6) using (16). Red curve: fit with a Cauchy law: a + b/λ2 + c/ λ4 Table 1 below summarizes the parameters found by using a Cauchy formula which fits well the refractive index evolution of samples M1 and M2 over a wide range of refractive index ([1.35-1.55] for M1 and [1.55-1.85] for M2) with a high accuracy. Tab. 1. Parameters of the Cauchy law, obtained by fitting the refractive index curves calculated from transmittance data (Figures 7 and 8). Cauchy Dispersion a + b/λ2 + c/ λ4 Formula Parameter Sample M1 Sample M2 a 1.19945 ± 0.00116 1.41611 ± 0.00168 b 3.24547 ± 0.03199 2.92247 ± 0.04639 c -0.39791 ± 0.2089 8.423 ± 0.30359 35 Journal of Science and Technique - N.209 (7-2020) - Le Quy Don Technical University 3. Conclusion In this paper, a simple method has been presented, in order to determine the refractive indexes of a Si wafer and two optical ceramic plates in the MWIR region, by use of transmission data. It has been verified that the refractive index evolution n() of the transparent materials are well fitted by a Cauchy dispersion formula. Based on the fact that this method is simple and does not require an expensive device for measurements, it may provide a tool in the development of fabrication technology of optical ceramics and in the determination of the refractive index of novel optical materials. References 1. 2. Gao, L., F. Lemarchand, and M. Lequime (2013). Refractive index determination of SiO2 layer in the UV/Vis/NIR range: Spectrophotometric reverse engineering on single and bi-layer designs. J. Europ. Opt. Soc. Rap. Public., 8, 13010. 3. Dodge, M. J. (1984). Refractive properties of magnesium fluoride. Applied Optics, 23(12), 1980-1985. 4. Fang, Y., et al. (2019). (Invited) Methods for determining the refractive indices and thermo-optic coefficients of chalcogenide glasses at MIR wavelengths. Optical Materials: X, 2, 100030. 5. Gerstenlauer, D., et al. (2014). Determination of the refractive index of TiO2-Y2O3 ceramic composites. Journal of Quantitative Spectroscopy and Radiative Transfer, 135, 44-49. 6. Mehling H, Kuhn J, Manara J, Brandt R, Fricke J (2001). Different methods for determining the refractive index of SiO2 glass in the range of 1.4-50μm. High Temp High Press, 33, 35-42. 7. Chang, C. S., M. H. Hon, and S. J. Yang (1991). The optical properties of hot-pressed magnesium fluoride and single-crystal magnesium fluoride in the 0.1 to 9.0 μm range. Journal of Materials Science, 26(6), 1627-1630. 8. Chandler-Horowitz, D. and P. M. Amirtharaj (2005). High-accuracy, midinfrared (450cm−1⩽ω⩽4000cm−1) refractive index values of silicon. Journal of Applied Physics, 97(12), 123526. 9. Olaf Stenzel (2016). Chapter 7 of "The Physics of Thin Film Optical Spectra: An Introduction" (2nd Edition). Springer Series in Surface Sciences. 10. Liu, J.-M. (2005). Photonic Devices. Cambridge: Cambridge University Press. 11. G. E. Jellison Jr. and F. A. Modine (1996). Parameterization of the optical functions of amorphous materials in the interband region. Appl. Phys. Lett., 69(3), 371-373. 12. F. A. Jenkins, H. E. White (1937). Fundamentals of Optics. Tata McGraw-Hill Education. 13. H. G. Dantanarayana (2012). Application of TLM for Optical Microresonators. PhD thesis University of Nottingham, UK. 14. https://en.wikipedia.org/wiki/Cauchy%27s_equation. 15. Němec, P., et al. (2014). Optical properties of (GeSe2)100−x(Sb2Se3)x glasses in near- and middle-infrared spectral regions. Materials Research Bulletin, 51, 176-179. 36 Journal of Science and Technique - N.209 (7-2020) - Le Quy Don Technical University XÁC ĐỊNH CHIẾT SUẤT CỦA VẬT LIỆU GỐM QUANG HỌC TỪ PHỔ TRUYỀN QUA TRONG VÙNG HỒNG NGOẠI Tóm tắt: Gốm quang học là vật liệu mang tính cấp thiết trong các thiết bị quang học làm việc trong vùng hồng ngoại. Việc xác định chiết suất của gốm quang học là một nhiệm vụ quan trọng nhưng vẫn còn nhiều khó khăn. Trong bài báo này, chúng tôi dẫn chứng một mối quan hệ toán học đơn giản giữa chiết suất và hệ số truyền qua, điều này cho phép xác định được chiết suất của gốm quang học được chế tạo bằng phương pháp ép nóng hạt nano MgF2. Độ tin cậy của phương pháp đã được kiểm nghiệm trên đế Si và so sánh với các kết quả công bố với độ sai lệch dưới 0,5%. Phương pháp tiếp cận này có thể được áp dụng cho các loại vật liệu quang học mới đang được phát triển. Từ khóa: Chiết suất; gốm quang học; phổ hồng ngoại truyền qua Fourier. Received: 14/5/2020; Revised: 22/7/2020; Accepted for publication: 28/7/2020 37

File đính kèm:

determination_of_the_refractive_index_of_optical_ceramics_by.pdf

determination_of_the_refractive_index_of_optical_ceramics_by.pdf