Analysis technical efficiency, technological gap and total factor productivity of vietnamese textile and garment industries

The study used meta- frontier framework, data envelopment analysis approach and

the global Malmquist total factor productivity index to analyse technical efficiency and

productivity change as well as its components of Vietnamese textile and garment firms

during 2013-2015. The results show that: (i) The total factor productivity of Vietnamese

textile and garment firms fell in the period 2013-2015, and technical change is the main

reason to constraint productivity growth. (ii) The private garment sector has taken real

effort to improve technology. On the other hand, state-owned and FDI garment sectors

have been significantly improving technical efficiency in the use of production factors.(iii)

FDI textile firms have been improving effectively technology, whereas state-owned textile

firms have showed improvements in technical efficiency. Meanwhile, the private textile

sector has experienced a slowdown in all components of total factor productivity. (iv)

There is a large technological gap among Vietnamese textile and garment sectors, which

has become wide for the garment industry. And this gap is the reason for differences in

total factor productivity between Vietnamese textile and garment sectors

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Trang 6

Trang 7

Trang 8

Trang 9

Trang 10

Tải về để xem bản đầy đủ

Tóm tắt nội dung tài liệu: Analysis technical efficiency, technological gap and total factor productivity of vietnamese textile and garment industries

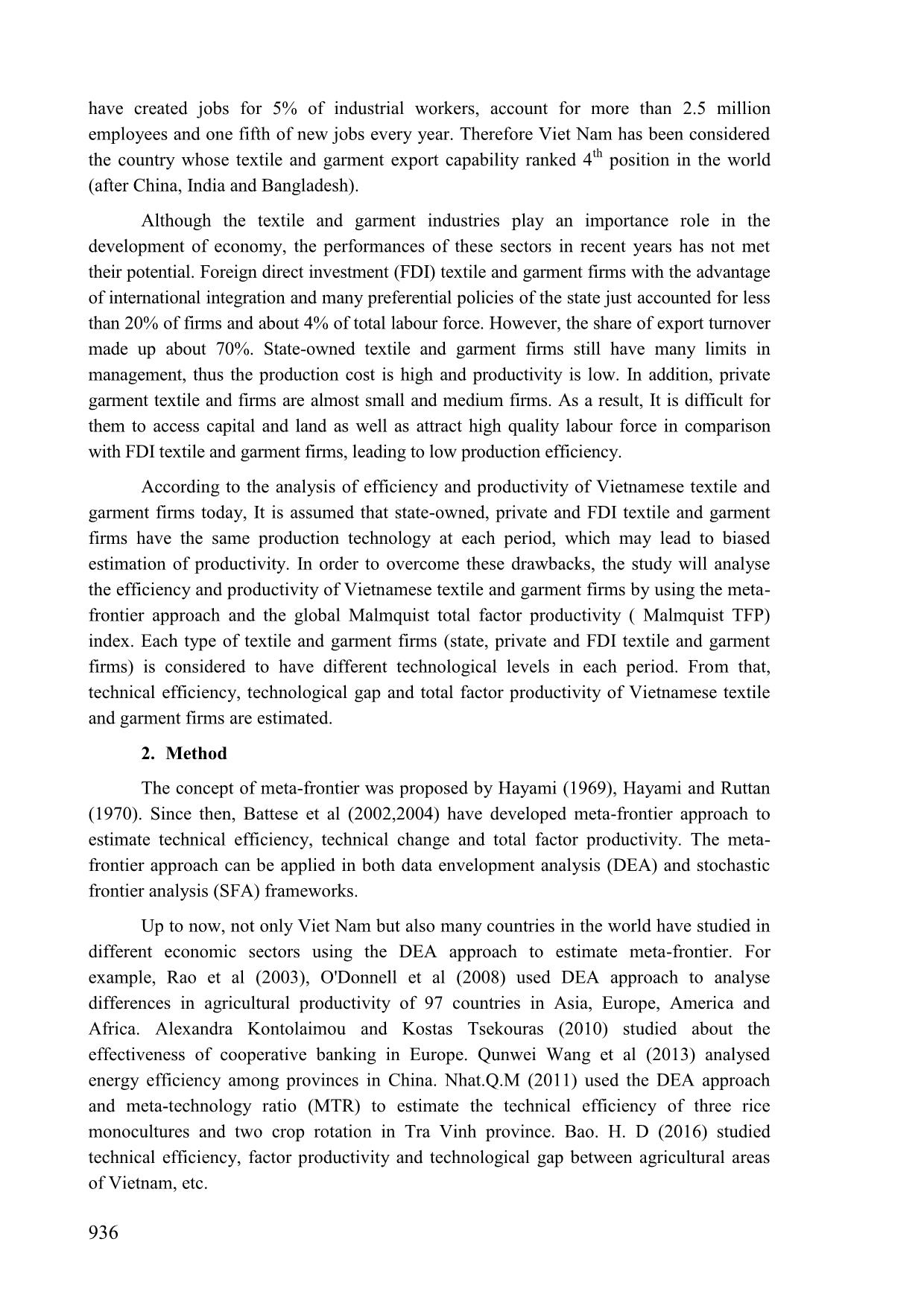

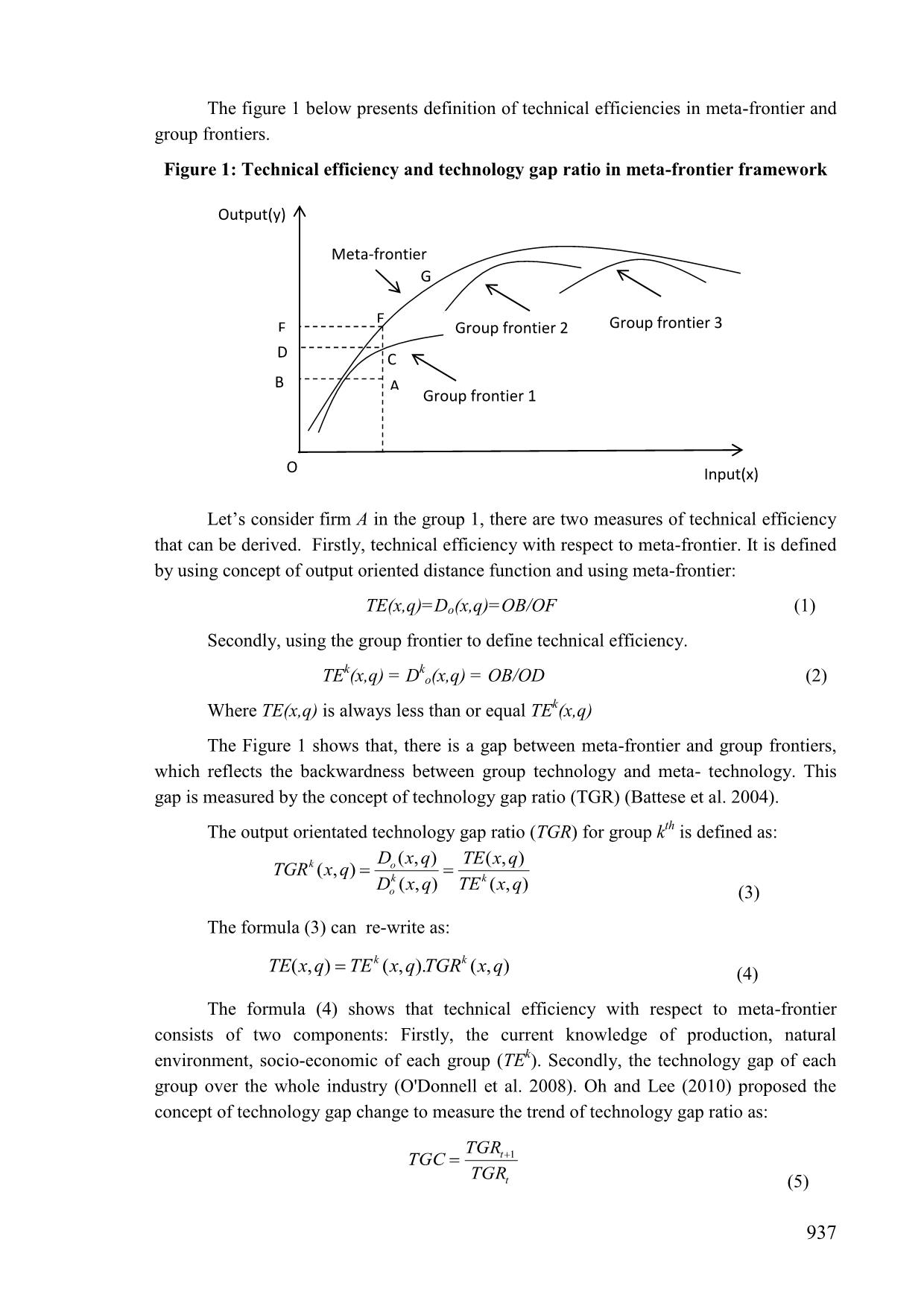

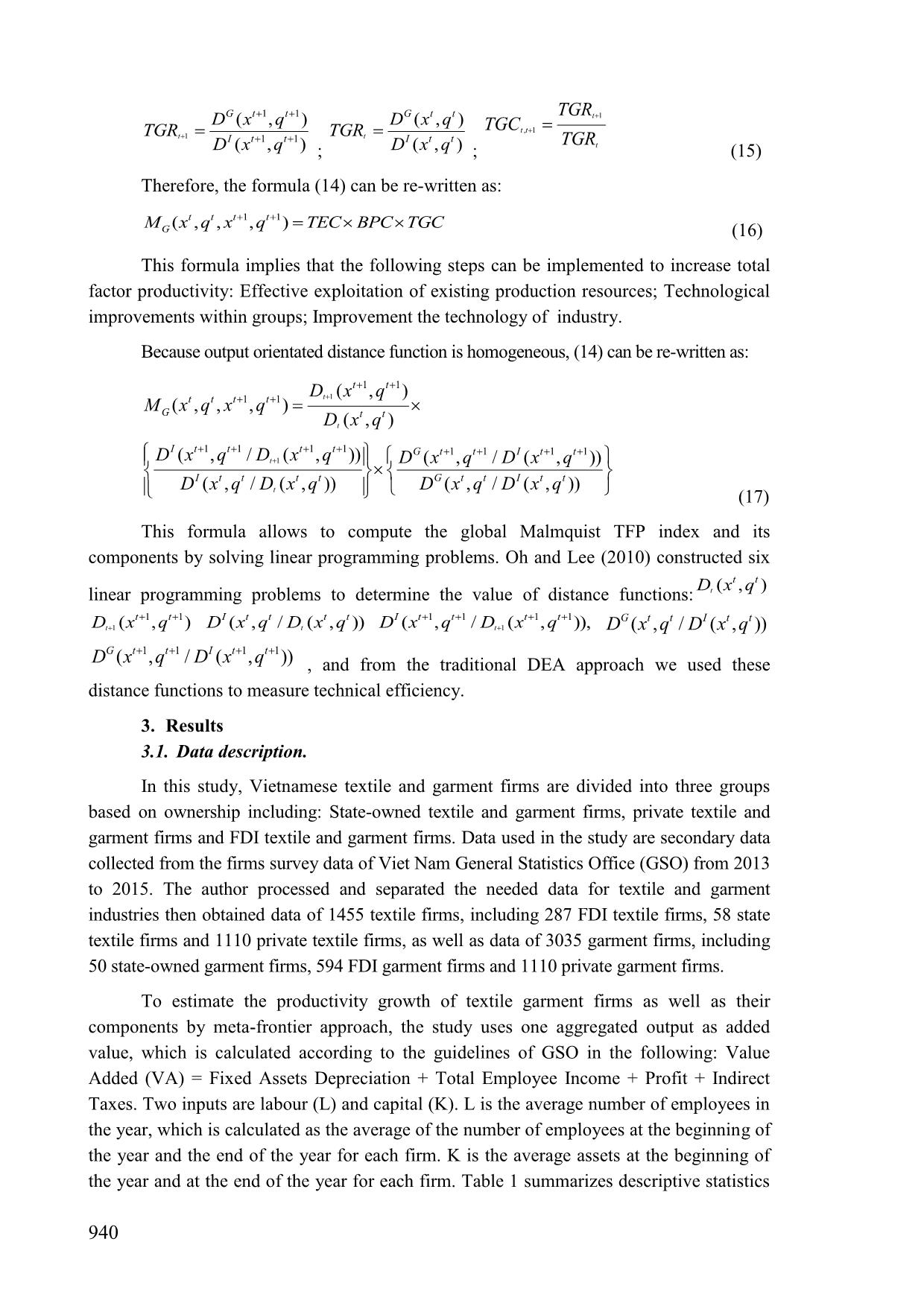

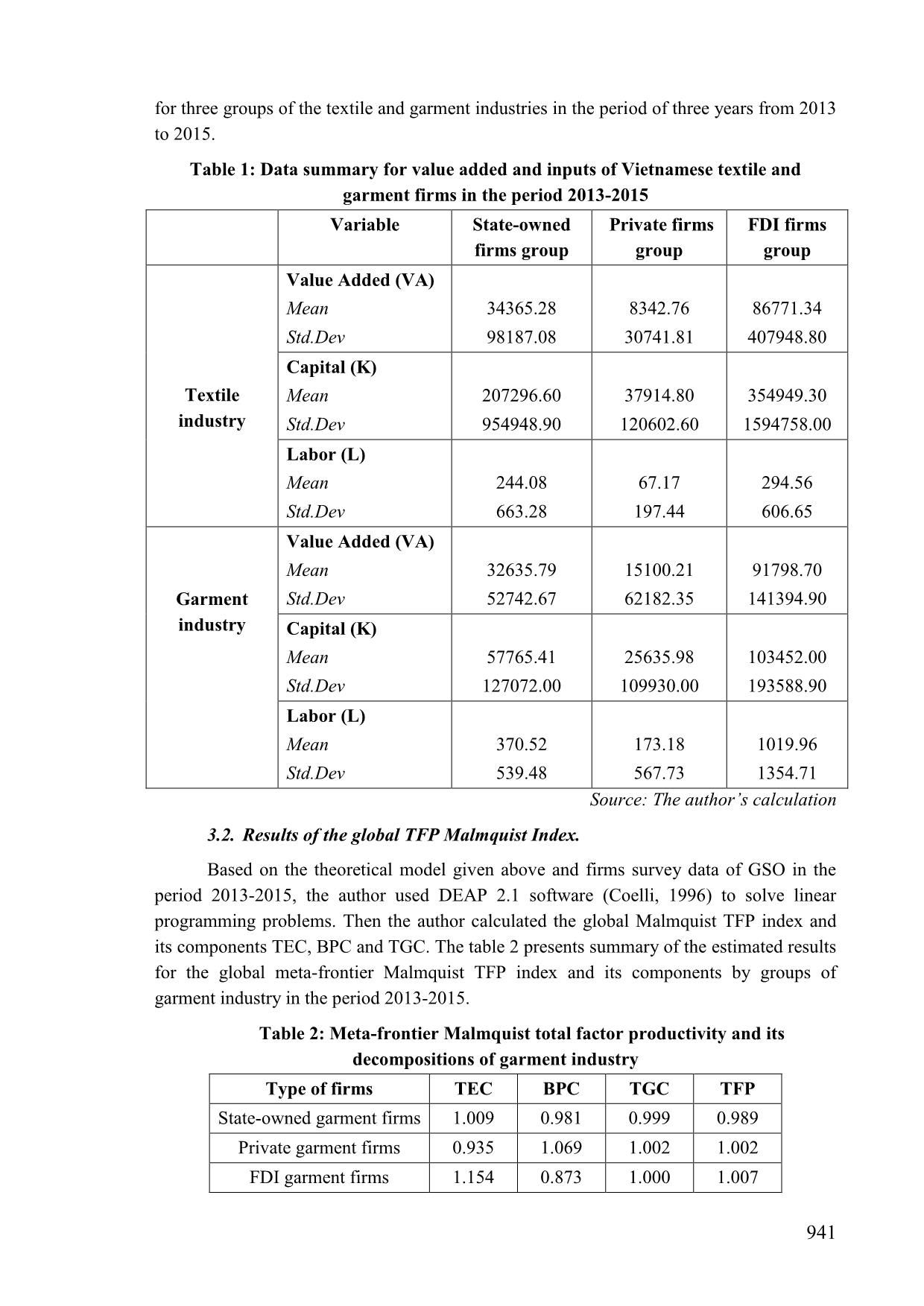

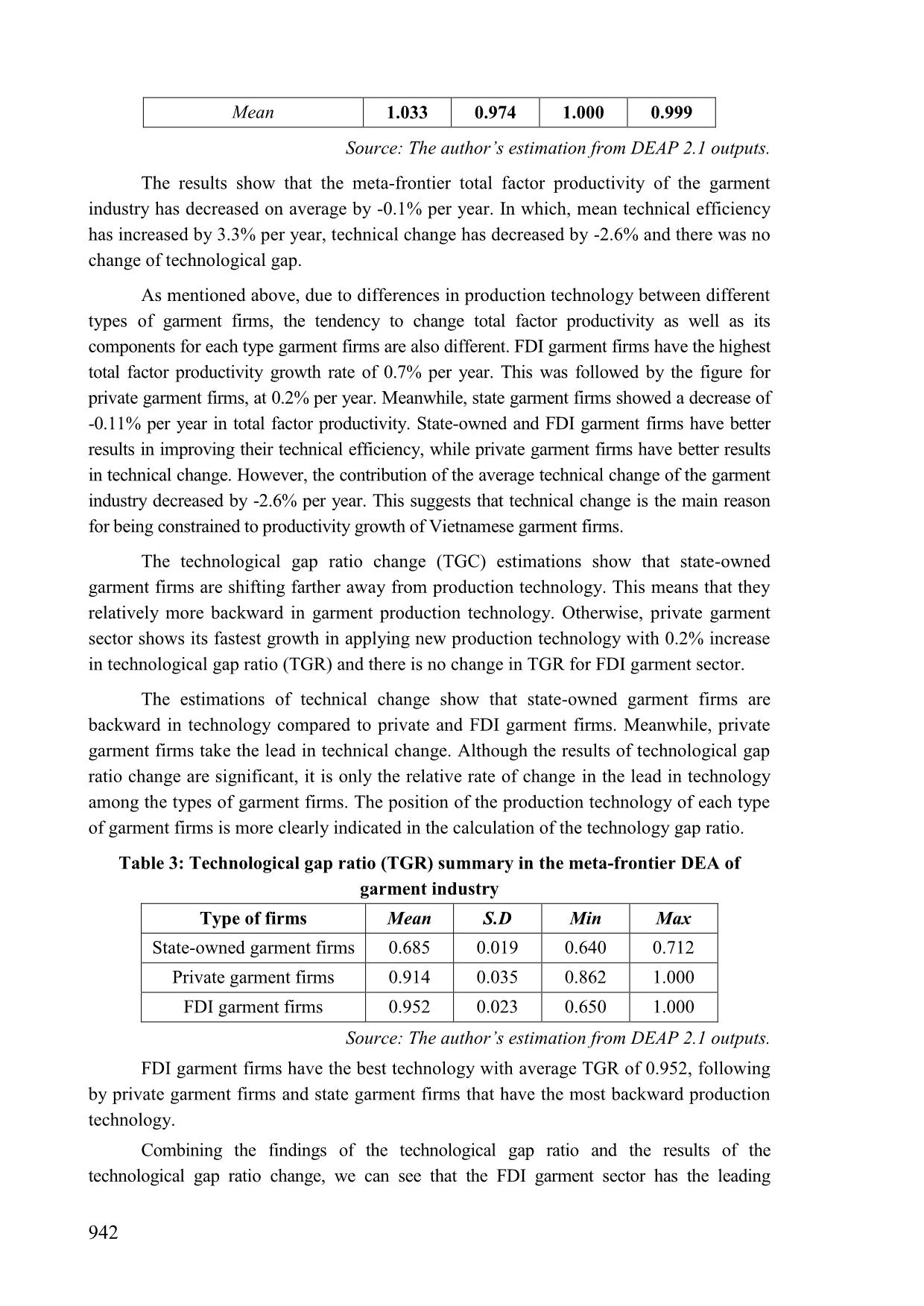

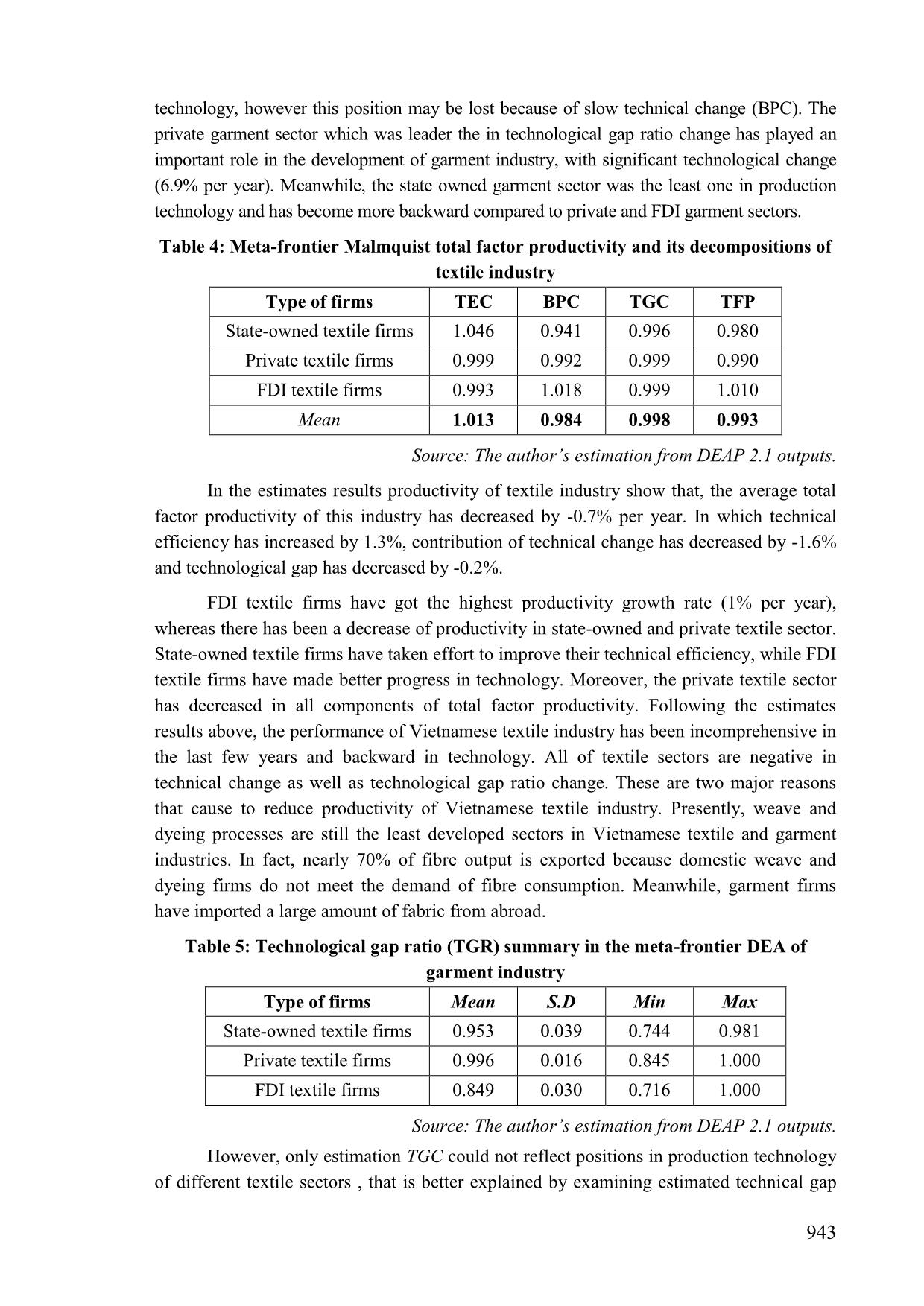

935 ANALYSIS TECHNICAL EFFICIENCY, TECHNOLOGICAL GAP AND TOTAL FACTOR PRODUCTIVITY OF VIETNAMESE TEXTILE AND GARMENT INDUSTRIES Nguyen Van Nguyenvan246.hh@gmail.com Faculty of Fundamental Science, Vietnam Maritime University, Hai Phong, Viet Nam Abstract The study used meta- frontier framework, data envelopment analysis approach and the global Malmquist total factor productivity index to analyse technical efficiency and productivity change as well as its components of Vietnamese textile and garment firms during 2013-2015. The results show that: (i) The total factor productivity of Vietnamese textile and garment firms fell in the period 2013-2015, and technical change is the main reason to constraint productivity growth. (ii) The private garment sector has taken real effort to improve technology. On the other hand, state-owned and FDI garment sectors have been significantly improving technical efficiency in the use of production factors.(iii) FDI textile firms have been improving effectively technology, whereas state-owned textile firms have showed improvements in technical efficiency. Meanwhile, the private textile sector has experienced a slowdown in all components of total factor productivity. (iv) There is a large technological gap among Vietnamese textile and garment sectors, which has become wide for the garment industry. And this gap is the reason for differences in total factor productivity between Vietnamese textile and garment sectors. Keywords: Data envelopment analysis, Global Malmquist total factor productivity, Meta-frontier, Technical efficiency. 1. Introduction In recent years, Viet Nam has taken part in international economic integration by signing many free trade agreements (FTAs) such as: Viet Nam-Europe Union free trade agreement, Viet Nam- South Korean free trade agreement, Viet Nam-Asean free trade area, etc ... In negotiation to sign these agreements, Vietnam textile and garment industries have always been considered to be the industry that have national fundamental interests, and able to gain great income when these agreements being put into force. According to the statistics data of the Vietnam Textile and Garment Association, the average growth rate of export value in the last 5 years is 14.74% per year, export turnover in 2016 have got 28.5 billion USD, account for 16% of industrial production value and became the industry whose export turnover was the second position in the country (after telephone and telephone accessories), contributed significant part to the national export turnover, and became one of five world's biggest textile and garment exporters. Having more than 6,000 large and small firms, textile and garment industries 936 have created jobs for 5% of industrial workers, account for more than 2.5 million employees and one fifth of new jobs every year. Therefore Viet Nam has been considered the country whose textile and garment export capability ranked 4 th position in the world (after China, India and Bangladesh). Although the textile and garment industries play an importance role in the development of economy, the performances of these sectors in recent years has not met their potential. Foreign direct investment (FDI) textile and garment firms with the advantage of international integration and many preferential policies of the state just accounted for less than 20% of firms and about 4% of total labour force. However, the share of export turnover made up about 70%. State-owned textile and garment firms still have many limits in management, thus the production cost is high and productivity is low. In addition, private garment textile and firms are almost small and medium firms. As a result, It is difficult for them to access capital and land as well as attract high quality labour force in comparison with FDI textile and garment firms, leading to low production efficiency. According to the analysis of efficiency and productivity of Vietnamese textile and garment firms today, It is assumed that state-owned, private and FDI textile and garment firms have the same production technology at each period, which may lead to biased estimation of productivity. In order to overcome these drawbacks, the study will analyse the efficiency and productivity of Vietnamese textile and garment firms by using the meta- frontier approach and the global Malmquist total factor productivity ( Malmquist TFP) index. Each type of textile and garment firms (state, private and FDI textile and garment firms) is considered to have different technological levels in each period. From that, technical efficiency, technological gap and total factor productivity of Vietnamese textile and garment firms are estimated. 2. Method The concept of meta-frontier was proposed by Hayami (1969), Hayami and Ruttan (1970). Since then, Battese et al (2002,2004) have developed meta-front ... 50 state-owned garment firms, 594 FDI garment firms and 1110 private garment firms. To estimate the productivity growth of textile garment firms as well as their components by meta-frontier approach, the study uses one aggregated output as added value, which is calculated according to the guidelines of GSO in the following: Value Added (VA) = Fixed Assets Depreciation + Total Employee Income + Profit + Indirect Taxes. Two inputs are labour (L) and capital (K). L is the average number of employees in the year, which is calculated as the average of the number of employees at the beginning of the year and the end of the year for each firm. K is the average assets at the beginning of the year and at the end of the year for each firm. Table 1 summarizes descriptive statistics 941 for three groups of the textile and garment industries in the period of three years from 2013 to 2015. Table 1: Data summary for value added and inputs of Vietnamese textile and garment firms in the period 2013-2015 Variable State-owned firms group Private firms group FDI firms group Textile industry Value Added (VA) Mean Std.Dev 34365.28 98187.08 8342.76 30741.81 86771.34 407948.80 Capital (K) Mean Std.Dev 207296.60 954948.90 37914.80 120602.60 354949.30 1594758.00 Labor (L) Mean Std.Dev 244.08 663.28 67.17 197.44 294.56 606.65 Garment industry Value Added (VA) Mean Std.Dev 32635.79 52742.67 15100.21 62182.35 91798.70 141394.90 Capital (K) Mean Std.Dev 57765.41 127072.00 25635.98 109930.00 103452.00 193588.90 Labor (L) Mean Std.Dev 370.52 539.48 173.18 567.73 1019.96 1354.71 Source: The author‟s calculation 3.2. Results of the global TFP Malmquist Index. Based on the theoretical model given above and firms survey data of GSO in the period 2013-2015, the author used DEAP 2.1 software (Coelli, 1996) to solve linear programming problems. Then the author calculated the global Malmquist TFP index and its components TEC, BPC and TGC. The table 2 presents summary of the estimated results for the global meta-frontier Malmquist TFP index and its components by groups of garment industry in the period 2013-2015. Table 2: Meta-frontier Malmquist total factor productivity and its decompositions of garment industry Type of firms TEC BPC TGC TFP State-owned garment firms 1.009 0.981 0.999 0.989 Private garment firms 0.935 1.069 1.002 1.002 FDI garment firms 1.154 0.873 1.000 1.007 942 Mean 1.033 0.974 1.000 0.999 Source: The author‟s estimation from DEAP 2.1 outputs. The results show that the meta-frontier total factor productivity of the garment industry has decreased on average by -0.1% per year. In which, mean technical efficiency has increased by 3.3% per year, technical change has decreased by -2.6% and there was no change of technological gap. As mentioned above, due to differences in production technology between different types of garment firms, the tendency to change total factor productivity as well as its components for each type garment firms are also different. FDI garment firms have the highest total factor productivity growth rate of 0.7% per year. This was followed by the figure for private garment firms, at 0.2% per year. Meanwhile, state garment firms showed a decrease of -0.11% per year in total factor productivity. State-owned and FDI garment firms have better results in improving their technical efficiency, while private garment firms have better results in technical change. However, the contribution of the average technical change of the garment industry decreased by -2.6% per year. This suggests that technical change is the main reason for being constrained to productivity growth of Vietnamese garment firms. The technological gap ratio change (TGC) estimations show that state-owned garment firms are shifting farther away from production technology. This means that they relatively more backward in garment production technology. Otherwise, private garment sector shows its fastest growth in applying new production technology with 0.2% increase in technological gap ratio (TGR) and there is no change in TGR for FDI garment sector. The estimations of technical change show that state-owned garment firms are backward in technology compared to private and FDI garment firms. Meanwhile, private garment firms take the lead in technical change. Although the results of technological gap ratio change are significant, it is only the relative rate of change in the lead in technology among the types of garment firms. The position of the production technology of each type of garment firms is more clearly indicated in the calculation of the technology gap ratio. Table 3: Technological gap ratio (TGR) summary in the meta-frontier DEA of garment industry Type of firms Mean S.D Min Max State-owned garment firms 0.685 0.019 0.640 0.712 Private garment firms 0.914 0.035 0.862 1.000 FDI garment firms 0.952 0.023 0.650 1.000 Source: The author‟s estimation from DEAP 2.1 outputs. FDI garment firms have the best technology with average TGR of 0.952, following by private garment firms and state garment firms that have the most backward production technology. Combining the findings of the technological gap ratio and the results of the technological gap ratio change, we can see that the FDI garment sector has the leading 943 technology, however this position may be lost because of slow technical change (BPC). The private garment sector which was leader the in technological gap ratio change has played an important role in the development of garment industry, with significant technological change (6.9% per year). Meanwhile, the state owned garment sector was the least one in production technology and has become more backward compared to private and FDI garment sectors. Table 4: Meta-frontier Malmquist total factor productivity and its decompositions of textile industry Type of firms TEC BPC TGC TFP State-owned textile firms 1.046 0.941 0.996 0.980 Private textile firms 0.999 0.992 0.999 0.990 FDI textile firms 0.993 1.018 0.999 1.010 Mean 1.013 0.984 0.998 0.993 Source: The author‟s estimation from DEAP 2.1 outputs. In the estimates results productivity of textile industry show that, the average total factor productivity of this industry has decreased by -0.7% per year. In which technical efficiency has increased by 1.3%, contribution of technical change has decreased by -1.6% and technological gap has decreased by -0.2%. FDI textile firms have got the highest productivity growth rate (1% per year), whereas there has been a decrease of productivity in state-owned and private textile sector. State-owned textile firms have taken effort to improve their technical efficiency, while FDI textile firms have made better progress in technology. Moreover, the private textile sector has decreased in all components of total factor productivity. Following the estimates results above, the performance of Vietnamese textile industry has been incomprehensive in the last few years and backward in technology. All of textile sectors are negative in technical change as well as technological gap ratio change. These are two major reasons that cause to reduce productivity of Vietnamese textile industry. Presently, weave and dyeing processes are still the least developed sectors in Vietnamese textile and garment industries. In fact, nearly 70% of fibre output is exported because domestic weave and dyeing firms do not meet the demand of fibre consumption. Meanwhile, garment firms have imported a large amount of fabric from abroad. Table 5: Technological gap ratio (TGR) summary in the meta-frontier DEA of garment industry Type of firms Mean S.D Min Max State-owned textile firms 0.953 0.039 0.744 0.981 Private textile firms 0.996 0.016 0.845 1.000 FDI textile firms 0.849 0.030 0.716 1.000 Source: The author‟s estimation from DEAP 2.1 outputs. However, only estimation TGC could not reflect positions in production technology of different textile sectors , that is better explained by examining estimated technical gap 944 ratio (TGR) of each sector in the period shown. The table 5 presents estimated technological gap ratio of each sector, which shows that private sector is leading by technology in the period 2013-2015. This is followed by state-owned textile firms and FDI textile firms that have the most backward production technology. However, because FDI textile firms have made a great effort in technical change (1.8% annual) while private and state-owned textile sectors decreased, FDI textile sector may develop strongly and become the best one. This can be explained by the fact that FDI textile firms investing in Vietnam have backward technology leading to low production efficiency. However, since the free trade agreements were signed by Vietnam, the wave of foreign investments in Vietnamese textile industry have become huge in order to gain benefit from export taxes of textile and garment products. Therefore, in the coming years, the FDI textile sector as well as Vietnamese textile industry might strongly develop. 4. Discussion and Conclusion This study uses meta-frontier approach and a global total factor productivity index to analyse total factor productivity change as well as its components in the Vietnamese textile and garment sectors. The empirical results show that: The total factor productivity of Vietnamese textile and garment firms fell in the period 2013-2015, and technical change is the main reason to constraint productivity growth. The private sector has taken real effort to improve technology. On the other hand, state-owned and FDI garment sectors have been significantly improving technical efficiency in the use of production factors. It is opposite to textile industry, FDI textile firms have been improving effectively technology, whereas state-owned textile firms have showed improvements in technical efficiency. At the same time, the private textile sector has experienced a slowdown in all components of total factor productivity. There is a large technological gap among Vietnamese textile and garment sectors, which has become wide for the garment industry. This gap is the reason for differences in total factor productivity between Vietnamese textile and garment sectors. The study uses the data envelope analysis method to estimate the meta-frontier and total factor productivity. Therefore it is sensitive to the dominant observations and the effects of statistical noise are not taken into account. However, from the study results, some recommendations can be considered for Vietnamese textile and garment industries as: The State should have direct support policies and facilitate for textile and garment firms to raise their scientific and technological capacity as well as increase technology in the production process. Especially, The government should encourage to invest in weave and dyeing industrial parks in order to meet the conditions of infrastructure, environment, technology, etc., that promotes the development textile industry to meet the demands of the garment industry. In recent years, the government has offered preferential policies for state-owned and FDI textile and garment sectors. However, the estimated results show that the technological change as well as the productivity of these sectors are inadequate. By contrast, the private textile and garment sector is facing many difficulties in such policies 945 to develop production. As a result, the state should have fair policies for textile and garment sectors. In the process of developing Vietnamese textile and garment industries, it is necessary to focus on the private textile and garment sectors. Because they are important sectors that account for about 80% of the total Vietnamese textile and garment firms and attract a huge number of the labour force in the textile and garment industries. The government should have policies to support private textile and garment firms to access land, credit support, etc that motivate the private textile and garment sectors development. 5. References 1. Bao. H. D. (2016), Analysis of technical efficiency and total factor productivity, Hanoi National University Publishing, Hanoi. 2. Nhat. Q. M (2011), 'Using metafrontier and metatechnology ratio tools to expand data envelopment analysis model in productivity and efficient evaluation.' Can Tho University‟s Journal of Scientific Research , 18 (1), 210-219. 3. Alexandra Kontolaimou & Kostas Tsekouras (2010), ‗Are cooperratives the weakest link in European banking? A non-parametric metafrontier approach‘, Journal of Banking & Finance, 34, 1946-1957. 4. Battese, G.E. & Rao, D.S.P. (2002), ‗Technology gap, efficieny, and a stochastic metafrontier function‘. International Journal of Business and Economics, 1(2), 87-93. 5. Battese, G.E., Rao, D.S.P. & O‘Donnell, C.J. (2004), ‗A metafrontier production function for estimation of technical efficiencies and technology potentials for firms operating under different technologies‘, J Product Anal, 21, 91–103. 6. Coelli, T.J. (1996), A guide to DEAP version 2.1: a data envelopment analysis (computer) program. CEPA working paper 96/8. Armidale, Australia, Department of economectris, University of New England. 7. Hayami, Y. (1969), ‗Sources of agricultural productivity gap among selected counties‘, American Journal of Agricutural Economic, 51(3), 564-575. 8. Hayami, Y. & Ruttan, V.W. (1970), ‗Agricultural productivity differences among counties‘, American Economic Review, 60(5), 895-911. 9. O‘Donnell, C.J. (2008), ‗ An aggreagate quantity-price framework for measuring decomposing productivity and profitability change‘, Working Papers, Australia. 10. O‘Donnell, C.J., Rao, D.S.P. & Battese, G.E. (2008), ‗Metafrontier frameworks for the study of firm-level efficiencies and technology ratios‘, Empirical Economics, 34, 231-255. 11. Oh, D.H. & Lee, J.D. (2010), ‗A metafrontier approach for measuring Malmquist productivity index‘. Empirical Economics, 38, 47-64. 12. Pastor, J.T. & Lovell, C.A.K. (2005), ‗ A global Malmquist productivity index‘ Economics Letters, 88(2), 266-271. 13. Q. Wang, Z. Zhao, P. Zhou, D. Zhou (2013), ‗Enery efficiency and production technology heterrogeneity in China: a meta-frontier DEA approach‘, Economic Modelling , 35, 283-289. 946 14. Rao, D.S.P., Coelli, T.J. (2003), ‗ Total factor productivity growth in agriculture: a Malmquist index analysis of 93 countries, 1980-2000, CEPA working paper 02/2003. Armidale, Australia, School of economics, University of New England.

File đính kèm:

analysis_technical_efficiency_technological_gap_and_total_fa.pdf

analysis_technical_efficiency_technological_gap_and_total_fa.pdf